Background to development of the 2006 New Generation

Honda’s RC211V won 14 of the 16 rounds in the 2002 season, followed by 15 of the 16 rounds in the 2003 season. From the opening round of the 2002 season, when the top class of the Road Racing World Championship changed to MotoGP, the overwhelming strength of this machine was demonstrated with a win rate of over 90% throughout these two seasons. Honda had a monopoly on the MotoGP world championships as well, taking out the riders’ title, constructors’ title (for motorcycle manufacturers), and teams’ title for two years running.

There were 16 rounds in the 2004 season as well, with three RC211V riders winning a total of seven rounds and Honda taking out the constructors’ title for the third year running. Unfortunately, it lost out to Yamaha for the riders’ and teams’ titles. It could be said that Honda lost to Valentino Rossi, who had moved to the Yamaha team after riding for Honda up until the previous year. Rossi won nine rounds and took out the individual riders’ title in the top class for the fourth consecutive year.

2004 Catalan Grand Prix

Valentino Rossi riding for Yamaha (left) and Sete Gibernau riding for Honda Gresini (right) competing for the lead

Honda’s developers took the situation seriously, and while they were proud that the RC211V was more than competitive, they acknowledged its faults as well. They also realized that Honda was competing against a rival manufacturer that was using a person considered the best rider ever, and who was able to outstrip Honda’s efforts by himself. On the opposite side, the RC211V was already a complete package, so Honda was unable to drastically improve performance with a machine that was simply an extension of that design. In other words, the developers felt that continuing as is would just be a repeat of the 2004 season, making it unlikely that they would beat the Rossi/Yamaha combination.

There was nothing else they could do. Honda made the decision to develop a new machine, with a major review starting from chassis dimensions. The machine would also include a newly designed engine. While the official name of the machine was still RC211V, Honda’s developers called it their “New Generation” machine. Built on a new generation philosophy that raised the level overall, the name expressed a desire to confront the new generation of MotoGP machines.

New Generation (NV5HG) RC211V in 2006

Improving performance in the three areas of deceleration, steering, and acceleration

