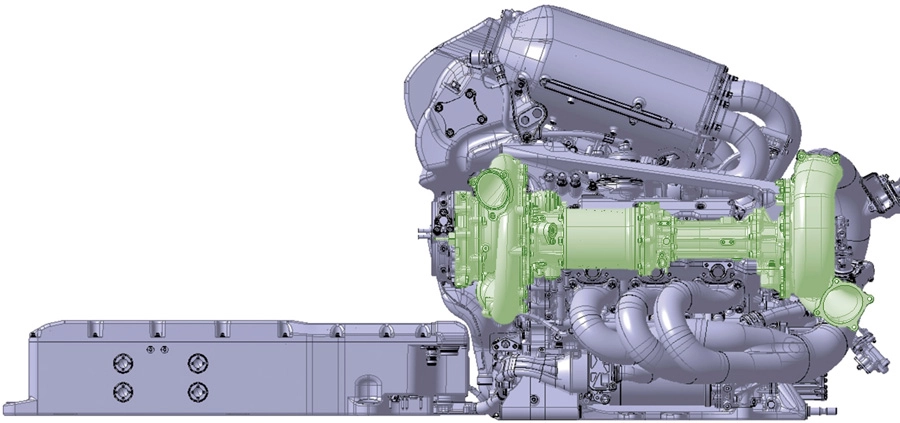

F1 Power Units, Comprising a V6 Turbocharged Engine and Two Types of Energy Recovery System

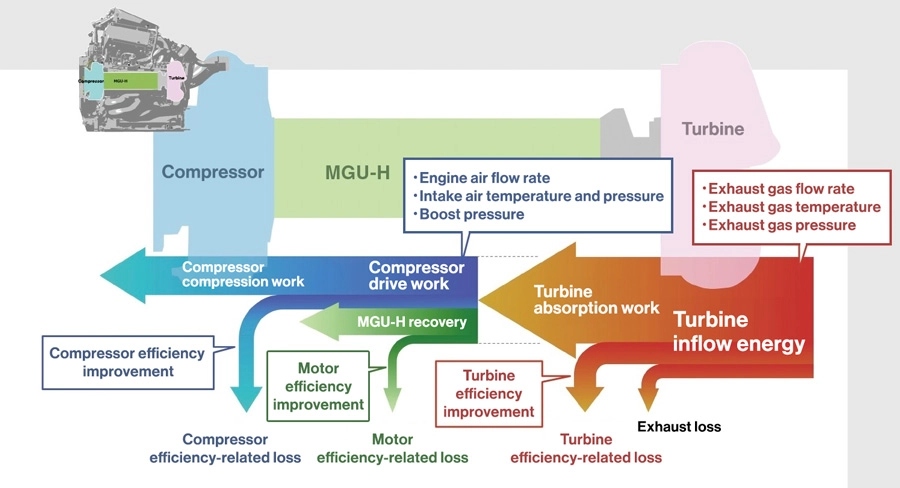

MGU-H energy flow: The turbocharger (comprising a turbine and a compressor) and MGU-H (converting heat energy into electrical energy) are both driven by exhaust energy from the internal combustion engine (ICE). Energy converted into rotational movement by the turbine is used for MGU-H and compressor work. Energy loss is reduced by improving the efficiency of the turbine, thereby increasing the amount of energy available for use by the MGU-H and compressor. By improving the efficiency of the MGU-H and compressor as well, the amount of work that can be done by each is increased.

