A Shadow Cast by the Popularization of Automobiles

Japan was just entering the age of motorization in the mid-1960s, when it began experiencing air pollution caused by vehicle emissions. In July 1966, the Japanese Ministry of Transport (later the Ministry of Land, Infrastructure, Transport and Tourism) issued new regulations for harmful automobile exhaust emissions, requiring that carbon monoxide (CO) concentration be reduced to 3% or less for all new models (gasoline-powered vehicles excluding k-cars) produced after September of that year. In August 1967, the Japan Basic Law for Environmental Pollution Control was duly enacted, and, in 1968, the Air Pollution Control Act went into effect. In 1970, it was identified that the blood lead levels of residents living near the busy Ushigome-Yanagicho intersection in Shinjuku Ward of Tokyo were unusually high. Also in 1970, the first case of health damages caused by photochemical smog occurred in Japan, in Suginami Ward of Tokyo. These issues brought national attention to air pollution from automobiles.

Meanwhile in the United States, the Federal Government enacted the Clean Air Act in 1963, to which the Motor Vehicle Pollution Control Act was added in 1965. Moreover, in 1966, the California State Government established its Air Resources Board, which began restricting emissions even further. Then, as a means of promoting public awareness and disseminating information about its activities, the federal government published its official Air Pollution Control Regulations in the March 20, 1966 issue of the Federal Register. The U.S. was determined to promote environmental policies against pollution. In 1970, the responsibility for environmental administration was transferred to the newly established Environmental Protection Agency (EPA) from the Department of Health, Education, and Welfare (HEW).

The same year, U.S. Senator Edmund S. Muskie submitted his clean-air bill to Congress - known as the Muskie Bill - which proposed to institute major revisions to the Clean Air Act of 1963. The regulations proposed by this bill were more stringent than ever before. It stipulated that, starting with the 1975 model year, or in just five years, automobiles should emit one-tenth of CO (carbon monoxide) and HC (hydrocarbon) compared to current models, and that 1976 and later model year vehicles also should emit one-tenth of NOx (nitrogen oxide). It was going to be a challenge. In fact, the U.S. Big Three, namely GM, Ford and Chrysler, and other automakers around the world argued passionately that such stringent regulations would be impossible to achieve. Undaunted by the industry’s complaints, the U.S. Clean Air Act of 1970 (known as the Muskie Act, especially in Japan) went into effect on December 31, 1970.

If Cars Are Polluting the Air, It’s the Engineers Job

to Make Them Cleaner.

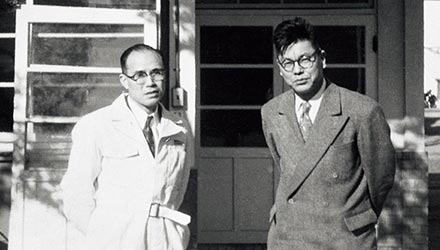

At Honda R&D, in the summer of 1965, Shizuo Yagi, then the leader of the division responsible for engine performance, put together a 10-member air pollution research group to begin gathering information on the latest trends in air pollution regulations in the U.S., with a view toward exporting Honda automobiles in the future. This was the low-key start of air pollution research at Honda.

In September of the same year, Kunpei Ito from the Technical Research Office held a debriefing session to share the results of his studies on cases of air pollution caused by automobile emissions, and air-pollution regulations, as well as how other automakers were dealing with the situation in both Japan and the U.S., which enlightened research and engineering design groups at Honda. Motivated by Ito’s briefing session, Tasuku Date (then Director of Honda R&D Co., Ltd.), Kazuo Nakagawa (then Chief Engineer of the Engineering Design Block), Yagi and some others came to agreement that Honda should pursue full-fledged research into emissions control. From that point on, they used every available opportunity to advocate for the need to establish an air pollution research laboratory.

However, at the time, Honda had just entered the automobile industry, so the business at hand was simply to develop its next car. Moreover, in January 1964, the company had brashly declared its intention to compete in Formula One (F1)TM racing. Because of such commitments, Honda did not have the luxury of allocating R&D members solely to air pollution research, something that hindered immediate results.

In June 1966, the Japan Automobile Manufacturers Association (JAMA) organized a survey team, which toured around the U.S. to observe and study the current situation of pollution and other issues caused by automobiles. From Honda, Yagi participated as one of the tour members. The tour lasted an entire month, and the members visited 23 research facilities at GM, Ford and Chrysler, as well as related government agencies and universities and studied the most current research on emissions and safety. This U.S. tour added impetus for Date, Yagi and Nakagawa to go to Hideo Sugiura, then head of Honda R&D, and report on the necessity for Honda to pursue air pollution research.

