The F200 "Komame" Mini-Tiller / 1980

The Long-held Dream of Developing a Mini-tiller

Japan was in a period of rapid economic growth in the late 1970s, when Honda saw its sales hit 1 trillion yen and introduced the five-day work week. Amid all this progress, people were beginning to focus more on the enjoyment of their lives.

The F200 Komame literally "cultivated" a market for mini-tillers.

This was about the time that Honda launched its new ME general purpose engine, a model that was to make Honda Power Products the third pillar in a global marketing trio. Under the million-unit target set for the ME family of engines, one plan was initiated to develop a new product equipped with the G100 derivative. Gunji Saito, who for most of his career at Honda had been involved in the development of medium- to large-size cultivators, had been given the order to develop a mini-tiller.

Saito, then in his thirties, was given the post of Large Project Leader (LPL) in order that he might tackle the development of a new mini-tiller, a size category he had never dealt with before. The reason he had joined Honda in the first place was to develop cultivators. Rather than work with large, industrial models such as those from Kubota and Yanmar, his goal was to create machines for avid gardeners and people who simply enjoyed gardening as a hobby. To him, the development of a mini-tiller was an excellent opportunity.

The worldwide agricultural industry was then experiencing a period of decline, but gardening was enjoying a boom in popularity.

Accordingly, Honda had begun organizing a sales network for lawn and garden products, preparing for the launch of its HR21 lawn mower. Saito thus made the determination to turn away from traditional farm users, defining the mini-tiller concept as a "beginner's machine for use in home and hobby gardening." With a goal of tapping new user markets, the specific target group was identified as home users who were looking for an alternative to hoes, shovels, and garden rakes. Incidentally, Saito knew someone who was into home gardening; a woman who had often complained to him, "I wish there was a cute, little cultivator I could use." Those words gave Saito extra confidence in defining his concept.

The Requirement: Small but First-class Handy Worker

Preliminary studies were conducted in order to identify potential markets outside Japan. Thus, the development team's first stop would be France, an agricultural giant. They had had no problem gathering information in France, which already was one of the major markets for Honda's cultivators and other agricultural machines. They had visited local dealers and studied the market, particularly with regard to small products. At the Paris Agriculture Show the team obtained some invaluable information regarding vertical engines. After traveling through Europe, the team flew to the U.S. Ultimately it was the United States that gave the team members the confidence they had need to push ahead with their mini-tiller.

It was there that they had confirmed the presence of a sizable market, particularly on the East Coast, and that there were many home users who would want such a machine for use in their flower and vegetable gardens.

Lawn mowers and snow throwers still had the lion's share of the power products market, though, so there was little attention left for mini-tillers. The development team had even found that mini tillers would be relegated to quiet corners in retail stores, where they had received little of the notice they were due. Saito, however, believed his mini-tiller would be different, since it was to be a "beginner's machine." However, to date so much emphasis had been placed on the image of a "mini" product that its performance had gone unrecognized. Then, just when he was about to give up on the American market, believing that this kind of cultivator could only sell in France,

Terumasa Kanazawa, then head of American Honda's Power Products Division, stepped forward with an inspiring comment:

"You must not forget that no matter how small the machine is and how basic its functions are, it is still a working machine. The key requirement for your mini-tiller, as a product, is to ensure its ability to do a first-class despite its small size."

Saito, greatly encouraged by those words, drew up a report on his flight back home, amid the cramped confines of his economy-class seat. The theme of the report was to develop a small cultivator that could do a first-class job by providing a level of performance not expected from a machine of its size. While writing the report he became absolutely confident that a successful mini-tiller could be developed. Upon the close of his research trip, Saito's development effort kicked into high gear.

The Vertical Layout for a Slim Profile

Various layouts had already been drawn, but the team was unable to come up with the right contour within the basic frame of a conventional cultivator. After all, it had to house the engine, transmission, and drive wheels. They knew it would be impossible to create a product that home users would expect simply by mimicking the traditional configuration on a smaller scale.

