Developing DCT: Pursuing More Comfort and More Fun

Dual-clutch transmission (DCT) for motorcycles was introduced in 2010, the year sales of the HFT-equipped DN-01 ended. The popularity of large tourer models was growing and the pursuit of comfort and convenience was trending, as seen by Yamaha’s adoption of a semi-automatic transmission in the FJR1300 in 2006.

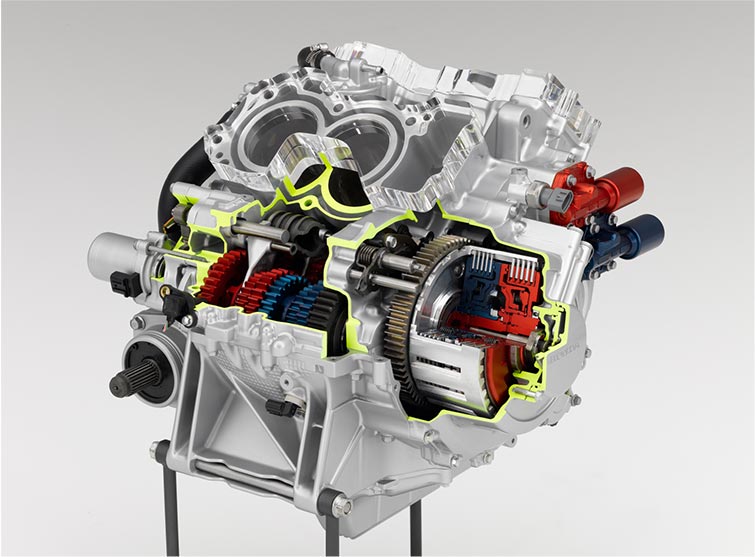

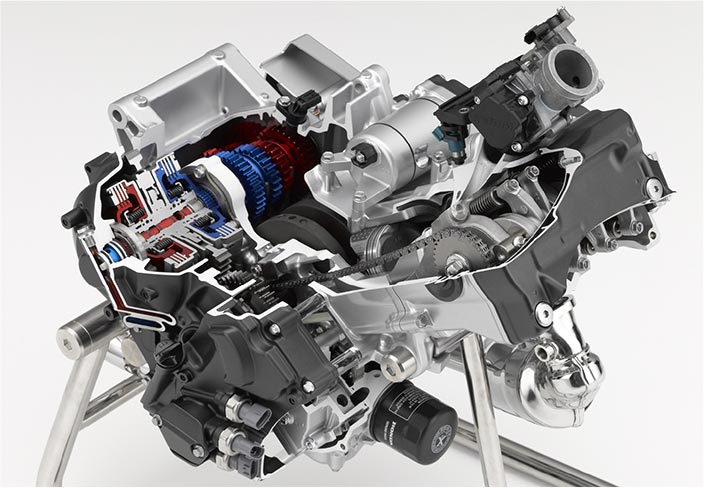

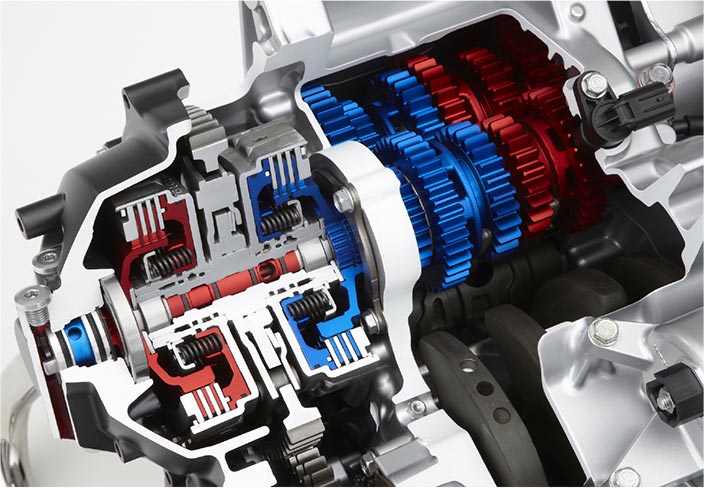

Honda, a frontrunner in automatic transmissions for motorcycles, was developing its own version of DCT for motorcycles, which was gaining prominence in the automobile market at the time. DCT is a mechanism in which two independent electronically controlled hydraulic clutches take care of odd and even gears respectively, eliminating the need for clutch operation when starting and shifting gears. Unlike the principle of existing automatic transmissions, the DCT is a manual transmission with automatic clutch operation.

