Evolving With Regional Needs

European big scooter users were somewhat different from those in Japan. A study of users in Italy revealed that many of big scooter riders commuted from their homes in the suburbs to urban areas via the Autostrada (highway). And they were dissatisfied with the size and weight of big scooters.

Although the big scooter was designed for highway riding, its size was too much to handle when riding in city traffic and parking on the roadside or in a parking lot lined with motorcycles to get to work. The SH300 was imagined as a fusion of the conventional SH125 / 150, which excelled in city traffic, and performance that would allow stress-free highway riding. The goal was to achieve the highest levels of performance and ease of use. Furthermore, as a high-end model, it was required to have elegant styling that would blend in with the European cityscape, and a high-quality ride that would allow it to ride gracefully over cobblestone streets.

SH300, the number one selling model in Italy, combined ease of use in the city and stress-free performance on the highway.

One of the most difficult challenges in developing the SH300 was to deal with the increased 300 cc engine size and heat generation, and increase in maximum speed. In particular, the combination of a powerful engine with a compact chassis caused a series of heat problems. In order to maintain the width of the chassis, which could not be compromised for improved usability, the muffler was positioned as close to the chassis as possible, as were the plastic protectors but these melted under the heat. Without hesitation, the team abandoned the existing layout and revised the exhaust system from the specifications and materials.

The frame was shaped like a large U in order to secure a wide floor space while riding on large-diameter 16-inch wheels, and an ambitious layout where each component was compactly mounted, was adopted. At the time, the frame was difficult to achieve, and the designers made numerous trips back and forth between Italy and Japan, to find solutions with Honda Italia Industriale Atessa (HIA), who would manufacture the model, the Kumamoto Factory, and Asaka R&D (HGA).

In 2007, the SH300 was launched to immediate acclaim and became the number one selling bike in its class in Italy. As the development team had hoped, the SH300 was welcomed by many business people, especially in urban areas, and its success led other manufacturers to launch 300 cc models with large-diameter wheels.

The Activa, the first model from Honda Motorcycle and Scooter India (HMSI), established in 1999 as a local subsidiary, changed the value standard of scooters. Until then, manual transmission scooters were the norm in India, and the occasional automatic transmission (CVT) scooter was of an older design, and its two-stroke engine was less fuel-efficient than a four-stroke. In addition, the reliability of the CVT system was inferior due to the effects of dust from the roads. In response, Honda introduced its latest automatic transmission scooter, the Activa. Honda’s goals were primarily to achieve good fuel economy, secondly to be durable and easy to repair, and finally to be big enough for the whole family.

Its 4-stroke 102 cc engine achieved 50 km/L (Mode test fuel economy, measured by Honda). Its exterior features included a combination lift-up independent cover mechanism that made it easy to remove the body cover for repairs, and steel plates that could be repaired in the event of damage, such as scratches or dents. Furthermore, the use of “tough up tubes,” puncture-resistant even on rough roads, gave the Activa a sleek appearance that eliminated the need for a spare tire, which was commonplace in India at the time. The unprecedented challenge of building a manufacturing plant and developing a motorcycle at the same time made SEDB (sales, production, development, and purchasing) collaboration even more important than before. Since HMSI was incorporated in 1999, trios consisting of a local purchasing associate, and Japanese purchasing expert and designer, traveled around India in five teams: materials, engine, frame, chassis, and electrical. A network of Honda dealers was also newly established. As a result, the first-generation Activa sold 2.47 million units*2 between 2001 and 2009, and had grown to hold more than 40%*2 of the scooter market.

Activa, the automatic transmission scooter which changed the value standard of scooters in India.

In the 2000s, the ASEAN*3 region was experiencing remarkable economic growth, and motorcycles were being used as commuters as a part of daily life, with Honda producing Super Cub-type manual transmission models locally in Thailand and Indonesia. Then Yamaha introduced numerous automatic transmission scooter models in 2003 and 2004, rapidly increasing its market share.

In order to respond quickly to this market change, development of a Super Cub-style torque converter automatic transmission model, which was well underway, was cancelled, and the Click, a scooter with a belt converter automatic transmission, was hastily developed.