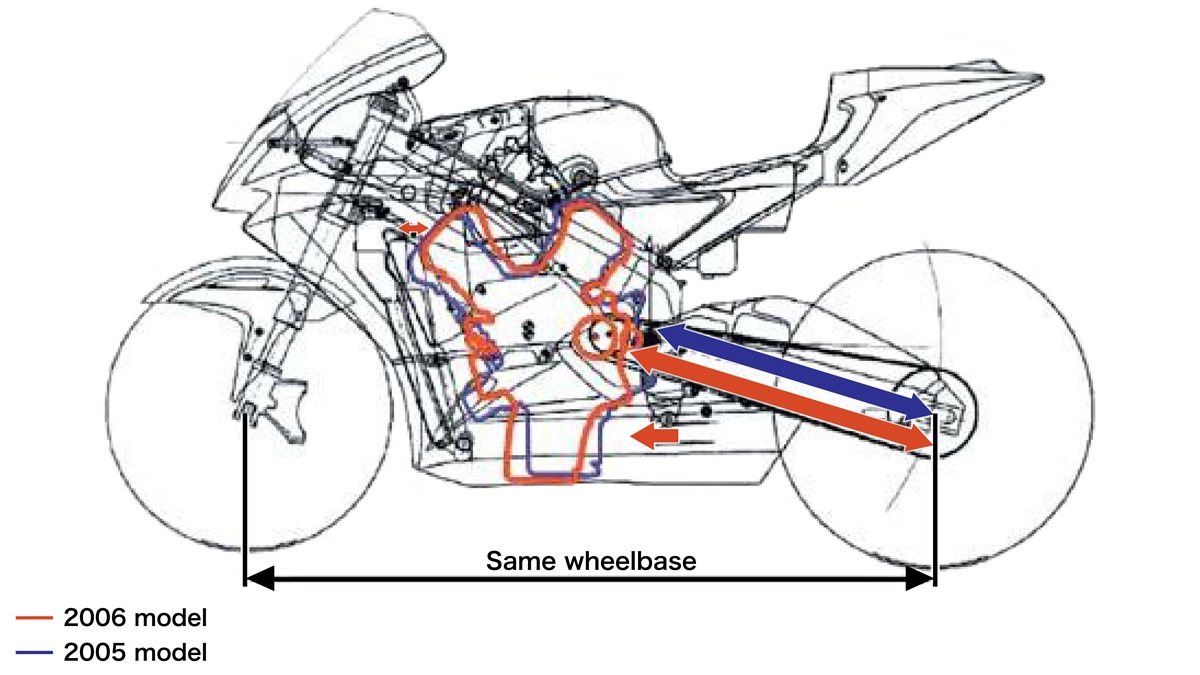

The New Generation was a machine through which Honda took on the challenge of improving deceleration, steering, and acceleration performance. As part of this, Honda pursued reduced moments of inertia for the finished machine. While this was Honda’s plan for the standard RC211V from the beginning, it redoubled its efforts with the New Generation. Nevertheless, the new RC211V had the same wheelbase as the standard one, at 1,450 mm. With no change to regulations in terms of minimum machine weight and tire size, and roughly the same level of engine output, Honda did not want to change a wheelbase that already had the most appropriate measurements for striking a balance of these parameters.

Honda could reduce moments of inertia for the whole machine, without changing the wheelbase, by building a smaller chassis. However, it could only achieve the level of chassis downsizing desired with the New Generation by reducing the size of its engine. This was the reason that Honda also designed a new engine for the New Generation.

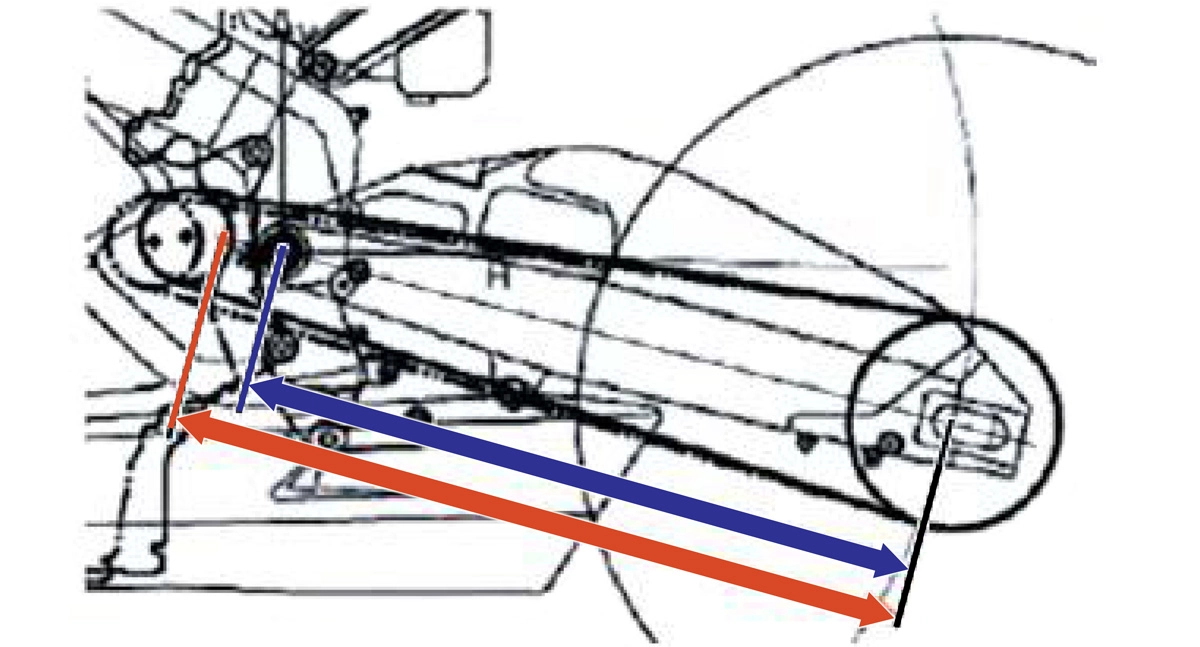

Comparison of engine mounting position and swing arm length between the New Generation RC211V (red) and standard RC211V (blue)

