Power Exporter e: 6000 and Power Exporter 9000 portable external power output devices

User-friendly portable external power output device enables the use of electricity taken out of a vehicle.

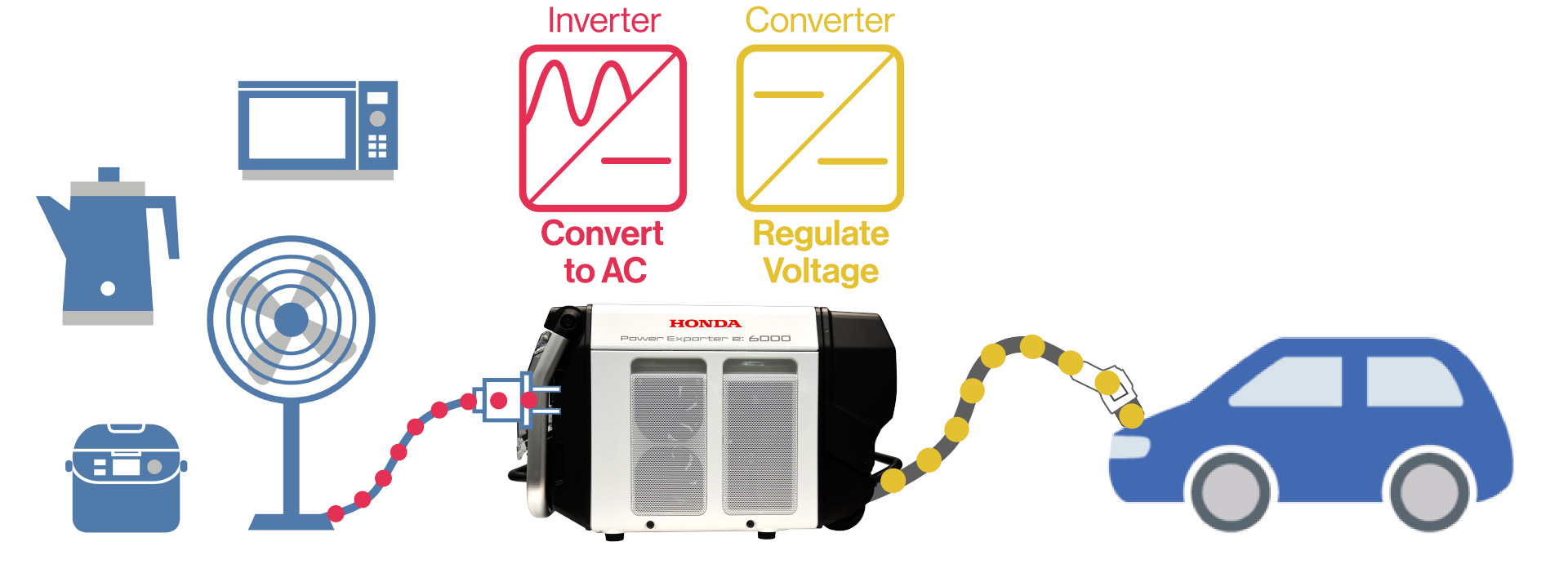

Electric vehicles (EVs) such as battery electric vehicles (BEVs), plug-in hybrid vehicles (PHEVs) and fuel cell electric vehicles (FCEVs) have an ability to store or generate a large amount of electricity. If such vehicle electricity can be externally output, electrified vehicles can be utilized as a "power source on wheels" in various places and situations.

