Taking on the Challenge to Evolve to the Next Generation

Super Cub

Pursuing Advanced Technology

The reason behind the Super Cub series being loved around the world, literally becoming the global standard, is that the first generation model, arguably an invention, was extremely rational, also realized high convenience, reliability, and economy. Over its six decades of history, Honda has always pursued further convenience and economy, inheriting the ideas of Honda, who developed the first-generation C100, and Fujisawa, who fostered it.

In particular, approaches to improving environmental performance and fuel economy have become essential over time, and various technologies have been explored in all areas to further improve comfort. However, the Super Cub’s worldwide market and wide range of applications, as well as its affordable price are important, and the adoption of new technologies has presented many challenges, including cost. Development of the Super Cub for its evolution is challenging, and at the same time, there are many advanced technologies that have not been introduced to the world.

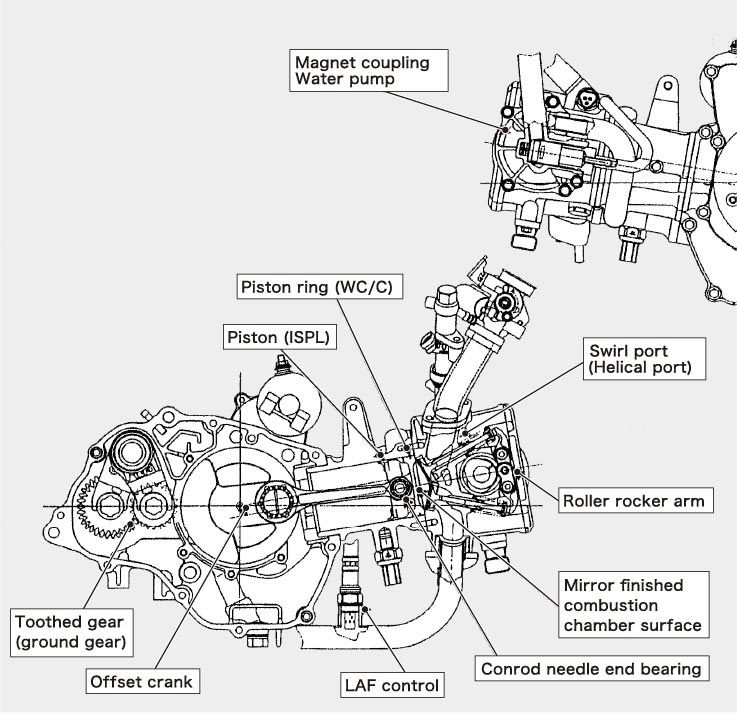

In response to the growing global environmental awareness in the late 1990s, Honda developed many areas in its quest for the next-generation Cub (mainly in basic engine research), focused on improving fuel economy through feedback control using LAF (Linear Air Fuel Ratio) sensors*2 to improve engine efficiency.

At the time, there were still many 2-stroke models in the ASEAN region, so the challenge was to realize a 4-stroke model with superior power and fuel economy. By replacing stoichiometric (theoretical air-fuel ratio) control using an O2 sensor with lean burn (lean combustion) control using an LAF sensor, linear air-fuel ratio control and ignition timing control could be performed when shifting to stoichiometry to mitigate torque fluctuations, aiming for improved fuel economy and smoother engine speed throughout the lean range.

- Sensor to measure combustion air-fuel ratio by detecting oxygen concentration in exhaust gas