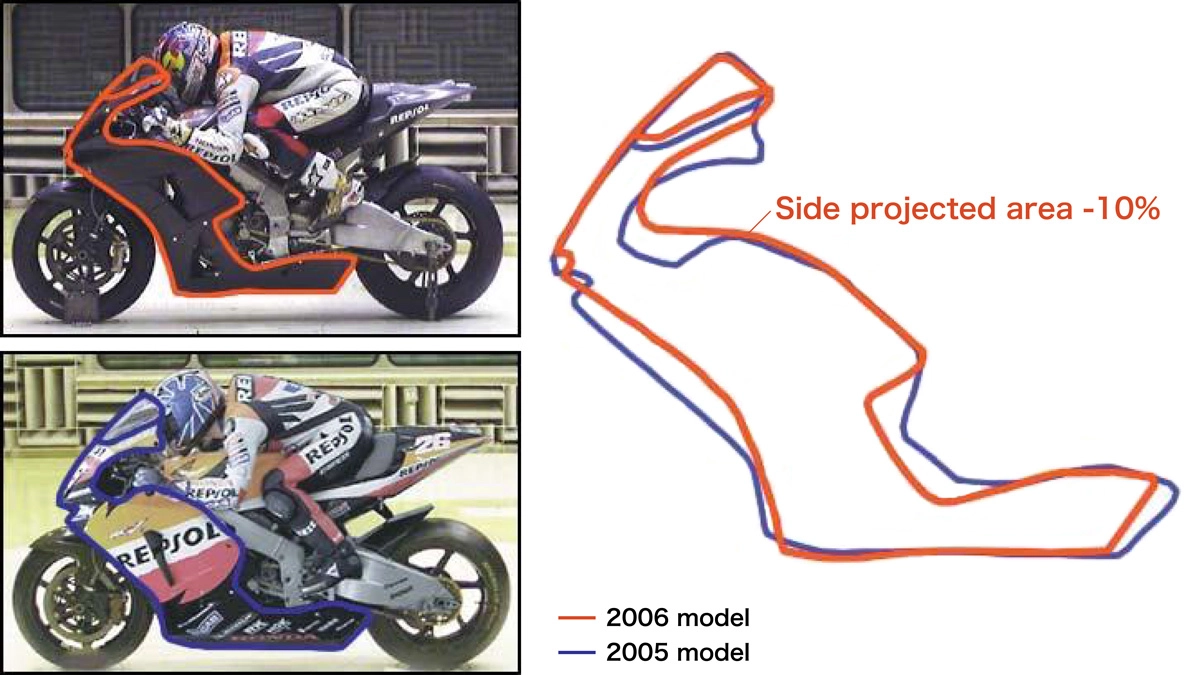

By reducing engine size, Honda was able to dramatically reduce the size of the chassis for housing that engine on the New Generation. With the same wheelbase as the standard RC211V, the new machine improved dynamic performance while minimizing the three moments of inertia—roll (rotation around the longitudinal axis), yaw (rotation around the vertical axis), and pitch (rotation around the lateral axis). By downsizing the chassis, Honda was also able to use a fairing (cowl) with a 10% smaller side projected area. This reduced aerodynamic drag in the lateral direction and enabled faster side-to-side movement of the chassis, faster leaning over in corners and, by extension, more agile handling.

At the same time, the reduction in engine size without changing the wheelbase enabled swing arm length to be increased by as much as 30 mm. The longer swing arm improved road tracking performance for the rear wheel. With this change, the New Generation improved rear wheel stability under deceleration, which was one of the problems with the standard RC211V, and improved traction under acceleration as well.

Comparison of fairings between the New Generation RC211V (red) and standard RC211V (blue)

