N-BOX Debuts to Represent Honda in the New Era

The N-BOX, the first of the N Series k-car models, goes on sale (2011)

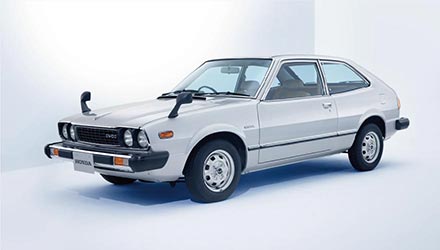

While dealing with the impact of a series of major crises, namely the global recession triggered by the 2008 global financial crisis, the Great East Japan Earthquake, and the flooding in Thailand, in December 2011, Honda, launched a new model with a hope to revive the sluggish Japanese automobile market. It was the N-BOX, a super-height wagon-type k-car, with the advertising slogan of “New, Next, Nippon (“Japan”), Norimono (“vehicle”).” The “N” signified “Norimono (vehicle) for people,” at the same time, the N was inherited from the N360, the best-selling k-car model Honda introduced in 1967. With the introduction of the N-BOX, Honda conveyed a strong message: “Honda will create new, next-generation vehicles for Japan.

The N-BOX featured a wide, reassuring field of vision, with eye level set at around 140 cm, the optimal eye level for a driver to have a wide view of the surroundings. Moreover, the robust chassis that received the highest rating for safety assessment, as well as a spacious cabin that strongly reflected the M/M (Man Maximum, Machine Minimum) concept, the basic approach to Honda car design, were well received in the market. Since the introduction, the N-BOX was the best-selling model among all new models in Japan for four consecutive years and for six consecutive years among all k-cars in Japan. With the introduction of more models, namely the N-ONE which was reminiscent of the N360, N-WGN and N-VAN, the N Series became a series that strongly coveys the presence of Honda in the mini-vehicle market even to this date.

Meanwhile, the Suzuka Factory, which was manufacturing the N-BOX, launched the SKI (Suzuka Kei Innovation) project in 2012. (“Kei” stands for the so-called “K-car” mini-vehicle category in Japan.)

The project team consisted of members from development, purchasing, production and sales divisions, and the team worked to improve the entire process of mini-vehicle business, from development to production and sales. The SKI project stimulated the communication among the members from different divisions and increased the speed of product planning and the development of new models. This made the N Series a great hit, enabling Honda to continue to thrive in the k-car category. The Suzuka Factory was built initially as a production plant for the Super Cub and supported the rapid growth of Honda in its early years. At this time, it served as the driving force that enabled Honda to overcome repeated hardships and to thrive.

Nine years and six months (115 months) after the introduction of the first-generation N-BOX, cumulative sales of N Series exceeded 3 million units.

Addressing Increasing Demand for Hybrid Vehicles

and Airbag Quality Issues

Following the highly successful N Series targeting the Japanese market, Honda launched the third-generation Fit as a strategic global model in 2013. It was the first model Honda developed simultaneously in six regions across the world to achieve significant cost reduction by thoroughly pursuing local production while optimizing production and procurement on a global basis. High expectations were placed on this Fit, as a model that would serve as a test of the advancement Honda had made to its six-region global operation structure.

The third-generation Fit was equipped with an unpreceded and innovative hybrid system, a newly developed extremely precise system called i-DCD (Intelligent Dual Clutch Drive). Unlike the conventional IMA System (Honda Integrated Motor Assist System) in which the motor and engine were integrated, the i-DCD system efficiently linked the motor and the engine and applied integrated and optimized control. This was a bold challenge Honda took on to create new technology; however, this new control program experienced a number of issues, and a third-generation Fit fell into a serious situation where it had to be recalled five times in a short period of time. In addition, the Vezel Hybrid, which featured the same hybrid system, also had to be recalled three times.

To achieve practical application of a new system that requires extremely complex control, the optimization has to be solidified as the joint work of the engine team, transmission team and chassis team. Ito believed that the underlying cause of these repeated defects experienced by Fit and Vezel was the imperfection of such optimization. He also analyzed and reflected on himself: “I am sure that our engineers at the spot were thinking that there were other ways of doing things. However, despite our attempt, management could not grasp and incorporate their thoughts.*3”

In response to the string of defects, Honda stepped up its quality control to be more thorough than ever. However, due to the impact of the repeated defects and the enhancement of quality control, market introductions of other new models were delayed. As if to add insult to injury, Honda was hit by another major quality issue. It was around this time that issues involving defects in airbags manufactured by Takata Corporation (Takata) became apparent.

