Honda’s New EV Development Approach

Generally, when trying to secure a long driving range for EVs, the battery capacity increases proportionally. This requires strengthening the body rigidity to accommodate it, typically resulting in larger vehicles that are thick and heavy. Honda’s vision for EVs is to evolve our Man-Maximum, Mecha-Minimum (M/M) philosophy and dynamics technologies that we have cultivated over the years. We aim to break free from these constraints by making EVs thin and light. Furthermore, by adding intelligent technologies, Honda will create original software defined vehicles (SDVs) and make the vehicles themselves wiser.

This new EV development approach is what we call “Thin, Light, and Wise.”

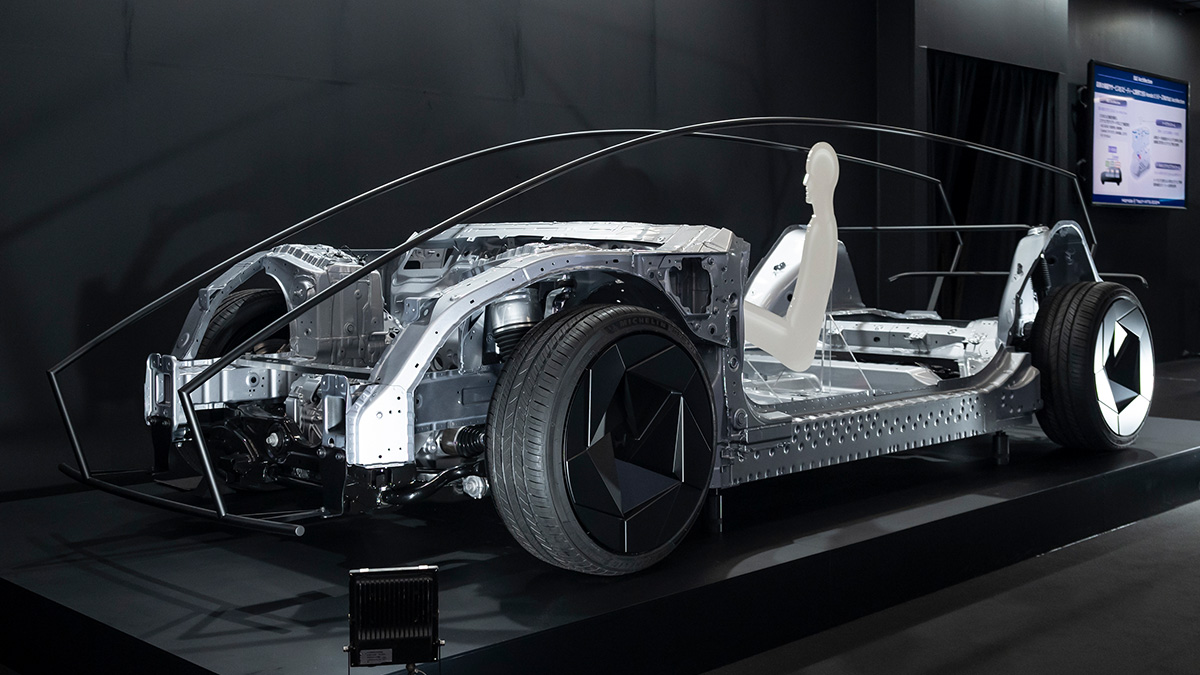

Embodiment of “Thin, Light”

Thin

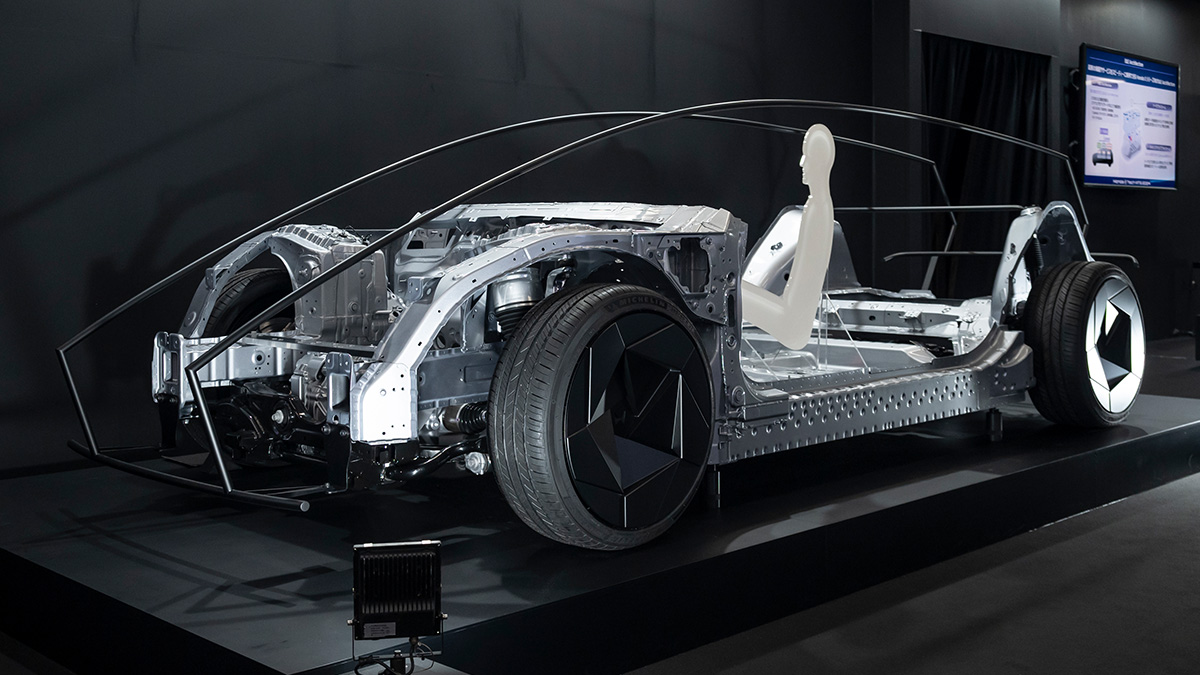

We aim to provide products that embody Honda’s cherished “M/M philosophy,” even for EVs. This will be achieved by combining attractive styling featuring low overall height and short overhangs like the “Saloon”—unprecedented for EVs—with a spacious interior. This is made possible through a specially developed ultra-thin battery pack, a thin floor using ultra-high-tensile steel sheets, and an e-Axle with an inverter miniaturized to the extreme, enabling horizontal mounting.

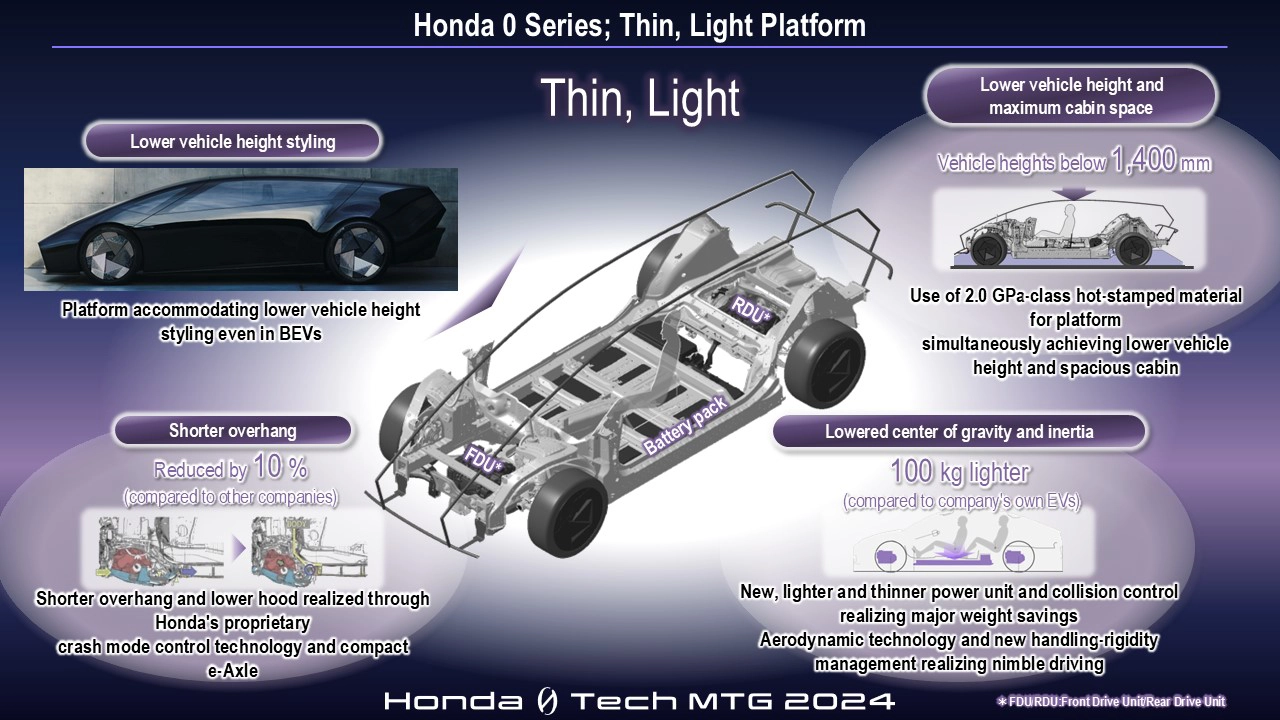

Light

In addition to weight reduction through the evolution of our proprietary collision logic, we have established a new index for handling stability. By effectively utilizing body deformation to control tire load during cornering, we achieve both a light, satisfying ride and weight savings. We have reduced the vehicle weight by 100kg (220 pounds) compared to Honda EVs. Furthermore, heavy components whose thickness, size, and weight have been reduced, such as the battery and power unit, are placed low and in the center of the vehicle body to realize a low center of gravity and low inertia. We aim to evolve the “sense of joy” that Honda has always valued in car manufacturing to new heights.

Moreover, we have significantly reduced energy loss through a compact and highly efficient e-Axle that further evolves the motor and inverter technologies cultivated in hybrid vehicle development. We have reduced driving energy through high aerodynamic performance that utilizes a newly developed active aerodynamic system. These technologies achieve the world’s top class electricity efficiency performance, realizing a driving range in the 300-mile class in the U.S. EPA mode.

Platform

The platform, which accommodates lower vehicle height styling even in EVs, controls the floor height by applying 2.0 GPa-class hot-stamped materials to the floor frame and using a thin battery pack. Honda’s proprietary crash mode control and the pursuit of a compact e-Axle realize short overhangs and a low hood. Furthermore, these efforts simultaneously achieve significant weight savings, contributing to a nimble driving experience and excellent electricity efficiency performance.

