On November 7, 2023, Honda unveiled new electronic control technology for motorcycles. "Honda E-Clutch" enables starting, shifting, and stopping without manual clutch lever operations by automatically controlling the clutch*1. It's a world's-first technology*2. In the spirit of "Technology for people", how has drivetrain technology evolved? Three developers reveal their inner thoughts concerning continuous and challenging development over 10 years.

*1Shifting operation using the shift pedal is required.

*2According to research by Honda (as of October 2023).

Assistant Chief Engineer

Vehicle Research Department

Vehicle Development Division

Development and Production Unit

Motorcycle and Power Products Operations

Honda Motor Co., Ltd.

View More

Close

Junya Ono

Read More

Assistant Chief Engineer

System Innovation Department

System Development Division

Development and Production Unit

Motorcycle and Power Products Operations

Honda Motor Co., Ltd.

View More

Close

Tatsuya Ryuzaki

Read More

Assistant Chief Engineer

Vehicle Research Department

Vehicle Development Division

Development and Production Unit

Motorcycle and Power Products Operations

Honda Motor Co., Ltd.

View More

Close

Aska Ito

Read More

Retaining the joy of riding a motorcycle. Creating a new world-view with "Honda E-Clutch"

What kind of technology is "Honda E-Clutch"?

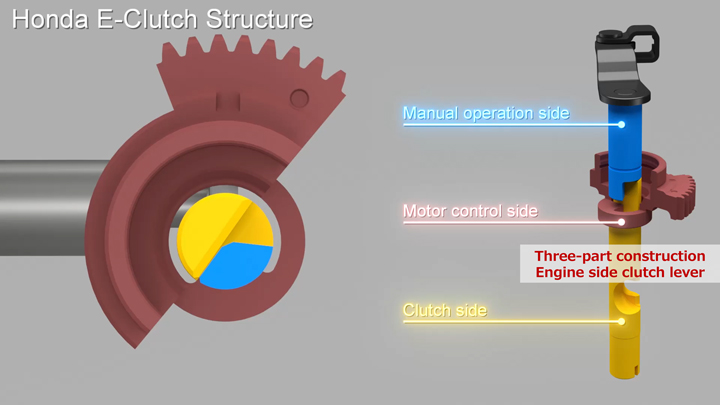

The core structure of the system, the three-part engine-side clutch lever. It consists of a manual operation lever (above diagram: blue), motor control gear (above diagram: brown), and clutch-side lever (above diagram: yellow). The structure allows independent operation of manual clutch lever operation and clutch control by the motor.

The core structure of the system, the three-part engine-side clutch lever. It consists of a manual operation lever (above diagram: blue), motor control gear (above diagram: brown), and clutch-side lever (above diagram: yellow). The structure allows independent operation of manual clutch lever operation and clutch control by the motor.

Honda was the first in the world to introduce the Dual Clutch Transmission (DCT) to motorcycles in 2010. How is "Honda E-Clutch" different from DCT?

For motorcycles equipped with DCT, there is no need for a clutch lever or shift pedal. The system takes care of clutch operation and shift changes on behalf of the rider. On the other hand, motorcycles equipped with "Honda E-Clutch" still have both the clutch lever and shift pedal. This is a significant difference. In the case of "Honda E-Clutch", there is no completely automatic (AT) mode. Riders need to perform the shift operations themselves, requiring the use of the left foot for the shift pedal.

The ability to perform clutch operation at any time is a significant feature of "Honda E-Clutch". Clutch operation is a point where differences in driving skills can be apparent. However, mastering challenging operations and turning them into skills is also one of the enjoyable aspects of the appeal of motorcycles. Rather than relying entirely on automatic transmission (AT) technology, riders can freely choose and operate in various riding scenarios. Sometimes opting for more comfort and at times opting for a more sporty feel. In this manner, I hope many people can experience the joy of riding.

At the EICMA 2023 (The International Two-Wheeler Exhibition) held in November in Milan, Italy, the exhibition booth for "Honda E-Clutch" attracted a large crowd.

