Automobile Business Strategy

Vision and Challenges for Zero Environmental Impact in the Automobile Business

Vision and Challenges for Zero Environmental Impact in the Automobile Business

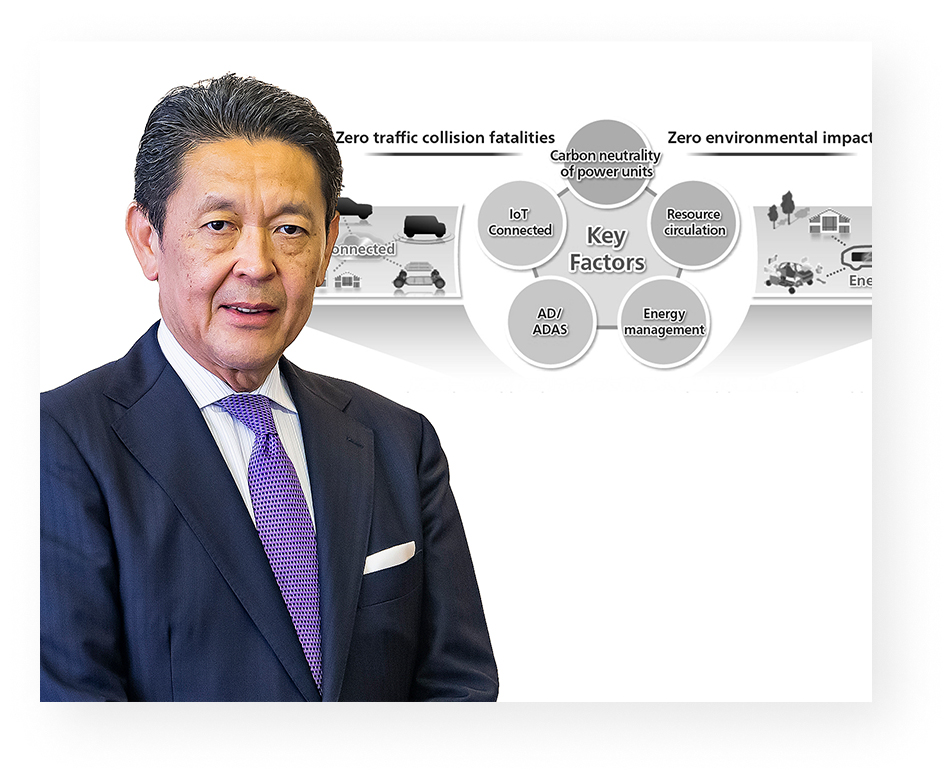

Honda is aiming to achieve zero environmental impact and has set a goal to have 100% of its global sales consist of Battery Electric Vehicles (EVs) and Fuel Cell Electric Vehicles (FCEVs) by 2040. While there is a perception that EV adoption has temporarily stalled in North America and Europe, Honda considers that, in the medium to long term, small mobility vehicles, including automobiles, will steadily shift to EVs. As a front-runner in electrification, we are committed to advancing our efforts towards electrification without any slack.

On the other hand, emerging EV manufacturers, primarily from China, are expanding globally, intensifying competition. To achieve its electrification goals amidst this turbulent environment, Honda considers it crucial not just to promote electric vehicles but also to address the entire lifecycle. This includes focusing on building a comprehensive value chain centered around core components like batteries, introducing EV models with Honda’s distinctive appeal, advancing production technologies, and expanding charging infrastructure.