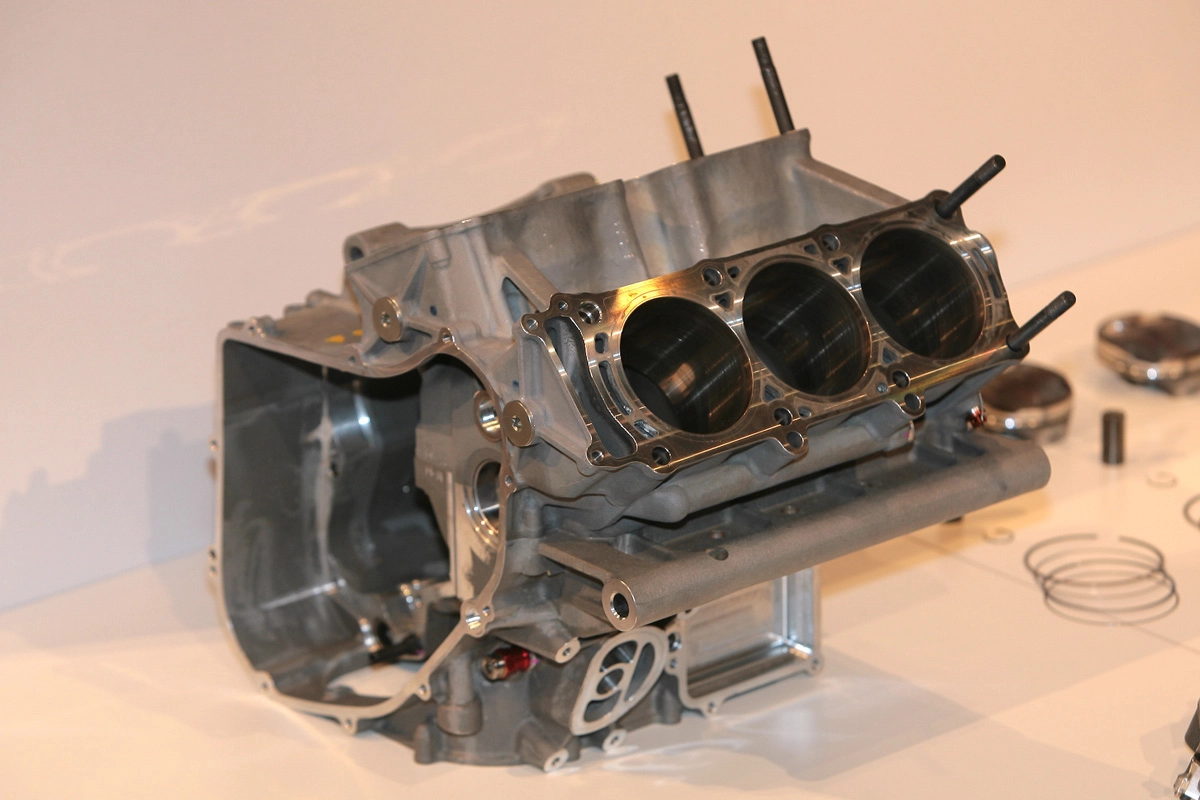

Increasing engine output while reducing size and weight

Remaking the engine is a major task, and one only infrequently undertaken by Honda over its long history with top-class road racers. Even so, Honda decided to revamp the engine as well on its New Generation RC211V, reviewing both cylinder number and layout. After careful consideration, it chose the same engine type as used on the existing machine, with a V5 engine, a three shaft configuration (crankshaft, main shaft, and countershaft, with the crankshaft rotating in the forward direction) and semi-dry sump. This was a reaffirmation of the superiority of the standard RC211V concept.

With a V-angle of 75.5° (angle between the two cylinder banks in a V-type engine), irregular interval ignition (firing order and ignition timing: cylinder #2 – (75.5°) – cylinder #5 – (104.5°) – cylinder #3 – (180°) – cylinder #4 – (75.5°) – cylinder #1 – (284.5°) – and back to cylinder #2), and bore and stroke of 75.0 mm and 44.8 mm respectively, the New Generation engine inherited a number of existing specifications.

