The “Honda Eco Mileage Challenge” competes in fuel efficiency rather than the speed of the vehicle. In preparation for the establishment of the Carbon Neutral (CN) Fuel Class next year, CN fuel was experimentally introduced at the National Competition held in October 2023. This time, we interviewed the Honda associate team and the Honda Technical College Kanto (Eastern part of Japan, including Tokyo) team, having joined for exhibition purposes, about their journey to the competition using CN fuel.

Eco Mileage is a place to pursue dreams of manufacturing. Aiming for the world’s most eco-friendly competition yet with CN fuel

The “Soichiro Honda Cup, Honda Eco Mileage Challenge”, “Eco Mileage” for short, started in 1981. In this competition, teams build their own machines based on the Super Cub engine and compete to achieve the best fuel efficiency, measuring how far they can travel on one liter of fuel. It is billed as the “world’s most eco-friendly competition.”

Machines that pursue the optimization of every element have appeared

Machines that pursue the optimization of every element have appeared

Named after the founder, it is the only event held by Honda with the founder’s name, and has been held for over 40 years with the desire to support the realization of young people’s dreams of becoming engineers. In this competition, approximately 70% of the total 217 teams consist of students who actively participate, fostering a place for practical technology and future endeavors by encouraging hands-on involvement and critical thinking.

In the National Competition of 2023, all 217 teams consisted of participants ranging from junior high school students to working adults

In the National Competition of 2023, all 217 teams consisted of participants ranging from junior high school students to working adults

With the aim of achieving CN conversion, Eco Mileage believes that it’s necessary to actively engage not only in business but also in external events. Therefore, the experimental introduction of CN fuel has taken place starting from this competition. CN fuel is a fuel made using renewable energy from carbon dioxide (CO2) collected from the atmosphere through plants or chemical recovery. When the fuel is burned, CO2 is emitted. However, since CN fuel is made based on collected CO2, it is attracting attention as a fuel in which atmospheric CO2 does not increase from production to use. The official establishment of the CN class will begin in 2024, but two teams are taking the lead in this exhibition run.

Because the competition is aimed at nurturing the future generation, providing the opportunity to experience CN fuel should hold significant importance. In the future, there are plans to provide opportunities for technical staff to give lectures and for participants to engage in discussions among themselves, aiming to deepen participants’ understanding of CN conversion. Starting with the introduction of CN fuels, we will strive to develop competitions that serve as opportunities to raise environmental awareness and remind people that Eco Mileage is the place to learn about and understand carbon neutrality.

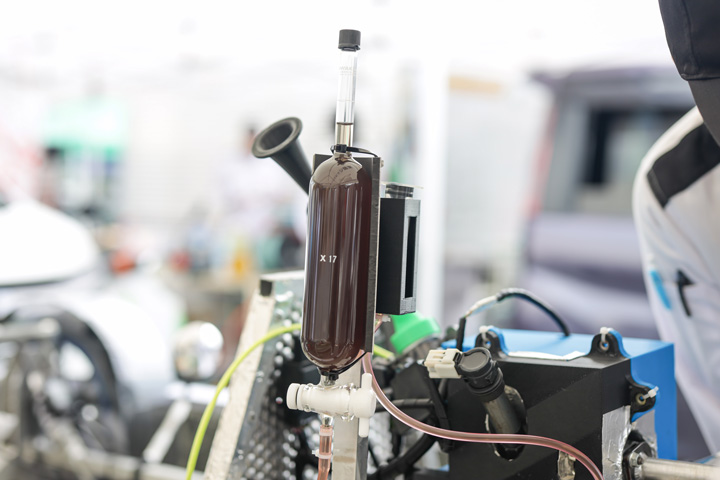

Carbon Neutral (CN) fuel, experimentally introduced from the 2023 National Competition. In this competition, plant-derived CN fuel is in use.