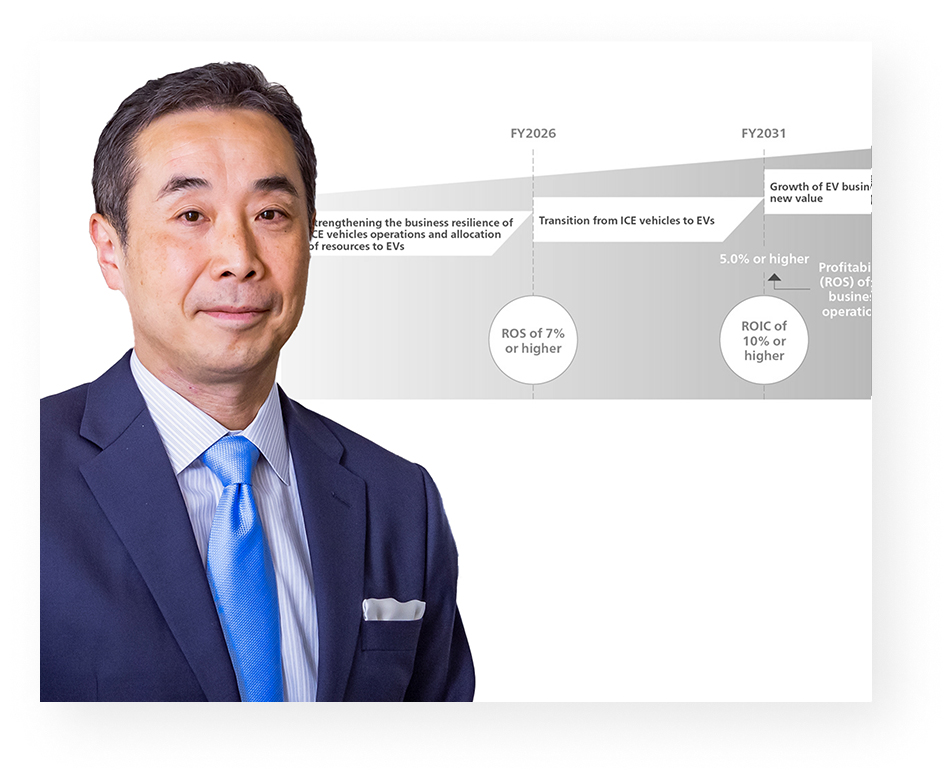

For the EV shift, Honda plans rapid product launches by 2026 and aims to establish a strong EV brand and business structure by 2030. Strengthening its internal combustion engine (ICE) business is essential to fund future electrification investments. Honda is making thorough preparations with a midium- to long-term perspective, anticipating the widespread adoption of EVs after the late 2020s.

Revenue Highlights (Sales/Operating profit/Units)

A Global Strategy for the Future EV Market

Given the current significant regional differences in the progress of electrification, we will actively introduce EVs tailored to regional characteristics and steadily build the foundation for future EV products and production systems by leveraging insights gained through alliances. Looking ahead to the global EV proliferation period starting in the late 2020s, we plan to launch a new global EV series, the “Honda 0 Series,” starting in 2026 and roll it out worldwide. By the Fiscal Year Ending March 31, 2031, we aim to achieve a global EV/FCEV sales ratio of 30% or higher. To realize these goals, we will focus on: 1) introducing attractive EVs unique to Honda, 2) building a comprehensive EV value chain centered around batteries, and 3) advancing production technology and factory evolution.

Direction of the Electrification of Honda Automobile Business

The Vision for Honda 0 Series

The Honda 0 Series is a completely new EV series created from scratch based on the new EV development approach of “Thin, Light, and Wise.” This series aims to further enhance the joys of “driving pleasure” and “joy and freedom of mobility,“ principles guided by Honda’s “M/M principle,” which has been fundamental to our approach to vehicle manufacturing. Additionally, the Honda 0 Series will continuously update the customer experience by adopting an optimal architecture designed with the evolution of software in mind.

Development Approach: “Thin, Light, and Wise.”

Thin: M/M Space for the EV Era

By integrating a newly adopted medium-to-large EV-specific platform with an evolved power unit, this EV model achieves an unprecedentedly low overall height and a short overhang design, setting it apart from other EVs. The motor room and floor utilize a newly developed compact “e-Axle” and a top-class ultra-thin battery pack to achieve extreme thinness. At the same time, through optimized component layout, reduced component count, and Honda’s unique collision control technology, it achieves over a 10% reduction in overall height compared to previous models while maximizing interior space.