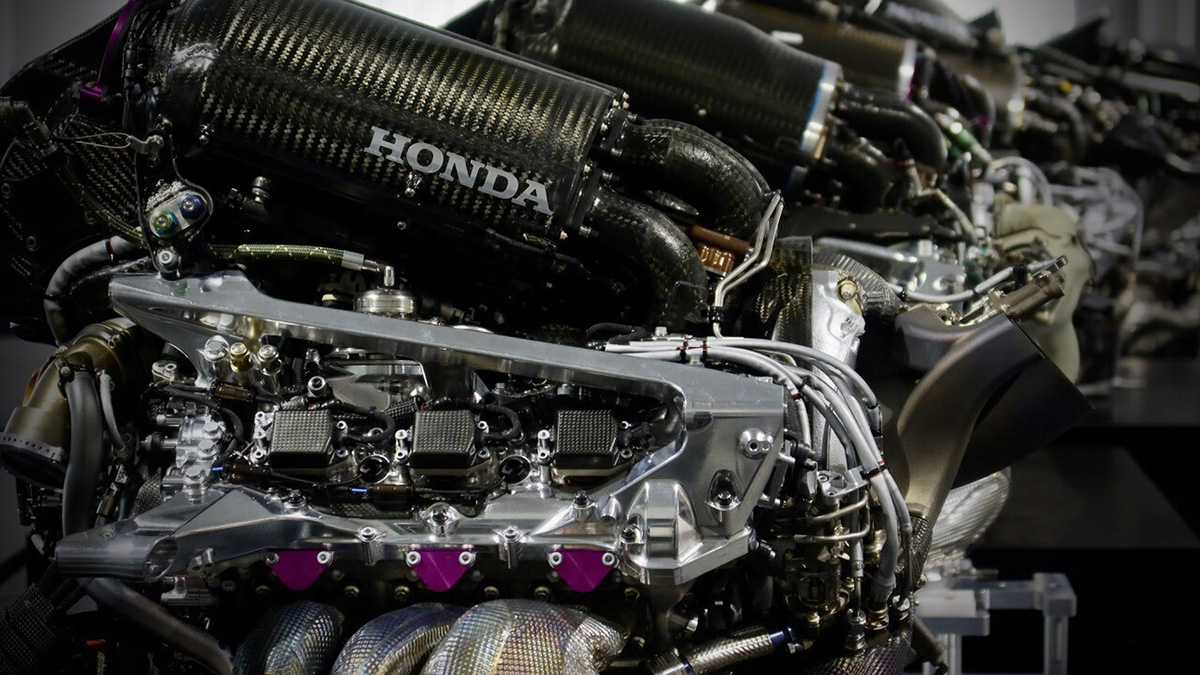

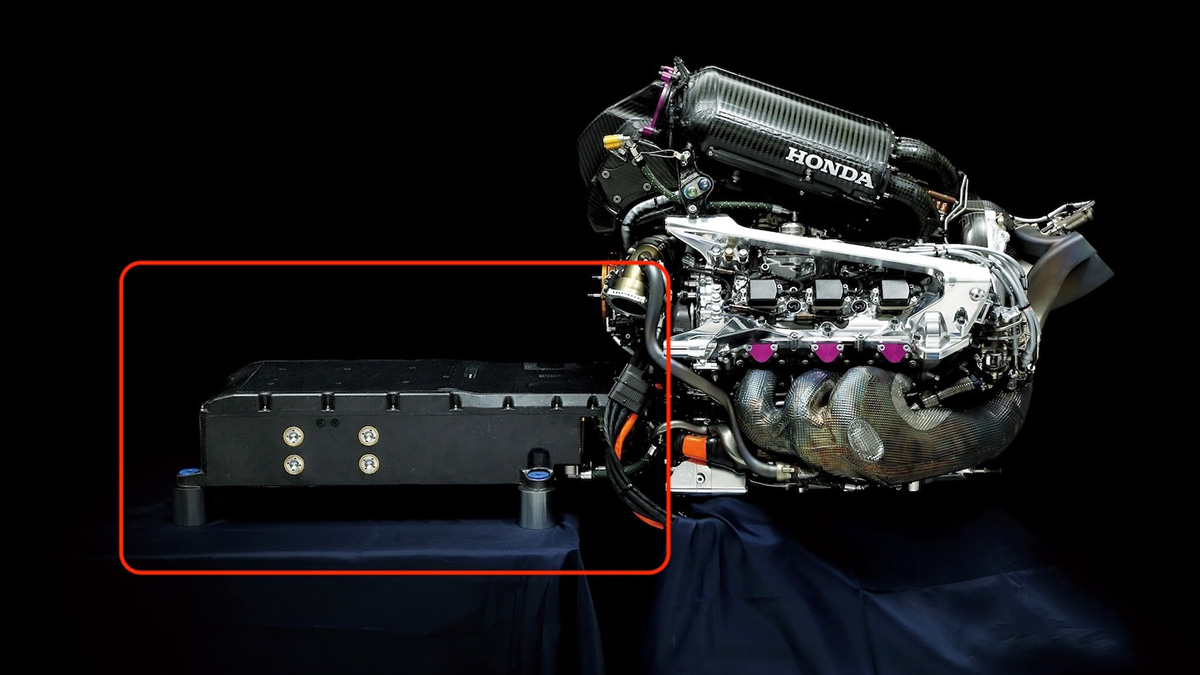

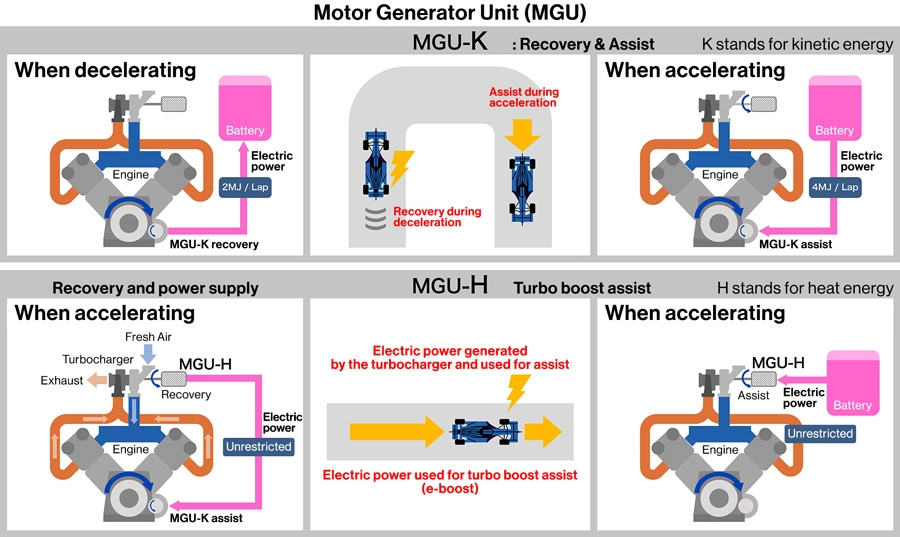

Since 2014, F1 power units have comprised a 1.6-liter V6 direct-injection single-turbo engine and two types of energy recovery system. One of those energy recovery systems is the MGU-K (Motor Generator Unit - Kinetic), a kinetic energy recovery system connected to the crankshaft with the main task of converting kinetic energy into electrical energy. Regulations specify a maximum output of 120 kW and maximum rotational speed of 50,000 rpm for the MGU-K.

The other energy recovery system is the MGU-H (Motor Generator Unit - Heat), a heat energy recovery system coaxially arranged with the turbocharger and with the task of converting heat energy from the exhaust gas into electrical energy. MGU-H output is not regulated, so there are no setting restrictions, but the regulations specify maximum rotational speed of 125,000 rpm.

The maximum amount of electrical energy that the MGU-K is allowed to send to the Energy Store (ES), which is essentially a lithium-ion battery, is 2 MJ per lap. At the same time, a maximum of 4 MJ of energy per lap is allowed to be sent from the ES to the MGU-K. There are no limits, however, on the amount of energy that can be output by the MGU-H, or exchanged with the ES.

Maximum engine fuel flow is specified at 100 kg/h. However, net output of the engine is calculated by subtracting exhaust loss, cooling loss, friction loss, and power for auxiliary drives from the fuel energy that enters the engine’s combustion chambers. An important focus of power unit development, therefore, is to reduce energy lost through these various routes to increase net output.

On the other hand, the energy remaining in exhaust gas is used to power the MGU-H assembly, which is the unit that integrates the MGU-H and turbocharger. Of the heat energy flowing into the turbine, a portion of that is lost depending on the efficiency of the turbine. Another portion is exhaust loss. After subtracting this lost energy, the remaining energy is converted into rotational energy through the absorption work of the turbine.

The rotational energy is then used for compressor drive work, to compress air, and for MGU-H energy recovery work, with losses occurring depending on the efficiency of the compressor and motor. The remaining energy is used for the compression work of the compressor and the power generation work of the MGU-H.