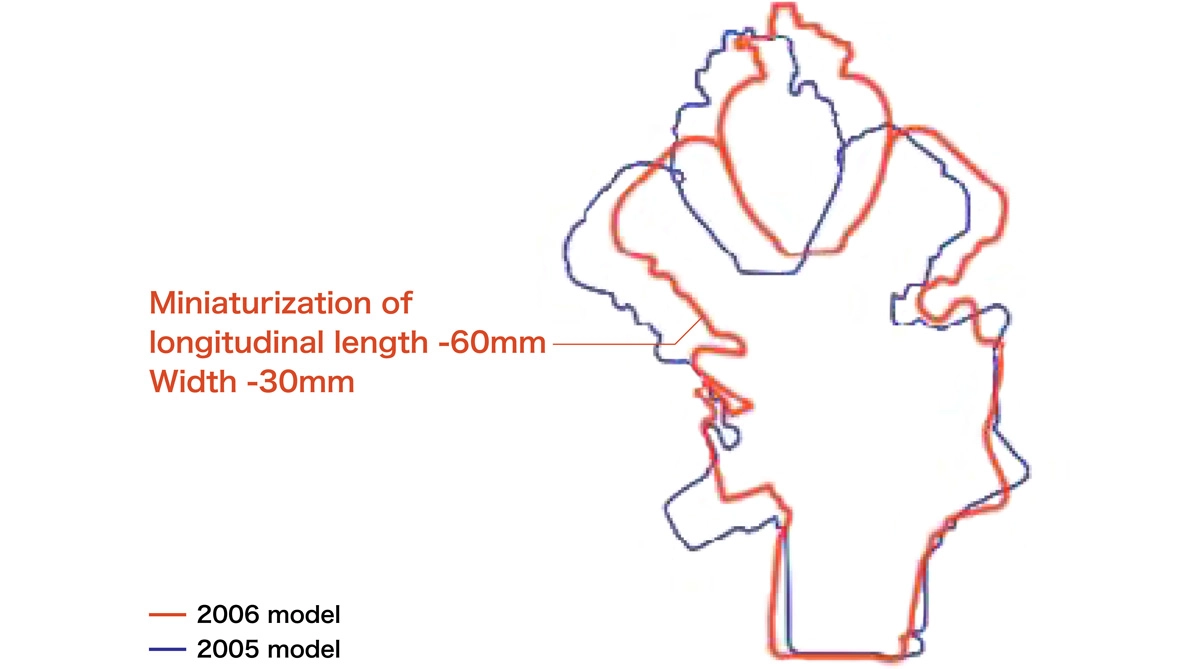

On that basis, Honda’s engine developers thoroughly investigated downsizing of the engine, which was a major theme for the New Generation. With the V5 engine mounted transversely, the front bank cylinder bore pitch was reduced to 80 mm from the standard 85 mm, while the same on the rear bank was reduced to 64 mm×2 from the standard 68 mm×2. The crankshaft length was reduced by as much as 21 mm, with the front/rear bank cylinder offset also being reduced by 1 mm. Space behind the crankshaft was reduced as well, and the distance between the crankshaft and countershaft was reduced significantly by as much as 27.3 mm. Various other detailed changes were made, combining to create a compact engine for the New Generation that was 60 mm shorter in the longitudinal direction and 30 mm shorter in the lateral direction, without adding to engine height. The new engine weight was 57.29 kg, compared to the standard RC211V engine weight of 61.69 kg (2005 model), to achieve lightweighting of 4.4 kg, or approximately 7%.

New Generation RC211V engine in 2006

Comparison of engine size between the New Generation RC211V (red) and standard RC211V (blue)

Honda engine developers then ventured to take on the difficult challenge of increasing engine output with a dramatically smaller engine on the New Generation RC211V, which they succeeded in doing. A major means of achieving this goal was to lightweight the reciprocating parts of the engine, including the piston pins that were lightweighted by almost 25%, from the standard individual weight of 38 g down to 29.3 g. A major factor in this achievement was daring to reduce pin diameter from 17 mm to 15 mm. It was also an area where the developers decided to take a chance in design of the New Generation engine. They also reduced individual piston weight from 127.3 g down to 122.4 g.

At the time, MotoGP engines used metal valve springs, and it was the performance of these parts that determined maximum engine speeds. For successive generations of the RC211V, Honda used its own unique valve spring material for all models up to 2005, which it changed to a new material for the New Generation. With this change, it was able to increase maximum speed to 17,000 rpm from the standard 16,500 rpm. This represented an engine speed that was very close to the limits for a high-output four-stroke engine using metal valve springs and producing about 38 kW of power per 198cc cylinder (total engine displacement of 990cc divided by five cylinders). Honda also increased the compression ratio considerably to 13.9 from the existing 13.2. These changes had the affect of dramatically increasing maximum output to 190.2 kW from 184.0 kW.