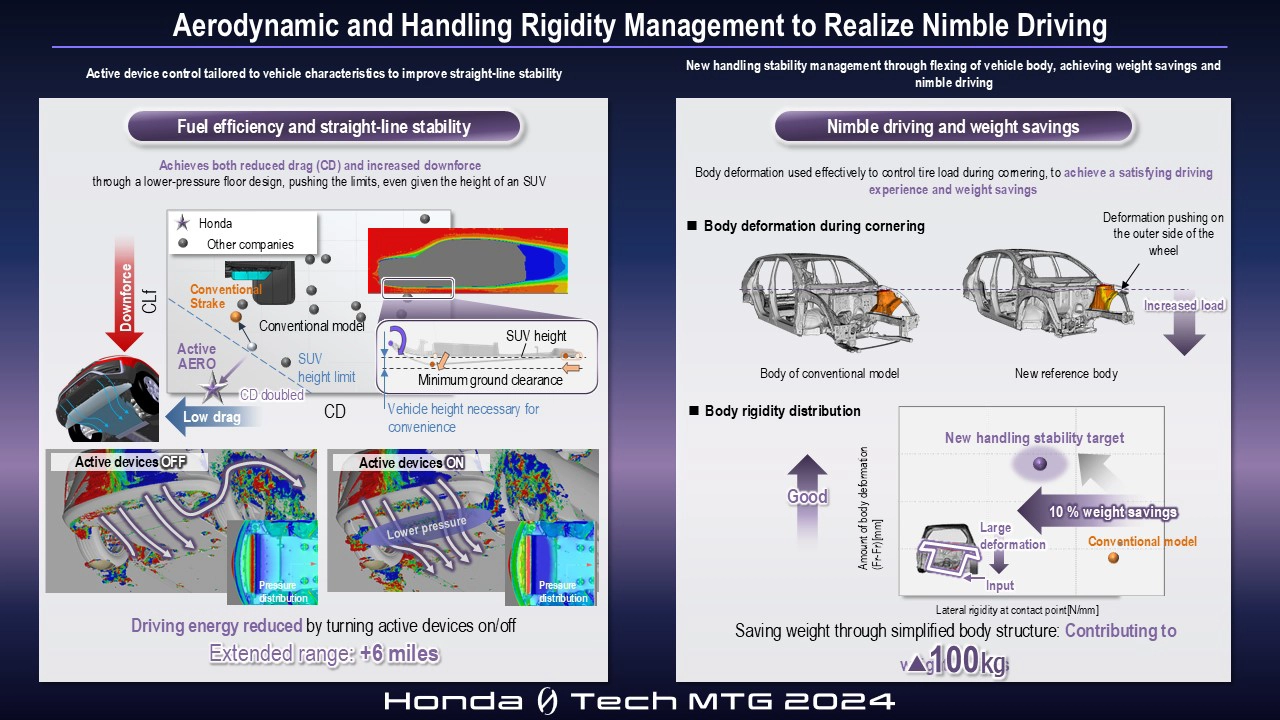

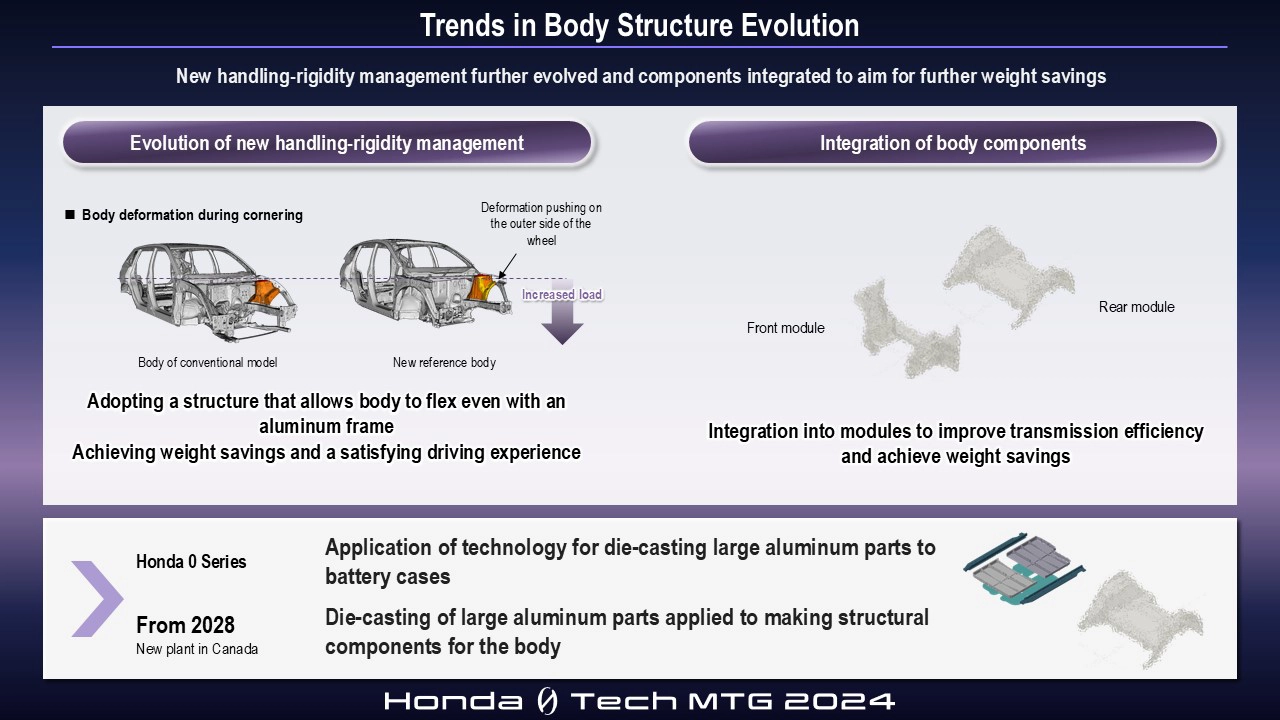

To enhance driving performance and electricity efficiency, we have adopted an active aerodynamic system and introduced a new body rigidity concept that we call “new handling-rigidity management.”

For EVs, air resistance significantly affects driving range. For this reason, we developed an electrically variable device that controls the airflow under the floor. By varying the front aero deflector installed under the front motor in response to vehicle speed, the flow velocity under the floor is changed, suppressing air turbulence caused by the tires and reducing air resistance.

This results in a 6-mile range extension effect in EPA mode compared to conventional device use. At the same time, the lowered pressure under the floor generates downforce, improving straight line stability.

To reduce body weight, we devised a new index different from conventional body rigidity indices that leverages Honda’s expertise. Rather than increasing rigidity to suppress body deformation, we simplified the body structure through a new handling-rigidity management system that creates nimble driving by allowing the body to flex. By intentionally restraining lateral rigidity at the contact points, body flexing during cornering is utilized effectively to control tire load. This achieves a satisfying driving experience and significant weight savings for the body frame.

Additionally, at the EV-dedicated complete vehicle plant in Canada scheduled to begin operations in 2028, we will introduce innovative production technologies and expand the application of large aluminum die-casting, currently used for battery cases, to body frame parts as well. In doing so, we will further evolve the nimble driving performance through weight savings.

Energy System

Honda 0 Tech MTG 2024 Technology Video: Platform/Energy System

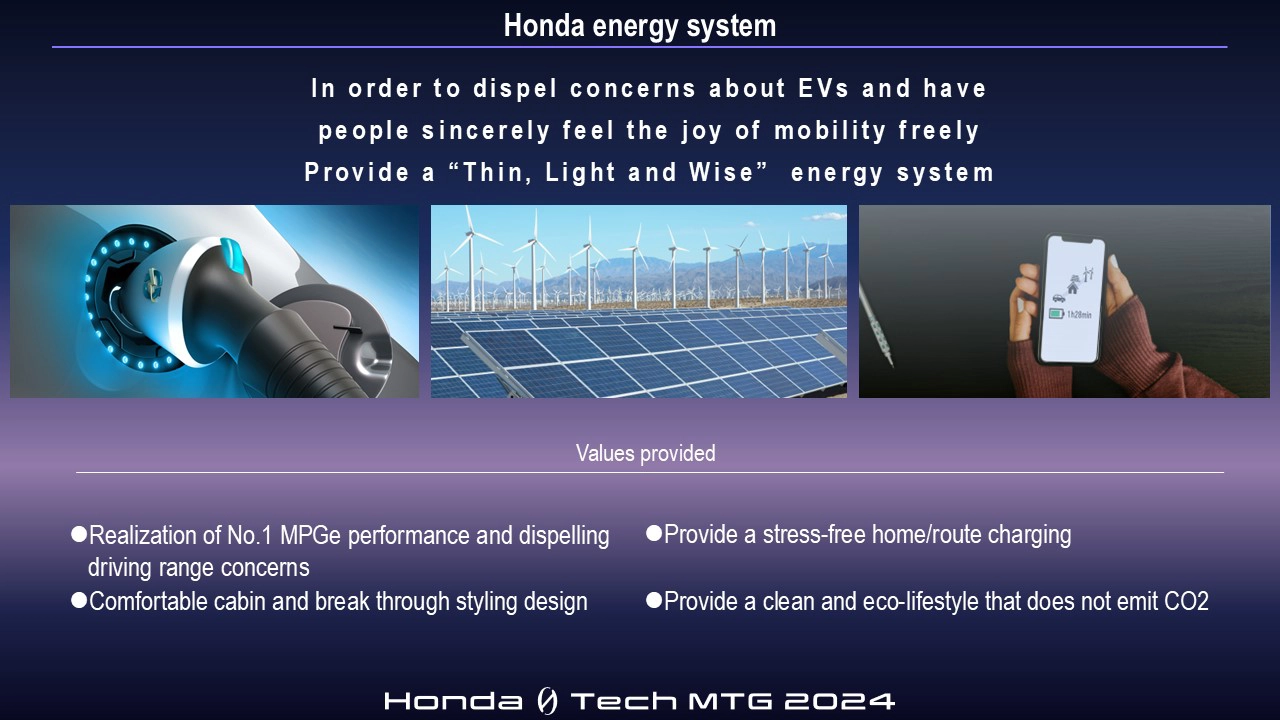

For EVs including the Honda 0 Series, Honda is pursuing highly efficient power units and energy management to dispel anxiety about range and allow customers to sincerely feel the joy of mobility freely. We are also promoting initiatives in energy services, such as expanding charging infrastructure.

Energy Management

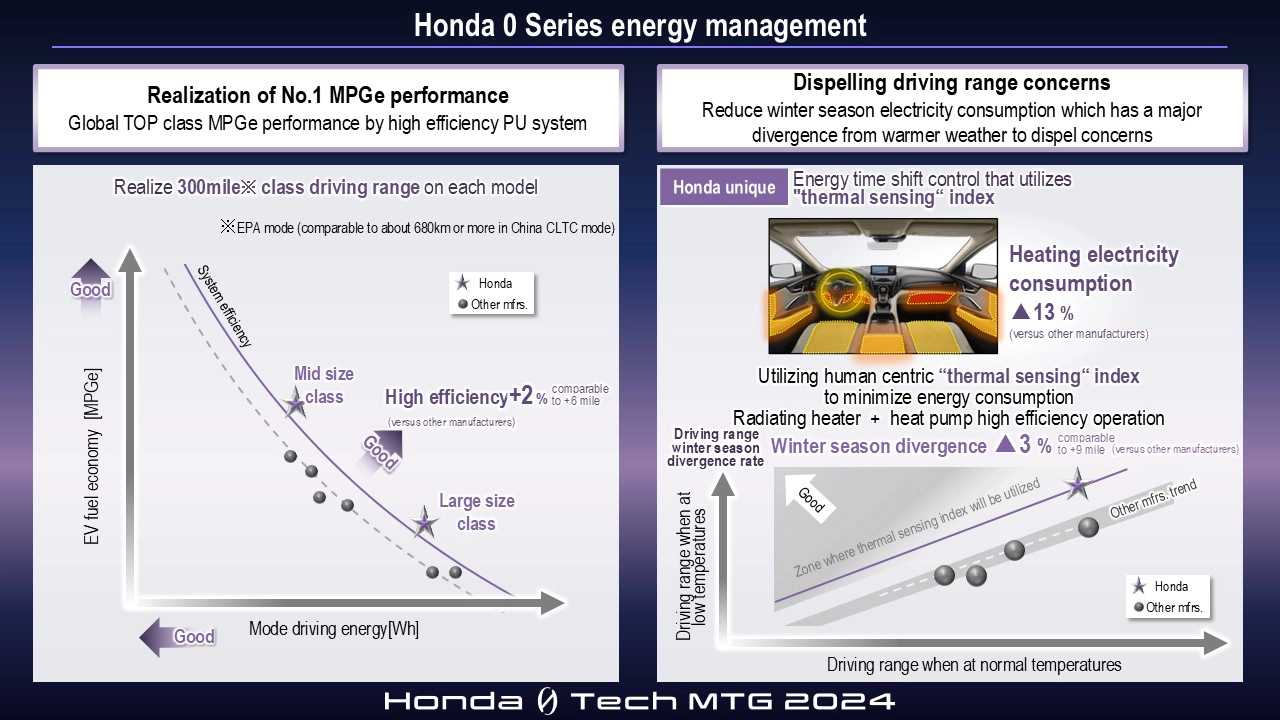

We aim to realize the world’s top-class electricity efficiency performance through highly efficient power units, lightweight platforms, and proprietary energy management. Compared to competitors’ trend lines, we have realized about a 2% improvement (equivalent to 6 miles) across all classes from small to large vehicles, securing a range in the 300-mile class in U.S. EPA mode.