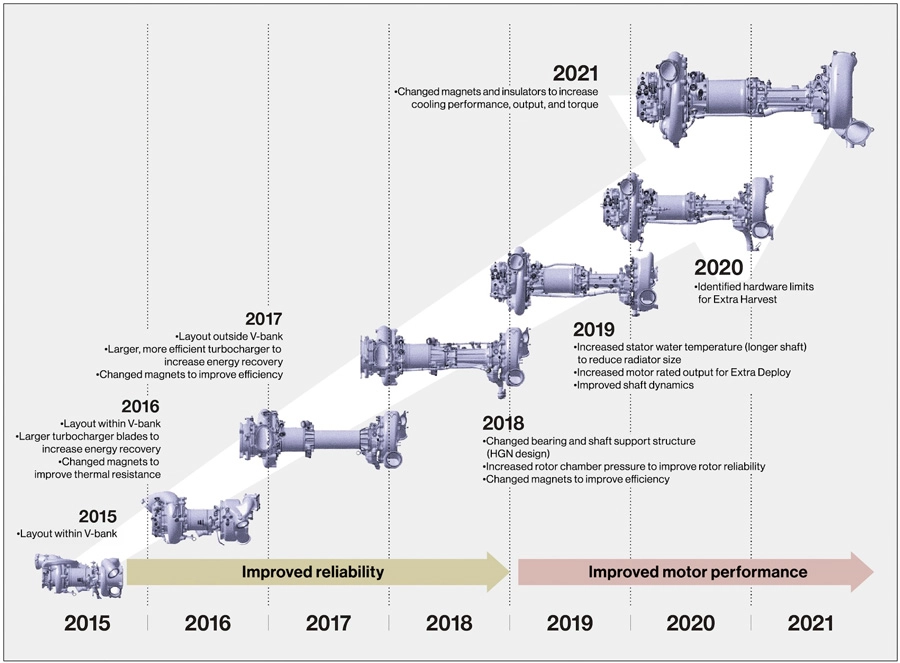

In this series of energy flows, if turbine, MGU-H, and compressor efficiency are improved, the energy recovered by the MGU-H increases. Although Honda originally focused on improving reliability when it started participating in the F1 as a power unit supplier in 2015, development has continued with a focus on increasing the rate of energy recovery through a variety of efficiency improvements.

In terms of engines, Honda’s development focus has been to improve net output through a higher compression ratio and specific heat ratio (Evolution of Technologies Boasting the Ultimate Combustion Efficiency). The regulations specify an upper limit of 18 for the geometric compression ratio, so the aim of development has been to get close to that upper limit.

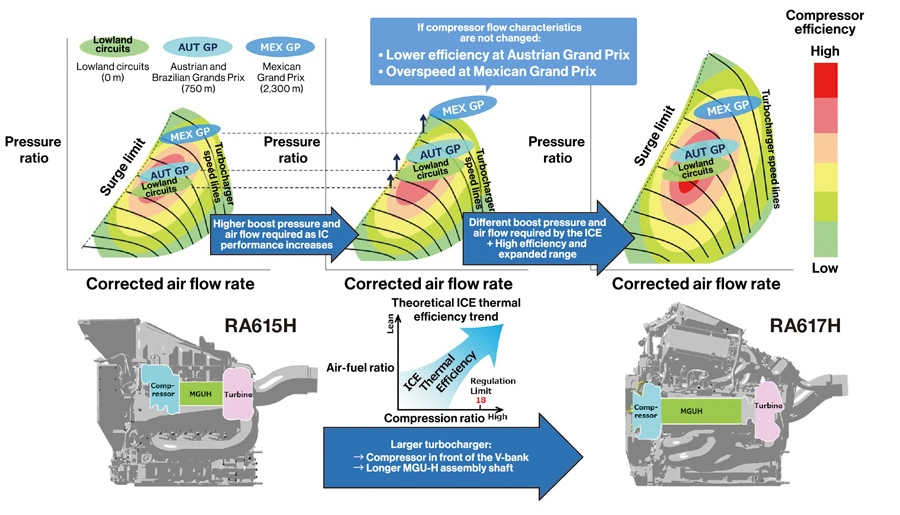

On the other hand, no upper limit has been specified for the specific heat ratio. The leaner the air-fuel ratio in comparison to the theoretical air-fuel ratio, the better the thermal efficiency and the higher the net output. Therefore, having to increase air flow into the cylinders to create a leaner air-fuel mixture, Honda worked on increasing the size of the compressor.