Carbon Neutral (CN) fuel, experimentally introduced from the 2023 National Competition. In this competition, plant-derived CN fuel is in use.

The Honda Technical College team, pooling their knowledge, took on the challenge of CN fuel

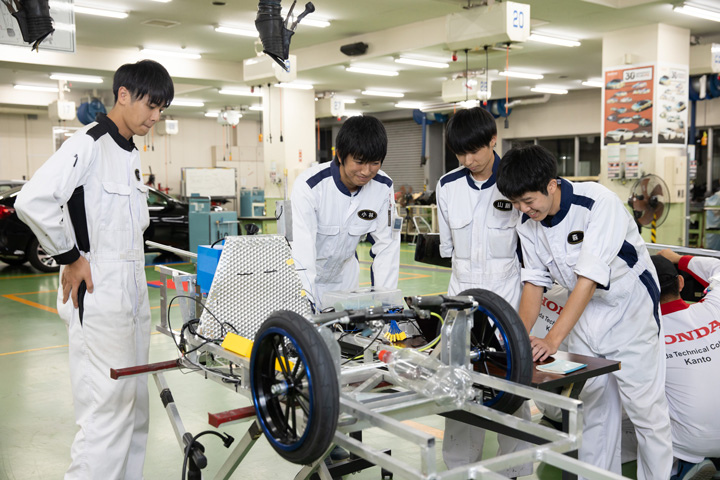

The Eco Run Club from Honda Technical College took on the challenge of the CN fuel exhibition run. Their first time, CN fuel was a struggle, but they talked about rediscovering the fun of manufacturing, the importance of taking action to find answers, and feeling the potential of the new fuel. This time, four members from the Development Design & Engineering Course (now the Research & Development Department) participated in the interview.

The team name is “H-TEC CN-Project”. Yuma Yamafuji, Harunobu Mori, Tomoya Ono, and Yuki Kobayashi (from left to right)

The team name is “H-TEC CN-Project”. Yuma Yamafuji, Harunobu Mori, Tomoya Ono, and Yuki Kobayashi (from left to right)

When the competition secretariat approached you about using CN fuel, you immediately agreed. What was the reason behind this decision?

Feeling the allure of a field where there is still room for me to make a difference, especially since new fuels have not yet emerged in society, I have been increasingly interested in working with new fuels. Upon hearing that the Eco Run Club would be dealing with CN fuel, I immediately decided to join the club.

The introduction of CN fuel was indeed a fantastic opportunity for everyone. Using CN fuel for the first time must have been challenging, given the lack of precedents and information.

It was quite challenging just to start the engine. It all began with thorough research on the characteristics of the injectors to determine the timing and amount of gasoline to spray into the engine. Then, we discussed and adjusted how to apply this knowledge to CN fuel through numerous discussions among the team members.

Gathering after classes, worked tirelessly day after day, through trial and error, to create a new machine

Gathering after classes, worked tirelessly day after day, through trial and error, to create a new machine

Information about CN fuel is limited and ambiguous. Some articles claim that the performance is equivalent to regular gasoline, while there is also information suggesting struggles, such as the postponement of CN fuel compatibility in this year’s SUPER GT races. It’s unclear which is true. Therefore, we had no choice but to try it ourselves and address each question one at a time.

Also, since CN fuel usage has already started in various areas of motorsports, we consulted with someone from HRC*1 about handling CN fuel. We heard that CN fuel doesn’t perform well unless the engine temperature is around 100 ℃, so we considered insulation methods. We tried various approaches and ultimately ended up making a cover for the engine itself using a 3D printer. It took some time to design the perfect size, but we were happy when it worked out well.

*1 Honda Racing Corporation (HRC). A subsidiary responsible for Honda’s racing activities, which is also advancing research and development of carbon-neutral technology in motorsports.

When we ran it on the test course the other day, we were able to accelerate to about 40 km/h initially, so I think we’ve achieved some results to a certain extent. Our goal is simply to finish the race no matter what during the event!