We are also addressing concerns about winter driving range in EVs through our unique energy management. Instead of warming the entire cabin, we adopt a “thermal sensing” index. By focusing on warming the area around occupants with radiant heaters and employing highly efficient heat pump operation, we reduce heating power consumption by approximately 13%*1 compared to other manufacturers. This improves the winter range divergence rate by about 3% compared to competitors’ trend lines.

*1 Compared to the standard component/function installed in currently available production EVs. (Honda internal research)

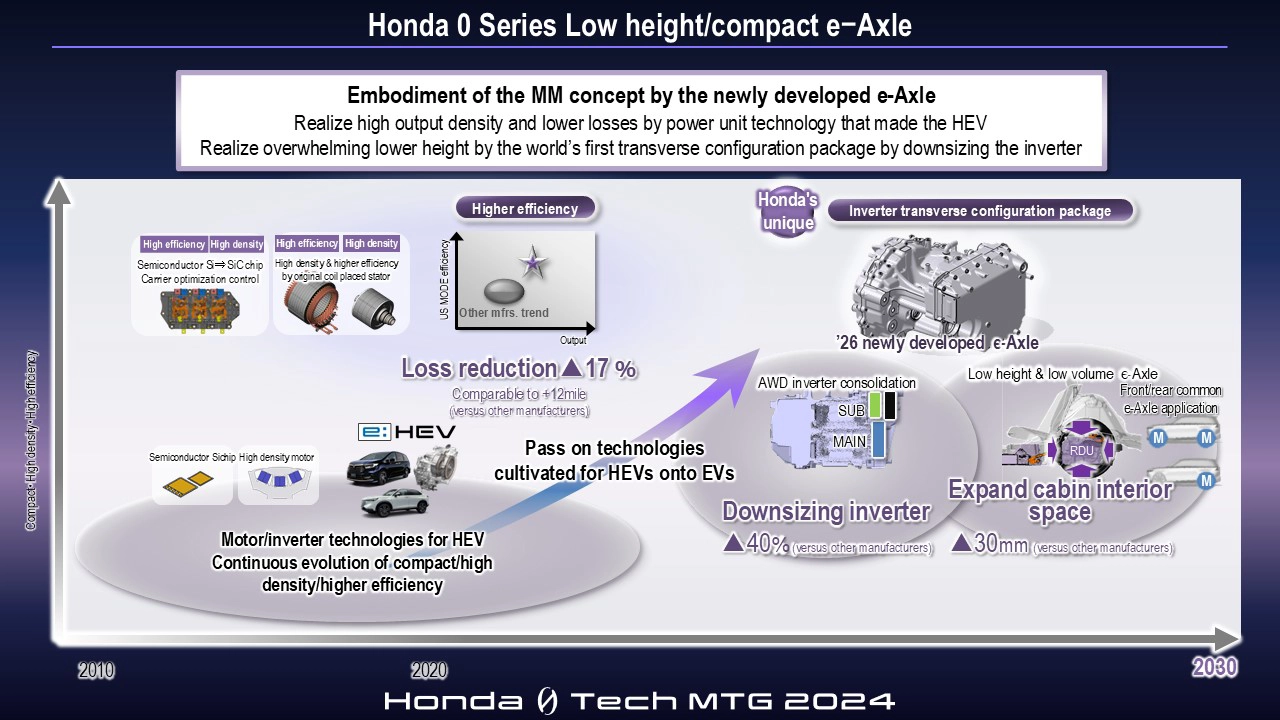

Low height, Compact e-Axle

The e-Axle, which integrates the drive motor, gearbox, and inverter, leverages technologies from Honda’s long-developed hybrid systems to pursue miniaturization, high output density, and low losses. By using SiC power semiconductors in the inverter and high-density motors with proprietary coil arrangements, we have reduced losses by about 17% compared to industry trends, enabling a range extension equivalent to 12 miles.

Regarding miniaturization, Honda’s unique horizontal inverter layout package greatly contributes to lowering the hood and shortening overhangs. We downsized the inverters by approximately 40% compared to industry trends to achieve placement side by side with the motor instead of above the motor or gearbox as in conventional designs. This e-Axle can be commonly applied to both front-wheel and rear-wheel drive, making it suitable for various vehicle types. Furthermore, the horizontal inverter layout enables the consolidation of inverters for AWD motors without affecting cabin space.

Lightweight/Thin Type Battery Pack

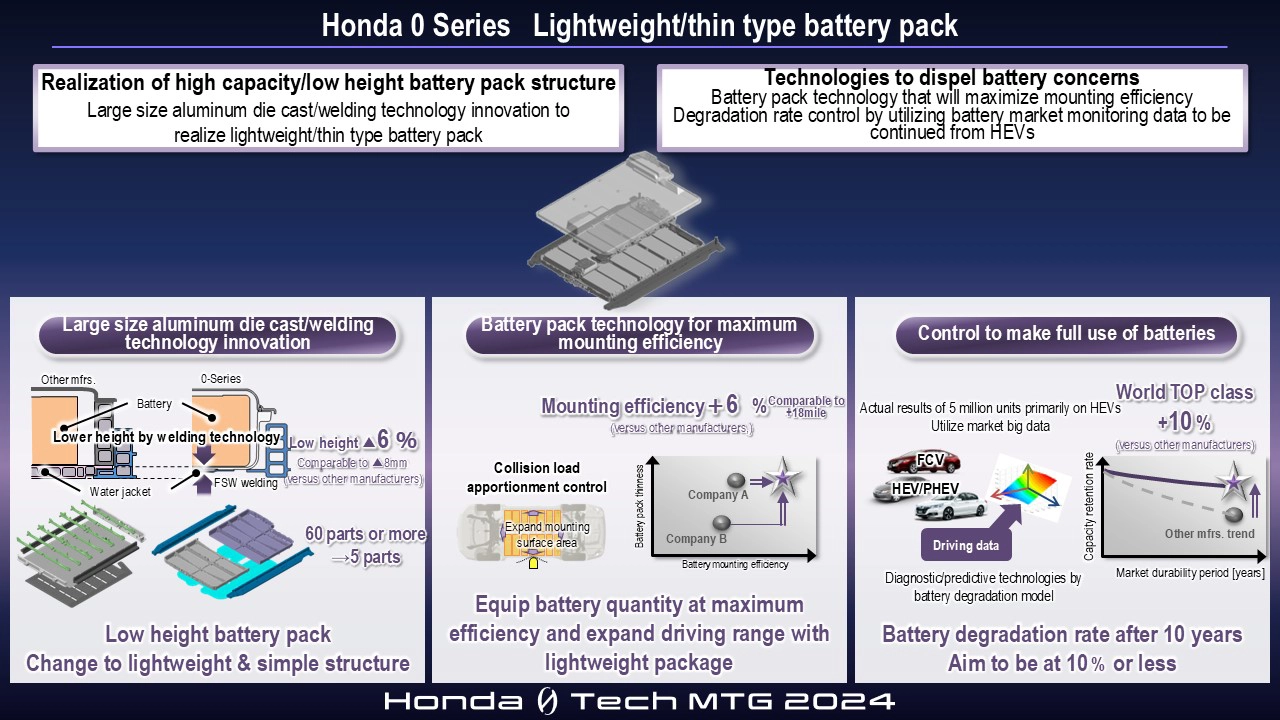

The battery pack, placed under the floor and affecting floor height, has been made thin through innovative production technology. The case is made by creating two large aluminum die-cast parts for the front and rear using mega-casting, then integrating them using friction stir welding (FSW). This two-part design allows for the creation of battery packs with different capacities through various combinations. This simplifies the structure from over 60 parts in conventional designs to just 5 parts, thus achieving weight savings.

Moreover, FSW is utilized to thin the water jacket used for battery temperature management. While conventional designs integrated separate water jackets with assembly parts, the Honda 0 Series integrally molds water channels into the battery case’s lower surface using mega-casting, then joins an aluminum plate using FSW technology. This achieves about 6% (equivalent to 8mm) thinning compared to conventional structures.

EV battery packs also absorb side impact loads. The Honda 0 Series optimizes the battery pack’s collision structure by integrating collision load distribution control between the body frame and battery pack. This improves battery cell mounting efficiency by about 6% compared to competitors, enabling a range extension of about 18 miles.

Honda has also introduced numerous electrified vehicles to the market, including hybrids. By utilizing the big data that has been accumulated, we have established diagnostic and predictive technologies based on our proprietary battery degradation model. We aim to limit the battery degradation rate after 10 years of use by approximately 10% compared to industry trends, targeting a degradation rate of 10% or less from the time of purchase.

Energy Services

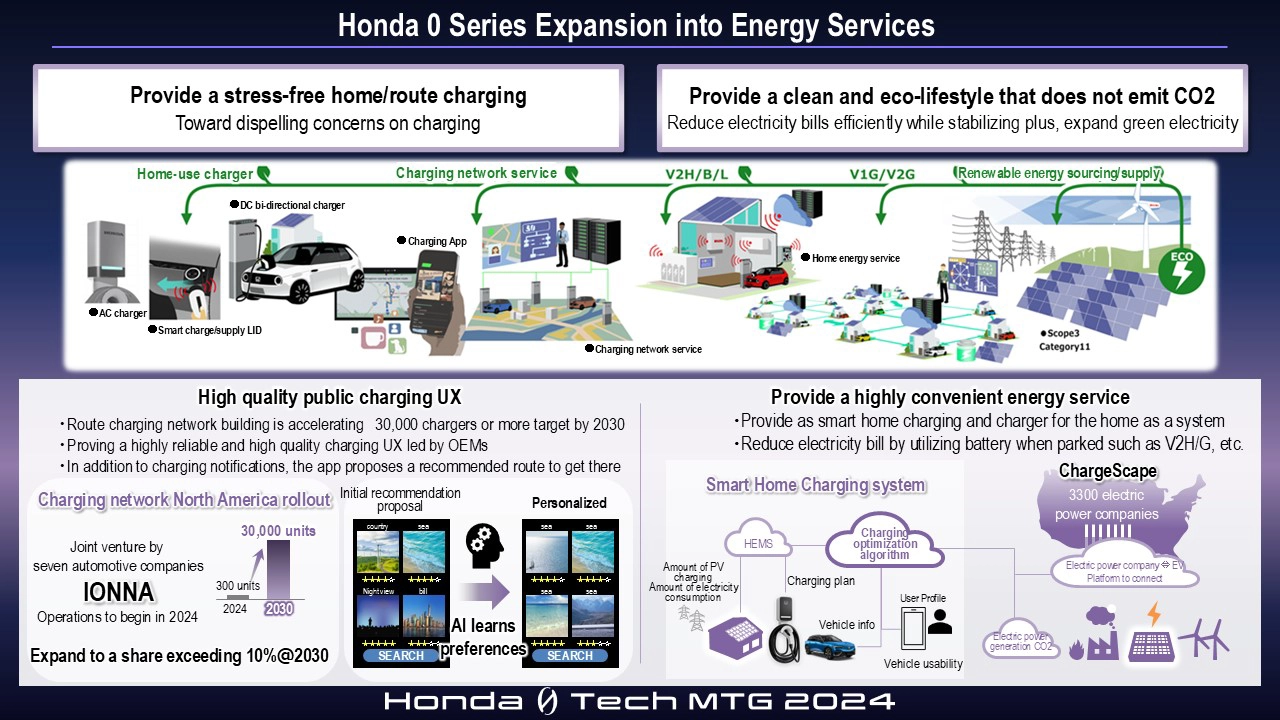

Honda is not only improving EV performance, but also providing energy services that contribute to expanding charging infrastructure and reducing electricity costs, enhancing overall EV convenience.