Incorporating HondaJet technologies

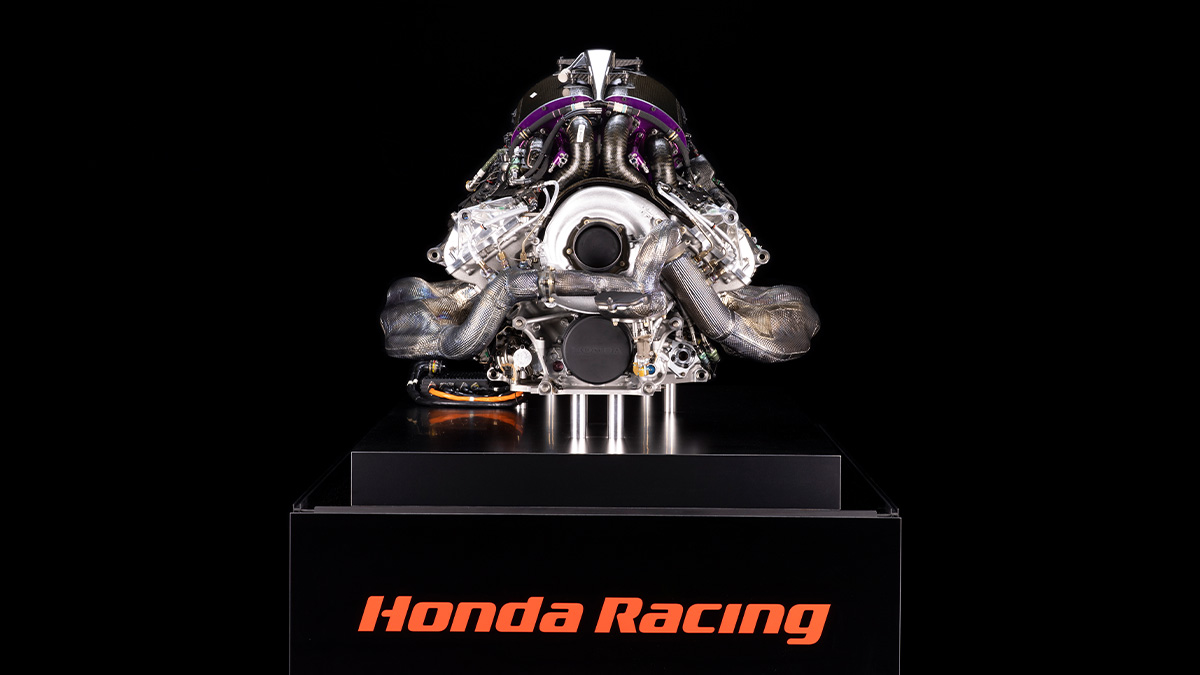

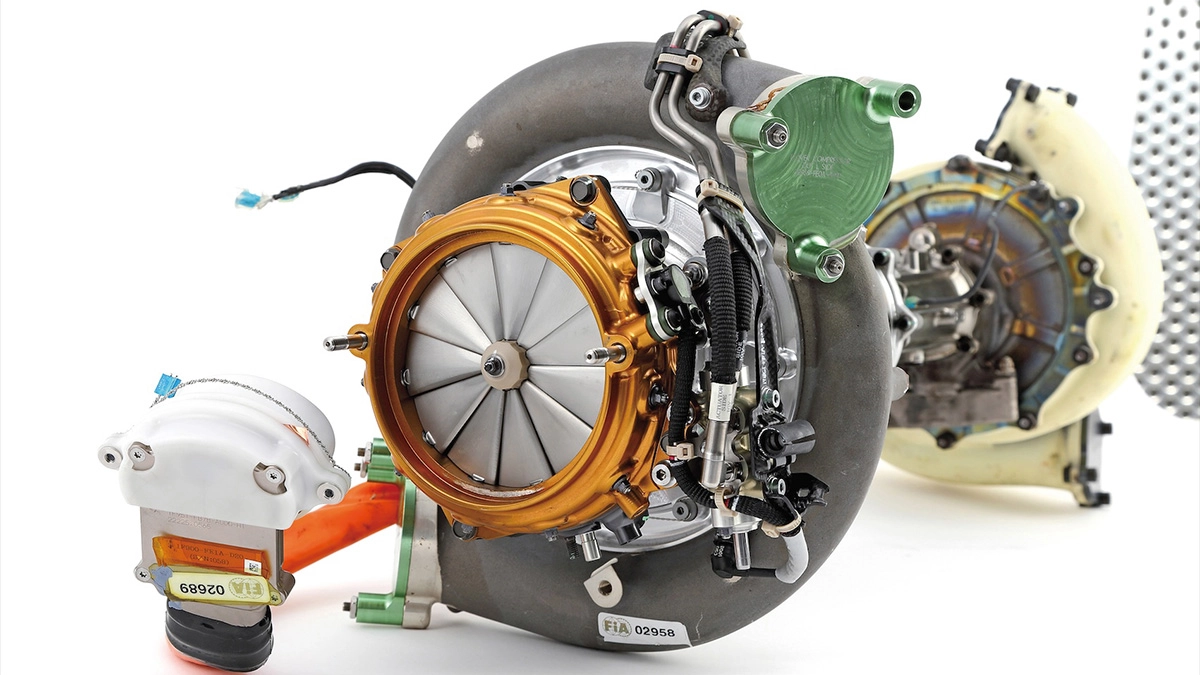

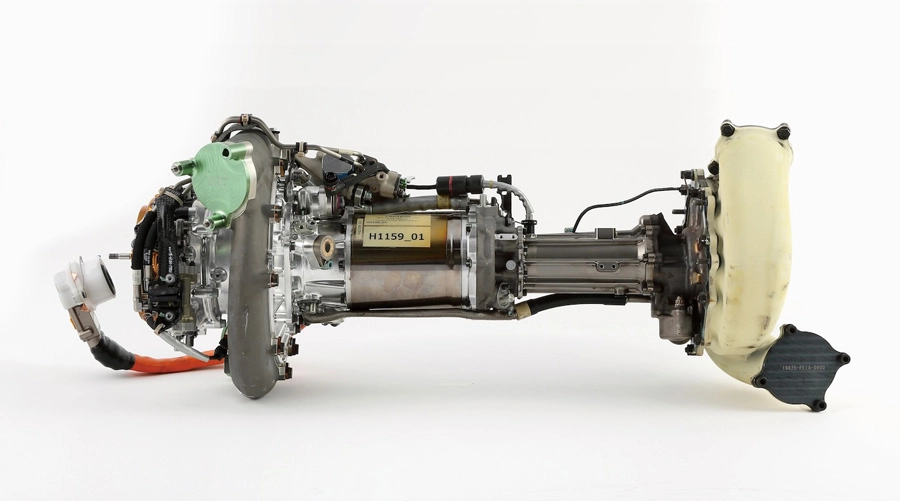

MGU-H (2021): The MGU-H assembly unit integrates the turbocharger and heat energy recovery motor. As pictured, the compressor, motor, and turbine are in a line from the front of the car (left).

With the MGU-H assembly designed to fit within the V-bank, the compressor used on the RA615H in 2015 employed a pressure ratio and corrected air flow rate (actual rate corrected to the reference rate) that was basically an extension from mass-produced turbochargers. This was in part due to spatial restrictions associated with the location within the V-bank, but also because the engine did not require a high pressure ratio or air flow rate.

However, Honda decided to use a larger compressor because the situation at the time could not ensure competitiveness. With the RA617H in 2017, the compressor was moved out of the V-bank and was increased in size. The RA615H was unable to satisfactorily achieve the boost pressure and air flow required on circuits located at higher altitudes, where air density is low, such as in Austria and Mexico (750 and 2,300 meters above sea level respectively). With the RA617H, on the other hand, a larger compressor and other modifications expanded the range of use to enable the power unit to achieve the boost pressure and air flow required at high altitudes.

On the other hand, another issue arose. The longer shaft resulted in a critical speed range in which the shaft’s amplitude of vibration increased at normal rotational speeds. Within this critical speed range, the MGU-H assembly was in danger of damage as amplitude increased in response to repeated large external disturbances, like driving over a curb. Collaborating with the HondaJet gas-turbine engine development team, Honda was able to solve the problem through a range of measures, including increasing bearing rigidity, improving lubrication and cooling, strengthening the bearing vibration damping structure, revising the shaft structure, and reducing imbalances. The improved MGU-H assembly was employed at the Bahrain Grand Prix, the second round of the 2018 season.

ICE evolution-related changes in compressor operating range, and MGU-H and turbocharger layout