However, Honda had to be cautious in developing an automatic transmission scooter. During the rainy season, roads are frequently flooded, and riding a scooter with small-diameter tires that have little clearance could easily flood the engine, damage the belt converter and, in the worst case, render the scooter impossible to ride.

There was considerable debate over the decision: Conventional torque converter or the belt converter which had concerns about risks? Another obstacle was the short development period. Normally, a new model takes around two years to develop, but Honda had planned to launch the new model in 14 months, in response to requests from regional sales associates who could not wait.

After many cautious discussions, the decision was made to adopt the belt converter through confirmation of local market suitability. At the same time, in order to dramatically shorten the development period, Honda approved the development of a mold for mass production while building a prototype. This was based on the idea of prioritizing a shorter development period over the monetary risk of having to rebuild the mold due to design changes. The schedule was achieved due to development team associates working closely together, by firmly defining the concept at the beginning of the development process.

With the launch of Click, the ratio of automatic models in the ASEAN region, especially in Thailand, grew dramatically. Young people, who had previously been focused on the Super Cub-style manual transmission models, turned their attention to the new, fashionable automatic transmission scooters, which surpassed the mainstream Super Cub-type Wave in terms of sales volume. As a result, Honda’s sales share in the region recovered.

- Honda research

- Association of South-East Asian Nations

From manual transmission to automatic transmission scooters

Click changed young people’s tastes

PCX Redefines Scooter Standards

Launched in Japan in 2010, the PCX was introduced as a global model with a common basic design for the frame, engine, and other major components worldwide. It was produced in Thailand and exported to Japan, Europe, and the United States, in addition to the ASEAN region. The concept of the PCX was “high quality and advanced styling beyond its class, high dynamic performance combined with environmental performance, and a scooter’s comfort and ease of use,” and was developed from Honda’s desire to differentiate itself by launching its own high-end model, other than following the competition.

One of the target segments was the affluent Thai population who were replacing their motorcycles with automobiles. For example, they would see the benefits of commuting by motorcycle to avoid traffic jams, but were reluctant to use ordinary models because they looked like everyone else. Honda envisioned such users.

Market research revealed that what people wanted was not a standard model, but one with advanced technology. The first step was to create a model with advanced technology, with a presence that would immediately distinguish it from previous models. Norihiro Imada, the large project leader (LPL) at the time, said:

“Any 125 cc class scooter looked big and splendid, but when you get on one, you would feel the large body straggling with a 125 cc engine. In terms of engine speed, it is about 7,000 to 7,500 rpm. We felt that if the rider’s impression before and after riding were so different, they would be disappointed, so we kept the revs below 6,500 so that the rider would have a consistent impression that would not disappoint. This was a major goal in our development process, which in turn contributed to the improvement of PCX’s fuel economy.

By looking at the distribution map compiled by the frame design team, they determined other models were heavier than 150 kg, which needed to be reduced to 130 kg in order to rev at 6,500 rpm. To that end, a wheelbase of approximately 1,300 mm was considered optimal, but another challenge arose.

”A major issue was front load distribution. The front and rear load distribution is determined by the rider’s position, so with a 1,300 mm frame, the rider would be riding toward the rear, which would reduce the load on the front. Ideally, load distribution should be 50:50 or 45:55, but at the beginning, the front load was only 40, which was far too low. Relying on the steering designer, who said ‘Don't worry, we'll figure it out,’ we tried various methods, such as moving the battery to the front.” (Imada)

During the development phase, the team conducted test-rides each time something was changed. The purpose was to make sure the design and testing teams were on the same page.

“For example, designers don’t want to change the initial drawings, and even if they are asked to make changes based on test results, they tend to protest saying it was too late. So, the team frequently test-rode the prototypes before and after the changes were made for comparison. By having the designers experience the difference, we were all able to share the same priorities for making a better model.” (Imada)

As a result, the completed PCX features a liquid-cooled SOHC engine, the first ACG starter and idling stop system for 125 cc scooters, 14-inch wheels designed for excellent ride stability and comfort, sporty-looking mirrors and wheels, chrome pipe handlebars, and a combination brake (front and rear wheel linked brake) for stable and efficient braking.

PCX, a global model manufactured in Thailand with a universal basic design of major components.