At the EICMA 2023 (The International Two-Wheeler Exhibition) held in November in Milan, Italy, the exhibition booth for "Honda E-Clutch" attracted a large crowd.

The motorcycles on the right in the photo are the CB650R and CBR650R, which feature the "Honda E-Clutch".

The motorcycles on the right in the photo are the CB650R and CBR650R, which feature the "Honda E-Clutch".

Project cancellations, the hurdle of mass production. Still, a relentless 10 years that couldn't be given up.

Tell us about the circumstances of development

During the advancement of DCT, there was a demand for the next technology that would be simpler in design, balancing cost considerations. While clutch control technology gained support, challenges such as the higher price range and increased vehicle weight compared to MT (manual transmission) motorcycles emerged. It was around 10 years ago that we began thinking about how to overcome these issues.

First, we started by leveraging the knowledge from DCT and thinking about applying that technology to develop an electronic control clutch (hereinafter referred to as "E-Clutch"). In the prototype stage, we believed we had developed a technology that we could confidently present. However, as we progressed with research and development aiming for integration into production vehicles, we faced challenges in achieving cost-effectiveness, lightweight design, and integration goals. There were many setbacks, and ultimately, the project was discontinued midway. As the development scale reduced, the team gradually dwindled, and eventually, the only ones left were Ryuzaki and me.

When the predecessor project was discontinued, there were feelings of regret, thinking, "If only we had done this differently, or if we had approached it that way". And the frustration from that time became the driving force behind the development of this project.

When the predecessor project was discontinued, there were feelings of regret, thinking, "If only we had done this differently, or if we had approached it that way". And the frustration from that time became the driving force behind the development of this project.

At that time, although the technology was technically viable, we couldn't overcome the barriers of cost, weight, and integration, ultimately leading to the project not moving towards mass production. Having had confidence that we could create something good during the development stage, it was a very frustrating experience.

What aspects of electronic control for the clutch were particularly challenging?

After the conclusion of the predecessor project, when initiating the Honda E-Clutch project, we reworked the concept around the theme of "Evolution of Manual Transmission Vehicles". During that process, it was non-negotiable that the clutch lever was deemed necessary. Capable of both automatic control and manual operation. Achieving the goals of cost reduction, weight reduction, and compactness while making it adaptable to a wide range of models and maintaining both automatic control and manual operation was necessary. To achieve these goals with the minimum necessary configuration, we adopted a technology that directly controls the clutch with a motor, something that had not been tried before. In the realization process, we incorporated Honda's expertise in robotics, including motor and sensor configurations and control theory for processing speed. Additionally, with the wealth of experience in mass production development of DCT and quick shifters*3, Ito, who is of similar mindset with me and joined the development at the same time, was a great support both technically and mentally.

*3This system uses a sensor attached to the shift rod of the bike to momentarily control the fuel injection amount and ignition timing during upshifts, allowing the rider to change gears simply by operating the pedals.

During the development, we had dynamic test evaluation members ride for testing, discussed improvement points, and programmed the logic. While trying various scenarios, we repeated this process, and including the predecessor project, we revised the software specifications more than 500 times in total.

Due to the characteristics of the system, members of the technical evaluation and veteran engineers around us opposed, suggesting that it might be better to change the control philosophy. There were months of discussions between the members advising to suppress the output through control intervention for the sake of system durability and the development team emphasizing the user-friendliness and operability for riders. In the end, we were able to reach a specification that everyone was satisfied with.

Through repeated trial and error until the team was satisfied, the performance of the completed motorcycle and the comments from test rides gradually became more positive. We began to feel positive and optimistic that we could mass-produce this world’s-first technology.

Through repeated trial and error until the team was satisfied, the performance of the completed motorcycle and the comments from test rides gradually became more positive. We began to feel positive and optimistic that we could mass-produce this world’s-first technology.

What kind of innovations did you make to realize this new technology?

Based on reviews of the predecessor project, we thoroughly reviewed costs, simplified the system, and worked on weight reduction. The incorporation of Honda Robotics expertise was significant in simplifying and reducing the weight of the system, as mentioned earlier.

