I see!

There's a lot of information packed into tyre size designations.

It's good to understand it well!

Huh? Isn't size simply a size, like S or L, like clothes?

Of course it also represents size, but it's not that simple.

Let me explain it !

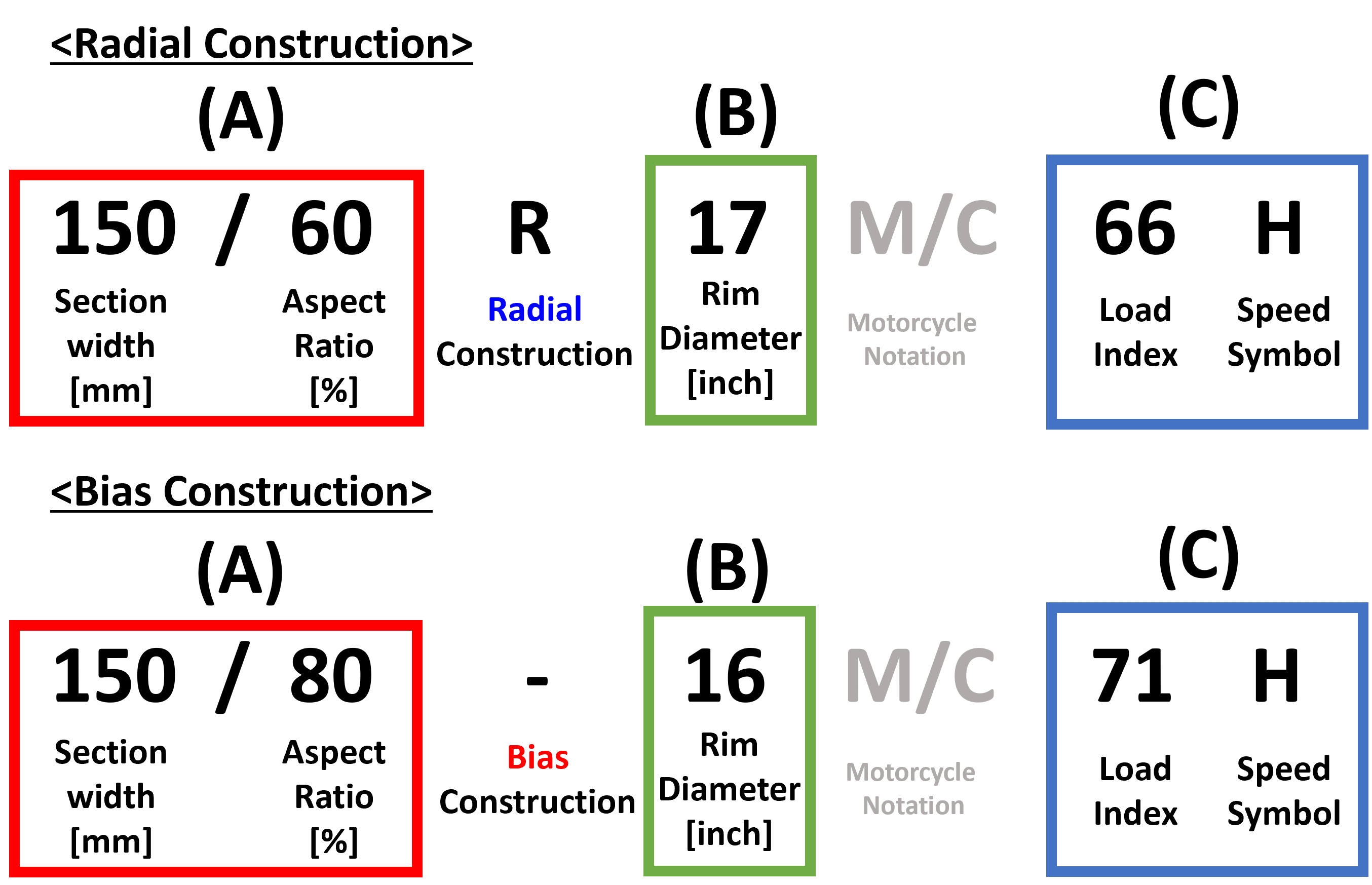

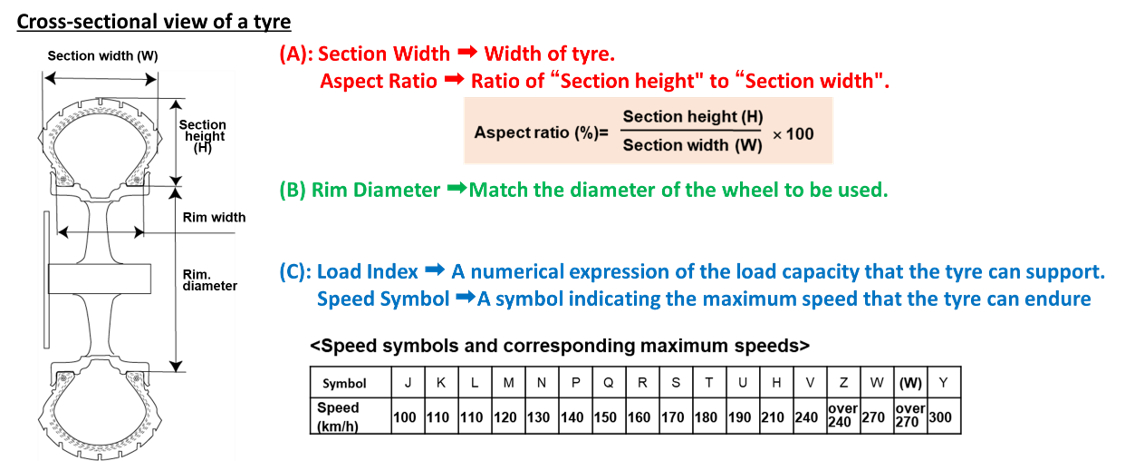

Mainly in tyre size designations,

“Section Width” “Aspect Ratio” “Construction” “Rim Diameter” “Load Index" "Speed Symbol"!