Through IONNA, which is expanding a rapid EV charging network in North America, we aim to establish a route charging network of 30,000 chargers by 2030. A smartphone app will also suggest personalized recommended stopovers.

Additionally, we will provide a smart home charging system that automatically charges at the most cost-effective times based on home solar power generation, power consumption, and EV usage schedules. Furthermore, by collaborating with power company platforms and utilizing V2H/V2G and repurposing of batteries, we will develop energy services that provide a clean, eco-friendly lifestyle without CO2 emissions through effective use of battery power.

The Embodiment of “Wise”

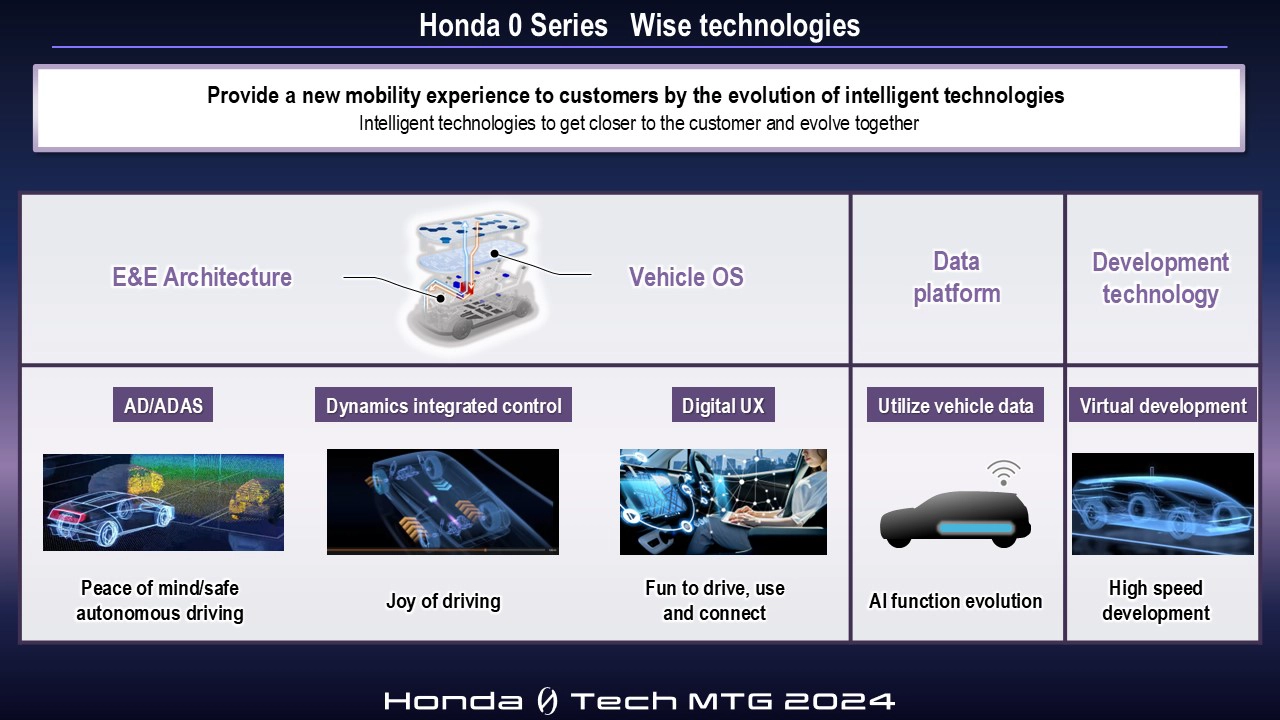

“Wise” is the unique value of Honda’s SDV vision, in which the vehicle itself becomes wiser through the application of the knowledge that Honda has amassed to date and by further advancing its intelligent technologies, providing new mobility experiences by responding meticulously to each customer’s thoughts and needs.

Specifically, this involves advancing vehicle functions such as AD/ADAS and dynamics, as well as providing digital UX that expands the enjoyment while driving and inside the vehicle. To achieve these, Honda is independently developing and implementing our own underlying E&E architecture and vehicle OS. By updating vehicle functions through Over The Air (OTA), we will continue to evolve the vehicle into an attractive product unique to Honda even after the customer purchases the vehicle, providing a digital UX optimized for each individual customer.

Additionally, we are preparing development technologies, including a data platform that evolves AI functions by utilizing vehicle data, as well as virtual development for rapid software development.

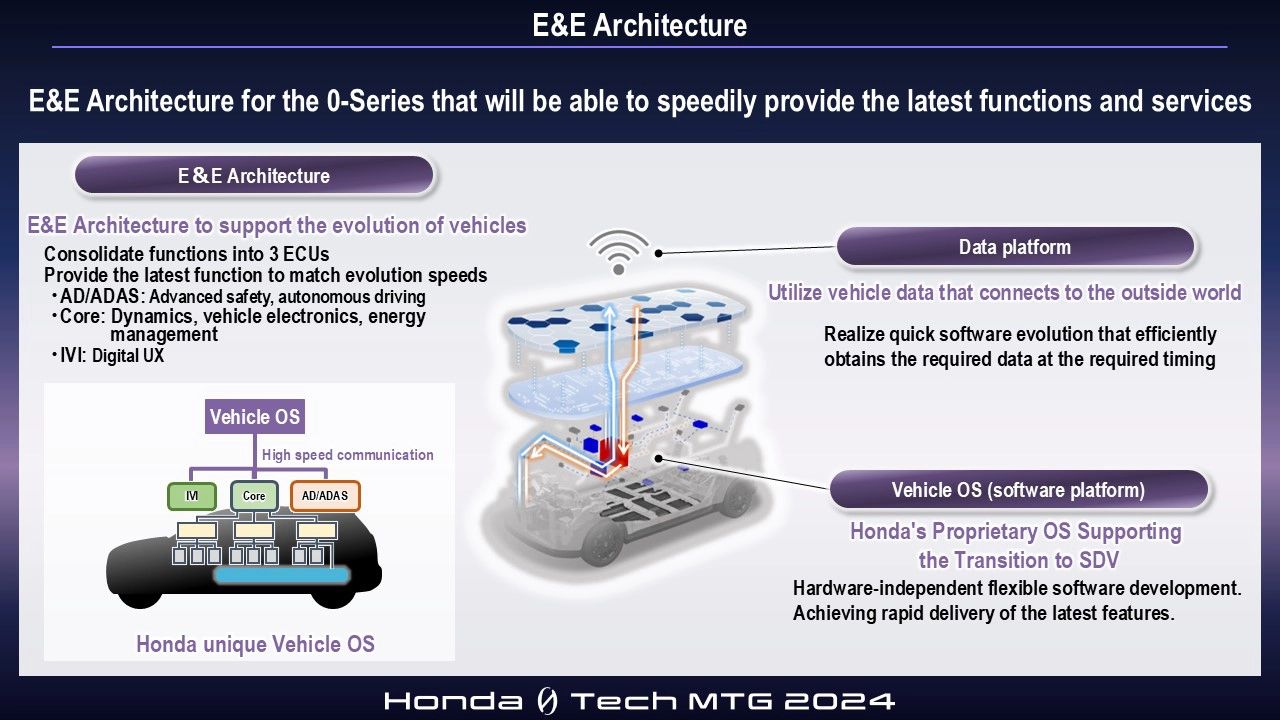

E&E Architecture

Honda 0 Tech MTG 2024 Technology Video <E&E Architecture>

SDV defines vehicle functions and value through software, enabling continuous addition of functions and performance improvements through software updates. The foundation for this is the E&E architecture. By independently developing not only the E&E architecture, but also the vehicle OS and applications, Honda can quickly provide the latest functions and services. Users can access new functions at any time through Over-The-Air (OTA) updates by operating the display audio or smartphone.

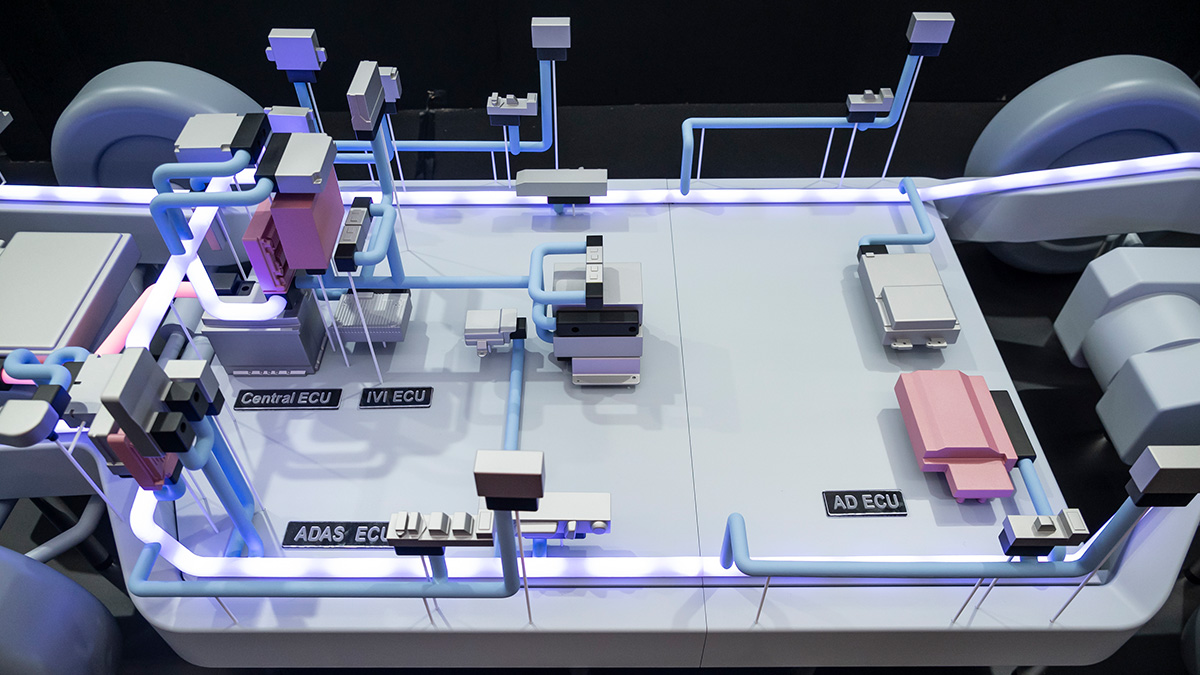

The E&E architecture to be installed in the 2026 model of the Honda 0 Series consolidates functions into three ECUs classified according to their evolution speed: “AD/ADAS” for automated driving and advanced driver assistance, “Core” for controlling basic vehicle functions, and “IVI” for providing high convenience through digital UX. Functions evolve by updating the software of each ECU.

Furthermore, by connecting these core ECUs with high-speed ommunication, we achieve real-time cross-domain control.

The data platform, which creates various values by utilizing vehicle data, contributes to function evolution tailored to customers by obtaining the required data at the optimal timing.

The vehicle OS, which connects hardware and software, enables hardware-independent software development. This improves development speed, allowing for rapid provision of the latest functions and services.