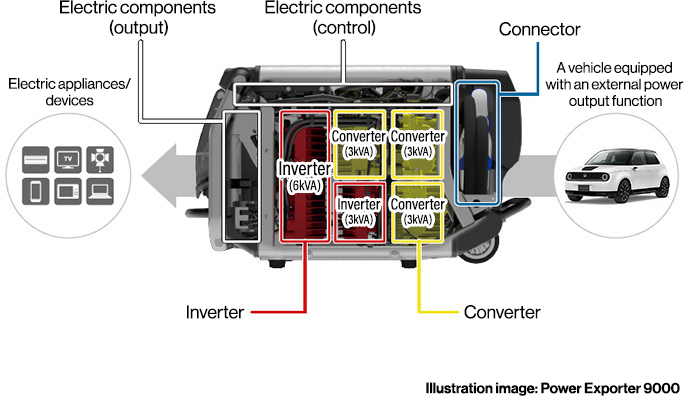

However, the electricity from the vehicle is direct current (DC) electricity and cannot be used as is for household appliances that require alternating current (AC) electricity.

When connected to a vehicle equipped with an external power output function, Honda Power Exporter e: 6000 and Power Exporter 9000, portable external power output devices can convert DC electricity from the vehicle to AC electricity. Then, they can externally output high-quality electricity not only for household electrical appliances, but also for precision instruments and musical instruments that require high-quality electricity.

Usage Image

One way to draw electricity from the vehicle for external output is to use a power outlet installed inside the vehicle; however, those outlets only provide output of approximately 1.5 kVA and cannot supply a large amount of electricity.

In contrast, the Power Exporter e: 6000 can output up to 6kVA (about twice the power consumed by an average household), and the Power Exporter 9000 can output up to 9kVA (about three times the power consumed by an average household).

Moreover, in addition to the 100V output, which is used for low-load household appliances such as smartphones, Power Exporter e: 6000 and Power Exporter 9000 also offer 200V output required for high-load electric equipment such as lighting equipment and air conditioning units. This enables them to serve as a power source for an entire event in normal times and as a backup power source for an evacuation center and/or a small office in the time of an emergency.

Honda original technology filled with know-how amassed over many years

The Power Exporter e: 6000 and Power Exporter 9000 incorporate a number of technologies Honda has amassed through its long history of developing portable generators.

