Developing Honda’s First Small Car, the 1300.

Reveals Turning Point in Corporate Structure

In 1967, Honda started development of the 1300 to enter the small passenger car market. Soichiro Honda, who spearheaded the project, paid particular attention to the air-cooled engine. Indeed, the N360, a k-car equipped with an air-cooled engine, had become a best-seller. However, the developers were doubtful whether an air-cooled engine could be associated with a small passenger car. There were too many issues unique to air-cooling, such as noise and heat. However, the developers decided to continue planning the small car with an air-cooled engine based on Soichiro’s confidence that the company had consistently produced air-cooled motorcycle engines and was the top manufacturer in the highly competitive motorcycle industry, and on the belief that air-cooled engines are easy to maintain, are resistant to changes in temperature, and can be used safely over a wide geographical area.

After many difficulties were overcome by the developers, the air-cooled engine was complete, and the 1300 was launched in May 1969. Many dealers had hoped that they would be able to sell a car with technology unique to Honda. However, the reaction from customers was extremely harsh. Despite doing its best from the conception stage to production, Honda was unable to achieve the expected sales volume.

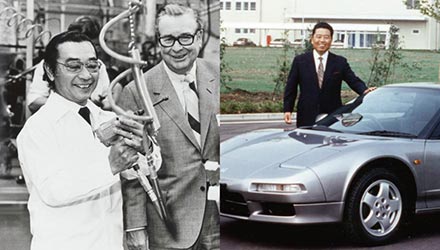

What was the 1300’s problem? Hideo Sugiura, then the head of the R&D Center (later chairman of Honda), looked back upon the time:

“Simply put, we didn’t quite understand what kind of product the automobile should be... During development we did not pay sufficient attention to the customer's perceptions. ... As a result, we neglected the most important measurement of quality and market value, meaning who was going to drive the car and how it would be used. That mistake was the most important lesson we learned from the H1300.”

Around two months after the 1300 was released, Sugiura and other visited Soichiro. Their purpose was to convey the voice of Tadashi Kume (later the third president of Honda) and others who had been involved in the design of air-cooled engines since the N360. Kume could see the limitations of the air-cooled engine. The development of an engine compliant with emission regulations was imminent. In front of Soichiro, Sugiura and others insisted on the necessity of developing a water-cooled engine. After much persuasion, the ban on water-cooled engines was finally lifted.

The lessons learned from the 1300 became the turning point for Honda’s product development that followed.

1300, the trigger for change in Honda’s development system.

From Development Based on One Genius,

to Development by Team

The 1300, with its constant design changes, was far from efficient in terms of development. Amid the ever-increasing lineup of Honda car models and expanding scope of engineering, it was no longer possible for a single genius (Soichiro Honda) to run the entire operation.

In April 1971, Kiyoshi Kawashima, then R&D Center’s acting-president from Honda, and later to be Honda’s second president, took formal leadership of R&D. Kawashima immediately began reforming the R&D structure. He launched a new R&D system (R&D development flow) with the goal of “creating original products with enthusiasm.” Kawashima focused on bringing together outstanding talents in individual specialized fields and heading in a united direction. Based on this idea, Kume took the lead in establishing the development system and reforming the organization.

Kume, who was instructed by Kawashima to “reform the R&D Center’s methods to a group leadership system,” was also told:

“Each one of us are ordinary people, unlike Mr. Honda. Nevertheless, I'm sure we all have at least one thing that is a little better than Mr. Honda's. Let’s bundle them up and work together.”

The framework of the new development system had the following elements:

- 1 The simultaneous, competitive development of different models, along with the separation of D-development and R-research, including research of technologies previously unknown

- 2 Promote participation of sales and manufacturing departments in the process from the start of development.

- 3 Set objectives and target requirements for each product development.

- 4 Establish a team-based promotional system.

- 5 Implement S·E·D evaluation at each stage of development.

- 6 Implement engineering evaluations as supplementary assessments.

(note)

- R-research: Fundamental research phase to complete unknown technology (individual or combined), and development of new technology as the basis for creating attractive products.

- D-development: Development of products to be offered for production and sale, and acquiring new technologies in the R research stage and developing products with these technologies.

- S: Sales

- E: Engineering

- D: Development

This development system was immediately utilized in the development of the first generation Civic and the CVCC engine, which had already been under Kume’s direction since the fall of 1970, to comply with the Muskie Act (U.S. Clean Air Act of 1970), an emission regulation in the United States.

Honda’s “A00,” Borne of First-Generation Civic

Development and Still Inherited Today

At the beginning of development of the first-generation Civic, Sugiura, the R&D Center’s director, issued “Seven Requests” to the development team. This was equivalent to the establishment of “objectives and target requirements” for product development, the third of six elements of the new development process framework.