The DN-01, a tourer model with a sporty ride and easy handling, was the first production motorcycle equipped with HFT.

In addition to the comfort provided by smooth gear shifting without clutch operation, the basic mechanism is a manual transmission, so power is transmitted in a linear and direct manner in response to throttle operation. This feature is ideal for “fun” motorcycles, where comfort and fun are critical. Honda first adopted DCT in the TRX420FA ATV released in 2008, followed by the world’s first large fun model equipped with DCT for motorcycles, the VFR1200F, in 2010.

VFR1200F

“When I first rode the prototype, I felt it had great potential, but there was a lot of work to be done before it could be mass-produced. The biggest problem was gear shifting management, as it did not shift when I wanted it to, and shifted when I didn’t want it to. I believed we had to pin-point the optimum settings data to make it suitable for mass-production.” (Arai)

Dai Arai, who had worked on DCTs for ATVs, moved in 2007 to working on the control program for DCTs for VFRs. While at school, he created electrical circuits and computer programs for robots and also rode motorcycles, so he was particular about the feel and comfort that riders demanded when developing control programs.

“First, I read through hundreds of pages of specifications, which contained all the control logic flowcharts. Then, I talked with the authors of the original specifications, and one by one, I fixed the problems and built a new control system. If there was a part that I thought wouldn’t work, that defied the laws of physics, I would correct it, and I also accounted for variations in actual clutches.

“I used a lot of brainpower there, because even we do our best to deal with a phenomenon theoretically, it often doesn’t work in reality. I spent every waking hour trying to come up with solutions. I was flat-out every day.” (Arai)

The most intensive part of the project was the study of the gearshift control program. In principle, motorcycle riders avoid shifting shift gears while turning, so it was important to find a way to make this the default setting. Since IMUs (inertial measurement units) to detect vehicle posture were not in widespread use at the time, the team decided to use throttle operation patterns and engine speed to determine the riding condition.

While turning, the throttle is basically in cruise mode (partially open), but there are also characteristic throttle operation patterns, such as fully closing the throttle when decelerating before the turn, or slightly letting up on the throttle while accelerating. Arai theorized that the ECU (Electronic Control Unit) would recognize this pattern and be able to determine that turning was in progress.

“I was thinking about what kind of shift schedule to use or not to use in that situation, and I was trying to figure out all these patterns at once in my head and put them together in a spreadsheet. The number of patterns was enormous. In particular, it took me a long time to think about how to connect the shifts to the next situation.”

It was the ultimate analog process. There were almost no reference materials available for motorcycles and almost no simulation tools, so Arai had no choice but to write down the patterns and ideas he had.

“I would draw graphs of how the motorcycle would move in a particular pattern and how it would move in another, and I would think of the controls and set them up myself. Basically, I and the mechanical control staff tuned the bike through trial and error.” (Arai)

VFR1200F equipped with world’s first motorcycle DCT

VFR1200F equipped with world’s first motorcycle DCT

The basic control program was completed, but there was one other major issue to be solved: the thumping sound typical to DCTs due to preliminary gearshifting. The sound originates with the dog-clutch, positioning the non-active gears in preparation for the next gear change.

This sound is normal with a manual transmission as the noise is caused by the rider's operation, but in the case of a DCT, the rattling noise occurs at a timing unrelated to the rider’s will. Measures were being devised from the beginning, to the end, of the development process.

“The noise was so loud that we felt it was not marketable, and we had to take measures from the very beginning. At the stage where the quality of the base manual transmission was not there, the DCT shifted gears on its own was out of the question, and there was a great deal of fuss even before we started developing the control system.” (Arai)

In addition, the engine, initially a 3-axis layout, was changed to a 4-axis layout during development, resulting in a situation where engine development, let alone DCT, was close to starting from scratch. The workload was substantial.