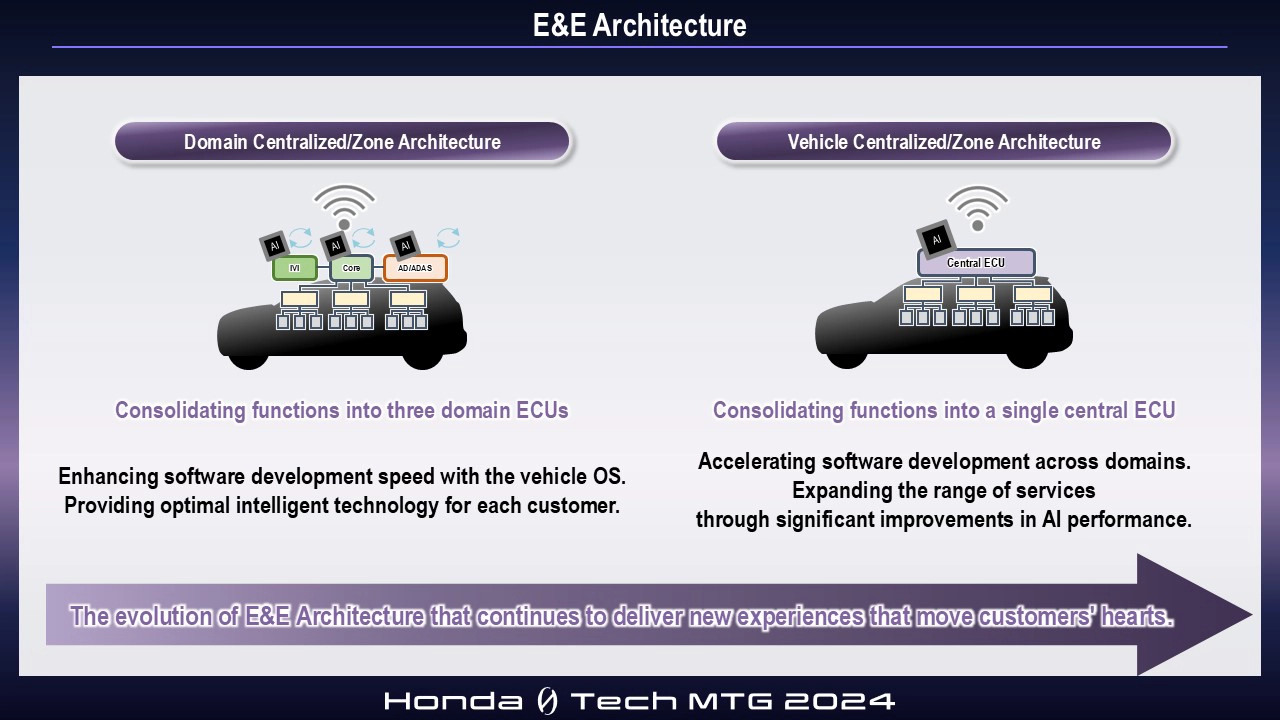

Furthermore, the next generation of E&E architecture will continue to evolve, aiming for further function integration to continuously deliver new experiences that move customers’ hearts.

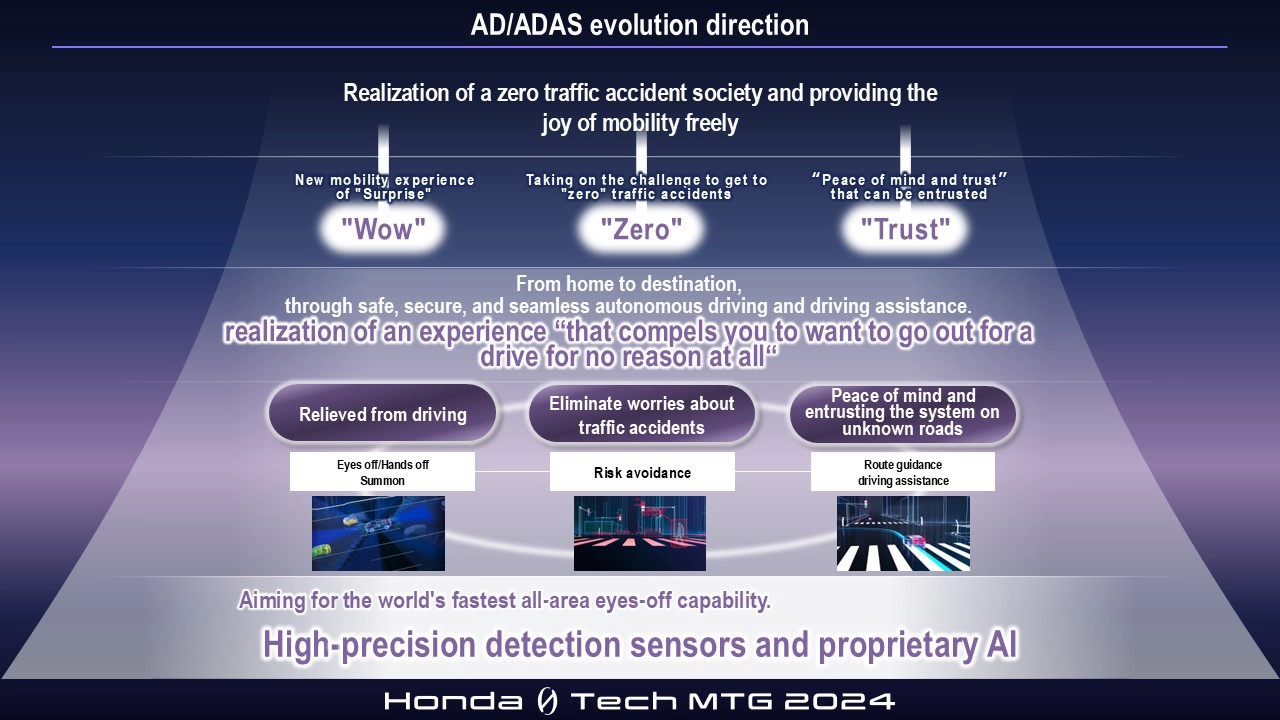

Automated Driving/Advanced Driver Assistance Systems (AD/ADAS)

Honda 0 Tech MTG 2024 Technology Video <AD/ADAS>

Honda’s AD/ADAS supports drivers in all driving scenarios, offering “experiences that make people want to go out spontaneously.” At departure, you can summon the car using a smartphone and board at your preferred location. Once the destination is set, it provides route guidance driving assistance, including on general roads, while predicting risks to prevent accidents, allowing for confident driving even on unfamiliar roads. On highways, hands-off driving is possible within the same lane and during lane changes. In traffic jams, eyes-off driving is possible within the same lane, providing free time that liberates people from driving.

Key to achieving this are high-precision detection sensors and proprietary AI that enable Level 3 automated driving (eyes-off).

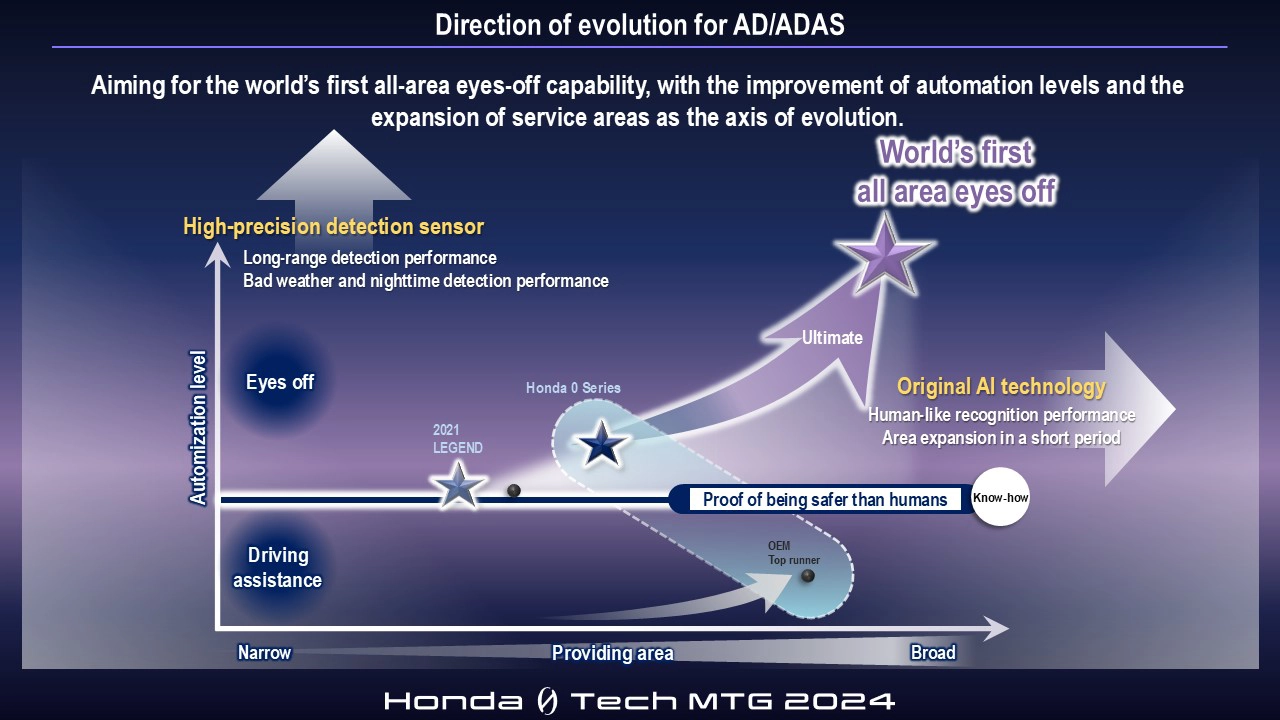

Based on Honda’s foundational technologies and know-how, such as Honda SENSING Elite, which achieved the world’s first Level 3 automated driving, and integrated dynamics control, we are advancing the improvement of automation levels through high-precision detection sensors and expanding the service area through proprietary AI. We aim to achieve the world’s fastest full-area eyes-off capability.

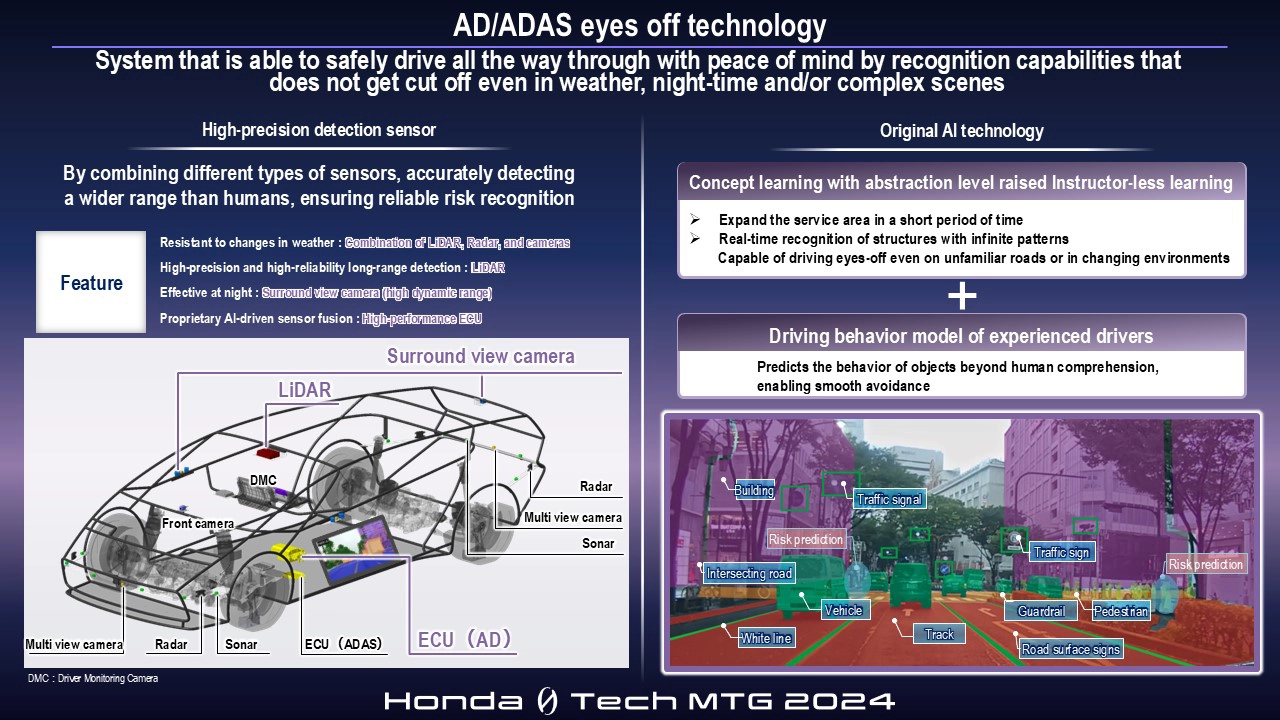

By processing sensor fusion of high-precision detection sensors and proprietary AI with a high-performance ECU, we aim to achieve robust performance in changing weather conditions and recognition even at nighttime and in complex scenarios, enabling safe, secure, and uninterrupted driving.

