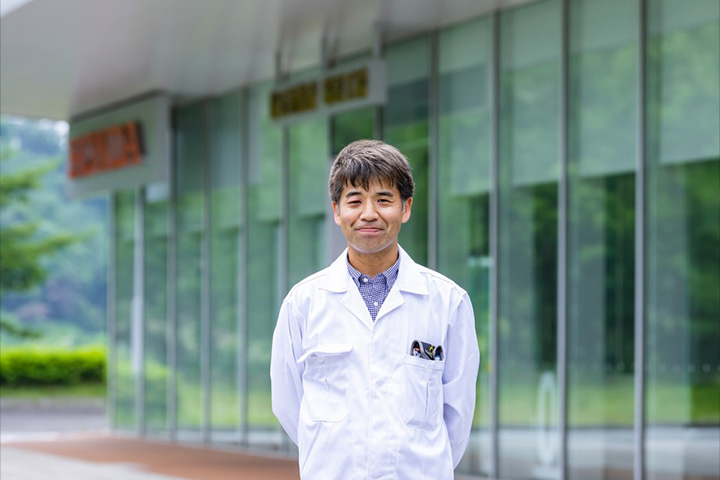

Hayashi has been in charge of maintaining production equipment for about 10 years with the desire to improve product quality through equipment maintenance. Currently, he is utilizing the knowledge and experience he has gained through maintenance work to reduce energy consumption in parts manufacturing equipment at the Honda Yorii Plant. We spoke to Hayashi, who says, “I don't want to leave any homework for the future” about his thoughts on achieving carbon neutrality, Honda 's corporate culture, and its vision for the future.

Plastics Department

Automobile Plant (Yorii)

Saitama Factory

Automobile Operations Production Unit

View More

Close

Tetsuo Hayashi

Read More

Contributing to energy reduction through maintenance work for equipment

First, please tell us how you joined Honda.

What kind of work is the maintenance specifically?

To put it simply, I have the image of an “equipment doctor”. Maintenance work involves maintaining factory equipment and responding to the voices of people in the field “We prefer to do this in this way ”, such as improving production efficiency and reducing defective products. If it becomes easier to work on-site, the quality of the products can be improved as a result. In that sense, I think it is an important job that plays a part in manufacturing.

You are currently working at Honda's Yorii Automobile Plant. What kind of work do you do?

In addition to being a manufacturing base, Yorii Plant also plays the role of disseminating Honda's technology to the world as a “plant to be considerate of people and the environment”. Our department that manufactures automobile bumpers and instrument panels is working to reduce energy consumption within our plant section, and update and remodel existing equipment to strengthen its infrastructure.

As an example, we have introduced a system to "visualize" energy for each module (component) of equipment. Two years ago, I updated the system, and it has become easier for people on site to understand and to visually check energy loss. In addition, we are reducing energy consumption in the air conditioning equipment used for bumper painting and the quality inspection process for instrument panels, and are currently incorporating simulation to find the optimal method to achieve maximum effect at less cost.

I can take on the challenge because I am trusted

You have also been selected as a member of the “Yorii Carbon Neutral Project”, which aims to build production technology that reduces environmental impact and strengthens the production structure. Could you tell us about your motivation and thoughts on this project?

Ever since I joined the company, I've wanted to contribute to solving environmental issues, so I'm very happy to be able to directly contribute in this way. There are many hurdles to overcome in making a production factory carbon neutral, but that's why I find it rewarding to introduce electrified equipment and explore ways to reduce energy consumption.

We are working on project measures with the cooperation of manufacturers other than Honda and people from other industries. It's fun to work together across company boundaries to expand the scope of our efforts.

From your perspective, what do you think are Honda's strengths and appeal?

One of Honda 's corporate culture characteristics is a spirit of challenge. Even in the carbon neutral project, when we team members put our heads together, we get excited and think, “This is how we can make it” and “Let's try harder”. As we share the desire to aim even higher within the company, we often come up with solutions naturally.

I also think that Honda's appeal is its culture of respecting people's opinions, regardless of their position. My direct superior does not deny the opinions and wishes of his subordinates, but rather trusts us completely and entrusts us with the work. If you have this much faith in me, I won't be able to do anything bad (laughter). Since we are trusted, we work with the desire to live up to expectations.

The presence of your boss is very important.

That's right. My boss has helped me a lot during my first five years at Honda. To be honest, I think, to my boss, it did not matter whether I was there or not at that time. However, about five years later, when I was on a business trip to China almost every week, he told me, “Without Hayashi, we won't be able to move forward with our work.” At that time, I thought, “I've finally become someone that people need” and I was so happy. “Now I can repay the favor”.

Passing down the inherited will to the next generation

Tell us about your future vision.

Our top priority is to make our production plants carbon neutral by 2050. This is both Honda's mission and the Japanese government's goal, so we want to share our technology with other manufacturers and people in other industries to ensure we achieve it.

Although it may not be well known, Honda developed the “CVCC engine” in 1972 , and has a history of being the first in the world to clear the extremely difficult exhaust gas control laws. Honda's environmental awareness has been high ever since then, and the development was based on the desire to leave a better legacy for the next generation.

As we move forward with our project to make our production plants carbon neutral, we hope to pass on this will that has been passed down in Honda to the next generation. I have children myself, and I don't want to leave “homework” behind in the future. That's why I think we need to do what we need to do.

Is there anything you would like to do to achieve your vision?

Over the next five years, I would like to use the experience gained at Yorii to spread the awareness of achieving carbon neutrality at production plants, both within and outside the company. First, we will demonstrate it in Yorii and pass on what we have accomplished to our juniors. Furthermore, we hope to pass on the technology and know-how we have cultivated to the local community and raise the level of environmental awareness in the world. Yorii Plant has a mission of “becoming an environmental top runner”, so we would like to embody that mission.

All of the members of the Yorii Carbon Neutral Project, myself included, have a strong determination to “accomplish the project since we have been selected”. I would like to continue working on my daily work with the belief that “our efforts will absolutely benefit the future of the Earth”.

Original article issued on October 9, 2023

<Related Articles>

I've loved cars since I was a child, and I first became interested in Honda through the influence of my father, who was a fan of Honda products. I entered technical school and worked on diesel engines for my graduation research. I had a vague idea that I wanted to work for a car manufacturer after graduation, but at the time Honda was selling the Accord Diesel in Europe, and I thought it would be interesting to develop a diesel car at this company, and I took the entrance exam.

However, the product development and engine domain departments were very popular and difficult to be assigned to. In the end, I was assigned to work in maintenance, but after hearing a story from a senior employee at the job offer ceremony, I learned that I could contribute to manufacturing through maintenance, so I decided to do my best in this job.