When considering costs, a significant decision point was determining which location would become the production base. In Honda's large motorcycle division, it is customary to produce major new technologies, such as world’s-first innovations, at domestic facilities. However, considering the frustrating experience from the predecessor project, there was a keen awareness of the need to align with the internal trends for the mass production of the E-Clutch. Therefore, we proceeded with considerations for applying it to models produced in Thailand, which would be advantageous in terms of cost. To succeed in this challenge, we overcame language barriers, engaged in numerous discussions, and matured the specifications. As a result, we were able to achieve an appropriate cost.

Furthermore, to fill the gap by involving stakeholders from various fields and departments worldwide, we conducted numerous test rides. Ultimately, we took the prototype to Europe for test rides, allowing participants to experience the allure of the system.

During development, ensuring the stable operation of the Motor Control Unit (MCU) and refining the control system took time. Handling tests and evaluation events was always a battle against time. To expedite the development in a short period, we introduced Model-Based Development*4, a technique commonly used in the development of automobiles, for the first time in Honda's mass-produced motorcycles. I believe the situation would have been challenging if we had proceeded with the previous approach.

※4A methodology that involves creating a model on a computer, replicating the real-world scenario without producing prototypes, and conducting development and validation through simulations.

This project has been a decade-long endeavor, counting from the start of the predecessor project. What kind of feelings kept you going throughout this journey?

The development of "Honda E-Clutch" involved repeatedly refining the basic concept. It was pushed forward while searching for suppliers willing to cooperate, all the while with uncertainties about the applicable models and production volumes. Moreover, amidst the COVID-19 pandemic with restrictions on in-person activities, it was a very challenging project to undertake a new technology configuration in a small team and within a short period. In the continuously challenging development, there were many times when I thought, "It's impossible, we won't make it", in my mind.

Until the full-scale mass production development of Honda E-Clutch began, there were moments of anxiety and loneliness, wondering if the technology developed would never be applied in mass production. To be honest, there was a time when I thought about leaving the company. Nevertheless, with the support of those who fought alongside me, the people who cheered us on, the suppliers, not only in Japan but also in Thailand, Europe, and many comrades from around the world, and with the cooperation of my family, who allowed me to focus on my work, I have been able to come this far. I feel that the various failures, experiences, and connections with the people involved over the past 10 years have finally borne fruit as the dots have connected. I got emotional when I saw the system working smoothly during the final inspection of the assembled motorcycles at the production plant in Thailand. Despite the challenges, what we have done was not in vain.

After the predecessor project was discontinued, I became involved in a different mass production development. However, because I was determined to bring the E-Clutch to fruition, I repeatedly appealed to my supervisors, saying, "Please let me focus exclusively on E-Clutch". Finally, I was able to gain their approval. During the COVID-19 period, we had numerous online “Waigaya”*5 sessions with Ono, thoroughly debating various aspects. The project we've been passionately working on together, almost to the point that others around us might find it excessive, (with a wry smile) made us reluctant to give up.

*5"Waigaya" refers to the unique culture of Honda to engage in open-minded and vigorous discussions about our dreams and how we work by sharing opinions regardless of the age or job title of the participants.

Successfully managed to persuade senior colleagues and supervisors who opposed the idea of proposing a new supplier for MCU development due to high risks. Amid this rechallenging project, the belief remained unwavering throughout.

Successfully managed to persuade senior colleagues and supervisors who opposed the idea of proposing a new supplier for MCU development due to high risks. Amid this rechallenging project, the belief remained unwavering throughout.

I joined the E-Clutch project later, having been in the mass production development group for a long time. Unlike mass production projects, a new project like the E-Clutch had the challenge of not knowing if our efforts would come to fruition, and proceeding with development without a clear future. I believe the two of them faced significant mental challenges. In such circumstances, witnessing the relentless determination of the two of them without giving up, when I was assigned to the project, I said to myself , "Finally I can join!" I also wanted to take the world’s-first technology to the stage of mass production, so I was determined to make it a reality. Looking back now, I am grateful for the opportunity to share thoughts with colleagues I trust and respect, envisioning the world after mass production. It was a fulfilling experience to work on projects that explore Honda's expertise and philosophy.