"All right, then," said Sugiura. "Let’s do it."

Soon thereafter, the Air Pollution Control Research Laboratory, commonly known as the AP Lab, was established, starting with approximately 30 members.

Starting the Research From Ground Zero

Although the AP Lab was established, the members assigned to the Lab were research engineers who had been pursuing high-revving, high-output engines and who had no experience in the field of exhaust emission control, so they had to start from scratch. The first things the AP Lab did were to look into exhaust emission control measures other companies were researching at that time, conduct its own surveys and research related to exhaust gasses, as well as the internal communication activities within Honda R&D.

The AP Lab conducted surveys and research in pursuit of a wide variety of possible solutions to address exhaust emission issues. This included the improvement of gasoline and diesel engines, adoption of a rotary engine and other alternatives such as a gas turbine engine, as well as exhaust gas aftertreatment approaches such as catalytic oxidation (catalytic converter) and re-combustion (thermal reactors), and it also explored the possibility of alternative fuels such as alcohol and hydrogen.

As part of its internal communications activities, the AP Lab published its own newsletter, AP News, and distributed it within Honda R&D and other relevant divisions of Honda. This newsletter shared information indicating how emissions regulations in Japan and the U.S. would be changing how things are done at every stage of automobile business including the design, manufacturing and maintenance of automobiles.

According to Junji Ohtani, then engineering designer of the Engine Performance Research Block, Soichiro Honda insisted on using existing engines and told members of Honda R&D, “Eliminating existing gasoline engines in the interest of exhaust emission control would be a monstrous ordeal. All automobile production facilities for the entire industry would have to be abandoned. There’s no way we can do that. Since these regulations are being imposed on existing engines, they should be achievable with those very engines. That’s why we have to work to modify the reciprocating engine (internal combustion engine, ICE) that we already have.”

Basically, the AP Lab decided to address exhaust emission issues through better control of air intake and combustion of the engine, and by using an aftertreatment device to treat harmful substances still to be emitted.

Catalytic converters of the time were designed for stationary facilities, such as factories, to treat soot and smoke, and typically consisted of pellet-shaped catalyst materials packed into cylinders. As catalyzers, they were at a level sufficient to clear the regulations set by the U.S. Clean Air Act of 1970. However, when installed in automobiles, those catalytic converters presented major durability problems such as wearing out due to vibration and the catalyzers themselves could burn out depending on the combustion conditions of the engine.

AP Lab members also looked into thermal reactors, which were designed to re-combust exhaust gas components which were not completely burned in the combustion chamber before emission. To ensure such re-combustion, it was necessary to supply a richer air-fuel mixture, but this significantly reduced the fuel efficiency of the engine.

Therefore, AP Lab members had to come up with a different solution. Soichiro Honda provided a host of suggestions to the members, including the enhancement of fuel evaporation with a new intake vaporizer system and increasing intake efficiency with a fuel injection system.

At the time, Professor Tsuyoshi Asanuma of the University of Tokyo was visiting Honda R&D once or twice a month as an advisor to provide technical guidance. Over the course of these discussions with Professor Asanuma, the research team members became increasingly convinced that the only method to reduce harmful CO, HC, and NOx emissions altogether was to achieve lean combustion, which would burn the fuel completely. However, they thought that achieving lean combustion was absolutely impossible with the technology level Honda had at that time.

“What can you learn without trying”

To put these words – a frequent remark by Soichiro Honda – into practice, the AP Lab members began conducting basic research into achieving lean combustion. They tested virtually every conceivable measure, such as preheating the air-fuel mixture, enhancing gas flow inside cylinders, increasing ignition energy, and adopting multi-point ignition. However, none of them yielded favorable results.

We Can’t Catch Up While Doing the Same Things.

So Let’s Do What Others Aren’t.

As this process of trial-and-error continued, AP Lab leaders came to realize that it would be difficult for Honda to catch up to other automakers with longer histories while working on the same research as others, so they decided to try out new methods that no other automaker was working on.

Then AP Lab members came up with an interesting idea: “Can we achieve lean combustion with an engine that has a prechamber, although a prechamber is not used for conventional gasoline-powered engines?”