Illustration of compressor performance comparison between the RA615H in 2015, with the MGU-H assembly located within the V-bank, and the RA617H in 2017, with a longer MGU-H assembly shaft and larger compressor located outside the V-bank. The RA615H employed a pressure ratio and corrected air flow rate that was an extension from mass-produced turbochargers, so it was unable to satisfactorily achieve the boost pressure and air flow required at the time on high-altitude circuits where air density is low, such as in Mexico in particular. With the RA617H, a larger compressor was used and other changes were made to meet a wider range of requirements.

Since the French Grand Prix in round 8 of the 2019 season, Honda has been further increasing the compressor pressure ratio in collaboration with the HondaJet gas-turbine engine development team. Looking at the annual changes, efficiency dropped off in 2020 and 2021, but only because the focus shifted from efficiency to pressure ratio. The decision was made because in the trade-off between pressure ratio and efficiency, it is a higher pressure ratio that contributed more to performance.

Using the latest design tools, it has become possible to design compressor blades with more complex three-dimensional shapes. And the greater the pursuit of efficiency, the more complex those three-dimensional shapes become. However, with complex shapes, the blades may resonate at their own natural frequency in operating mode, leading to serious shaking that can cause damage. To prevent this, power unit test benches and other means were used to reproduce the effect of the engine’s exhaust pulsation and confirm sufficient durability and reliability before employing the new shapes on an actual car.

For the French Grand Prix in round 8 of the 2019 season, the compressor was designed to specifications that covered pressure ratios and corrected air flow rates that were far broader than that of mass-produced turbochargers (for 1.5-liter engines). In addition to the wider specification range, it also achieved high efficiency over a wide operating range.

Turbine efficiency was also dramatically improved when switching to the longer shaft in 2017. Consequently, the MGU-H energy recovery rate also increased. HondaJet gas-turbine engine development knowledge was again used for the turbine introduced with the RA620H in 2020. Like the compressor, the blades were changed to a more complex three dimensional shape.