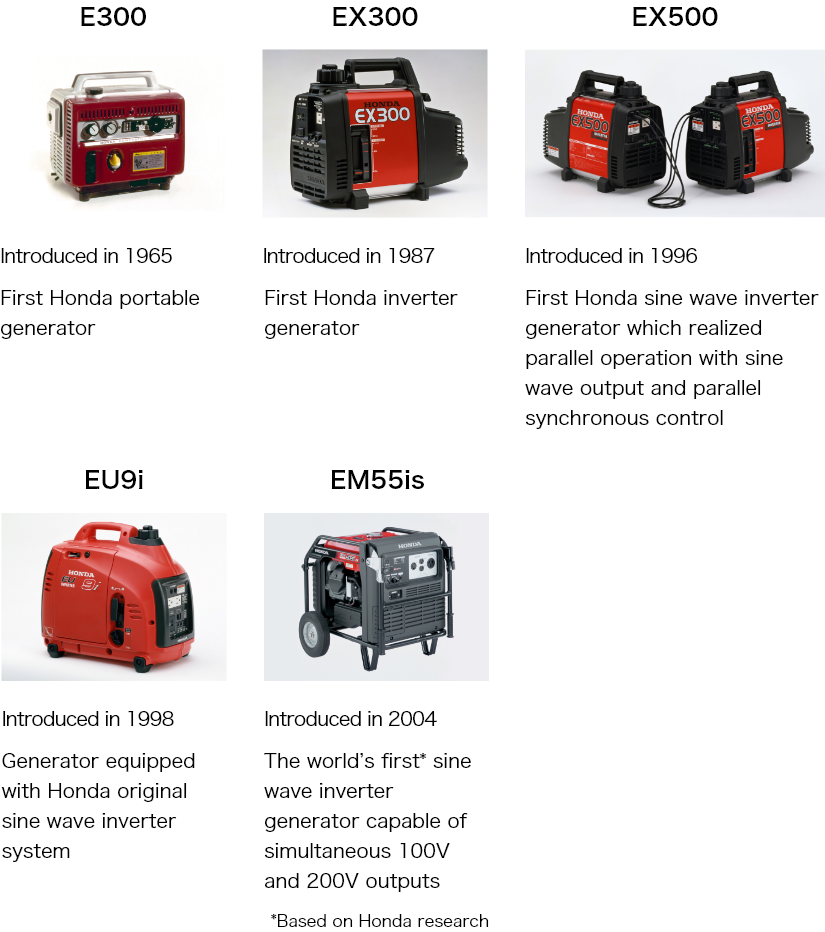

The history of Honda generators began with a compact, portable, gasoline-powered generator introduced in 1965. Today, Honda generators are used by many customers all around the world. Portable generators are products in high demand not only as a power source for work and leisure activities, but also as a backup power source in the event of a power outage; therefore, portable generators must be compatible with a wide range of electric equipment, just like household electrical outlets.

History of Honda portable generators

Honda's original sine wave inverter features high performance in reducing waveform distortion, which causes adverse impact on electric equipment, and outputting pure sine wave in accordance with electric-load (usage), which enables the use of electricity for a wide variety of electric equipment.

For the converter, LLC current resonance drive

Power Exporter e: 6000 and Power Exporter 9000 utilize these technologies: the converter converts the high-voltage direct current (DC) electricity supplied by the vehicle into a constant output, then the invertor produces a clear sine wave and outputs alternating current (AC) electricity.

*1 LLC current resonance drive: Switched-mode power supply (SMPS) which can draw a specific current regardless of changes in input voltages. It features a low parts count, high efficiency and low noise.

*2 To use Power Exporter e: 6000 or Power Exporter 9000 to power medical equipment, please consult in advance with relevant parties involved, such as medical equipment manufacturers, physicians and hospitals.

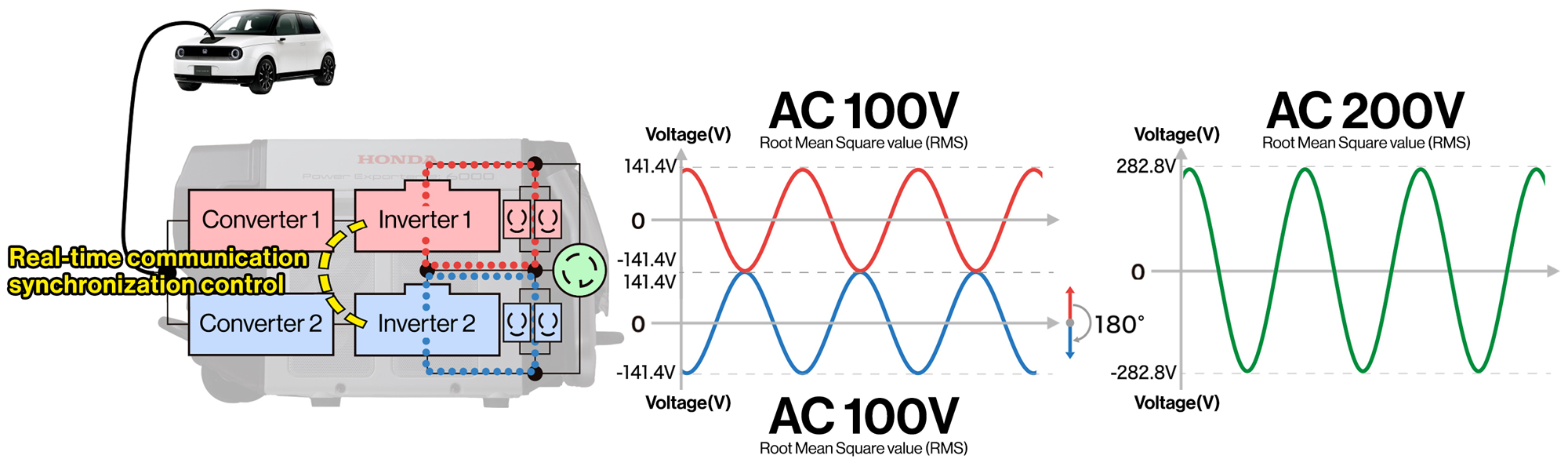

Technological strengths of Honda made simultaneous 100V and 200V outputs possible

Thanks to dual-voltage inverter technology, the Power Exporter e: 6000 and Power Exporter 9000 can output both AC 100V and AC 200V simultaneously.