While a prechamber had already been put into practical use in some diesel engines, for gasoline engines, it was only being researched for the purpose of enabling the use of low-grade fuels or to improve fuel economy. Since no one else was researching engines with a prechamber for the purpose of air pollution control, it was certainly worth a try. The team began design modifications using the N600 engine.

Soichiro Honda frequently showed up in the design room, looking over drawings and providing lots of instructions and advice. Junji Ohtani, who was then in charge of design modifications, recalled, “We were just putting the finishing touches on our drawings when Mr. Honda gave us new instructions, and we had to start all over again.” Soichiro Honda had no patience to wait for the completion of the engine prototype, so he advised, “We have a general-purpose engine with a prechamber. Why don’t you use it for the research until the prototype engine is ready?” Thus, preliminary testing began using the GD90 general-purpose engine. The GD90 was a 479 cc air-cooled V-twin diesel engine that featured a prechamber, thus making it a suitable base engine for this experiment. First, a spark plug and a gasoline injection nozzle were installed in the prechamber. Then, the engine was modified to allow the compression ratio to be adjusted between 8:1 to 16:1. Engine tests with this modified GD90 were conducted from December 1969 through February 1970. Test results were generally favorable, and suggested the possibility of a gasoline engine achieving lean combustion.

In January 1970, the long-awaited 300 cc single-cylinder engine based on the N600 engine was finally completed, and testing based on this prototype engine began as part of the basic research on lean combustion through which optimal conditions for a prechamber were identified.

Furthermore, the team made a decision to conduct research using a water-cooled engine, which was essential for effective exhaust emission control. However, Honda didn’t have a water-cooled automotive engine that could be used for this testing. Since the team could not afford the time to build its own water-cooled engine, tests were conducted using engines of other automakers, such as a Nissan Motor Co. 1600 cc engine. The use of other companies’ engines also generated an unexpected side benefit of allowing Honda to collect more generally applicable data.

Also Honda reorganized and enhanced its environmental research system and capability at this timing. The AP Lab was disbanded in December 1970, and Research Lab 4 and 5 were newly created. From this point onward, more than 100 associates were constantly working on environmental research activities.

Announcing the CVCC Engine With Muskie Act Compliance

Finally in Sight

Upon hearing the news that the team completed the basic research and saw the possibility of reducing harmful exhaust components, Soichiro Honda declared that Honda would publicly announce the impending release of its low-pollution engine. As for making a public announcement while the engine was still in the research phase, Soichiro Honda said to the research team, “If I asked you guys, you would never tell me it’s perfected. If I wait for that, this company will go bankrupt!” And he decided to go ahead with announcing it at this timing. As Honda associates at the time described it, “moving everyone upstairs and then kicking out the ladder,” was Soichiro Honda’s typical way of urging further progress in research and development. He was motivating the engineers involved, including himself, by making the announcement first, then working hard to live up to what was announced.

As long as the new engine was going to be announced, it needed a name. Date, Yagi, Nakagawa and several others got together in a reception room at Honda R&D. Date explained, “Although we already had a good prospect at this point, our research was still ongoing. So, naturally, we were still in the process of applying for patents. Unveiling this engine under such circumstances, we didn’t want a name that would reveal any part of its basic composition or configuration. Also, since we hadn’t yet decided what fuel injection method we were going to use, we tried to give it a unique and punchy name.” The name they chose for this new engine type was the CVCC, standing for Compound Vortex Controlled Combustion. C (“Compound”) represented the engine mechanism with two combustion chambers: main and auxiliary. V (“Vortex”) represented the vortex, or swirl, generated in the main chamber. Caused by a jet of flame from the prechamber injected via a torch nozzle, the vortex had the effect of increasing the engine’s combustion speed. CC (“Controlled Combustion”) represented the engine’s ability to properly control the speed of combustion.

CVCC combustion chamber cutaway model with spark plug and gasoline injection nozzle in the secondary combustion chamber

CVCC combustion chamber cutaway model with spark plug and gasoline injection nozzle in the secondary combustion chamber

On February 12, 1971, Honda held a press conference at Keidanren Kaikan located in the Otemachi business district in Tokyo, and announced, “We now have the prospect of developing an internal combustion engine that would clear 1975 emission regulations, and we will begin installing this engine to our products in 1973.” Soon thereafter, Soichiro Honda also communicated to all Honda associates in a special issue of the Honda newsletter published on February 26, 1971, that with its new CVCC technology the company now has a prospect of complying with the regulations set by the Muskie Act (U.S. Clean Air Act of 1970).