14-inch tires realized safe riding in urban areas with over varying road surface conditions.

25-liter helmet storage under the seat

1.5-liter front inner box built in to the instrument panel.

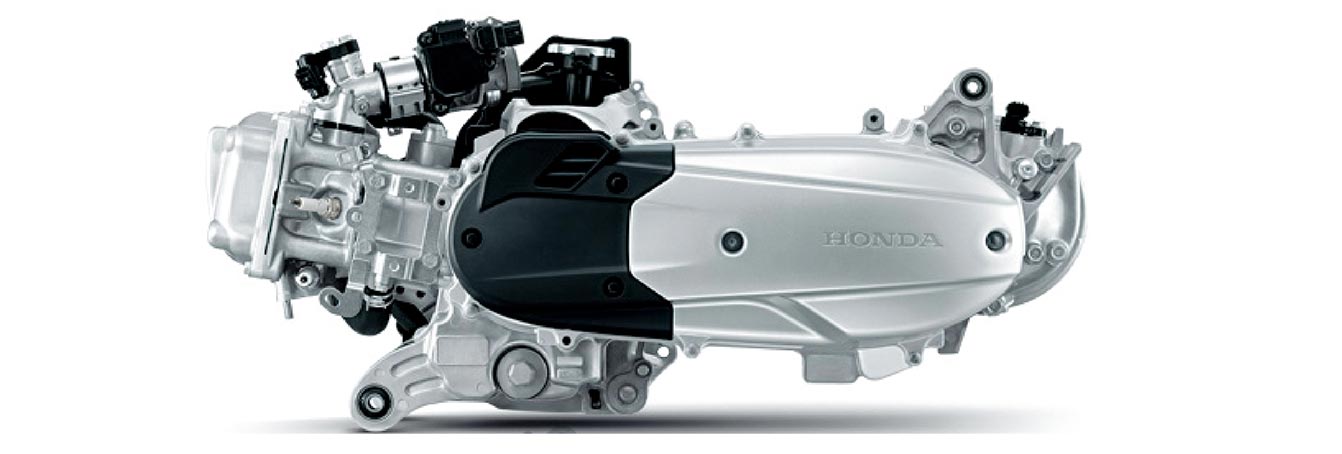

eSP global scooter engine adopted in 2012.

It also featured a switch-operated fuel tank and seat openers, a 25 L-capacity helmet storage space under the seat, and a 1.5 L-capacity front inner box. The sharp styling, designed in Thailand, hid screws and bolts. Despite this full load of advanced technology and luxury equipment, the PCX’s weight is kept down to 126 kg, and maximum torque was 12 Nm at 6,000 rpm.

The PCX, which has successfully achieved its initial goal through unrelenting development, became a big hit in Japan, with orders for more than 7,400 units within three weeks of its launch, achieving more than 90% of the planned annual sales volume by that stage. In 2012, the PCX was partially upgraded with the newly developed eSP, a global engine for scooters with improved fuel efficiency. The PCX150 was also newly added. In 2014, production of the further matured and perfected second generation PCX series was transferred to Vietnam. Its styling was sharpener, and dynamic performance was reviewed to an unchanged maximum torque of 12 Nm at a lower engine speed of 5,500 rpm.