The built-in Inverter 1 and Inverter 2 each output AC 100V, and their phases are shifted 180° by real-time communication synchronization control. This makes it possible to output the synthetic wave as AC 200V, which makes both the Power Exporter e: 6000 and Power Exporter 9000 compatible with household appliances, as well as a wide range of large-load electric equipment such as office-use air conditioning units and store-use refrigerators.

Dual-voltage inverter technology

200Volt three-phase power output will come in useful in the time of an emergency

To further expand its use applications, the Power Exporter e: 6000 is equipped with three-phase AC output function. Three-phase power is a 200-Volt power source that combines three single-phase lines with voltage phases separated by 120 degrees.

The three-phase power output is widely used to power industrial equipment that requires large amounts of power, such as large air conditioning units and elevators in factories and buildings, watering pumps for agricultural use, large refrigerators and dairy farming equipment. Because of its three-phase power output function, the Power Exporter e: 6000 is expected to play an effective role as a backup power source that can supply power to equipment for which early recovery of power supply is desirable, even in situations where restoration of power supply would be difficult, such as in the event of a disaster.

Three units of Power Exporter e: 6000, each connected to an electrified vehicle, are connected to a current collecting box which leads to electric load. Then each unit of Power Exporter e: 6000 is switched to three-phase output mode. With the three-phase output mode, the phase difference between the inverters is changed from 180 degrees to 120 degrees with real-time communication synchronization control. The parallel synchronous control technology enables synchronization of waveforms without signal communication, making three-phase output possible*3.

*3 For this usage, a current collecting box is required.

Realizing compact size and lightweight in pursuit of user-friendliness

In order to use a vehicle equipped with an external power output function as a “power source on wheels” it was essential to make the external power output device portable. Both the Power Exporter e: 6000 and the Power Exporter 9000 provide large output, yet are compact enough to be transported by a car.

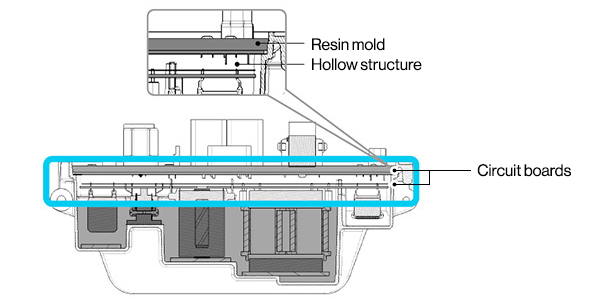

One of the reasons the compact size and lightweight were realized was the change in the layout of the converter. The converter unit’s circuit board structure was changed from one layer to two layers, and a hollow structure was adopted for the space between the circuit boards. Also, by leaving the space between the two circuit boards hollow, only one side of each board is molded. Although this causes different thermal expansion rates for each side of the circuit board and increases the risk of warping and cracking of the board, this issue was addressed by adding breathing holes which will reduce the board’s expansion and moisture absorption. Through this change in the converter layout, the compact size and lightweight were realized.