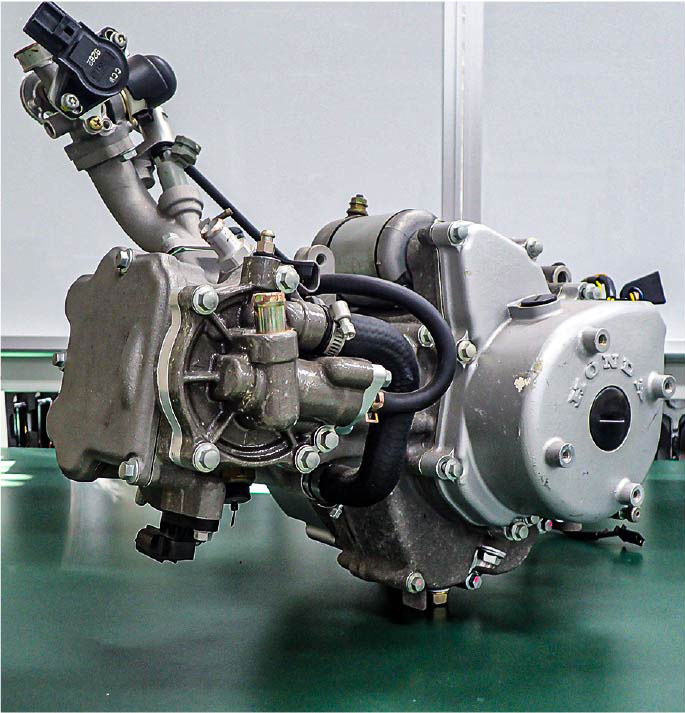

Engine developed with LAF sensors to realize

with 4-stroke engine superior performance and

fuel economy with 4-stroke engine with superior power performance and fuel economy over 2-strokes.

“The main issue was to improve usability, but one direction was to almost double the displacement to 195 cc and cut the peak rpm in half. We thought that if the same maximum output as a two-stroke engine could be achieved at half the rpm, fuel economy would improve even if the displacement was doubled. The goal was to therefore halve fuel consumption,” said Toru Hayashi, a senior researcher at the time.

In addition to the LAF sensor, attempts were made to improve combustion efficiency by reducing heat loss through the use of swirl ports to promote combustion, dual plugs to accelerate flame propagation, and mirror finish of the combustion chamber surface to reduce absorption of radiant heat.

”We also tried direct cylinder fuel injection. In this case, very fine fuel particles must be injected in a short time, so high-pressure injection is necessary. However, if we just injected at high pressure, the fuel would accumulate on the cylinder wall and form lumps. It was very difficult to adjust that part of the injection, but we managed to make it work. But, there were no manufacturers willing to make the small fuel pumps to be installed in the Super Cub. They must have been overwhelmed as at that time, direct fuel injection was gaining attention in the field of F1 racing engines,” said Hayashi.

Many new mechanisms were developed to reduce friction to improve fuel economy, including roller rocker arms, offset cylinders, and offset port technology. Hydroforming (hydraulic molding) was also developed for the body to reduce weight. In addition, the tire pressure, pattern, and compound were reviewed to reduce rolling resistance, the screen and front cover were slanted to reduce aerodynamic drag, and the seat height was lowered by 45 mm. The result was a 52% reduction in fuel consumption compared to existing models.

“We achieved our goal, but the 200 cc Cub was amazing in a sense. For example, a 100 cc engine runs at 6,000 rpm, but a 200 cc engine would rev at 3,000 rpm, so it had a very strong torque (combustion) feeling. When Kawamoto, president at the time, test rode it, he came back after one lap and said, ‘Is this a Cub?’” recalled Hayashi.

In the end, this research was ended with the confirmation of its effectiveness in field tests in Asia, the largest market for the Super Cub series, at a motorcycle R&D center in Bangkok, Thailand.

“Hydroformed frames increased design freedom in terms of strength and rigidity balance, while at the same time simplifying the frame structure, and the total body weight could be reduced by approximately 20%. We could introduce this method in Indonesia, Vietnam and Thailand, which are large markets, with a little investment. However, since the Super Cub series is also produced in Cambodia, Malaysia, and the Philippines, it was difficult (in terms of cost-effectiveness) to introduce the technology there, and in the end, it had to be a partial frame modification evolution. This is the difficulty of having 16 production sites around the world,” said Hayashi.

These technologies and findings from R&D efforts were later adopted in many models. In 2000, Honda declared its intention to go four-stroke, and the new Super Cub series reflected the research conducted at that time. Around the same time, research was also conducted on the cone CVT, which had no gearshift shock due to the infinitely variable drive train gear ratio, and the world’s smallest torque converter designed for the Wave 125.