The high-precision detection sensors use sensor fusion (combination of different types of sensors) such as LiDAR, Radar, and cameras. This makes them resilient to weather changes and capable of detecting human blind spots and distant objects with high accuracy, thus recognizing risks.

Our proprietary AI can expand the service area in a short period with a small amount of data through concept learning with raised abstraction levels. Furthermore, it offers real-time recognition of structures with infinite patterns, such as buildings and guardrails, making it resilient to environmental changes and capable of providing uninterrupted support even on roads driven for the first time. Additionally, by combining diverse experienced driver behavior models, it recognizes risks posed by objects just like an experienced driver, achieving smooth assistance.

Dynamics Integrated Control

Honda 0 Tech MTG 2024 Technical Video <Dynamics>

Honda’s unique integrated dynamics control seamlessly coordinates various control devices. It stabilizes the vehicle in any scenario and achieves the desired behavior, providing drivers with a sense of joy in handling within a highly reassuring environment.

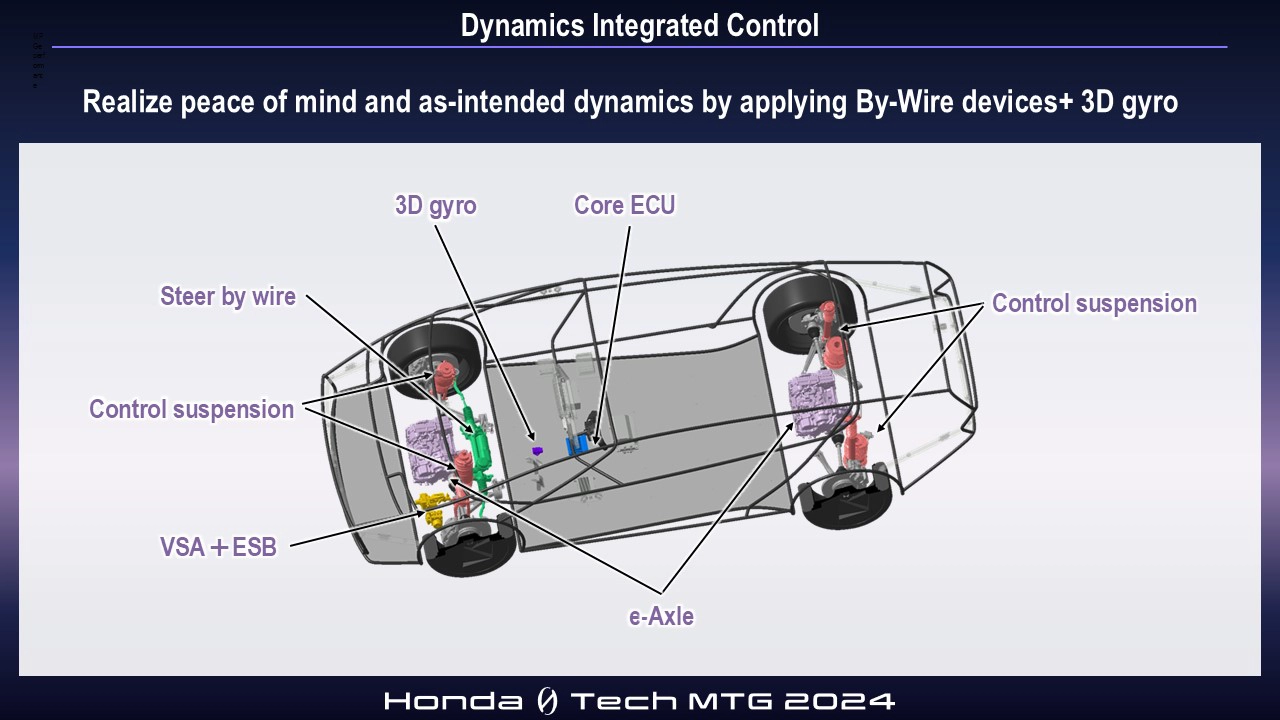

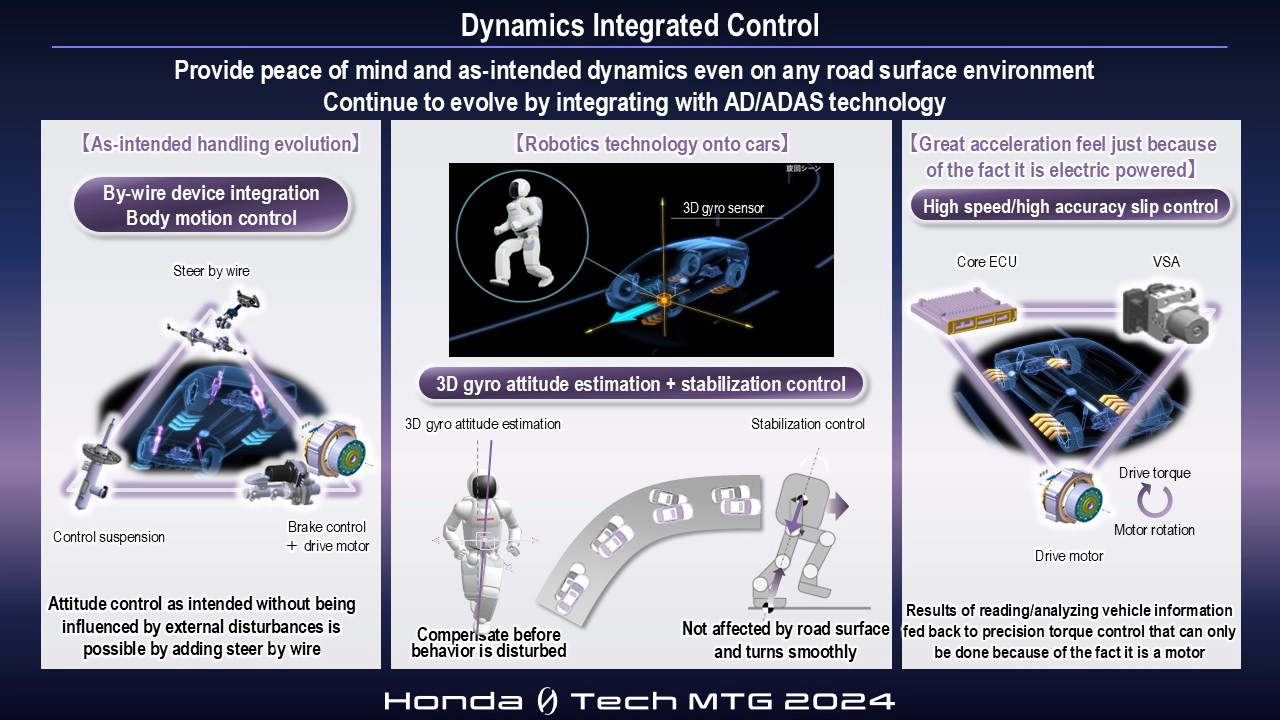

In addition to the dynamics control technologies that Honda has refined over the years, such as VSA and Adaptive Damper System, we also utilize posture control technology from bipedal robots. High-precision posture estimation is performed using a 3D gyro sensor, integrating control of by-wire devices such as steer-by-wire, controlled suspension, and e-Axle.

For example, when cornering on a slippery surface, during deceleration, regenerative braking and controlled suspension work together to stabilize the turning posture. Steer-by-wire adjusts the tire angle according to the situation, balancing desired turning performance and stability.

For control during turns, we utilize technology from Honda’s bipedal robots. In addition to adopting a 3D gyro sensor that detects yaw, roll, and pitch along with acceleration applied to the vehicle body, we apply the logic used to estimate posture during walking to four-wheeled vehicles, detecting even minute behaviors three-dimensionally. Early behavior stabilization can be achieved through brake and steering control by detecting behavioral changes early. Furthermore, we incorporate predictive motion control from bipedal robots, which predicts the next movement in real-time and shifts the center of gravity in advance, enabling smooth control intervention even with sudden changes in road surface conditions, resulting in a natural feeling.

When accelerating out of corners, e-Axle drive torque control and VSA brake control work together to independently and precisely control the driving force of all four wheels. This allows for comfortable acceleration even on slippery surfaces.

By continuously performing such control in various scenarios, we provide worry-free and desired dynamics without the driver being aware of it.

In the future, we plan to further evolve dynamic performance by incorporating feedforward control utilizing external sensing such as cameras and LiDAR mounted for AD/ADAS purposes.

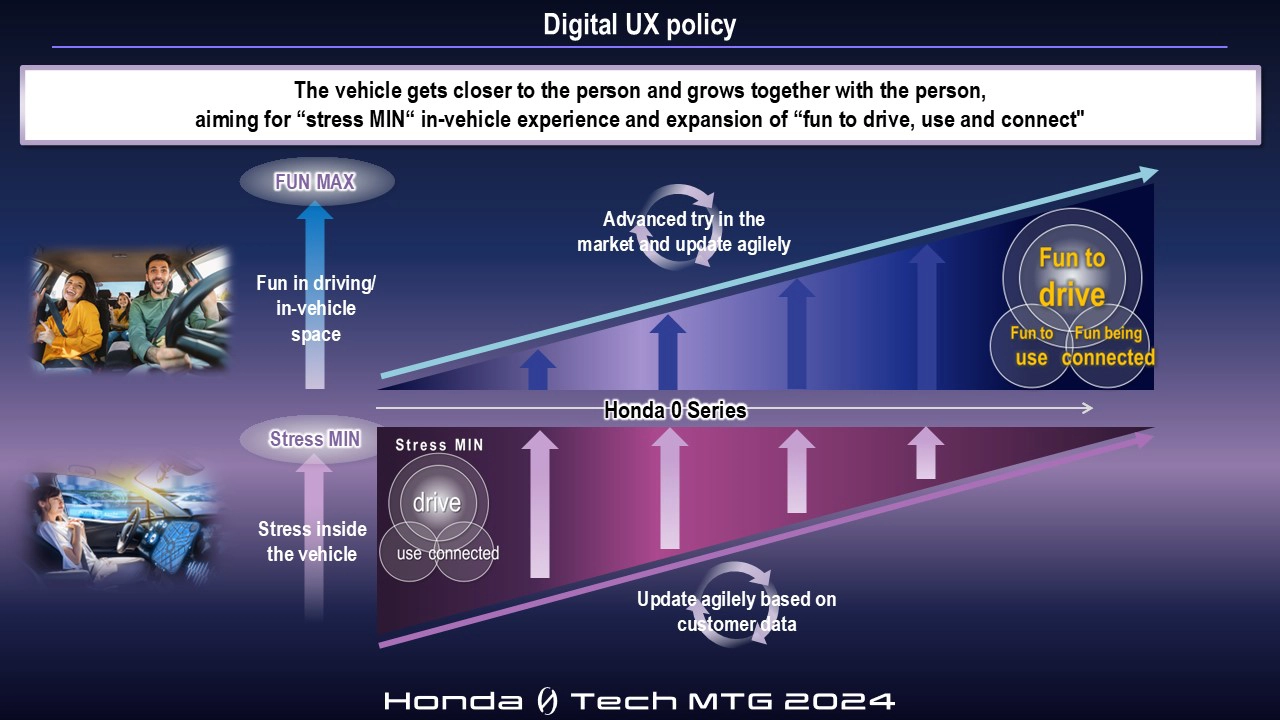

Digital UX

Honda aims to minimize various car-related stresses not only while in the vehicle, but also before and after getting in, and even when away from the car. Additionally, Honda uses software and IT technologies to create enjoyable experiences in driving, using, and connecting. The vehicle gets closer to the person and grows together with the person, providing optimized functions and services for each individual.