Approximately 50% of automobiles produced by Honda at that time were equipped with Takata airbags. In 2004, an airbag malfunction occurred during a traffic collision involving a Honda vehicle in North America. Initially, the cause of the malfunction was believed to be something other than the gas-generating-propellant (inflator); however, time passed without being able to determine a definitive cause. Then, starting around 2007, multiple cases of airbags malfunctioning during a collision occurred.

Finally, in 2014, the American Honda, the Honda subsidiary in the U.S. conducted an investigation in response to a special order from the National Highway Traffic Safety Administration (NHTSA) of the U.S. Department of Transportation, and Honda became aware of information that would suggest that Takata had misrepresented or improperly reported test data on their airbag inflators.

The six-region global operation structure facilitated the autonomy and self-reliance of each regional operation outside Japan; however, as an adverse effect, it made it difficult for the Japan head office to fully understand every detail of quality assurance measures being taken in each region, and it was undeniable that the physical and psychological distance between Japan and the U.S. was a barrier to active communication.

As not much progress had been made in Takata’s investigation into the cause of the defect, Honda decide to take proactive measures and recalled a large number of Honda vehicles equipped with Takata airbags, while continuing its own effort to determine the root cause of the defect. That was the decision made by Honda management with the utmost respect for the company’s long-held belief in “putting the customer’s safety first.”

- An exclusive interview featured on the January 17, 2015 issue of the Weekly Toyo Keizai magazine.

The third-generation Fit

Takahiro Hachigo Assumes the Role as President of Honda

to Further Advance the Six-Region Global Operation Structure

and Continue Creating Products that Challenge Industry Norms

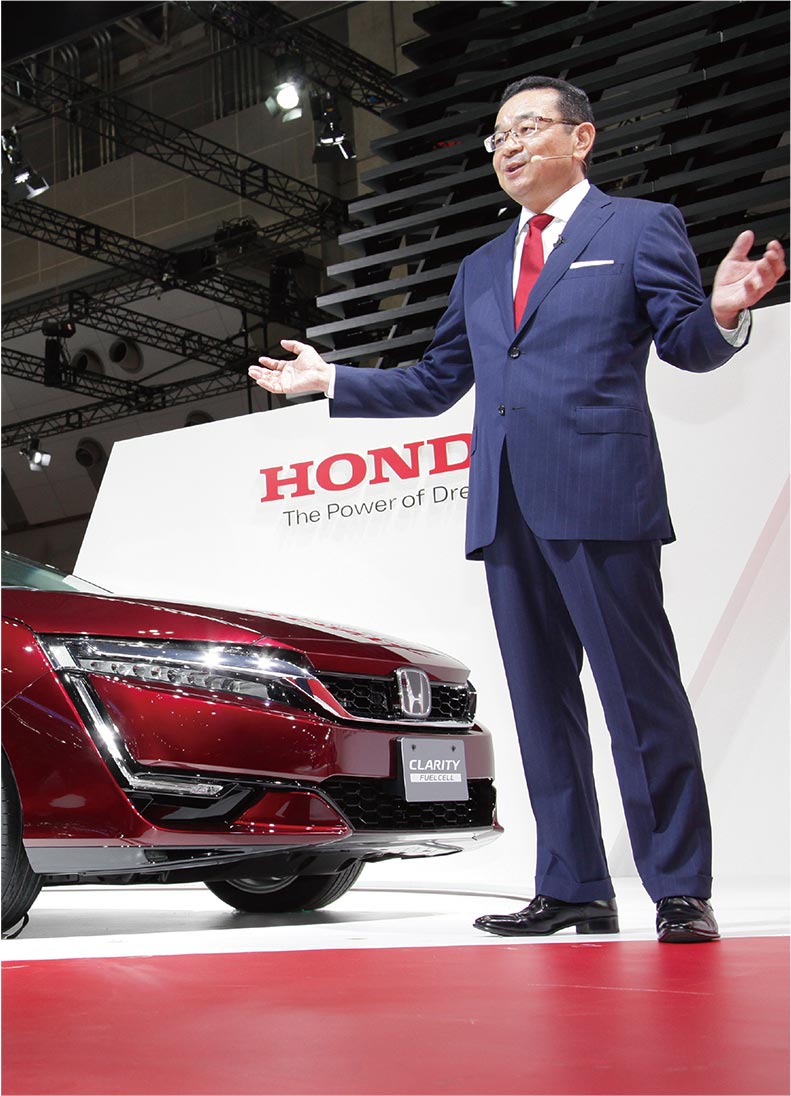

Takahiro Hachigo at the 44th Tokyo Motor Show 2015 (at the press information session)