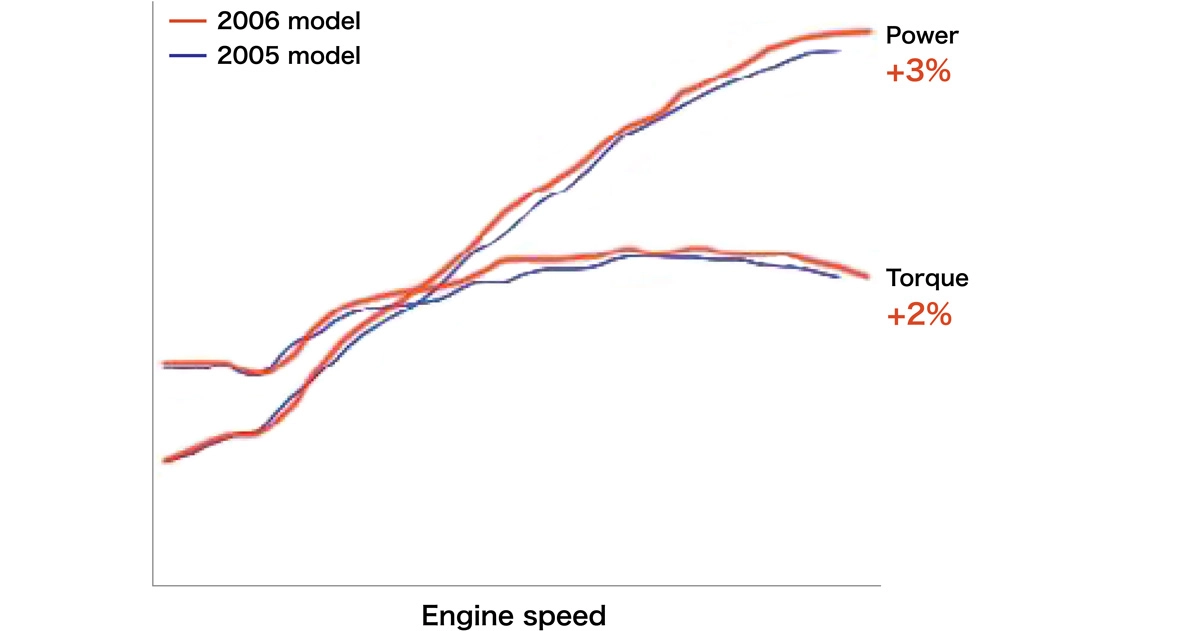

Comparison of engine output (+3%) and torque (+2%) between the New Generation RC211V (red) and standard RC211V (blue)

In the meantime, increasing maximum engine speed to increase output while reducing engine size and weight shifted the physical strains on the engine, which came out in durability. With RC211V models from 2004, Honda overhauled the valve train roughly every 700 km, but the valves could only be guaranteed for less than half that distance with the New Generation engine. For this reason, it adopted a rotation whereby engines used from the start of each race week would be removed on the Friday after finishing racing for the day. New engines would then be installed for the preliminary heats on the Saturday and the final race on the Sunday, running the engines for between 100 and 130 km at a time.

The 2006 season of the MotoGP comprised 17 rounds, but only Nicky Hayden, one of Honda’s two works riders in that season, rode the New Generation RC211V. Even so, Honda manufactured a total of 76 New Generation engines. Meanwhile, there were another six riders in Honda-affiliated teams, including the other works rider Dani Pedrosa, who rode 2006 model RC211Vs with standard specifications, but Honda only manufactured 78 of those engines in total. In relation to the 76 New Generation engines, a huge number of test engines were included as part of the new development, showing just how focused Honda was on this initiative at the time. It was also a situation only possible when there were no limits on the number of engines that each rider could use in a single season. (By contrast, riders were limited to seven engines each during the 2024 MotoGP season.)

Honda also evolved its engine-based deceleration control. Other standard RC211Vs at the time employed electronically controlled throttles with uniform opening for all cylinders. However, the New Generation employed wired control directly linked to opening of the throttle grip by the rider for the three cylinders in the front bank, and the electronically controlled Honda Intelligent Throttle Control System 2 (HITCS-2) for the two cylinders in the rear bank only. This provided control that was more in line with the linearity really required by the rider in situations needing precise throttle control. In actual use, this gave the New Generation higher cornering speeds than the standard RC211V, with minimal variation of engine speed under deceleration and greater throttle opening after deceleration.