To achieve this, we are promoting digital UX development with two approaches. First, we minimize various stresses associated with vehicle use, such as during driving and getting in and out. We also analyze user data and continuously release improved features through OTA software updates. On top of that, we make new value propositions to maximize the enjoyment of the car. We conduct agile development by introducing the latest IT technologies to the market ahead of time and listening to market feedback, maximizing the enjoyment related to driving.

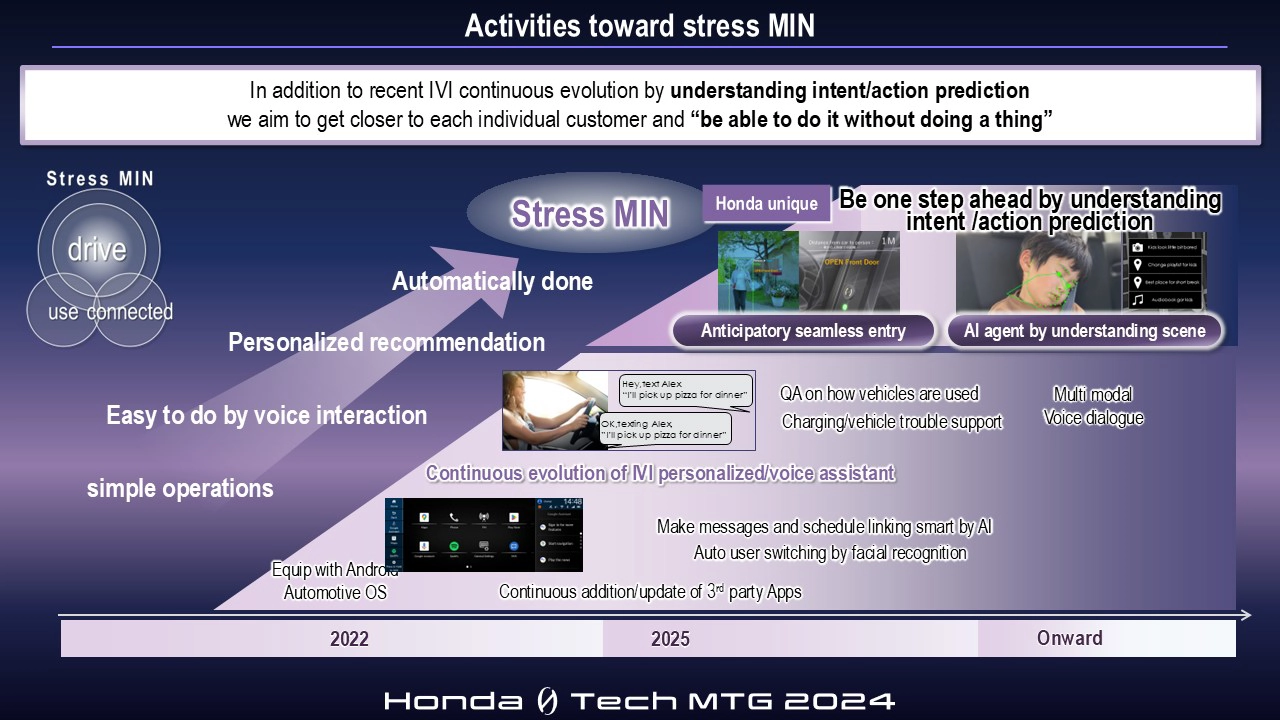

We are developing in stages to minimize stress. We simplify and streamline the operation of the infotainment system, evolve the interface with voice assistants, and enable proactive suggestions through understanding user intentions and predicting behavior. We aim to achieve a UX where people are “able to do it without doing a thing”.

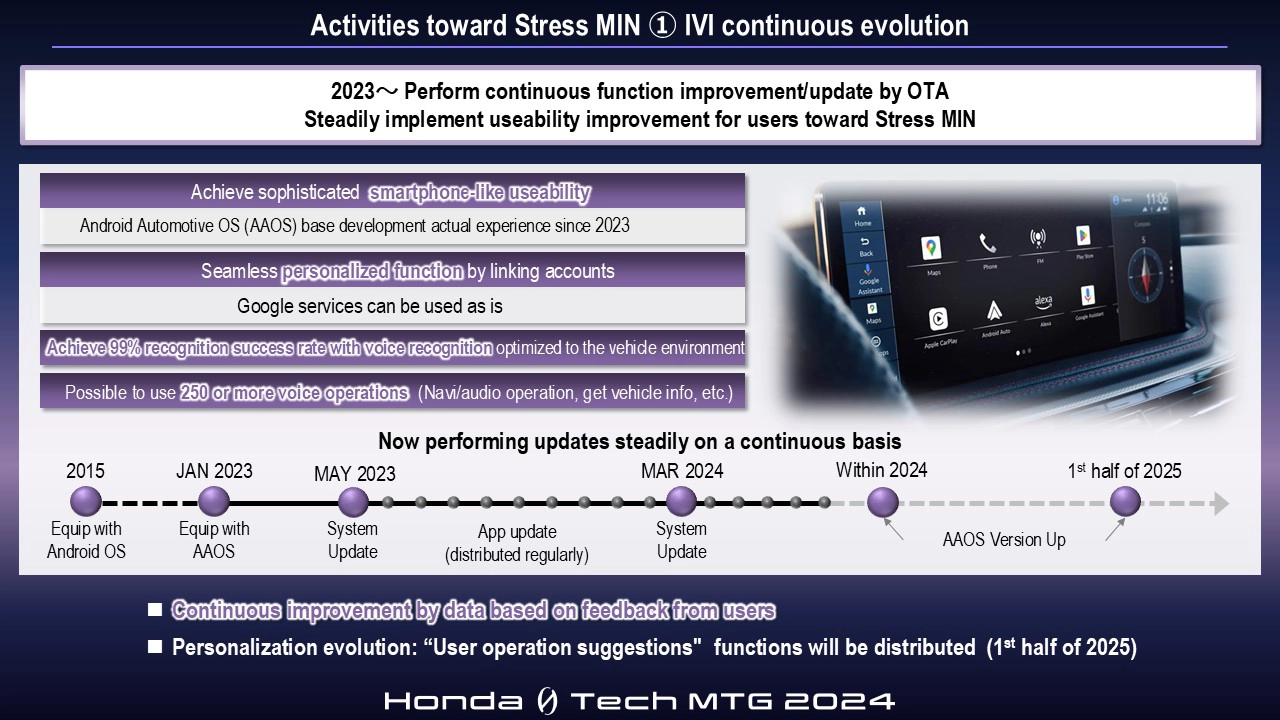

Activities toward Stress MIN (1) IVI continuous evolution

Honda has been deploying Honda CONNECT displays equipped with Android Automotive OS since 2023. It achieves industry-top level performance with high voice recognition accuracy and seamless personalized functions through Google account integration. In addition, we will continue to improve and evolve through continuous OTA updates based on user usage and feedback.

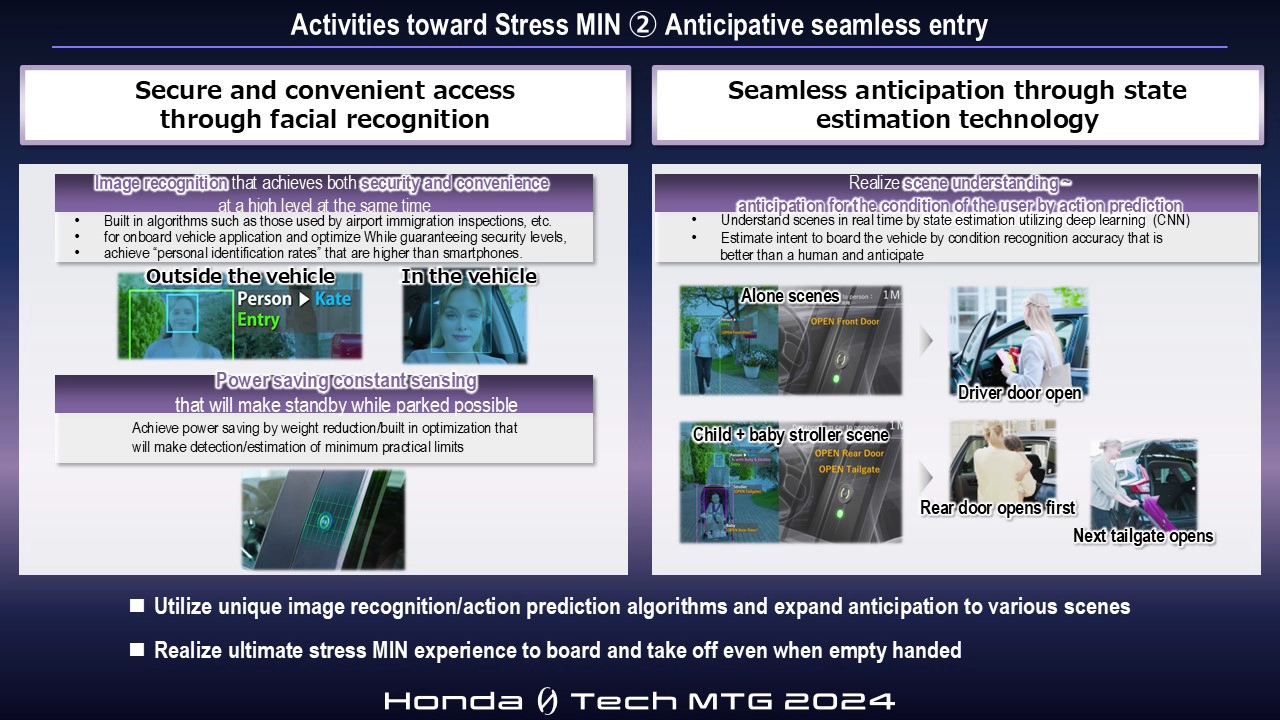

Activities toward Stress MIN (2) Anticipative seamless entry

The Honda 0 Series will be equipped with a predictive entry function using proprietary image authentication and behavior prediction algorithms.

A camera mounted on the center pillar recognizes users approaching the car and performs boarding intention judgment and facial authentication. For pre-registered users, the car unlocks and opens the door just by approaching, even without carrying anything, enabling seamless boarding. By adopting algorithms used in airport immigration inspections and optimizing them for in-vehicle use, we achieve a high-level balance between the security required for cars and convenience with a higher true accept rate than smartphones.

Furthermore, we realize scenario understanding and prediction of user situations through state estimation technology. For example, when a user approaches while pushing a stroller, the rear door opens first, allowing the child to be smoothly placed in the child seat. Predicting that the user will then fold the stroller and put it in the luggage compartment, the tailgate opens. Finally, the driver’s door opens for the user to get in.