The first prototype unit of the CVCC engine was completed in a brief period of only two months from the start of the planning. Then, an additional 100 units were manufactured with the help of the Honda Saitama Factory. After bench testing basic performance, the engines were installed in the chassis of a Nissan Sunny and tested on a chassis dynamometer. As initially predicted, lean combustion achieved with the use of the prechamber greatly reduced CO, NOx and HC emissions although the HC level did not quite clear the 1975 regulations of the U.S. Clean Air Act of 1970. However, subsequent research into the engine’s exhaust system, particularly the manifold, the optimal combination of main- and pre-chambers and the optimal method of supplying fuel to the chambers, resulted in the desired oxidation reaction within the exhaust pipe. This was due to heat retained from the exhaust gases, which contributed to a further reduction in HC emissions. With this achievement, Honda engineers finally saw the light at the end of the tunnel and gained confidence in complying with the U.S. Clean Air Act of 1970 regulations without using a catalytic converter.

CVCC engine combustion process

Achieving Goals with Our Own Hard Work

and Technological Strengths

October 11, 1972 became a landmark day for Honda. The CVCC engine was unveiled in its entirety to journalists from Japan and around the world at the Akasaka Prince Hotel in Tokyo. The venue was decked out in blue panels to convey the impression of clear blue skies for this new low-emissions engine. The event was attended by all company directors, including President Soichiro Honda, and the engineers involved in the development, who introduced the CVCC engine in detail, including its development process, engine characteristics and combustion theory.

The main features of the CVCC engine introduced at the event included the following:

- 1) The CVCC engine is built by modifying an existing internal combustion engine, therefore existing engine production equipment can be retained.

- 2) Cleaner combustion is achieved inside the engine, eliminating the need for a catalytic converter or other exhaust purification systems, and causing no risk of secondary pollution.

- 3) Since only the cylinder head needed to be modified, the CVCC system could easily be applied to engines of other automakers, enabling broad use of low-pollution technology.

These key features clearly indicated that Honda successfully realized the engine the company was envisioning since the beginning of the development.

“Other companies also had excellent research ideas and directions, but they didn’t have technologies to realize their ideas. At Honda, we conceived of, researched and perfected this technology entirely on our own,” said Yagi, emphasizing Soichiro Honda’s teaching of the “importance of developing Honda’s original technologies.” By the time of the unveiling event of the CVCC engine, 230 patents had been applied, including ones comprehensively covering the principle of the CVCC system, as well as others for peripheral technologies.

Sharing Anti-Pollution Technologies With Many Automakers

This groundbreaking announcement caused quite a stir both domestically and internationally. In the U.S., the EPA promptly requested Honda to submit CVCC-equipped vehicles for testing, and three vehicles were sent to the EPA’s emissions laboratory in Ann Arbor, Michigan. Two of the three vehicles had 15,000 miles on their odometers, and the third vehicle had already completed 50,000 mile-endurance testing before the submission.

The EPA testing was conducted from December 7 through 14, 1972, in the presence of Honda representatives, and the Honda CVCC engine became the first engine to clear the stringent 1975 emissions requirements of the U.S. Clean Air Act of 1970. Test data was taken with the CVCC engine installed in a Nissan Sunny. At the time, Honda didn’t yet have a vehicle large enough to accommodate the CVCC engine, so Honda had no choice but to undergo the EPA testing using another automaker’s chassis and body, which had already been used since the engine’s early development tests.

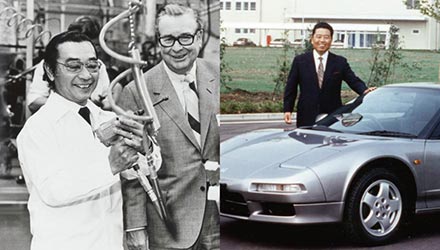

Soichiro Honda had long before announced his policy of releasing the company’s anti-pollution technologies to the public, and thus Honda made the CVCC technology available to other automakers. Responding to this offer, Toyota Motor Corporation made an inquiry, and Toyota engineers visited Honda R&D, test drove the vehicle and received a technology briefing. Toyota thoroughly evaluated the CVCC technology, and on December 13, 1972, Honda and Toyota signed a licensing agreement for the technology. “The fact that Toyota became the first to sign had a very positive impact on both the CVCC and Honda,” said Koichiro Yoshizawa, who was then in charge of external negotiations regarding the licensing of the technology. “As soon as it appeared in some newspapers that we had licensed the technology to Toyota, we immediately received inquiries from both Japanese and U.S. manufacturers.” The CVCC technology was eventually licensed to Ford, Chrysler and Isuzu Motors Ltd., as well, and during this period engineers from the world’s major automakers were frequent visitors to Honda R&D.