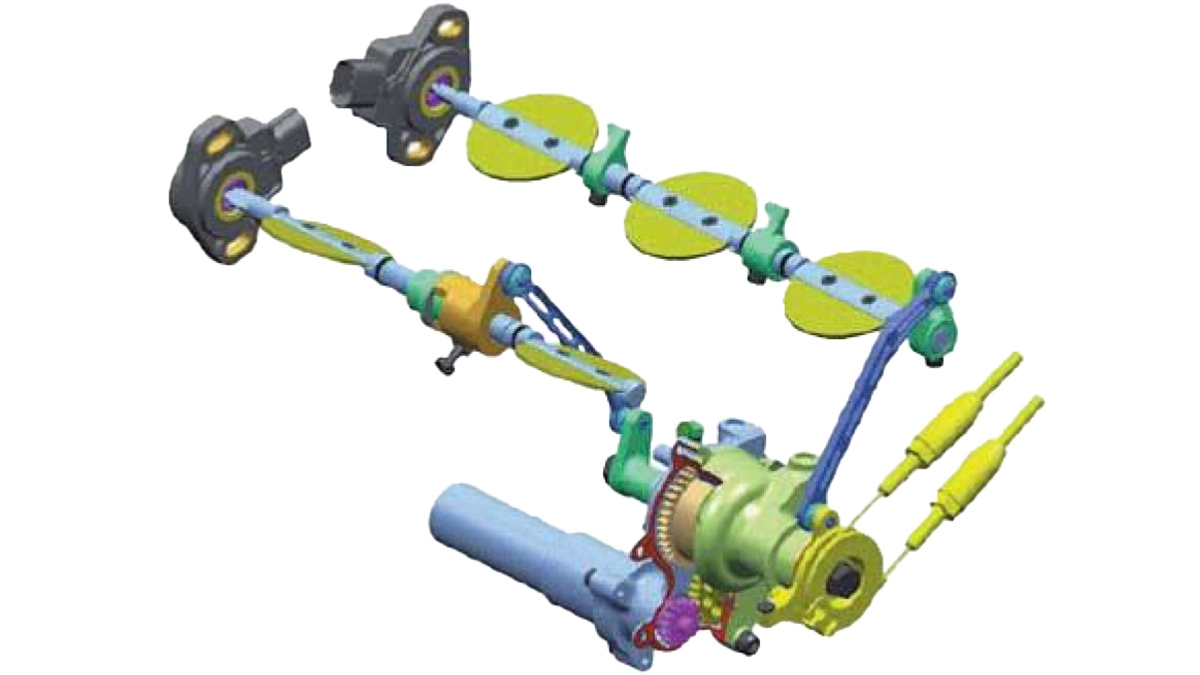

HITCS-2

A more compact chassis with rebalanced rigidity

Through the strenuous efforts of the engine development team, Honda created a compact engine that met the demands of the chassis development team, with the chassis itself determining overall layout for the machine. Thankfully, this enabled use of a 30 mm longer swing arm on the New Generation RC211V while keeping the same wheelbase as the standard RC211V.

Comparison of swing arm length between the New Generation RC211V (red) and standard RC211V (blue)

In other words, Honda created a brand new frame and swing arm for the New Generation that did not share design with the standard RC211V. In that process, the developers reconsidered the rigidity balance of the chassis. They used computer-aided engineering (CAE) analysis to clarify which members impacted handling stability, and conducted a series of field tests on test machines with prototype parts in search of the optimal balance.

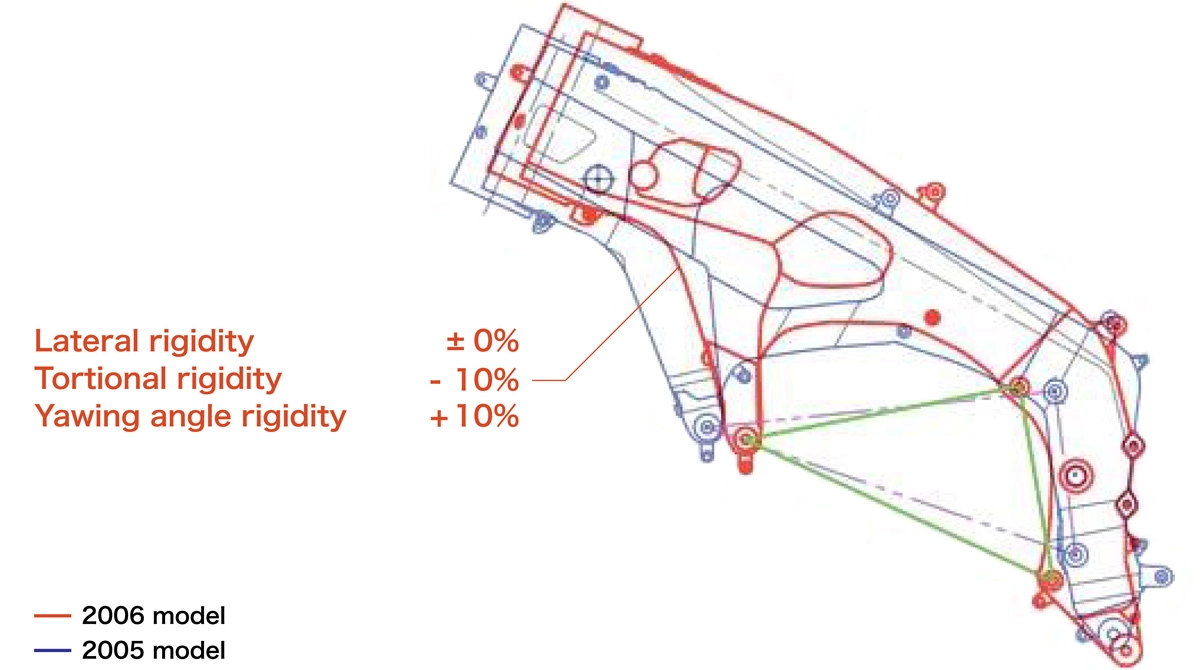

With motorcycles, handling is better on machines with a certain degree of chassis flexing, or deformation. Rather than just focusing on the numbers when developing the chassis for its RC211V, Honda worked out the technical specifications by also emphasizing how the machine felt to the riders. As a result, it kept the same rigidity relative to the bending moment in the longitudinal direction, but increased bending rigidity in the lateral direction, which was deliberately set quite low for the standard RC211V, by 10% for the New Generation. It also reduced torsional rigidity, which was conversely set quite high, by 10% in a rebalancing of rigidity for the chassis.