Using a proprietary state estimation algorithm with deep learning (CNN*2), we perform real-time scenario comprehension and user boarding intent estimation with higher situational recognition accuracy than humans to execute anticipatory actions.

Through these features, we realize the ultimate stress MIN experience, where users can board and take off without carrying a dedicated key or even a smartphone digital key.

*2 Abbreviation for Convolutional Neural Network.

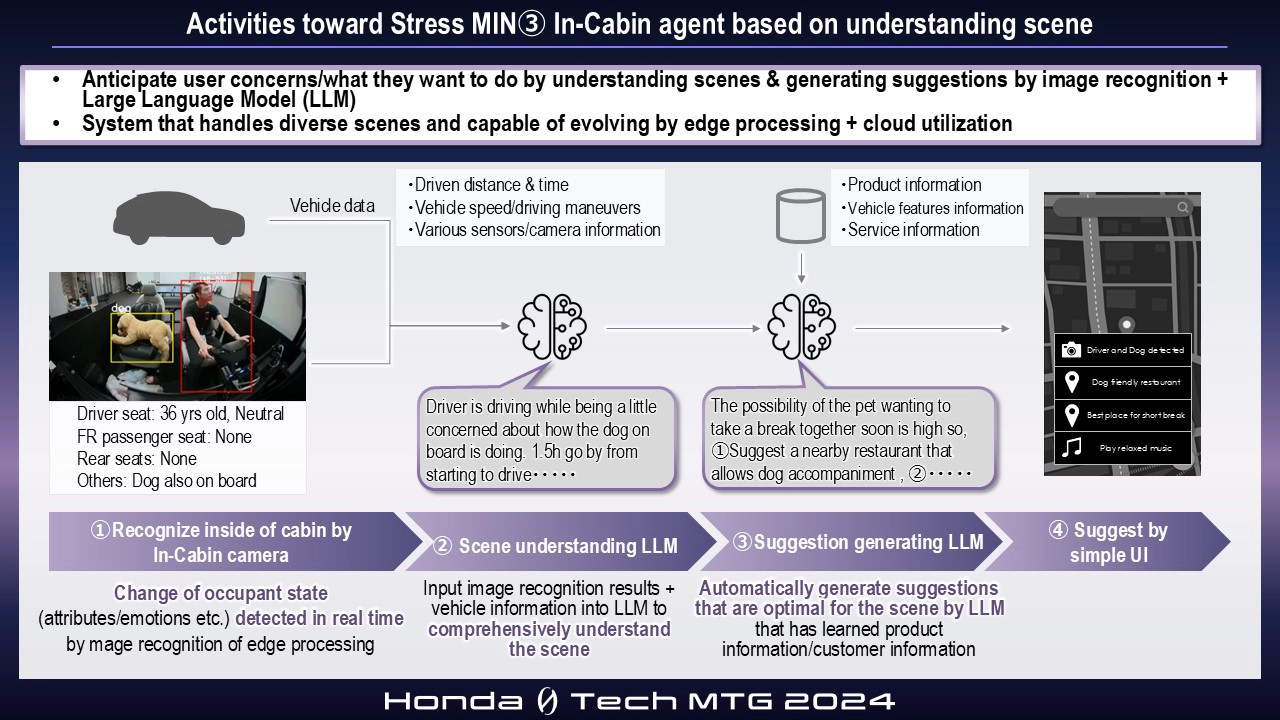

Activities toward Stress MIN (3) In-Cabin agent based on understanding scene

Even after boarding, we use image recognition and generative AI to understand scenarios and make proactive suggestions inside the vehicle. A cabin camera installed near the rearview mirror monitors the interior, detecting real-time changes in the occupants’ conditions, including their facial expressions. Various vehicle sensor and camera information, along with speed, driving operations, time, location, and other data are input into a scenario understanding large language model (LLM*3) to comprehend the current situation in a multimodal manner. Based on this, a proposal generation LLM, trained on vehicle equipment information and customer data, anticipates and suggests user needs. For example, it might automatically generate suggestions such as recommending a break at a pet-friendly facility during a long drive with a pet, or playing music to cheer up a crying child in the back seat.

*3 Abbreviation for Large Language Models.

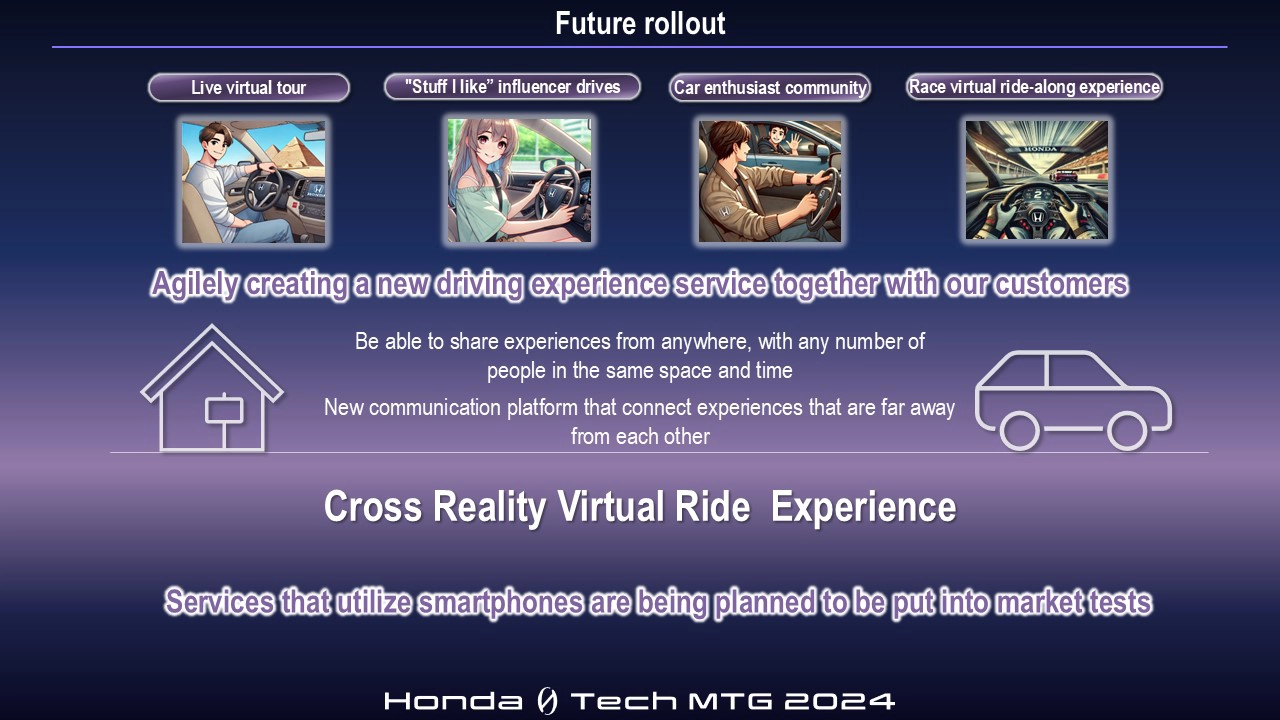

To propose new value that maximizes people’s enjoyment of cars, we are working on initiatives to refine unprecedented apps and services with users by first introducing them for smartphones, allowing for a more multifaceted enjoyment of driving. We are also working on initiatives that utilize Cross Reality (XR) technology, which fuses the real world with the digital virtual world.

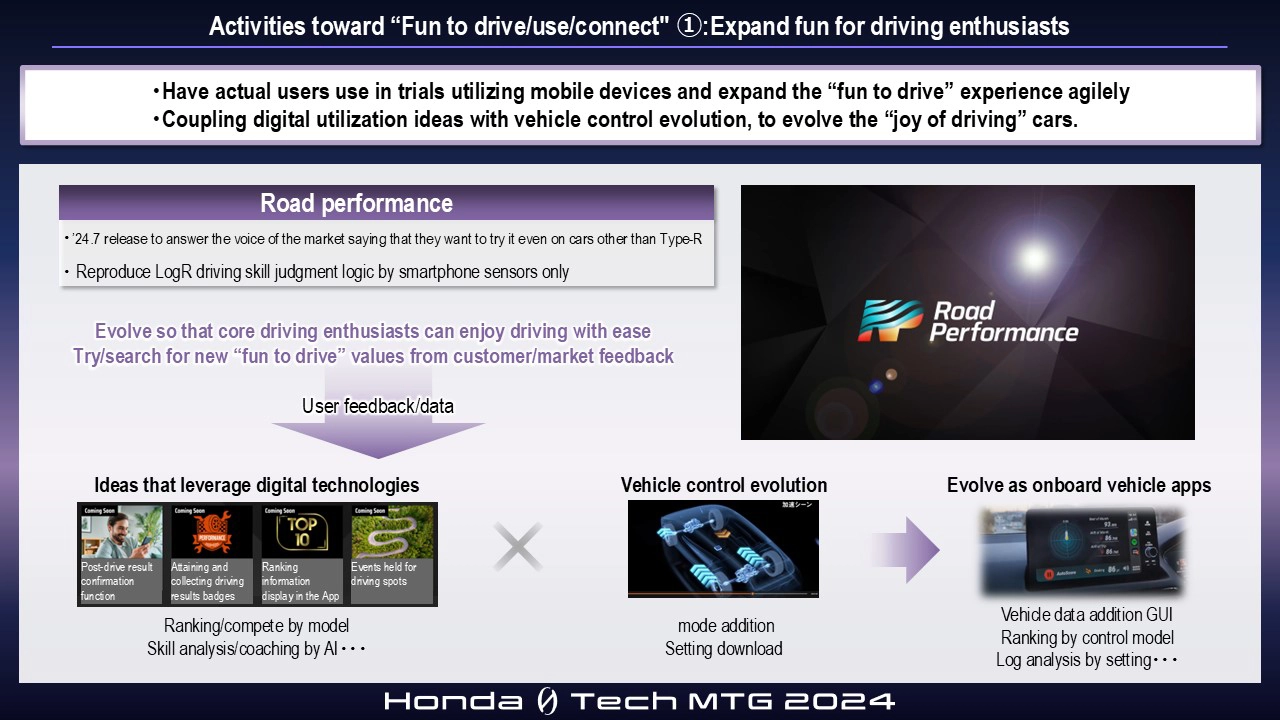

Activities toward “Fun to drive/use/connect” (1):Expand fun for driving enthusiasts

In July 2024, we released*4 “Road Performance,” a smartphone app developed to make the driving scoring feature of Honda LogR 2.0, which was installed in the CIVIC TYPE R, more accessible and enjoyable for all drivers. Using only the sensors built into smartphones, it scores driving skills such as acceleration, deceleration, and cornering.

We are actively developing such apps and services that driving enthusiasts can easily enjoy and creating new value while utilizing user feedback. Furthermore, by integrating these with the car’s functions, we will evolve them in an agile manner as in-vehicle applications.

*4 As of July 2024, the app is being provided as a trial version.

Activities toward “Fun to drive/use/connect” (2): “Cross Reality Virtual Ride Experience” virtual ride-along experience

We have developed a virtual ride-along experience (Cross Reality Virtual Ride Experience) using XR technologies such as VR and AR, which allows users to feel as if they are riding in a car that is actually driving, even when they are away from the vehicle. By applying Web Real-Time Communication (Web-RTC), which enables real-time voice, video, and data communication between browsers and mobile apps, to the in-vehicle environment, and combining it with our proprietary communication capacity reduction logic, we create a sense of presence that makes you feel as if you are actually there.

This XR technology enables us to provide experiences that transcend what is real. It can be used for various driving experiences such as live virtual tours, riding along with your “favorite person,” and car enthusiast communities. As a unique Honda proposal, we will continue to develop new experiential value through Cross Reality, with the possibility of evolving into services where you can experience professional drivers’ driving in actual race ride-alongs.