After trial and error, shaped their ideas into an engine cover that they created

After trial and error, shaped their ideas into an engine cover that they created

How did you feel about actually handling CN fuel?

I initially thought handling CN fuel would be difficult, but after facing it head-on, we realized that even we could get the engine running properly. It made me feel the potential for the future. I hope that through Eco Run, CN fuel will become more recognized by many more people.

“After actually using CN fuel, I am now able to recognize its challenges and have started considering, in my mind, how we can utilize it in commercial vehicles in the future. As I plan to participate in Eco Mileage again next year, I aim to build on the experience gained this year.

It’s clear that everyone gained a lot by participating in Eco Mileage activities. Finally, please tell us what dreams you hope to fulfill in the future by utilizing what you’ve gained from this experience.

There have been many frustrating failures, but I’ve learned the joy of creating. After graduation, I plan to work in control engineering, and my dream is to develop autonomous control systems that prevent fatal accidents. Like my hometown, cars are essential in suburban areas with underdeveloped transportation networks. As the elderly population grows, I aspire to create a society where everyone can move safely.

Eco Mileage is a source of inspiration, providing a valuable opportunity to apply and adapt the skills we learn. I believe I’ve developed the ability to solve problems by actively engaging my hands and mind. After graduation, I plan to work in development at Honda, and I hope to be involved in the field of gas turbine engines. Indeed, it’s precisely the domain where CN fuel is used. I want to be involved in the development of eVTOL*2 and make air travel accessible to everyone. The knowledge and spirit cultivated in the Eco Run Club will surely be valuable in my future life.

*2…Electric Vertical Take Off and Landing

The H-TEC CN-Project successfully achieved its goal of finishing the race. They have penned a new page in Eco Mileage history (with a record of 709.018 km/l)

The H-TEC CN-Project successfully achieved its goal of finishing the race. They have penned a new page in Eco Mileage history (with a record of 709.018 km/l)

Even technical professionals join the fray with a sense of mission towards realizing CN

While everyone has different daily tasks, they come together as “Team-Truth” united towards the goal of Eco Mileage. Takayoshi Nakamura, Yudai Ishide, Hideaki Sumi, Toshiyuki Inaba, Anri Hayashi, Yu Arakawa (from left to right)

While everyone has different daily tasks, they come together as “Team-Truth” united towards the goal of Eco Mileage. Takayoshi Nakamura, Yudai Ishide, Hideaki Sumi, Toshiyuki Inaba, Anri Hayashi, Yu Arakawa (from left to right)

Representing the general class, the Honda employee volunteer team "Team-Truth", which includes members involved in CN fuel in their professional duties, participated in the exhibition run. We also spoke to the six members of the team who are working on CN fuel as a special self-development activity about their challenge with CN fuel.

What kind of tasks do you usually face in your daily work?

I’m involved in a project for DAC (Direct Air Capture) to collect CO2 from the atmosphere, while Sumi is involved in a project to synthesize CN fuel from the collected CO2.