DCT, from our perspective, was primarily led by the seniors who were one generation before us, and they played a central role in its mass production. Therefore, we were determined to bring E-Clutch to fruition during our generation no matter what. However, over time, the determination to bring it to the world became a shared goal among all the people involved in the development.

DCT, from our perspective, was primarily led by the seniors who were one generation before us, and they played a central role in its mass production. Therefore, we were determined to bring E-Clutch to fruition during our generation no matter what. However, over time, the determination to bring it to the world became a shared goal among all the people involved in the development.

Because it's us, because it's Honda, we do what only we can do. We want to give back through new technology.

What expectations do you have for how "Honda E-Clutch" will change the world?

While preserving the charm of riding and controlling the bike manually, I believe that with the assistance in clutch operation, riding will become even more enjoyable. With the ease provided in cornering and other aspects, controlling the machine as intended becomes more effortless. I hope this feature attracts a lot of users.

I believe that the performance is good enough that you won't need to grip the clutch lever under normal riding conditions. Actually, the level of completion is just that high. Since we kept the manual lever, even when the system is off, you can still shift, and it's also possible to engage a gear while parking on a slope to prevent the vehicle from rolling down the hill, because the wheels don’t turn.

For example, let's say you're going camping. There may be scenes where the road to the campsite is unpaved and has poor footing. Thanks to the automated clutch operation, the rider can focus solely on controlling the vehicle on rough terrain without the risk of stalling. The expanded options for motorcycle touring are expected to broaden the range of activities and destinations. I hope we can expand the possibilities of new motorcycles.

Honda has the slogans “The Power of Dreams” and “How we move you.”. What dreams do you have for the future?

I wanted to work in technical development when I was looking for a job. I considered various fields for development, including home appliances, but what intrigued me about emotionally driven mobility, such as motorcycles used as a hobby, is that it can show various facets depending on the customer and the usage scenario. That's why I joined Honda. I want to continue advancing motorcycle technology as products that stimulate human senses, offering pure enjoyment. Just as DCT has continued to evolve, I aim to further advance motorcycle technology in the next 10 years.

These past 10 years felt like walking through a dark tunnel, with Ono and me constantly on edge, unsure when the project might be terminated. Nevertheless, by refusing to give up and resolving to move forward, we managed to introduce the technology to the world. The understanding, support, and encouragement from those around us played a significant role in this achievement. It might be part of Honda's corporate culture. This development experience has elevated our technical expertise and contributed to our personal growth. While we are grateful to the company that gave us a chance despite being initially discontinued, we hope to repay that gratitude by bringing smiles to people worldwide through Honda-style products and services.

I have always wanted to develop technology that can change the world. If we are going to do something, I have always believed that we should not just follow the path that our predecessors have paved, but rather, we should do something that only we can do. I want to make customers happy with that technology, create something even more enjoyable. With that determination, I joined Honda, so perhaps the slogan "The Power of Dreams" naturally resonated within me. After ten years of continuous development, I have many things I want to do and numerous ideas. The evolution of one technology can lead to the development of others, sparking further innovation. I want to continue creating technologies, products, and services that can change the world in the future.

The past technologies that have shaped Honda's history have also overcome numerous challenges to come into existence. So, there's no reason we can't do it ourselves. The lineage of passion for development will continue in the future.

The past technologies that have shaped Honda's history have also overcome numerous challenges to come into existence. So, there's no reason we can't do it ourselves. The lineage of passion for development will continue in the future.

Original article issued on December 22, 2023

It's a technology designed to make riding manual transmission (MT) motorcycles even more fun. The joy of riding a motorcycle using the throttle, brakes, clutch, and shift pedal with both hands and feet is the essence of riding. With "Honda E-Clutch," you can retain that joy while enjoying smart and smooth acceleration as well as seamless and quick gear shifts, without manual clutch operation. In various riding scenarios such as starting, shifting, and stopping, the system performs the required clutch operations. This allows veteran riders to enjoy sporty riding with ease, while beginner riders can experience comfortable and enjoyable rides tailored to their respective skill levels.