Two-layered converter unit circuit board

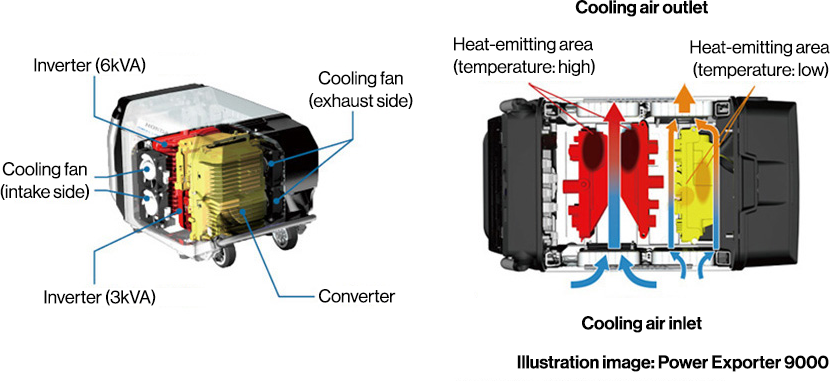

The highly efficient packaging of the Power Exporter 9000 was achieved by subdividing the unit into five units. In addition, the number of cooling fans was reduced by devising the flow of cooling air so that the heat emitted from the high-capacity converters and inverters can be efficiently discharged. By Incorporating various ingenuities, the compact size was thoroughly pursued.

Configuration

Efficient placement of cooling fans

For the Power Exporter e: 6000, the internal configuration was reviewed in pursuit of further weight reduction, resulting in a weight of 41kg (90 lbs.), which is approximately 20% lighter than that of the Power Exporter 9000, which weights 51kg (112 lbs.).

