1985 NSR500 Technical Specifications

text=KIYOKAZU IMAI

translation:SHINTARO URASHIMA

Innovative Aluminum Frame With Two Ribs Inside

The Champion Machine Completed in Four Months

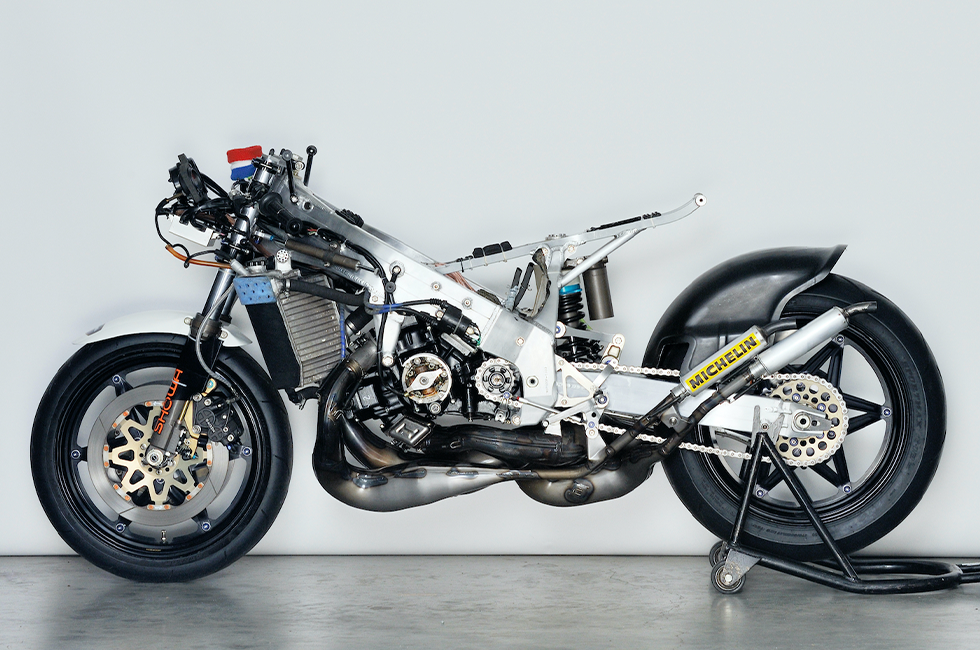

The NV0B's overall dimensions are based on those of its previous model, the NV0A, and the wheelbase is almost the same. However, the NV0B's swingarm is about 15 mm longer than the NV0A because HRC modified the frame to increase the front load. The NV0B also lowered the center of gravity by about 10 mm more than the NV0A, whose fuel tank was under the engine. (Photo/Shinobu Matsukawa)

1985 NSR500 [NV0B] (Photo/Shinobu Matsukawa)

Comparing the NV0B, the 1985 NSR500, with its previous model, the NV0A, gives the impression of being completely different. However, Kaoru Yamamoto, who was in charge of the NV0B's chassis design, said, "To put it in extreme terms, we made the NV0B by revising the layout of the NV0A's parts to match the conventional body layout."

1984 NSR500 [NV0A] (Photo/Yoshihiro Ishizuka)

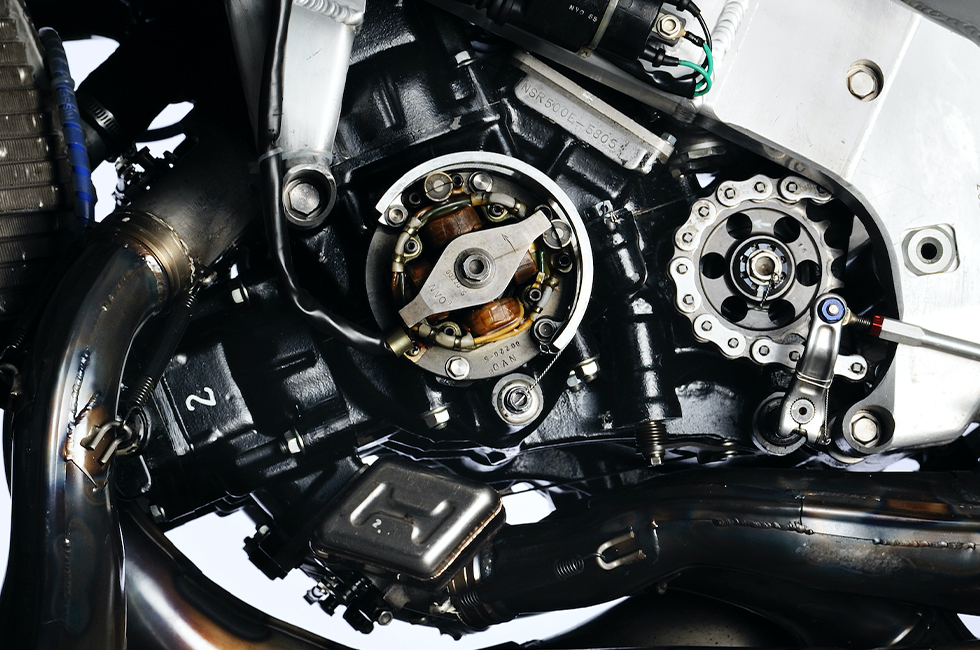

The engine is a two-stroke 500cc V4 with a 90-degree V bank angle, crankcase reed valve intake, single-shaft crank. Its basic configuration is the same as that of the NV0A. However, the most significant change was that the NV0A had four shafts, but the NV0B had three shafts (crankshaft, main shaft, countershaft). The omitted primary shaft was iron and heavy, but this change made the NV0B's engine about 4kg lighter than the NV0A.

The remaining shafts were also narrowed down to redesign the crankcase, making it more compact than the NV0A's. On the other hand, the cylinder's design, with a 54.0 mm bore and a 54.5 mm stroke, remains unchanged from the previous model. HRC also inherited the design of various other parts, and the number of newly created parts was kept to a minimum, allowing the NV0B engine to be completed in a short period that would have been impossible with a completely new development. This approach was possible because the NV0A's engine had sufficient performance.

The NV0B's engine is a V-type 4-cylinder with a 90-degree V angle, just like the NV0A's, but the front bank is slightly lower than horizontal, and the rear bank is tilted somewhat forward rather than vertical. The aluminum box with the "H" stamped next to the exhaust pipe coming out of the second cylinder in the photo is the sub-chamber of ATAC (Auto-controlled Torque Amplification Chamber), which increases torque in the low and medium speed range. At low revs, the valve of this sub-chamber is opened to allow the exhaust to flow in, increasing the pulsating pressure wave, preventing the mixture from blowing out of the cylinder without being ignited, and increasing low-speed torque. ATAC is equipped on each cylinder. (Photo/Shinobu Matsukawa)

The crankshaft of the NV0A, which had four axes, rotated in the opposite direction of travel, but the NV0B, which had three axes, rotated in the forward direction. The direction of the crankshaft rotation, which generates inertia, affects how the load is applied to the wheels and how it is handled. Since forward rotation acts in the direction that lightens the load on the front wheel, the development engineers were concerned that this would somewhat impair the feeling of the front tire touching the ground, which is very important for the rider. Although there was not much of a negative impact, Freddie Spencer complained that the engine revved too quickly, making it difficult to get traction. So, early in the season, a crankshaft with a slightly heavier counterweight was introduced to milden the engine speed increase, which proved effective.