The Champion Machine Completed in Four Months

The newborn NV0B headed to Daytona, the preliminary race for the Grand Prix.

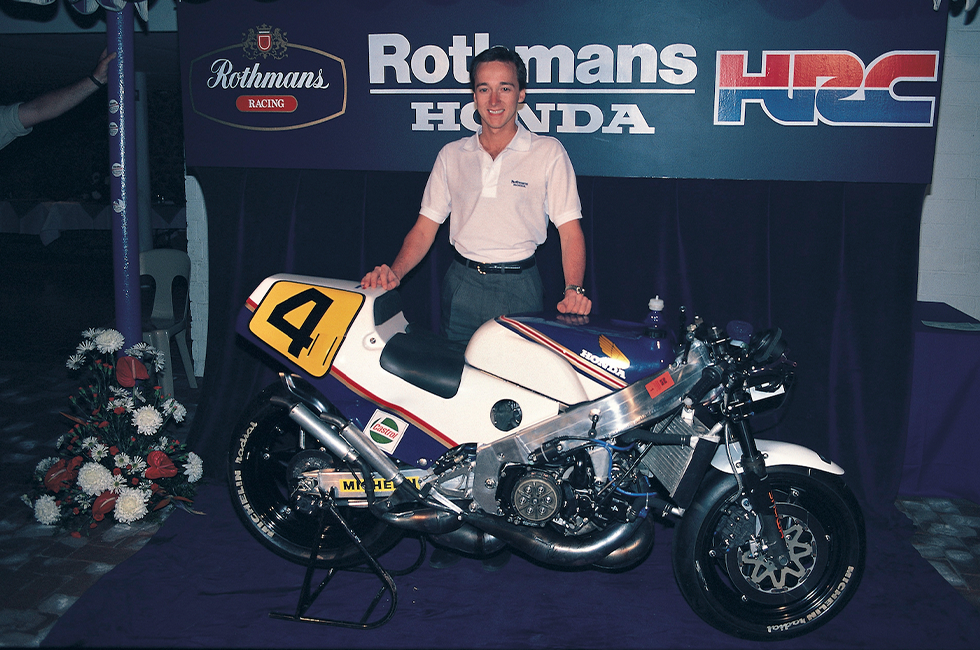

Honda held a press conference at the opening round of the 1985 FIM Road Racing World Championship, the South African GP. The NSR500, redesigned to the standard chassis layout, was unveiled with the cowl removed. Freddie Spencer, the only rider to regularly ride this machine in the World Grand Prix, had gained practical experience with the same machine at Daytona two weeks before and was confident in his abilities. (Photo/Jiro Ishida)

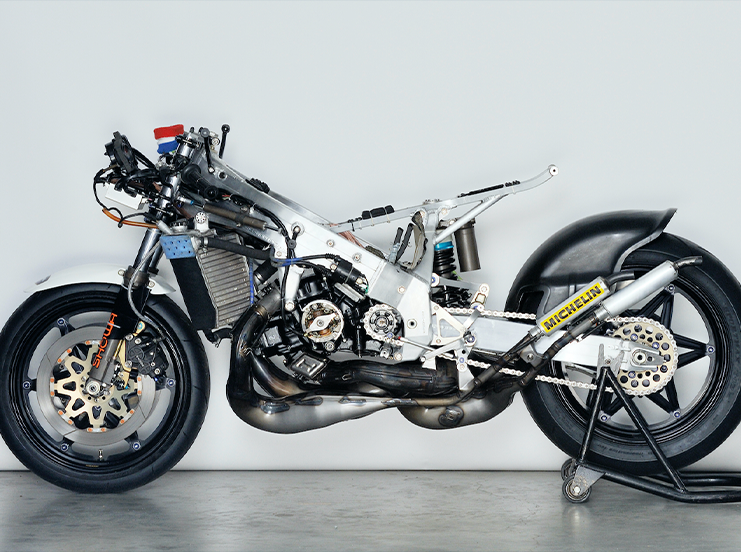

The engine follows that of the NV0A, although it wasn't the same as before. HRC made improvements mainly to reduce weight. The same goes for the body, and although the layout is familiar, they used new materials and manufacturing methods. One was a twin-spar frame made of extruded aluminum with two ribs inside. Honda first used this new technology in the 1985 GP250 Works Road Racer RS250RW, coded as NV1A, developed about six months before the NV0B. The aluminum frame with two ribs inside, which HRC had established with that machine and had already confirmed to be good, was also applied to the NV0B. Components such as the suspension, wheels, and brakes were used with proven technologies that have been improved since the NR500 era. By making the bike this way, it was possible to develop it quickly.

In the end, HRC completed the NV0B in mid-February 1985, four months after the official start of development. HRC test rider Koji Iida first rode the bike. Once it was confirmed to be in working order and given the OK, it was immediately packed up and sent for air freight. The new second-generation NSR500 was sent to Daytona Beach, Florida, USA, to gain real-world racing experience before competing in the World Grand Prix.

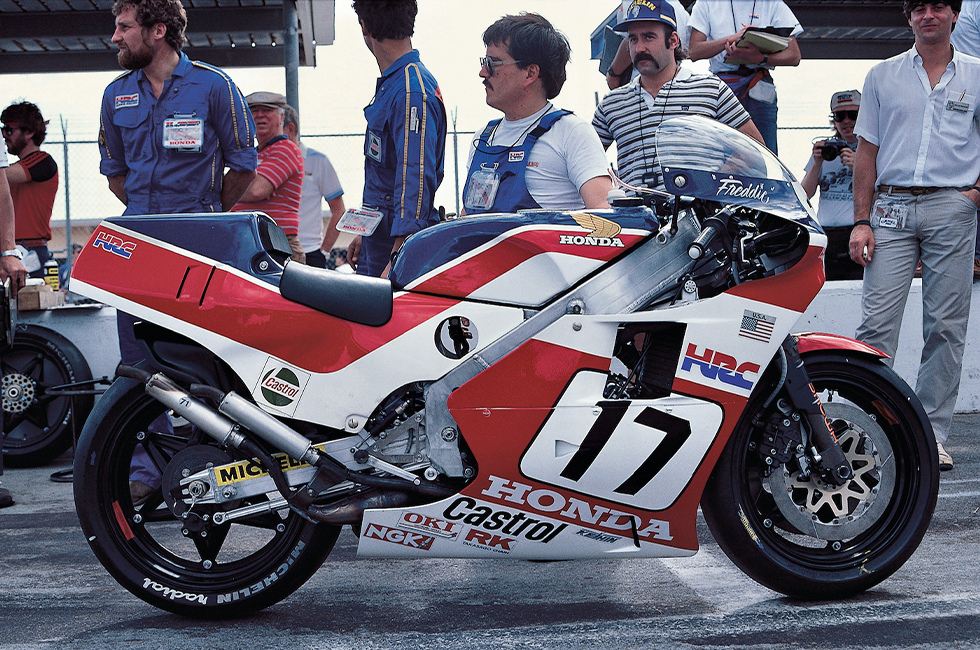

The NV0B debuted in the Formula 1 class at the traditional Daytona Bike Week, ridden by Freddie Spencer. His bike number in the USA is "19," but since another rider used that number in the 1985 AMA (The American Motorcyclist Association) Road Racing Championship, he chose the less familiar "17." The seat cowl of the NV0B was shaped like the one in the photo only at Daytona and the South African GP. Still, after verification in wind tunnel tests, a design was created in which the left and right sides of the rear end of the seat cowl protruded sideways like a hat brim. Spencer used it in races from the second round, the Spanish GP, onwards. (Photo/Shigeo Kibiki)