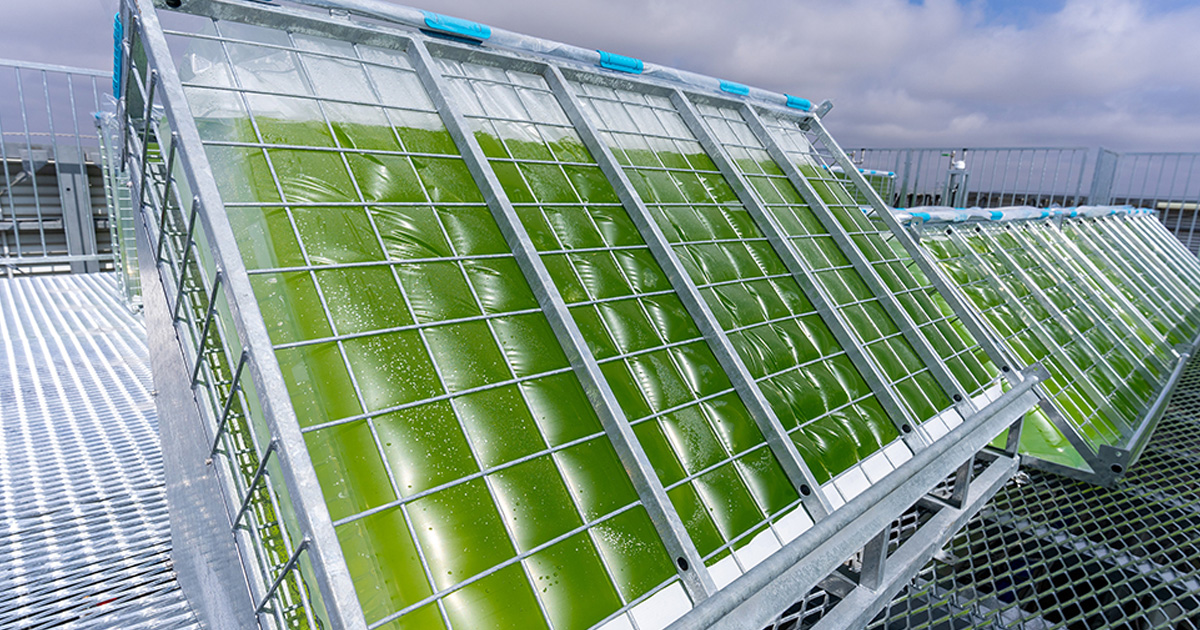

I am involved in the “Honda DREAMO” project, which cultivates algae using collected CO2, as one approach towards achieving CN conversion. The algae grown by absorbing CO2 have the potential to be used as food or as raw material for CN fuel.

About half of you seem to be involved in tasks closely related to CN fuel in your daily work. How did you arrive at the challenge of CN fuel at Eco Mileage?

As motorsports shift towards CN fuel, “is it appropriate for mobility manufacturers to continue using gasoline in Eco Mileage as it is? In the future, I want to run with CN fuel made from the CO2 that we collect!” I discussed that with Sumi and then contacted the secretariat to inquire about it. Then, I was asked if I would like to participate in the exhibition run since they were just in the process of introducing CN fuel. The timing was perfect.

All members are dedicated to Eco Mileage, and they approach their activities with a sense of mission towards carbon neutrality.

All members are dedicated to Eco Mileage, and they approach their activities with a sense of mission towards carbon neutrality.

After that, we really didn’t have much time... In the end, we didn’t even fire up the engine for the first time until early August (laughter). While understanding the fuel characteristics based on the information gathered beforehand and leveraging our experience with ethanol fuel, we were able to start the engine. Surprisingly, the fuel was quite easy to use, and once the engine was warmed up, we found fewer challenges than expected.

The biggest challenge was that the energy output per liter was lower compared to gasoline. We adjusted the gear ratio to the limit, which significantly influenced fuel efficiency. I used to be in charge of transmissions in my professional work, so I’m good at calculating gear ratios.

Hayashi-san wants to increase fuel efficiency by keeping the engine speed low, but as an engine specialist, I warned her that pushing too hard might prevent the engine from starting. To find the right balance for smooth running, we often sat together beside the vehicle, discussing earnestly.

Ishide and Hayashi, who were in the same circle during university and joined Honda together as colleagues, have been progressing with adjustments while engaging in heated debates.

Ishide and Hayashi, who were in the same circle during university and joined Honda together as colleagues, have been progressing with adjustments while engaging in heated debates.

In the course of our activities, I realized that Honda’s technological prowess is indeed reliable. Each member brings their own expertise to the table, but if there’s something we don’t know, we can always ask within the company and get an answer from somewhere. I think one of Honda’s strengths is that there are many people who are supportive and helpful.