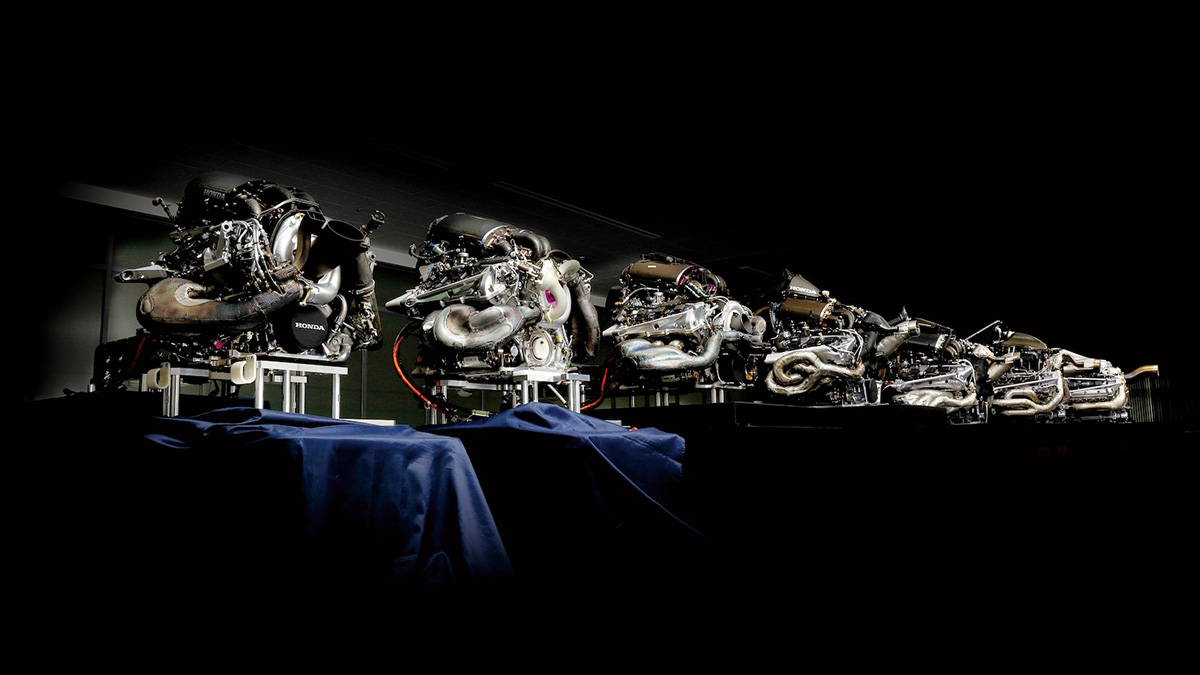

History of MGU-H development

Looking at the MGU-H from the developer’s perspective, the main focus of development through to 2018 was improved reliability, which changed to improved motor performance from 2019. The layout within the V-bank was subject to dimensional restrictions until 2016, but motor output requirements were not great until then anyway. Overall dimensions were compact as a result. HGN design in 2018 refers to collaborating with the HondaJet gas-turbine engine development team at the Wako R&D Center. Extra Deploy in 2019 and Extra Harvest in 2020 are both energy management technologies.

At the start of F1 participation in 2015, there were few demands on MGU-H motor output in the same way that the engine did not require a high pressure ratio or air flow rate. The turning point was when a longer shaft was used in 2017, after which there has been a strong focus on improving energy recovery rates.

With the RA618H in 2018, Honda made a significant change to the shaft support structure with the help of the HondaJet gas-turbine engine development team. There was also a change from greased bearings to oil lubrication. With high motor speeds of 100,000 rpm or more, air resistance results in what is known as windage loss. Therefore, while windage loss is generally reduced by placing shaft supports within a vacuum environment, a pressurized structure was employed instead to ensure oil sealing and prioritize reliability. The compressor was used to pressurize the structure.

With the RA619H in 2019, the rated output of the MGU-H was increased to enable high motor output for extended periods of time. This change was made in response to the greater frequency of MGU-H use accompanying advances in energy management technologies (Evolution of the ESS Battery Unit and Control Technologies).

With the RA620H in 2020, the main focus of development was the turbocharger and while MGU-H hardware did not change much, the way it was used was improved. With the RA621H in 2021, high magnetic flux density magnets and high thermal conductivity insulators were used to improve cooling efficiency and increase MGU-H output and torque. By increasing torque as well, rather than output only, Honda was able to expand the range of operation to achieve efficient energy recovery even at low rpms in line with advances in energy management.

