DESIGN

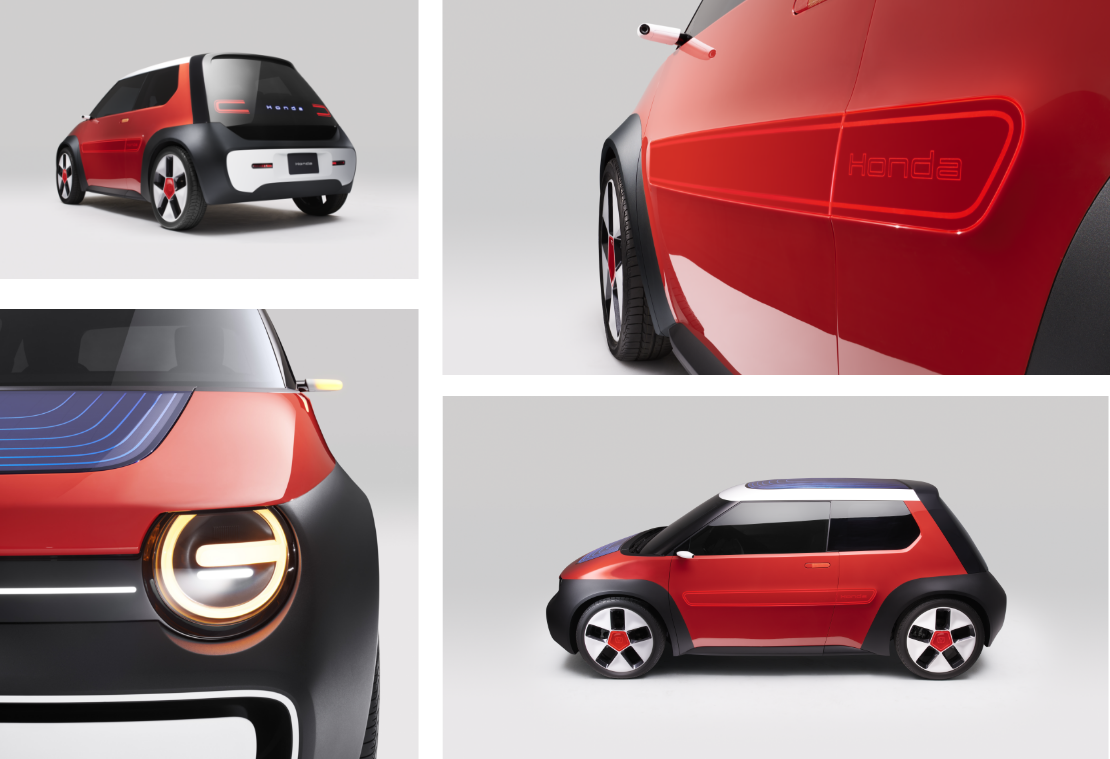

The concept model for an electric vehicle that could potentially free us from the restraints of finite resources. The brightly colored vehicle body panels are made by reusing the acrylic resin materials recovered after previous use.

We have developed the SUSTAINA-C with the aim that this resource circulation could potentially help free us from the restraints of finite resources, and could enable us to ensure both protection of the global environment and the joy of freely moving around in vehicles in the future.

CONCEPT

Amid the rising need to implement further environmental measures on a global scale, Honda’s aim is to help achieve a world where we can fully address environmental concerns while each person can enjoy freely moving around and doing what they want to do in a responsible manner, instead of having to stifle their wishes and activities by coping with environmental measures.

The SUSTAINA-C is based on the concept of EGO (what you want to do) and ECO (environmentally friendly) at the same time.

