- Top

- Japan

- North America

- South America

- Europe

- Asia

- China

Honda Activities to Support Efforts to Prevent Novel COVID-19 Infection in Japan:

- Specially customized vehicles designed to transport infected people

- Production and donation of face shields

On April 13, as a part of its activities to support efforts aimed at preventing COVID-19 infection, Honda began offering customized vehicles designed for safe transportation of infected people. The first deliveries were made in Tokyo to Minato Ward and Shibuya Ward Offices. Honda is planning to offer these customized vehicles to more communities in Japan while prioritizing areas with the greatest number of infections, such as the Tokyo metropolitan area.

In addition, before the end of May 2020, Honda will begin production of protective face shields which are in high demand among medical providers. Moreover, Honda is continuing to explore the possibility of supporting the production of ventilators.

Details about Honda support activities

- Donation of customized vehicles designed to transport people infected with COVID-19:

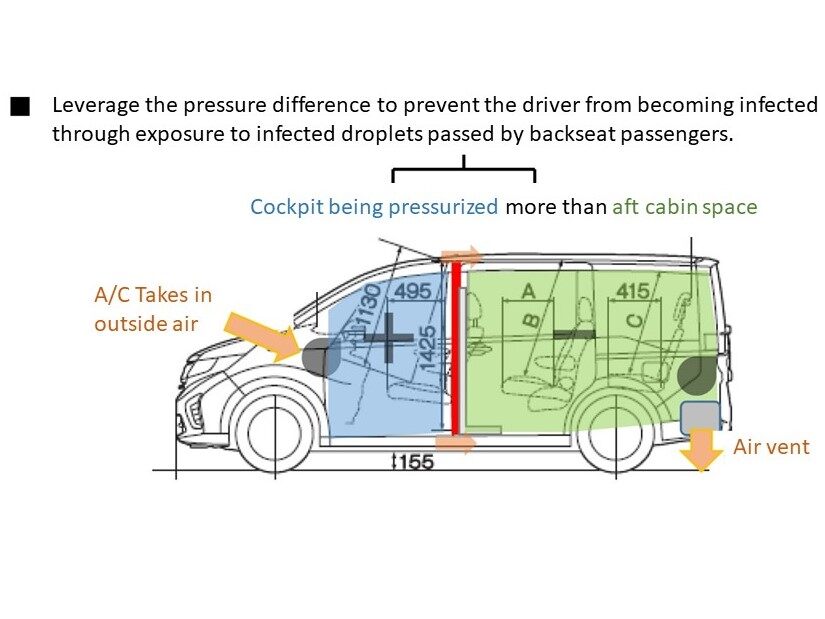

•Honda will offer vehicles which will support transportation of infected people with no/mild symptoms. These vehicles will be lent to local governments/municipalities in Japan. On April 13, 2020, Honda delivered custom vehicles to Minato Ward and Shibuya Ward of Tokyo. Honda is planning to deliver these vehicles to more communities while prioritizing areas with the greatest number of infections, such as the Tokyo metropolitan area. Honda customizes minivan models such as Odyssey* and Step WGN by installing a partition between the front and rear seating areas which will reduce the risk of infection during transportation. The front seating area is pressurized more than the rear seating area to prevent air flow from the rear cabin into the driver’s area to inhibit droplet infection by leveraging the pressure difference.

•Production of the customized vehicles has started at Honda’s Saitama Factory (Sayama Plant) and is scheduled to be expanded to other Honda operations in Japan.

*Note: Odyssey in Japanese market is a different model from Odyssey in North America.

- Face Shield Production

Honda is planning to begin production of protective face shields which are in high demand among medical providers, before the end of May 2020, at Honda operations in Japan such as the Monozukuri Centers in Tochigi, and offer them free of charge to medical institutions.

Messages from Associates

Press Module, Sayama Automobile Plant, Saitama Factory

Our plant manager mentioned wanting to make customized vehicles designed to transport people infected with coronavirus—this was something I was keen on doing as well, so I decided to participate in the project.

The project entailed doing things I had never done before, and I found it difficult until I got used to things. However, I was motivated to deliver as many vehicles as possible, as quickly as possible, to the people who needed them.

With the Odyssey transport vehicle, we expanded the field of view by adjusting the size and position of the windows. Our goal was to make the vehicle as easy to drive as possible, and to provide passengers (patients) in the back of the vehicle with peace of mind; to this end, we created numerous prototypes before deciding on the appropriate size and position of the windows.

Since we wanted the passengers seated in the rear of the vehicle to feel as calm as possible, we chose white for the color of the partition. Each partition is hand-painted by individual experts. We used the Honda logo to symbolize the passion and action of Honda associates worldwide to do everything in their power to help.

After the transport vehicle had been perfected, the units were delivered to the people who needed them. For someone involved in monozukuri (“manufacturing”), there is nothing better than seeing something you have made contribute to other people’s happiness. Going forward, we intend to continue supporting the people working on the front line of the battle against COVID-19 through our monozukuri.

Let us each think about what we can do, turn these thoughts into action, and overcome the current difficult situation together.

Die/Mold Production Division, Production Engineering Supervisory Unit

In order to allow people on the medical frontlines to focus on healthcare safely and with peace of mind as much as possible, a project was undertaken with speed and quantity in mind to deliver products to the frontlines in the fastest time possible.

Using our knowledge in developing molds and dies for large products such as bumpers, we are producing molds that allow several products to be made in one go.

As we hope to offer products that anyone can easily use, do not get in the way, and are friendly to people, the project members—which include industrial physicians—made modifications to the shape by trial and error. Corners are also chamfered after forming so that products can be used safely.

We undertook this project with the belief that monozukuri firmly based on the spirit of genba and genbutsu is what we can do to show our support for society. As these products are different from those that we usually produce, there are many things which we had to consider from scratch, including shapes, molds, production methods, and distribution. While we struggled to advance this project within a short time, we felt joy and wonder at being able to achieve production with a sense of speed by becoming one team with staff from the relevant departments.

Although they are simple products, these are face shields filled with the wishes of Honda. Let us give shape to our wishes and defeat this difficult time with the strength of each and every person so that more people can regain their daily lives safely and with peace of mind.