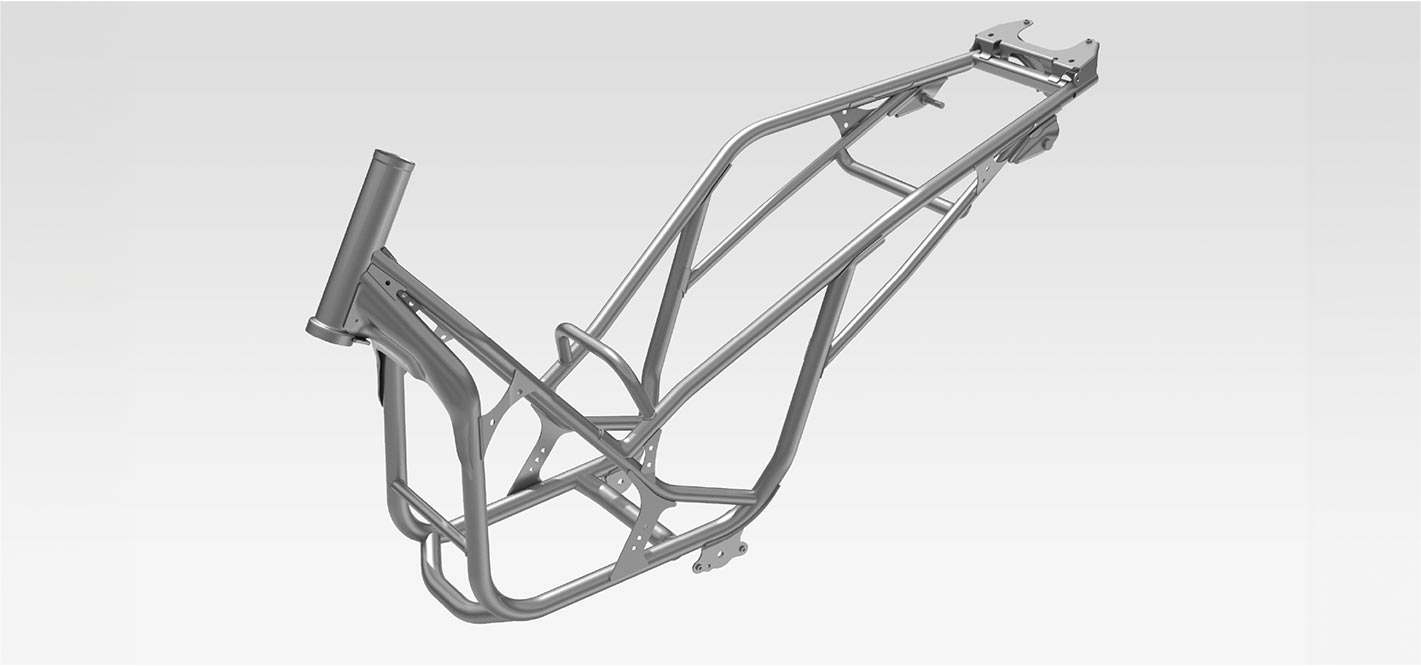

The PCX’s major evolution arrived with the third generation model, introduced in 2018. The frame was drastically changed from an under-bone to a double cradle pipe structure. The purpose was to secure the necessary strength and rigidity while lightening the frame. In conjunction with this change, the size of the front and rear tires was increased, and the suspension was strengthened.

“In terms of mass production, under-bone frames are by far the easiest to make, while double cradle frames require a considerable amount of time and effort to assemble. At first, the factory said they could not make such a difficult frame, but we met the Kumamoto factory executives to state our case.” (Imada)

3rd generation PCX frame structure changed to double-cradle.

Frame strength and rigidity maintained despite lighter weight.

The biggest topic was the launch of PCX Hybrid (later revamped as the PCX e:HEV in 2020), the world’s first mass-produced hybrid motorcycle. Drive assist is provided to the ACG starter that starts the engine and generates electricity. The motor assists the engine during acceleration while adjusting the amount of assist according to throttle operation. A high-output 48V lithium-ion battery is used for this purpose.

The battery is located behind the luggage box, which has a capacity of 23 liters and can fit a full-face helmet, and the power drive unit is stored under the front cover, allowing the hybrid to be efficiently installed in a limited space without sacrificing the convenience and easy handling of the PCX. The lightweight and strong double cradle frame also helped to keep weight to 135kg, only 5kg more than the gasoline version. An electric model, the PCX ELECTRIC, was also added exclusively for lease to businesses.

The fourth generation model, launched in January 2021, was equipped with a newly designed 4-valve eSP+ engine, the new Honda Selectable Torque Control, and an enlarged luggage box for even greater ease of use. At the same time, the PCX150 became the PCX160 with a larger engine.

The PCX remains one of Honda’s main models in 2023. The success of the PCX is a testament to this. When the company was founded, Soichiro Honda had said that “good products know no national boundaries.” As such, Honda’s products must be good products, despite the changes in the environment surrounding manufacturing and society itself. The PCX’s success is proof of the company founder’s words.

Hybrid scooter PCX e:HEV

PCX ELECTRIC EV system overview. PCX ELECTRIC was designed to lease to companies.