Takahiro Hachigo at the 44th Tokyo Motor Show 2015 (at the press information session)

Beginning with the global recession that changed the world order, Honda faced a number of difficulties during Ito’s time as president, including the Great East Japan Earthquake and tsunami, the flooding in Thailand, the recalls of a newly developed hybrid system, and the prolonged airbag recall issue. However, Ito forged ahead with challenging initiatives to shape the future of Honda, including selecting business areas for Honda to concentrate its resources, reforming the SED system, strengthening the six-region global operation structure, and implementing forward-looking initiatives to reduce CO2 emissions.

In 2015, six years into his presidency, Ito announced the appointment of Takahiro Hachigo, then Senior Managing Officer, as the next president of Honda. In a message to associates, Ito explained the reason for stepping down at this time: “For Honda to make steady growth into the future, I want Honda to make another leap forward with young energy under new leadership. I made the decision thinking now is the right time.”

Although Hachigo became the first president of Honda who did not serve as the president of Honda R&D, Hachigo had been involved in research and development mainly in the area of automobile chassis design, and served as the design leader of the first-generation Odyssey for the North American market and as the project leader for the development of the second-generation CR-V. Then he was stationed in the U.S. for two years, where he was actively involved in local development of Honda and Acura models. After his assignment in the U.S., Hachigo held a wide range of executive positions, including General Manager of the Purchasing Division, General Manager of the Suzuka Factory, and Vice President and Director of Honda Motor Europe Ltd. (HME), and Representative of Development, Purchasing and Production (China). By serving in these positions, Hachigo gained insight into a wide range of operations.

To support the strengthening of the six-region global operation structure under Ito, Hachigo played an important role in implementing a series of measures at the spot of the various operations. At the time of the Great East Japan Earthquake, Hachigo was the General Manager of Suzuka Factory, and he led the establishment of the satellite office of Tochigi R&D Center within the factory, which paved the way to complete development and start the production of the N-BOX.

At his inaugural press conference, Hachigo expressed his intention to further strengthen initiatives which were put on track by Ito, saying, “I want to further advance our six-region global operation structure and enable Honda to continue developing products and technologies that challenge industry norms.”

Going Back to the Honda Philosophy and Building

“Team Honda”

Immediately after becoming the president of Honda in June 2015, Hachigo said, “Now is the time to go back to the Honda Philosophy, more specifically, Respect for the Individual and The Three Joys.” To this end, he conveyed one clear message represented by the term “Team Honda.”

Behind this was Hachigo’s impression upon returning to Japan after spending time at Honda operations in Europe and China. He felt that Japanese business operations lacked a sense of unity and were confined to their own divisions and areas of expertise. Honda had grown in size and expanded its business globally. However, Hachigo believed that the source of Honda’s strength had always been its team unity. This was why Hachigo wanted to take Honda back to its starting point.

Hachigo described his ideal image of “Team Honda” this way:

“A group of associates who share a common goal. The members of this cross-functional team have respect for each other's individuality and move forward to achieve the goal. Even though each member may have a different way of thinking, area of expertise, or position within the organization, they all share the same desire to reach the goal. Because all team members understand the goal and each other’s passion to achieve the goal, they naturally develop a sense of mutual trust and pride in each other. Because of this nature of the team, all members can think of their respective roles with their own head and fully devote themselves to their roles.”

“Team Honda” expressed Hachigo’s aspiration for a corporate culture unique only to Honda, which enables all associates to excel in their own respective areas and fully demonstrate collective strengths as a team. Honda had been embodying the management philosophy of “building products close to the customer” and enhancing the autonomy and self-reliance of each regional operation. However, with an increasing amount of authority delegated, each region began to incline toward “regional optimization” by acting in accordance with their own respective strategies. Hachigo looked back on his time in China and said, “It was inevitable that I put the priority on my own region*4”

The term “Team Honda” conveyed his message that all regional operations must see the big picture of Honda business from the perspective of ‘overall optimization’ and think what each region can do from the viewpoint of ‘Global Honda’ while thinking about regional optimization at the same time. Hachigo emphasized that the new challenge Honda must take on was to advance its six-region global operation structure while striking a balance between regional and overall optimization. This challenge would pay off only when all Honda operations around the world can work together as one team. Hachigo’s “Team Honda” was a concept developed with an eye toward the further strengthening of Honda’s six-region global operation structure.