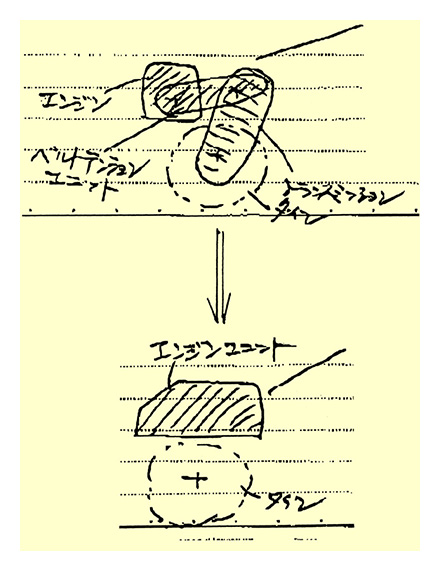

To achieve a compact profile, the team examined a vertical layout that arranged the components along one line. (Courtesy of Gunji Saito)

Therefore, following several discussions the team decided they would break from tradition and give their product a new look. It would be a look designed for maximum appeal among home gardeners. Then Saito remembered a machine he had seen at the show in Paris.

It was a mini-tiller made by a little-known Italian manufacturer. It had been placed in a corner of the exhibition hall, as if someone had inadvertently left it there. The machine, Saito recalled, had a simple structure holding a two-cycle vertical engine with its shaft extending downward. A worm gear was used to turn the rotor tines. Yet, despite its rough construction, the plain-looking little tiller appeared to be a user-unfriendly, low-performance machine.

Saito was very impressed with its design, however, which was decidedly different from conventional, belt-driven models. Indeed, it was when he saw this machine that Saito got a general picture of how his mini-tiller would look.

Accordingly, the development team's final structure featured a perpendicular layout, with the transmission and rotor tines installed below the engine along a vertical line. The design's obvious intention was to offer a cute, slim look that would distinguish the new machine from large, bulky cultivators.

A Planetary Gear, Courtesy of the Road Pal

The mini-tiller's development team had quickly abandoned the conventional method of joining the engine and transmission with a belt, since that kind of structure would have made it impossible to achieve the desired look. Alternatively, they considered the use of a planetary gear. Though the reduction ratio had to be dropped to around 30:1, the planetary gear could make possible the kind of design that the usual belt/gear configuration could not. However, adopting this gear raised a concern regarding the price of accuracy. To increase it, the mini-tiller's cost target would have to be compromised.

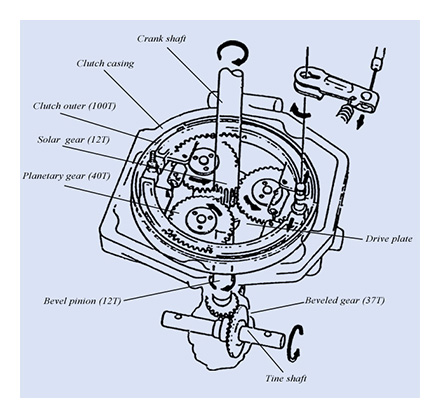

The deceleration mechanism using a planetary gear incorporated a range of technologies Honda had accumulated through motorcycle and automobile engineering.

Honda's Asaka R&D Center was at the time developing model derivatives based on the Road Pal, in the process adopting planetary-gear technology. Faced with the same problem, the center had come up with the idea of stamping the gear with a press machine instead of machining it, thereby lowering the cost of production. Saito had, in fact, visited the Asaka R&D Center repeatedly in the hope of understanding the technology. As for the bevel gear used to turn the tine shaft in reverse, the team consulted automotive experts at Saitama Factory's Wako Plant in an effort to use precision forging to achieve cost reductions. The team also incorporated other new technologies developed for motorcycles and automobiles, thus making the new mechanism more feasible. For example, the mini-tiller's clutch mechanism was based on a motorcycle's brake system.

The process helped Saito to realize that Honda's vast technological expertise, encompassing motorcycles and cars as well as power products, was what gave the company its competitive edge. The ability to access various technological systems and information in order to produce cost reductions provided an important key in solving the team's development problems.

The body design was another area of emphasis, in which the engine cover was made not from steel sheet but resin. The exterior was painted in a contrasting red-and-white theme. "The design and color look fresh even today, making the machine look as appealing as a Honda car or motorcycle," said Saito proudly.

As for the usual attachments found on conventional cultivators, the new machine adopted a unique specification. Of course, the new mini-tiller was designed as a "complete product," so that its tiller unit was standard equipment rather than a unit sold separately.

This was done in order to make the machine appear more user-friendly to amateur gardeners. It was also in keeping with the machine's primary requirement, which was to satisfy the user with an ably performed single function (tilling soil). This solved the problem of handling attachments, which was often difficult and time-consuming.