- *e-Axle: A system which converses energy from power to motion, consisting of a motor, inverter, and gearbox.

Light: Agile Performance

In addition to weight reduction of the body structure, Honda will achieve approximately 100 kg of weight reduction compared to conventional models by adopting a new, lightweight, and slim power unit that leverages the technology developed through its F1 and hybrid system development. Furthermore, by positioning heavy components such as the battery and power unit low and centrally within the vehicle, Honda aims to lower the center of gravity, stabilize vehicle behavior, and achieve agile performance.

Wise: New Mobility Experience

By integrating our proprietary vehicle OS with advanced connected technologies, we provide a digital UX optimized for each individual customer. We develop the foundational E&E architecture, the vehicle OS layer above it, and all the applications on top of it independently.

The functions based on Honda’s unique vehicle OS work together to deliver new and exciting experiences that were previously impossible. The vehicle will understand the driver’s intentions and the environment’s condition, autonomously anticipating and suggesting actions, thus providing a uniquely Honda experience. Additionally, by complementing the driver’s abilities, we eliminate driving anxiety and make operation easier by recognizing environmental factors and voice commands.

Honda, based on its development approach called Wise, aims to enhance vehicle autonomy and intelligence to protect and support occupants while providing safety and peace of mind.

By tailoring to each customer’s preferences and needs with advanced intelligence, we aim to provide a new and exhilarating experience.

To achieve this, we will consolidate the roles traditionally managed by numerous Electronic Control Units (ECUs) into a core ECU, adopting a central architecture where the entire vehicle operates as a single brain. This core ECU will incorporate System on Chip (SoC) semiconductors equipped with essential AI for automation and intelligence evolution, while also being customized by Honda to optimize power consumption. This approach will enable mobility that perceives and judges like a human.

Value Proposition of the Honda 0 Series

The Honda 0 Series, developed under the “Thin, Light, and Wise.” approach, offers five core values:

1. Safety and Confidence through AD/ADAS

In 2021, we launched the Honda SENSING Elite-equipped LEGEND (for the Japanese market), which features advanced technology compliant with Level 3 automated driving: conditional automated driving in limited areas, marking the practical implementation of Level 3 automated driving. To deliver this technology to customers worldwide, the Honda 0 Series will be equipped with the latest ADAS technology. Furthermore, by the late 2020s, it is expected to feature even more advanced next-generation autonomous driving technology.

This autonomous driving technology is based on Honda’s safety philosophy of “human-centered,” further advancing intelligent technologies such as AI, sensing, recognition, judgment, and driver monitoring. This will offer a seamless mobility experience from the moment you get in the car to the moment you get out, providing a safe and secure autonomous driving space with AD/ADAS that closely aligns with human sensibilities.

We will also expand the areas where the hands-off feature can be used. Currently, it is available only on highways, but we are developing it to be safely used on regular roads as well. These features will be continuously updated via Over-The-Air (OTA) updates, which will enhance and evolve them into even more appealing products with Honda’s unique touch.

Realizing AD/ADAS that is closely aligned with human sensibilities from the moment of getting on the vehicle until getting out

2. New Spatial Value Brought by IoT and Connected Technology

Honda provides value through connected technology with the aim of making driving enjoyable, usage fun, and connectivity engaging. By leveraging AI and big data, the car learns the user’s preferences and driving habits, offering personalized suggestions. As the car and user become more familiar over time, the vehicle evolves to support personal growth, satisfy curiosity, and transform everyday life with “connected fun.” The goal is to achieve a seamless user experience with zero stress, where users can immediately do what they want through an intuitive UX and UI.