MGU-K

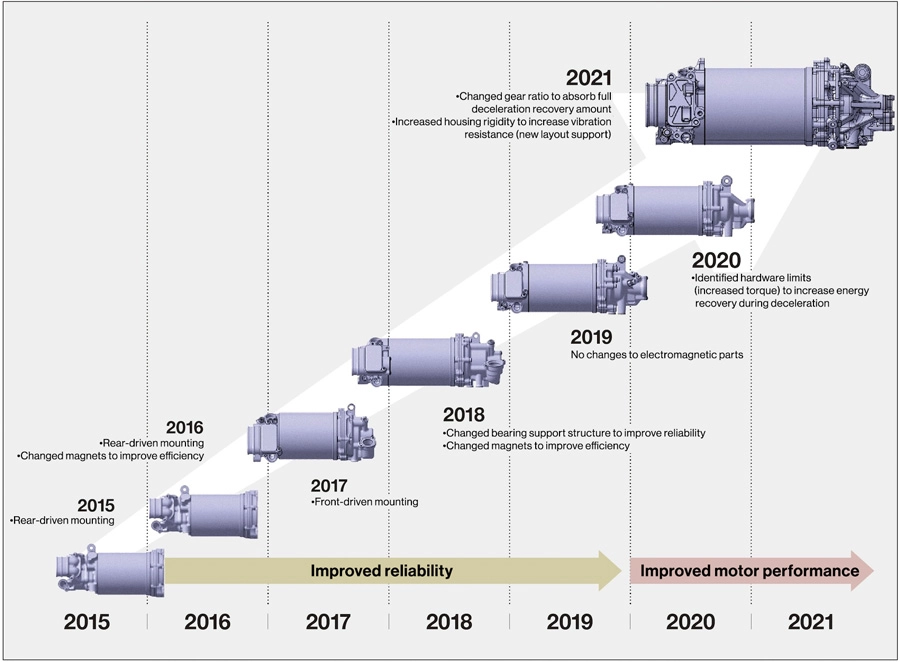

The MGU-K is mainly used to recover kinetic energy during deceleration and to assist engine output during acceleration. Technical regulations specify maximum output of 120 kW and maximum rotational speed of 50,000 rpm.

History of MGU-K development

Like for the MGU-H, the main focus of MGU-K development through to 2019 was improved reliability, which changed to improved motor performance from 2020. The bearing support structure was changed in 2018. While no problems were found at all when bench-testing motors on their own, they would break down when installed and operated in actual power unit bench tests. This was due to insufficient bearing allowable loads in terms of radial load. With the new-layout ICE introduced in 2021, combustion pressure increased and vibration became more intense. Housing rigidity was increased to improve vibration resistance.

As explained above, the MGU-K is restricted to a maximum output of 120 kW, with maximum torque also restricted to 200 Nm. With the RA620H in 2020, MGU-K torque was increased within the specified range to enable energy recovery at maximum output from low engine speeds. With the RA621H in 2021, a gear ratio change allowed the MGU-K to recover energy at maximum output at even lower engine speeds.

At the beginning, a major challenge was to ensure MGU-K reliability. However, an issue with shaft damage arose when torsional resonance occurred as a result of connecting, via the gear, a high-inertia crankshaft with a smaller (but appropriate) -inertia MGU-K. A number of measures were implemented to solve this problem, including making the shaft a weaker spring. With another issue related to heat, the magnets were changed with the RA616H in 2016 to improve thermal resistance.

With the RA617H in 2017, the rear-driven mounting used previously, to connect the MGU-K via a gear to the rear of the engine, was changed to a front-driven mounting to connect it to the front of the engine. When mounted to the rear, the drive mechanism of the MGU-K was positioned at the bottom left of the engine lower case, which interfered with the body shape and affected aerodynamic performance. The mounting position was changed to the front to eliminate this impact.

With the RA618H in 2018, the bearing support structure was changed to improve reliability. While this resulted in a longer shaft, the focus had been on reliability and no bearing-related trouble occurred since then. In 2021, MGU-K housing rigidity was increased to improve vibration resistance. This was done to solve an issue with increased vibration occurring with the increased combustion pressure of an engine with a new layout.

During a development process aimed at achieving thermal efficiency for the engine, Honda worked to improve the pressure ratio and air flow rate while improving efficiency of the compressor, which is part of the MGU-H assembly, to develop an MGU-H with high output and torque. As with the MGU-H assembly, it focused on achieving MGU-K reliability when it started participating in the F1, while also ensuring the ability to recover energy at maximum output even at low engine speeds. Over these seven seasons of the F1, the MGU-H and MGU-K both evolved considerably.