- An editor-in-chief interview featured in the November 21, 2016 issue of the Nikkei Business magazine.

Production line for the European version of the Honda Civic (Honda automobile plant in Swindon, the UK)

Formulating the 2030 Vision: Serve People Worldwide

with the “Joy of Expanding Their Life’s Potential”

In 2017, Hachigo formulated the 2030 Vision, eyeing 2050, when Honda will be more than 100 years old.

The 2030 Vision Statement:

Serve people worldwide with the joy of expanding their life’s potential.

- Lead the advancement of mobility and enable people everywhere in the world to improve their daily lives –

To fulfill this vision, the company set the direction of initiatives the company would pursue in three areas – Creating the Joys, Expanding the Joys and Ensuring the Joys for the Next Generation – which were identified under the “Direction for the 21st Century” – Strive to be a company society wants to exist.

For “Creating the Joys,” Honda set the direction to “provide people with the “joy and freedom of mobility” and the “joy of making their lives better” by creating value for mobility and people’s daily lives. Mobility, robotics, and energy solutions were identified as three specific areas of focus.

For “Expanding the Joys,” the direction was set to “accommodate the different characteristics of people and society,” aiming to expand the joys of people by providing the best products and services that accommodate diverse characteristics of society, cultures and value systems of people around the world, regardless of advanced or emerging countries.

For “Ensuring the Joys for the Next Generation,” Honda set the direction toward the realization of a clean, safe and secure society. Striving to become No.1 in the areas of the environment and safety, Honda announced its plans to invest more resources to lead the efforts to achieve a carbon-free and collision-free society.

Moreover, to fulfill the 2030 Vision, Honda made a major shift of focus from quantity to quality, and clearly reaffirmed the longstanding Honda commitment to “growth through the pursuit of quality,” which Honda considered the essence of manufacturing.

The world was on the verge of a major turning point. In terms of technology alone, electrification and the application of intelligent technologies on mobility products were proceeding rapidly, and various environmental technologies were advancing at a tremendous pace. The global political, economic, and market environment also was undergoing dramatic changes. As major IT companies enter the mobility industry one after another, competition was expected to become even more fierce, not only among existing automakers, but also with newcomers from different industries. To survive in such a tough environment, Hachigo believed that embodying Honda strengths would be more important than anything else.

In his 2018 New Year address, Hachigo discussed two major strengths of Honda.

As the first strength, Hachigo emphasized the importance of “offering new value with passion.” He elaborated his point: “We must create products and conduct business with a desire to convey our passion to our customers and please them.” He cited the Super Cub as an example. In 2017, cumulative worldwide production of Super Cub series motorcycles reached the 100 million-units milestone. Hachigo explained that this success was possible because the passion Honda put into this series remained unchanged, even as customer needs had changed over time in each region. Even to date, the Super Cub series has been continuously creating and expanding the joys for customers around the world by always offering new and youthful models without being bound by the past. Hachigo explained the importance of a continuous offering of new value through products and services filled with Honda passion, just like with the Super Cub.

This belief was based on his own experience with the development of Odyssey for the North American market. As the assistant large project leader, he helped lead a multi-national development team that consisted of members form Japan, Canada and the U.S. and challenged the North American culture and market with a minivan model that offered new values, which resulted in establishing a new industry standard. Having a successful experience in taking on challenges while sharing a strong desire to please customers with fellow team members who were in completely different positions, Hachigo was keenly aware of the importance of a strong passion to unite the team.

The other strength Hachigo mentioned was the “collaboration and cooperation among different regions and businesses.” Hachigo elaborated, “Honda’s strength lies in its wide range of products and technologies, including motorcycles, automobiles, power products, aircraft, jet engines and robotics, as well as its operations around the world, and the 30 million customers it serves each year.”

Honda motorcycle business has a strong presence mainly in Asia, Africa and other emerging markets, while its automobile business focuses mainly on North America and China, and its power products business is evenly distributed in advanced countries in Europe and North America and emerging countries in Asia. Honda has been unique in that each of its product-based businesses complements the others in a well-balanced manner in terms of its global presence. Such a strong business foundation has enabled Honda to boldly take on challenges in new areas such as aircraft, jet engines and robotics.

“Our diverse business operations and the six-region global operation structure are the unique strengths of Honda, which no other company has,” said Hachigo. “By advancing collaboration among our regional and business operations, we will further strengthen our ties with customers around the world.”

Cumulative worldwide production of the Super Cub series models reached the 100 million-units milestone in 2017.