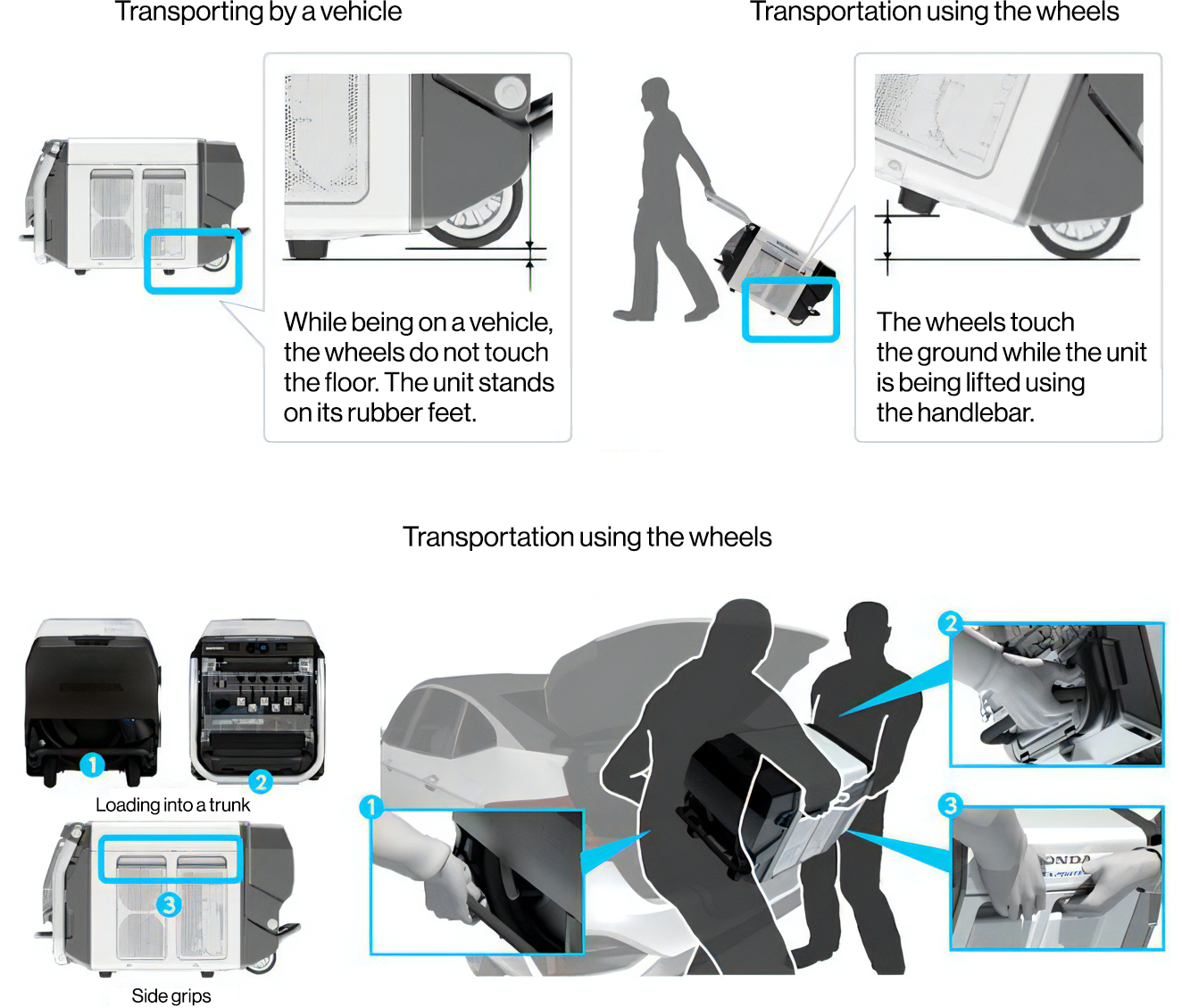

The handlebar and wheels were also carefully designed to enable one-person to carry it. Both Power Exporter e: 6000 and Power Exporter 9000 feature large wheels and a handlebar which enable the unit to go over small bumps smoothly while maintaining a good balance. Moreover, the Power Exporter e: 6000 and the Power Exporter 9000 were designed to achieve high stability while being transported in a vehicle, and high operability while being pushed or pulled on their own wheels. To be more specific, the wheels are structured to touch the ground/floor only while the handlebar is lifted. This design ensures stability while being transported in a vehicle because wheels are not touching the vehicle floor, and ease of movement while using the wheel by lifting the handlebar. In addition to the handlebar, large grips are placed at the front, rear and on both sides of the unit to alleviate any user burden while loading/unloading the unit into/from the vehicle.

Image of transporting Power Exporter

Both Power Exporter e: 6000 and Power Exporter 9000 are extremely simple to use; plug in the connector to an electric vehicle and press the “power” and “start” switch buttons to start power output.

The cable used for power output can be stored in a compartment which is part of the unit, which is one of the features carefully designed to enhance ease of use.

The Power Exporter e: 6000 comes with a 2.1 m (6.9 ft) connector cable, which was made longer and thinner compared to the 1.2 m (3.9 ft) cable of the Power Exporter 9000, further enhancing ease of use.

The Power Exporter e: 6000 and the Power Exporter 9000 are external power output devices which are filled with original Honda know-how. Both can supply high-quality electricity consistently, and thus enable many people to use them with complete peace of mind. With their large capacity and high portability, the Power Exporter e: 6000 and the Power Exporter 9000 can accommodate a wide range of needs, from powering up everyday devices including various household appliances, to providing power to evacuation centers in times of a disaster, thereby expanding the range of people’s daily lives.

Obtaining the world’s first*4 CHAdeMO Association V2LGuideline DC Certification.

Honda Power Exporter 9000 is the world’s first*4 external power output device to be registered with the CHAdeMO Association’s V2L*5 Guideline DC Certification. The certification was granted in February 2016 based on guidelines*6 formulated to ensure electrical safety and compatibility between the vehicle and connected equipment.

The Power Exporter e:6000 also obtained the same certification in May 2023.

This certification ensures compatibility not only with Honda electric vehicles, but also with other automakers’ vehicles equipped with an external power output function that complies with the guidelines, enabling the Power Exporter e: 6000 and the Power Exporter 9000 to achieve a high degree of versatility.

*4 As of 2016.

*5 V2L (Vehicle to Load): To utilize the vehicle’s function to store and generate electricity and output the electricity directly from a vehicle equipped with an external power output function to electric appliances/devices.

*6 EV charging/discharging system guideline V2L DC version by EVPOSSA

INDEX

TechnologyPower Exporter e: 6000 and Power Exporter 9000 portable external power output devices