The Honda Civic went on sale in Japan on July 12, 1972. Honda developed this model with its back to the wall and with a sense of urgency that the company might have to consider withdrawing from the automobile market if the car sold poorly. Contrary to such concerns, the Civic was an instant hit on the market, winning the 1973 Car of the Year Award under the auspices of Japan’s Motor Fun magazine. The following year, on December 13, 1973, the 1,500 cc four-door Civic CVCC was launched, making the Civic a steady fixture in the Japanese automobile market.

Starting Exports of the Honda Civic CVCC to the U.S. Market With the 1975 Model.

In order to be exported to the U.S., the Honda Civic CVCC first had to be certified by the EPA as a vehicle in compliance with the 1975 regulations of the U.S. Clean Air (Muskie) Act of 1970. Although the CVCC engine alone had already passed compliance tests in 1972, it had not yet been tested as the Civic CVCC.

In November 1974, the 1975 model year Civic CVCC was brought before the EPA. “I felt like I was waiting for the result of my college entrance exam, while waiting for the computer to do the calculations and output the test results,” said Takeo Fukui, the first engineer with a degree in chemical engineering hired by Honda, who was then in charge of the certification process in the EPA project. Following the examination of the testing results, the EPA inspector offered a handshake and said, “Congratulations!” Fukui was just happy and relieved to hear that the Civic CVCC was successfully certified, but the EPA inspector told him that the Civic CVCC received the highest rating for fuel economy. “We were so intensely focused on emissions that we didn’t give any thought to fuel economy at all. But to them (the EPA), complying with emissions regulations was a given, and fuel economy was the key to the future,” said Fukui.

The Civic CVCC kept improving its fuel economy rating with each passing year, and was rated by the EPA as the most fuel efficient vehicle in the U.S. for four consecutive years through the 1978 model. In 2000, the SAE’s monthly magazine, Automotive Engineering, named the Honda Civic the Best Engineered Car of the 1970s among it’s the Best Engineered Car of the 20th Century selections.

Civic with CVCC engine

For the Children of the Future

Civic CVCC campaign poster titled “CLEAN AGE CAR”

Civic CVCC campaign poster titled “CLEAN AGE CAR”

Honda had consistently pursued high-revving, high-output engines since its 1954 declaration to compete in the Isle of Man TT Race. Leveraging engine technologies Honda had amassed through such pursuits, the company took on the challenge of developing low-pollution engines as a critical issue Honda has to address. The road Honda took was not an easy one, but Honda engineers were motivated by the strong belief that compliance with the U.S. Clean Air Act of 1970 was not a business interest of Honda, as much as it was the duty of the automobile industry as a part of its responsibility to society.

After the development of the CVCC engine, Honda not only kept developing products that comply with laws and regulations of the time, but also pursued the reduction of the environmental impact of its products by applying technologies Honda has in its hands.

In 1991, Honda introduced the VTEC-E lean-burn engine that achieved both low emissions and low fuel consumption while providing excellent driving performance.

In 1998, in the U.S. and Canada, Honda launched Accord and Civic models which received the “Ultra-Low Emission Vehicle (ULEV)” certification based on the emission regulations of the State of California. This requirement strictly mandated reducing the emission of hydrocarbons, a major cause of photochemical smog, to 10% of the previously approved level. Moreover, in 2000, Honda introduced an all-new Accord model which complied with the SULEV (Super Ultra-Low Emission Vehicle) regulations set by the most stringent of California’s new Low-Emission Vehicle Regulations (LEV II). For both ULEV and SULEV certifications, the Honda Accord became the world’s first production gasoline vehicle to be certified.

Furthermore, in 2011, Honda established its global environmental slogan “Blue Skies for Our Children,” which Honda has continued to follow with its initiatives toward the reduction of its environmental impact. This long held commitment started from the words of the engineers working on the development of the CVCC engine in the 1970s.

Currently, as a part of its corporate and social responsibilities, Honda continues to take on challenges in the pursuit of “zero environmental impact” throughout the entire lifecycle of its products – from the procurement of materials, production, logistics and to disposal – and for the entire corporate activities including social contribution activities.