FEATURE 01

The impact-resistant acrylic resin with horizontal recycling possible

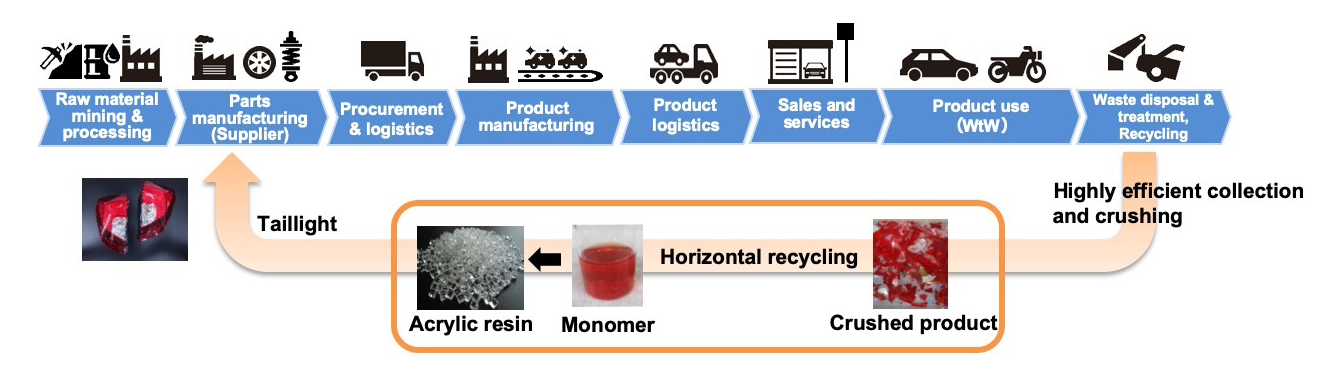

Because acrylic resin has excellent weather resistance and surface smoothness, as well as outstanding coloring properties and transparency, it is possible to ensure high design quality without the need for coating, so acrylic resin has been used for automobile taillights and other parts from before.

In dealing with used acrylic resin, however, the technical difficulties in ensuring sorted collection and appropriate recycling meant that only the thermal energy generated in incineration has hitherto been recovered and used. Also, a weakness of acrylic resin that it could easily crack when impact is applied has made its widespread use in vehicle body panels difficult.

Through its joint development project with Mitsubishi Chemical Corporation, Honda has succeeded in turning the acrylic materials collected from used products into recycled materials with the performance and quality levels equivalent to those of new materials, by applying advanced recycling technologies. By also establishing the horizontal recycling technology for consistently manufacturing products of the same type and developing new acrylic resin materials that achieve both high-level impact resistance and moldability, Honda has kept up its activities to overcome conventional weaknesses of acrylic materials.

Establishing these technologies has made it possible to use recycled acrylic resin as uncoated body panel materials. By considerably reducing the CO2 emissions generated through body painting processes and promoting resource circulation, Honda will continue moving forward towards achieving its “Triple Action to ZERO” goal by the year 2050.

FEATURE 02

The body panel capitalizing on the properties of acrylic resin

We have also worked on promoting the designs that capitalize on the properties of acrylic resin with no coating necessary.

The use of the body colors with excellent chroma saturation, by drawing on the excellent surface smoothness and coloring properties of acrylic resin, and the effective placing of fluorescent acrylic materials with high transparency, would help enhance the design quality.

The resin streaks generated in body panel molding processes are used also to express marble patterns, as a part of the endeavors to further pursue the design characteristics distinctive of acrylic resin.

FEATURE 03

The screen-like tailgate made by drawing on the characteristics of acrylic resin

By capitalizing on the excellent transparency that is a characteristic of acrylic resin, the tailgate has been formed as one panel, like a smartphone screen, leading to the adoption of a “screen-like tailgate,” with the light of the tail lamps, etc., being transmitted from the back side.

Mini LED display lights are used for the tail lamp light being transmitted from the back side of the acrylic material. The display lights are used not only for the lamp lighting function but also for showing the state of charge while parking and communicating with other vehicles nearby, through various imagery expressions and text messages, thus presenting an expanded possibility of how vehicles could be used in a new way.