3. High Energy Efficiency

Honda has provided electric vehicles (include HEV) to over 5 million customers worldwide. Building on this extensive experience and technology, the new Honda 0 Series will achieve even higher energy efficiency. We will use high-efficiency e-Axles and high-density battery packs. Additionally, improvements in aerodynamics will reduce battery volume while achieving a sufficient range of over 300 miles for each model.

To address concerns about charging times and battery degradation for EVs, the Honda 0 Series models, to be released in the late 2020s, will aim to reduce rapid charging times from 15% to 80% to around 15 minutes. At the same time, we will implement battery system control technologies to minimize degradation, targeting a degradation rate of 10% or less after 10 years of normal use.

4. The Joy of Driving in Perfect Harmony with the Vehicle

“The Joy of Driving” is Honda’s timeless philosophy that remains unchanged through the ages. By leveraging Honda’s unique electric and dynamics technologies within a EV-specific architecture defined as “Thin, Light, and Wise.” we aim to deliver a next-generation driving experience that is both exhilarating and integrative, uniting the driver and the car physically and emotionally.

The flagship concept model “SALOON” of the Honda 0 Series embodies “Thin, Light, and Wise.” In addition to adopting steer-by-wire technology, it further advances Honda’s proprietary motion management systems, such as posture control developed through its robotics technology, to achieve precise control for the driver across various driving scenarios. Additionally, the Honda 0 Series’ low overall height style incorporates aerodynamics technology developed in motorsports, seamlessly blending dynamics performance, aerodynamic efficiency, and design at a high level.

5. Artistic Design That Evokes Resonance

The design of the Honda 0 Series embodies “The Art of Resonance,” a concept that resonates with individual sensibilities and fosters creativity. The bold and pure shape of the vehicle, which stands out distinctively at first glance, awaken new perspectives in the viewer. With exhilarating visibility and intuitive controls, the Honda 0 Series creates a driving experience that resonates with the driver’s senses, elevating the car from merely a mode of transportation to a companion that aligns with individual sensibilities.

Establishment of a Comprehensive Value Chain

Since the early 2020s, Honda has been sourcing batteries from the most suitable partners in regions such as North America, China, and Japan, ensuring reliable procurement while minimizing costs.

By the mid-2020s, we will begin battery production through joint ventures with partner companies. In the U.S., a battery plant in joint venture with LG Energy Solution is scheduled to start operations in 2025, producing 40 GWh of batteries annually. This will help establish the largest value chain in North America and achieve competitive battery costs. Additionally, we will enhance product’s appeal by equipping the Honda 0 Series with lightweight, compact battery packs produced using high-density packaging technology.

Through the establishment of the new company ALTNA Co. Ltd * and other initiatives, we will expand into lifecycle business beyond vehicle production, covering charging services, energy services, and reuse/recycling to establish a stable business foundation.

In the late 2020s, we aim to further expand our scope by building a comprehensive, vertically integrated EV value chain, encompassing raw material procurement centered around batteries to vehicle production, battery reuse, and recycling. In Canada, we will commence in-house production of batteries co-developed with GS Yuasa Corporation. For major components, we will produce cathode materials for automotive batteries in a joint venture with POSCO Future M Co., Ltd., and separators for automotive batteries in a joint venture with Asahi Kasei Corporation, advancing our in-house production capabilities.

Regarding solid-state batteries, Honda plans to establish a pilot production line in the fall of 2024, aiming for integration into models released in late 2020s. Honda’s goal is to optimize battery costs and secure stable procurement, ensuring competitive advantage across the entire value chain, from upstream to downstream, and achieving more than a 20% reduction compared to current levels in battery costs in North America by 2030.

- *ALTNA Co. Ltd: A new company established by Honda and Mitsubishi Corporation in July 2024. It focuses on battery leasing and smart charging businesses, among other activities.

Establishment of a Comprehensive EV Value Chain with a Central Focus on Batteries

Optimal Production Technology Deployment According to EV Adoption Speed

During the transition period from ICE to EV, we will make full use of existing production facilities while proactively introducing and evolving advanced technologies required for EV production, such as mega-casting.