Actually handling CN fuel, you felt that with some ingenuity, it can be used at a level comparable to gasoline. In terms of your professional work, how do you plan to utilize CN fuel in the future?

Honda is advancing electrification in motorcycles, automobiles, and power products. In aviation, electrification is challenging due to weight considerations, so expectations are high for CN fuel as an alternative. Since I’m also involved in the CN conversion project for aviation, I would like to work towards realizing eVTOL as well as other related technologies.

I was previously involved in engine development, and because I wanted to stay connected to engines even in Eco Mileage, I continued with it. First, I want to improve the efficiency of the DAC system I’m working on now and contribute to the practical application of CN fuel.

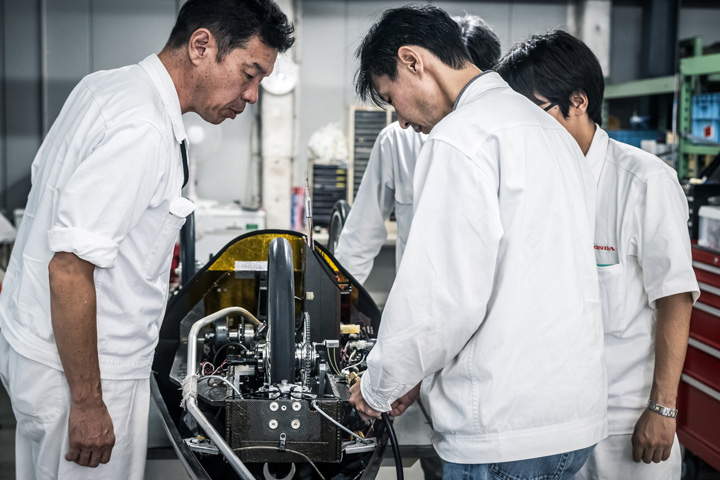

Regardless of seniority, they collaborate based on each individual’s expertise to tackle the challenges together.

Regardless of seniority, they collaborate based on each individual’s expertise to tackle the challenges together.

Eco Mileage activities serve as a place for everyone to improve your skills and indulge in your passions

For me, Eco Mileage is always a challenging place, much like a dojo (martial arts gym) where I am constantly tested. Being able to realize what I want to do with my own hands and seeing the results directly impacting me is incredibly rewarding. In reality, creating an actual car is too much for one person to handle alone, so in my job, I only handle a small portion of the car. However, in Eco Mileage, I can build an entire car by myself. It serves as a reminder of the essence of manufacturing, making me realize the feeling of handling an entire car’s worth of work.

On the final day of the national competition, ahead of all classes, an exhibition run using CN fuel was conducted. Both teams successfully completed the exhibition run. While showing relieved expressions for successfully fulfilling the significant role of CN fuel debut in Eco Mileage, the team members immediately discussed improvement points after crossing the finish line. Moving the equipment with one’s own hands, verifying, and improving. At the Eco Mileage site, there was the essence of manufacturing.

Team-Truth achieved a record of 1,206.419 km/L. Using CN fuel, the distance traveled from Mobility Resort Motegi (Tochigi Prefecture) to Fukuoka Station (Fukuoka Prefecture) is equivalent to zero CO2 emissions

Team-Truth achieved a record of 1,206.419 km/L. Using CN fuel, the distance traveled from Mobility Resort Motegi (Tochigi Prefecture) to Fukuoka Station (Fukuoka Prefecture) is equivalent to zero CO2 emissions

Original article issued on October 13, 2023

![[Event Report] Honda eVTOL development leader speaks at the University of Tokyo: The mobility in the skies envisioned by Honda](/content/dam/site/global-en/stories/cq_img/071/social.jpg)

CN conversion is spreading primarily in Europe, but we feel that this wave is also coming to Japan. There were many opportunities to learn about the environment in class, so when the opportunity arose, I immediately responded with “Let’s do it!” without any discussion with the team members.