“As far as I remember, we were developing three types in parallel: a torque converter, an electric button gear changer (electric changer), and a belt converter. The electric changer was the first to fail in terms of cost, and the choice was whether to use a torque converter or a belt converter, and since a competitor had adopted a belt converter for their scooters, we ended up with a belt converter. Since the torque converter is a fluid coupling, there is inevitably slippage. With automobiles, this could be used in place of a starting clutch, but with motorcycles, the efficiency was inevitably reduced and fuel efficiency tended to deteriorate. The Super Cub is known to have three elements: fuel economy, ease of use, and performance, but the most important is fuel economy, and factors such as the ability to change gears freely and high efficiency are ultimately factors for improving fuel economy,” added Hayashi.

Emission-related proposals and fuel efficiency improvements are now commonplace themes, but in reality, Super Cub users in particular would not purchase them unless they offered high performance at an affordable price. In this sense, the Super Cub series development needed realize both highly advanced technology, and at the same time the lowest cost possible.

In addition, there are many users in the ASEAN region and subsequent emerging markets, and the Super Cub series is the backbone of sales in those regions. Many people, companies, and manufacturing bases are involved in the Super Cub. A major failure in terms of sales could not be tolerated. For this reason, the Super Cub series must always aim to be more perfect.

“Cost is not a goal, it’s a hurdle. If we can overcome this hurdle, many customers will buy our products. Our goal is high, but so it the hurdle. Kume, the third president, said, ‘When you set an impossible goal, you will find more epoch-making things in the process of trying to achieve it, than in actually achieving it. That is where the value lies. If it can be done easily, there is little value in it.’ Even reducing fuel consumption to half of the normal level would have been impossible with ordinary efforts, and since it was impossible, we had to pursue all sorts of methods, but I think there was a lot of technology packed into the process,” said Hayashi.

Since 2000, the models produced and sold in the ASEAN region had been switched to 4-strokes. In 2003, the Wave 125i, the first model equipped with PGM-FI, was fitted with two large condensers to store enough power so that the engine could start even if the battery ran out.

“Thanks to this, we didn't have to worry about the flat batteries. The Super Cub still has to be kickstarted. It may not look like much, but it has already surpassed the Super Cubs of the past.” (Hayashi)

Wave 125i, the first model to be equipped with PGM-FI

Research of the next generation Super Cub is utilized in new models

Cumulative Global Production Exceeds 100 Million Units

Super Cub has Become the Beloved Icon of Honda

Transcending Time and Borders

In October 2017, the Super Cub series reached a cumulative global production of 100 million units, a record that has taken 59 years since its launch in 1958. The year after reaching 100 million units, in 2018, the Super Cub series celebrated its 60th anniversary with the release of a 60th anniversary model. It is an astounding long-selling product that has continued from the 20th, into the 21st century.

The 100 million unit milestone was achieved in large part due to global expansion. The Super Cub series reached a cumulative global production volume of 50 million units in FY2005. Although 47 years had passed since its launch, it took only 12 years to accumulate 50 million units more. This was largely due to the explosive market expansion in Indonesia, a miracle after the Asian currency crisis.

Indonesia has the largest population in Southeast Asia at over 200 million, and for the average citizen, a TV, a refrigerator, and a Super Cub are the three sacred items that make life affluent. Originally, most of these items were purchased through high interest loans, but the relaxation of credit checks for loans after 2000 had been effective, and by 2004, about 7,200 Super Cubs per day (over 20 million vehicles per year) were being sold.

As of 2023, the Super Cub series is sold in 160 countries around the world, but outside of urban areas, there are many regions that lack public transportation and other infrastructure, and the benefits of the freedom of movement provided by a single motorized vehicle are immeasurable. The 100 million unit milestone is undoubtedly a result of the Super Cub series supporting the lives of the masses around the world for more than 60 years, while meeting the needs of each region.

60th Anniversary model celebrating 100 million Super Cubs