Comparison of frame shape and rigidity between the New Generation RC211V (red) and standard RC211V (blue)

In achieving a chassis with balanced rigidity, Honda also adopted a new manufacturing method for the New Generation frame and swing arm. Instead of making these parts by joining and welding box beams from aluminum sheet metal parts formed into U-shaped channels, fabricated according to the shape of each member, it adopted a method of machining aluminum ingots into the desired shapes. With evolutions in machining technologies enabling fine changes to be made to sheet metal thickness and other factors, Honda was able to achieve considerably more appropriate rigidity for each chassis member.

The forwardmost fastening point (called point “A” by Honda), where the engine was attached to the frame, was much lower on the standard RC211V than existing machines at the time. However, Honda lowered this point A further again on the New Generation. Lowering point A created a larger frame cross-section in the vertical direction, thereby gaining torsional rigidity. At the same time, the distance of point A from the main frame pipe facilitated lateral movement (and therefore lower lateral rigidity). Honda was able to achieve balanced rigidity by pushing this technique even further.

Incorporating these new philosophies and technologies, the New Generation chassis achieved reductions in the various moments of inertia by as much as 0.9% in the roll direction, 0.5% in the yaw direction, and 3.4% in the pitch direction. It also led to improvements in stability under deceleration, cornering performance, and traction (acceleration performance).

New Generation racing results and evaluation

The New Generation RC211V only ever competed in one season of the MotoGP, in 2006. While that was the way it ended up, Honda had originally wanted to introduce the model as early as possible in the 2005 season. In other words, the New Generation was planned to follow on from the 2005 RC211V (type NV5D), so it was really the NV5G. (Letters E and F were not used for model types because of the possible confusion with E for engine and F for frame.) It was actually raced for the first time in the opening round of the 2006 season because it took a lot of time to achieve durability in an engine that had to be both more compact and deliver higher output. Therefore, while the 2006 RC211V with standard specifications was actually the NV5H (being a modified version of the NV5D model in 2005), it became known as the NV5HD, and the New Generation became known as the NV5HG to differentiate the two.

In any event, the New Generation raced in all 17 rounds of the 2006 MotoGP season, and Nicky Hayden, its only rider, performed brilliantly to take out the championship. The 2006 season was also the end of the 990cc engine era of the MotoGP but even so, Honda had achieved its goal of developing a new racing machine with a redesigned engine.

2006 Dutch Grand Prix

Nicky Hayden, winning the 2006 Dutch Grand Prix on the New Generation RC211V and giving Honda its 200th victory in the top class of the Road Racing World Championship

Hayden was often a little slow off the start in the finals of the 2006 season, with only two outright victories, but he completed 16 of the 17 rounds, with three second places and five third places, for which he accumulated points. The smaller, lighter, and higher-output engine achieved durability that remained just within the bottom of acceptable levels throughout. However, it was able to consistently finish at a high level thanks to the great efforts of Hayden and to the determination and technical strength of a totally committed Honda, as evidenced by the 76 New Generation engines it manufactured for what turned out a machine for his exclusive use.

The 2006 RC211V with standard specifications (NV5HD) was also evolved from the previous year, producing a total of six wins for the season. They came from Pedrosa (two wins), Marco Melandri (three wins) riding for Fortuna Honda, a Honda satellite team (an independent team paying a fee to use Honda works machines), and Toni Elias (one win), another Fortuna Honda rider. While proving the validity of the standard RC211V concept throughout the era of 990cc machines, this result was also the driving force behind Honda recapturing the constructors’ title that year.

Standard (NV5HD) RC211V in 2006

While recognizing that the New Generation was not necessarily outstanding in every aspect, Honda's developers believed that their machine concept was the right one. That belief was embodied in the RC212V, Honda’s new machine that it debuted the following year, in the 2007 season. From this 2007 season, the MotoGP era of machines with maximum displacement of 800cc began. The RC212V that Honda introduced that year was an even more compact machine than the New Generation RC211V, but it was a machine built on a concept evolved from the New Generation.

2007 RC212V(NV6A)