“I thought it was going to be tough before we started, but there were more problems and issues than I had imagined. At the beginning of development, my boss told me, ‘If we can’t do it by a certain point, we’re pulling the plug,’ but even though we were well beyond that, he did not do so. When I asked him about it, he said, ‘DCT is different,’ and I was lost for words. If this was what I had to deal with all the time, I felt like leaving motorcycle development altogether after the project was complete.” (Arai)

After many twists and turns, the VFR1200F with DCT was launched in 2010, after four years of grueling development.

VFR1200F

Perfecting Performance that Better Matches Human Senses

The DCT for motorcycles offers two drive modes, AT for automatic gear shifting and MT for manual gear shifting, with the AT mode selectable between D mode for cruising and sport riding, and S mode for sport riding that shifts at higher engine speeds. Shift timing control in S mode is designed to provide a feel closer to the human senses when the driving force changes under acceleration/deceleration or engine braking, providing the rider with the joy of riding.

In addition, the VFR1200X released in 2011 automatically resumes AT mode if the rider overrides the automatic shifts, but the lack of this feature in the earlier VFR was unpopular. Arai, however, was unconvinced.

“How do we switch back to AT mode? What does the rider want to do when he overrides AT mode? And what would be a good trigger to switch back to AT mode? I thought about all these situations, which ended up in the 2012 VFR1200X and VFR1200F models. We also put in a little bit of control sort of halfway between D and S modes when the rider is riding in a relaxed way even in D mode, so the rider doesn’t feel uncomfortable.” (Arai)

The second-generation DCT with the new control logic was adopted in the three New Mid Concept models including the 2012 NC700X, and was widely accepted. The third generation DCT, which employed various types of power control such as uphill and downhill estimation, was adopted in the CRF1000L Africa Twin (launched in Europe) in 2015 and the Gold Wing in 2018. The current, fourth-generation DCT with IMU (inertial sensor) attitude control system is featured in the CRF1100L Africa Twin released in 2019.

NC700X

Although DCT evolved along with the development of new sensors used for electronic control, Arai’s control logic based on the throttle position and engine speed, is still the base logic, with more and more detailed logic routines added. While Arai was involved in the project, he had already worked on gearshift control with IMU, and by the time IMU was being considered, the groundwork had already been done to a large extent. Arai recalled a memory from a technical evaluation during development:

“Since it was my first time working with this mechanism, I did a lot of checking, and when I reported the results, I was asked if there were any problems I hadn't seen yet. I had already considered every imaginable problem in my report, but I was told to ‘Prove it.’ I remember thinking, ‘What on earth is he talking about?

“When I asked what I should do, he replied, 'Get everyone on board.' Associates involved in the development were always subconsciously inclined to defend the weak points of the mechanism or to give orders not to use it in such a way. If they ride the bike under there assumptions, there is a chance that they would not be able to identify any real defects. So, we brought in a few people who had never ridden a DCT before, and asked them to help us identify the problems. In the end, we found nothing.” (Arai)

NC series equipped with second-generation DCT. Honda continued to evolve DCT control modes, pursuing

an operating feel closer to human senses.

The Study of Humans is the Basis to Make Superior Products

“When I first rode a DCT, I realized that although I thought I was unconsciously operating the clutch and shifting gears [on a manual transmission motorcycle], I was actually using my brain a lot. I was surprised to discover that I was using my brain so much. Once I understood this, I was able to concentrate more on controlling the behavior of the bike, and riding became a lot more fun.

“Because of this, I think it took a little time for DCT to be accepted. We have made improvements little by little over the years, and now we are finally at the point where people are saying, ‘DCT is good.' Now it is generally regarded as natural, but I think there are still some things that could be better. I am sure though, that this is a matter of individual taste and sensitivities. In order for DCT to evolve in the future, we need to study humans even more.” (Arai)

Currently, seven models, mainly in the large FUN domain, are equipped with DCT. In addition to its convenience, its uniqueness has clearly led to more DCT than manual transmission variants of the same model being sold. The DCT is becoming a major feature of Honda motorcycles, and it is fair to say that its value stems from the fact that in the early stages of development, the control patterns were conceived in the minds of the engineers, from the rider’s point of view.

CRF1100L Africa Twin