Advancement in Production Technology and Facilities

Mid-2020s

In the production of thin battery packs, which is crucial for EV manufacturing, we will accelerate the evolution of some advanced technologies by integrating them into existing equipment. The technologies developed and refined here will be later applied to EV-specific factories to build even more efficient production systems.

At the new battery case production line being set up at the Anna plant in Ohio, we will introduce a 6,000 metric ton class high-pressure die-casting machine known as a mega-cast. This will significantly reduce the number of components in battery cases and related parts from over 60 to just five. Additionally, by combining this with Friction Stir Welding (FSW) technology, we aim to balance investment reduction with increased production efficiency. We are also testing the production feasibility of Japan’s first 6,000 metric ton class mega-cast machine at our Tochigi-based production technology R&D facility. This technology will continue to evolve and expand its application to large aluminum cast body structural components in the future.

In the battery pack assembly line, Honda will advance its unique “Flex Cell Production System,” which combines modular part configurations and cell production methods according to vehicle characteristics. This system will allow for flexible responses to changes in production models and volume fluctuations.

Moreover, we will utilize Digital Twin technology to replicate real production line conditions in cyber space in real-time, optimizing parts supply, production volume, and speed. This will enable timely product supply in response to market demands.

Late 2020s

These initiatives are planned to be expanded to the production of whole vehicle at Canada’s dedicated EV factories by the late 2020s, reaching their final form. This will achieve world-class production efficiency, including significant improvements in operational rates and reductions in fixed costs, aiming for a roughly 35% reduction in production costs compared to conventional mixed production lines.

Introduction of Optimal Lineups for Each Series

Honda 0 Series

Starting with the launch of the Honda 0 Series in North America in 2026, the Honda 0 Series lineup will be globally expanded. By 2030, it is planned to introduce seven models ranging from small to mid-sized vehicles.

“e:N” “Ye” Series

In China, where EV adoption is advancing, we plan to introduce 10 EV models globally from 2022 to 2027, and to transition all automobiles to EVs by 2035. Following the current“e:N” series in China, a new EV series named “Ye” will be launched. This will accelerate the expansion of the EV lineup, challenging and evolving in the rapidly changing Chinese market. Specifically, the “Ye P7” and “Ye S7” are scheduled for release at the end of 2024 or later. Additionally, a mass-production model based on the “Ye GT CONCEPT” is planned for release within 2025 as the second phase of the Ye series.

Small EV Series

Starting with the release of the small commercial EV ”N-VAN e:” in Japan, we will sequentially introduce small EVs in regions with high demand. By 2025, a small passenger EV model will be introduced, followed by compact EVs designed for driving enjoyment in 2026.

Strengthening Our Ability to Adapt Flexibly to Environmental Changes

To achieve a high level of both fuel efficiency and a refined, enjoyable driving experience, Honda will advance its unique two-motor hybrid system “e:HEV” and update its platform. The e:HEV system will enable weight reduction and high efficiency, significantly lowering implementation costs. Additionally, we will advance plans for improving efficiency and standardizing the platform, aiming to achieve a substantial weight reduction of 100 kg.

To provide “safety” and “driving enjoyment,” we will adapt EV development technologies for use in hybrids and employ electric four-wheel drive systems powered by EV motors. This approach allows for improved maximum driving force and more responsive, precise control of driving force distribution compared to traditional mechanical four-wheel drives. Additionally, by coordinating with the motion management system, we can enhance driving performance while stabilizing vehicle behavior.

Honda aims to strengthen its ICE (Internal Combustion Engine) business by offering advanced hybrid models to a global customer. We will also ensure stable revenue by flexibly responding to changes in demand and the environment through mixed production of EVs. The capital generated will be invested in new businesses, including EV businesses as well as other areas, with the goal of further growth.

Advancement of Hybrid-Electric Models: Starting Introduction in 2026