There are so many, I don't really understand.

Let's understand it then by looking at some examples of actual size designations.

In this article, I will explain how to read the most common "Metric" labeling!

So it represents not only size, but also payload and speed limits !

But what is a “Radial Construction“ and “Bias Construction” ?

Well noticed !

In fact, tyres contain cords called “Carcass” that form the backbone of the tyre !

Depending on the structure of the carcass cords, tyres are classified as “Radial” or “Bias” tyres !

It looks kind of difficult.

Do the different constructions mean they have different characteristics ?

Of course.

Let me explain with a diagram to make it easier to imagine !

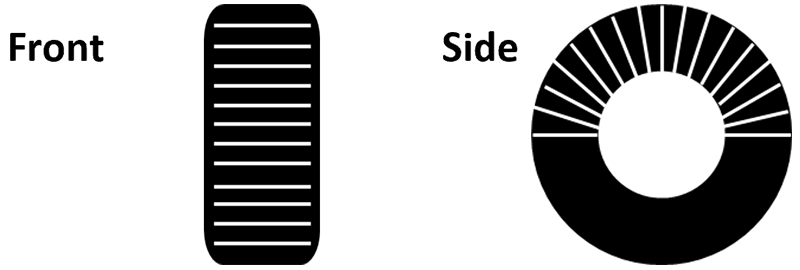

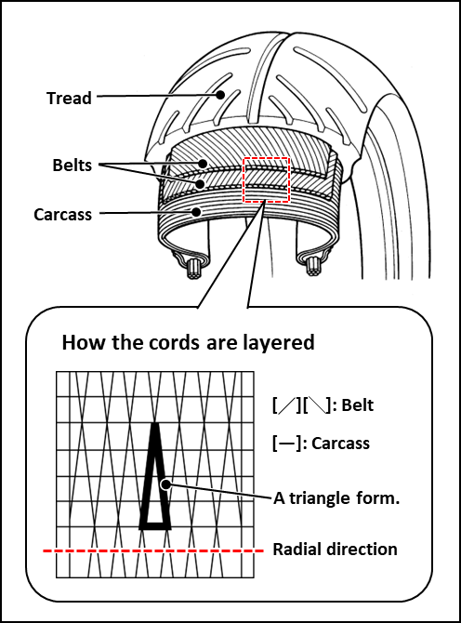

<Radial Construction>

Let‘s start with the “Radial Construction” !

As the name suggests, this construction has carcass cords arranged in a radial pattern when viewed from the side !

<Image of carcass cord structure>

Furthermore, the reinforcement cords, called the belt, and the carcass cords overlap each other to form countless triangles.

This triangle and the belt tightening ensure that the tyres are less deformed, even in situations where strong centrifugal forces are applied, such as at high speeds !

Because of its high durability at high speeds, this construction is often used on road sports type motorcycles.

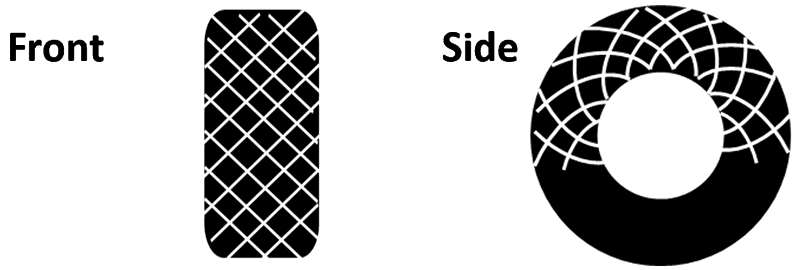

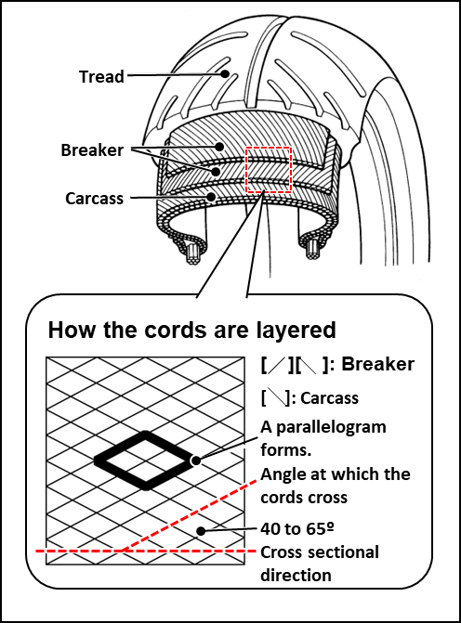

<Bias Construction>

Let us now look at the “Bias Construction” !

Bias construction have the carcass cords and reinforced codes layered so that they cross at an angle between 40 to 65 degrees in relation to the cross sectional direction.

<Image of carcass cord structure>

The layering of these cords forms countless parallelograms.

This parallelogram form is flexible and absorbs shocks from the road surface !

Therefore, they are generally used for motorcycles, which require a greater comfort.(such as motor scooters)

I see !

The backbone construction is different, so there are differences in durability and ride comfort !

That's right !

Let's all check the tyre size designations on your motorcycles and check what characteristics they have !

If we understand the tyre construction and characteristics, we will be able to enjoy riding more !

At my last periodic maintenance, it was recommended that I should replace my tyres soon because the grooves are worn out.

I've checked the size designation stamped on the side of the tyre to consider a new tyres, but I'm not sure what this actually means.