Design Innovation

Innovation 3

New Design Integrally Molded Carbon Composite Fuselage

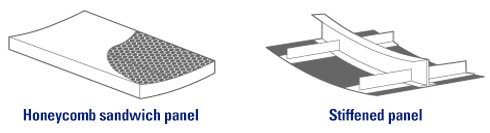

HondaJet employs lightweight yet strong carbon composites for the fuselage structure. For the fuselage fabrication, Honda developed a unique manufacturing technology to combine and integrally co-cure two types of panel structures – honeycomb sandwich panel and stiffened panel. The adoption of carbon composites and the integral co-curing technology resulted in reduced weight and increased stiffness as well as the beauty of HondaJet’s exterior styling.

Integrally molded composite fuselage

2 types of panel combined in layout that gives optimum performance

Benefit: Lightweight and high-stiffness airframe enables a high-altitude, high-speed and high-stability flight with high fuel efficiency

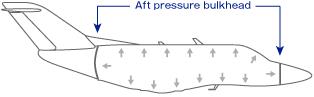

As the atmosphere becomes thinner and air pressure drops at high altitudes, a proper cabin pressure for the comfort of occupants must be maintained by sealing the plane's interior with an airtight wall and circulating air via an air conditioning system. In this situation, cabin air tries to expand outward where air pressure is lower to reduce the pressure differential. The aircraft’s maximum operating altitude is determined primarily by how far the fuselage can withstand this expansion of the air. HondaJet can fly high as it features a strong fuselage made of integrally co-cured carbon composites.

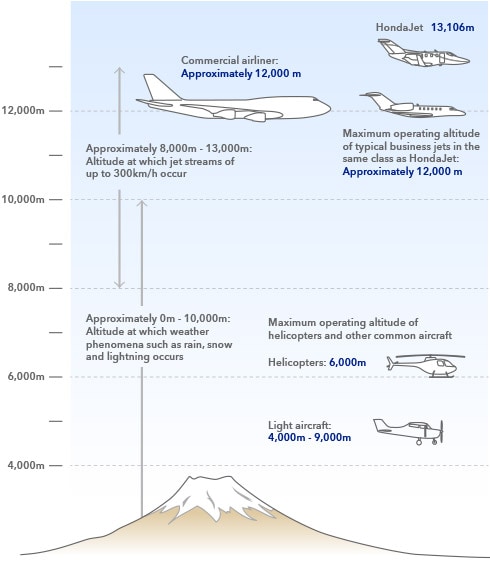

As the altitude increases, the atmosphere becomes thinner and aerodynamic drag declines. Therefore, aircraft can fly faster at high altitude than low altitude. Moreover, at high altitude, aircraft can fly more smoothly as it is less affected by bad weather and/or turbulence caused by jet streams. Also, the reduction of airframe weight contributes to the improvement of fuel efficiency.

Image of maximum operating altitudes of different types of aircraft