- (1)A car that k-car users want to drive next

- (2) A car that can be sold through Honda’s sales network and maintenance system

- (3) A car that can be exported to the U.S.

- (4) A car that can be mass-produced and mass-sold

- (5) A car that is uniquely Honda

- (6) Completion of development by the end of 1971

- (7) The body last 3 years, the engine should last with head replacement, and production should continue beyond 1975.

These items clarified what was to be created and made it possible for the entire team to share this information. These seven items, “objectives and target requirements” for product development, were the beginning of “A00,” which has been used as the starting point for Honda projects to this day.

“A00” was coined at the development workplace. Kume, who led the development of the Civic and CVCC engines, described the situation at that time:

“Since we were all working together, it was necessary to have thorough cooperation. That is why we would hold ‘Waigaya’ (Honda’s unique tradition of open-minded and vigorous discussion) sessions. ...We would Waigaya until we all understood what the challenge was, and deepened our understanding of what our goals were. ... We would then define the system for how we would work. ... We even changed how the R&D Center worked. We created an evaluation system, and then we set up the evaluation requirements in stages of D0, D1, and so on. Then, by chance, we came up with the term ‘A00.’”

The development concept was formulated, and the seven objectives and target requirements were fulfilled. When the Civic was launched in July 1972, it created a sensation in the compact passenger car market.

The Civic, developed upon clearly defined objectives and target requirements

The “A00” emerged from the development process.

SED Development System Results from New Honda Program

SED development system:

SED development system: Honda’s system in which sales, engineering

and development act as one to develop

products.

Systemic reforms that began with Honda R&D in 1971 at Kiyoshi Kawashima’s direction evolved into the New Honda Plan (NHP), a company-wide project in 1972. The plan identified problems that had emerged in all divisions, organized them on a company-wide basis while emphasizing the importance of interdivisional linkages, and promoted problem-solving. As one of these efforts, a system that would become the foundation of Honda’s product development system today was established after approximately two years of study.

The SED development system, launched in 1974, aimed to reflect the customer’s voice from the product planning stage, with the S, E, and D departments working together organically to develop products that satisfy and please customers.

This enabled the three divisions to proceed simultaneously, so that the opinions of the market and the production side were directly reflected in the development process, shortening development time and reducing design changes, while at the same time enabling products that met market needs to be launched.

The SED development system was used with the development of the Accord, which was positioned as a higher-end version of the Civic. A joint project team was formed from each of the SED divisions to set objectives and goals based on “requirements first,” opinions based on their respective positions and experiences were exchanged, and product development that incorporated everything from production to sales planning proceeded. Market research was conducted not only in Japan but also in the U.S., and development was pursued with the aim of creating a full-fledged compact car that would be accepted worldwide as a higher grade series compared to the Civic.

Exhilarating styling, packaging that reflects the M/M-philosophy, and an easy-to-operate

instrument panel. The Accord received high acclaim in the market.

Once launched in May 1976, the first generation Accord (Accord CVCC hatchback) was highly acclaimed for its design, comfort, ease of use of equipment, ride comfort, and quietness at a test drive event for journalists held in Hakone. It was also well received in the market upon launch, and together with the four-door saloon launched the following year, it became a phenomenal hit. The SED development system was a huge success.

SED development system was built in the U.S., which produced the Accord Wagon

Making the SED Development System Locally Independent:

Local Development of the US Accord

Once exports of the Accord began the same year it was launched, in 1976, the rapid increase in sales in the U.S. and other markets, took total production to 1 million units by January 1980. In 1982, local production began at Honda of America Manufacturing (HAM)*1, Honda’s subsidiary in the United States. The Accord 4-door saloon began to roll off the line.

Honda had already been promoting localization of production based on the idea of “building products close to the customer,” but in the U.S., the world’s largest automobile market, considered it necessary to strengthen its structure by localizing SED completely. In 1984, Honda established Honda Research of America (HRA, later Honda R&D North America) in the D-development area, and the following year, in 1985, established Honda Engineering America Branch (EG-A)*2 to provide technical support for E-engineering. Together with American Honda Motor (AH), for S-sales, this established the complete SED development system in the United States.

With this newly created system, local development of the Accord Special Edition (1989 model) began in 1987, and soon progressed to full-scale local development of North America-exclusive models, starting with the first-generation Accord wagon (1991 model). This was followed by the 1996 model, the Acura CL, which marked a milestone in local development. Today, many models developed independently by Honda in the U.S. are accepted by customers because Honda has established a local development system,and has continued to strengthen its structure.

- On April 1, 2021, Honda Development and Manufacturing of America (HDMA) was established through the integration of the U.S. automobile production including HAM and development functions.

- Incorporated in 1988, Honda Engineering North America, Inc. (EGA) was established.

SED development system was built in the U.S., which produced the Accord Wagon

Acura CL developed by HRA based on the Accord