Komame's Debut: Soaring Beyond Every Expectation

The prototypes went through repeated tests, after which the product went into mass production, in February 1980. There was, however, still an amount of concern about how well the machine would do in the market. Consumers had indeed turned their focus toward greater enjoyment in life, but Saito was not sure whether they would accept the idea of a mini-tiller. In fact, when he showed the prototype to associates in Sales, the staff did not even take it seriously. "It looks like a toy," they joked. In those days, most companies were still looking at cultivators as agricultural machines. No one had given much thought to selling them as tools for home gardening.

A brochure for the new product, Komame

The F200 mini tiller, nicknamed "Komame," (meaning "diligent worker") nevertheless made its debut in March 1980, about a year after the project first started. It was the product of a devoted effort directed by Saito and his team, which involved experts in key components including engines, transmissions, frames and design. The company, however, had decided to test Komame's marketability by releasing it in limited markets in Japan. For this reason Komame's initial sales target was a mere 2,000 units, while the other new products all had five-figure targets. "It was as if the company had no interest in selling it," said Saito, laughing.

Komame's sales, however, began to rise shortly after its launch. To their surprise, sales grew among users at general agricultural farms rather than the intended home market. The machine was perfect for the elderly person tending a small garden at the back of the farm, or for the landowner who wanted to rid his property of weeds. By April and May, Komame's sales were soaring. Then in June, having been astonished by the results, the staff conducted a survey of retailers. However, the store-owners were just as confused. "They did not understand why it was selling, either," said Saito, again with a laugh.

The nickname was one reason for the product's success. "Komame" was coined by Masaru Miyata, then in charge of Power Products domestic sales, who had characterized the machine as being "small and cute." Successful, too, was the second year's TV commercial produced by the sales-promotion team and a marketing campaign by the domestic sales team using the slogan, "Weekend Gardening." As a result, sales in the home gardening market, Komame's initial target, also grew.

Saito and the other members of his development team were convinced that convenience had motivated sales of Komame, a feature that conventional machines had failed to provide. With Honda's mini-tiller, the gardener could take the machine out and use it anytime he or she wanted. However, most importantly, Komame provided the performance needed for a first-class job despite its size. This was the concept the development team had given top priority. The body was stable because the center of gravity was directly above the tiller unit, and the engine could rotate the tines at high speed. These features made Komame a very efficient machine, allowing the user to seed a plot of earth immediately after the soil was tilled. These were precisely the benefits for which Komame was created.

Komame was exhibited at the Paris Agricultural Show later that year, earning rave reviews. In fact, by the end of its first year the mini tiller had sold 38,600 units (with domestic sales and exports accounting for equal portions). Ultimately it became a best-selling product, recording peak annual sales of 50,000 units in Japan alone.

Honda's mini-tiller, eighteen years after its release, is still selling 20,000 units annually in combined domestic and overseas sales. In that sense, it is a "perennial" seller. Moreover, Komame's introduction changed the views of leading agricultural machinery makers, who also began manufacturing mini-tillers for market segments they had once dismissed. Sales of mini-tillers skyrocketed, creating an annual market of 130,000 units by 1982.

A Mountain of Letters: The Greatest Honor an Engineer can Receive

Saito was sincerely moved by the mountain of letters that had come in from Komame users. They were, in his words, "the greatest honor an engineer can ever receive." Each letter thanked him for developing such a wonderful product. More than the sales figures, it was the user comments that rewarded Saito for all the effort and hardships he and his team had shared.

"The most important thing in any difficult task," Saito said, "is to set a high goal at the beginning. We should not set goals based merely on logic or reason. Instead, the goal should reflect our personal enthusiasm, because it is not machines but human beings who will work to achieve it."

"For example, when walking down the street or listening to other people, you may suddenly get an inspiration. Just when you think you are struggling to crawl along the bottom of the ocean, an idea may suddenly strike you. It becomes your goal. What is so important is the process of setting a goal and doing everything possible to see it through. An engineer cannot grow unless he experiences this process.

"We should not set targets based on what we want to do. Instead, we must think of how we can develop and sell products that satisfy the customer and win their recognition. We set each goal to achieve this, and it's the ultimate reward."

These words are a testimonial to Saito's passion as an engineer.