Introducing the Accord / 1976

In Search of a Cleaner, More Economical Car

A popular theme among the world's automakers in the 1960s was "larger, more luxurious-looking and more powerful," and this was the most readily apparent concept in their designs. In fact, most of the luxury models produced during that decade were developed along those lines. Such cars appeared to glorify the excessive use of resources, as if doing so could be easily justified.

Regulations concerning auto emissions, though, became much stricter in 1970 with the U.S. government's passage of the U.S. Clean Air Act. Japan immediately followed suit, moving to tighten its own regulations. Then, in October 1973, war in the Middle East broke out, sending the world's crude-oil prices to a level four times higher. The result was an oil crisis that caused significant confusion to the global economy.

The oil crisis and new emissions regulations also brought about a shift in the passenger-car market, reflecting an emerging consumer trend. That trend was one in which car buyers were no longer satisfied to own cars that eschewed any degree of functionality in favor of outright size and luxury. Instead, they wanted cleaner, more economical family cars that offered greater fuel-efficiency.

The tide of social sentiment was turning toward Japan, and consequently, Honda responded by introducing the Civic in 1972 as a full-scale, economy vehicle. The Civic CVCC model equipped with a low pollution CVCC engine followed in 1973, further answering the market demand for a clean-burning car. However, since it was the newest entrant in a huge and hotly contested market, Honda was quickly saddled with the reputation as a small auto maker with only a handful of models, like the Civic and mini cars.

Therefore, Honda R&D rolled into 1972 with a project designed to develop a full-scale, compact car for mass production. "Quiet ride" was a key phrase at the start of the project, and in that regard all phases of design were to reflect a high degree of integrity and attention to detail.

The development staff believed the use of an inline six-cylinder powerplant would offer the best assurance of a quiet ride, so it was decided that the new model would carry a 2000 cc, vertical inline 6-cylinder engine. Their design, to go forward under the "653" development code, would be a luxury four-door sedan incorporating the front-engine/front-wheel-drive (FF) format that Honda had been using since the N360. Thus, with the basic concept in place, development of the 653 was officially under way.

Project development, however, soon encountered difficulties due to changes in the market, prompting several design changes. For all their effort, though, the team had failed to bring the maturity, total balance, and other elements to the required levels. Ultimately, in 1974, the project was canceled.

It was an era of dramatic world change, and the times demanded reforms in the methods that manufacturers used to design their cars. The impact of popular sentiment and governmental regulation was so strong, in fact, that the world's auto makers had to subject their manufacturing philosophies to the most fundamental scrutiny. However, for Honda it was a great opportunity, since the company was at that time lagging behind the more established companies. All automakers were forced to begin again at the same level of development. In the race to develop new compact cars offering greater economy and comfort, yet which could meet the tougher pollution laws.

A New Development System is Introduced

Hiroshi Kizawa, a chief research engineer at Honda R&D, was in September 1974 suddenly told to return to Japan from the U.S., where he had been stationed to help transfer Honda's CVCC technology to Ford. Actually, he had been assigned that post because of his experience as manager of the Civic development project.

Kizawa, upon his return to Japan, received an official order from the Board of Directors at Honda R&D to develop a car one class above the Civic; a model that would be the logical step for Civic owners wanting to upgrade. Hence, a project to develop an upscale version of the Civic began, with Kizawa acting as development manager. Given the development code "671," the car was to answer two requirements.

First goal was to ensure comfortable cruising at 130 km/h. "At the time, every new car was being developed for exportation to the U.S. and Europe," said Kizawa. "However, Japanese cars still had high noise levels of around 70 dB at 100 km/h. To make the 671 a world-class car, we decided to reduce the noise level to 70 dB at 130 km/h." Assuming the local driving patterns of the U.S. and Europe, the team again set its sights on a quiet ride, this time emphasizing low noise levels during high-speed cruising.

The second requirement was to make full use of the Civic's parts. Honda had already invested heavily in the Civic and CVCC engine, and was not in a position to invest additional funds toward the development of another model. Hence, the company had to carry out its development with minimal investment. Specifically, it had to promote the use of existing facilities, including the engine plant and as many of the Civic's parts as possible.

The car also had to offer sufficient visual appeal and interior comfort in order to merit its presentation as a higher-class expression of the Civic. For the development staff, this represented a true dilemma.

In the hope of enhancing its product development, Honda had earnestly begun the implementation of a new S•E•D system. It was intended that the new system would involve the Sales, Production Engineering, and Development departments in the product-development process, thereby promoting the exchange of ideas with various perspectives. An original system of product development, the S•E•D system emerged from a speech given by Kiyoshi Kawashima on the occasion of his appointment as president of Honda R&D, in which he asked the company’s board to "think of ways we can work effectively so that 100 ordinary persons can produce achievements on the level of one genius, Soichiro Honda."

The new system dictated that each product development be promoted by a joint project team comprising personnel from various departments in the areas of sales (Sales), production and production engineering (Engineering), and product development (Development). Its purpose was to allow the team members to discuss matters from the standpoint of their respective positions and experience, and to integrate all three aspects into development.

A basic concept for the new model was thus established, according to the two chief requirements. That concept described "a compact car that is easy to use and has a stylish, sporty look." It reflected the image of an ideal car; one that the development staff would want for themselves. They now had a concept, but first the team had to determine the priority of body styling. In other words, they had to determine whether development would begin with a four-door sedan or three-door hatchback.

Looking at both domestic and overseas market studies, the team found there were too many compact sedans in the Japanese market, while the demand for four-door sedans was small in the U.S. compact car segment which was comprised of models displacing 2000 cc or less. Moreover, the team looked at the success of the Civic, whose unique three-door hatchback style had been well received at home and in the U.S. With that, they reasoned that the hatchback design could duly satisfy the three key conditions of "roominess, stylish design, and excellent running performance." Thus, they decided to start with the three-door hatchback.

The design of the body was then to proceed with formal adoption of the free-competition approach, meaning the concurrent pursuit of competing projects. After all, it was a system that had already proved itself in the development of the Civic. Accordingly, the team was split into two groups, each of which was to function independently and competitively. It was their firm belief that such a system would produce more effective results.

Following a period of study, the first group proposed a sleek, invigorating design featuring a great expanse of glass and a low overall height. Actually, the look they were after was significantly influenced by the Lotus Elite, a British sports car. The second group suggested a more orthodox, two-door coupe design, the novelty of which was a set of flowing contours reminiscent of a speeding bullet. Of the two proposals, the team chose that of the first group, based on its striking good looks, apparent agility, and breakaway styling. Their next step was to take this basic design to the next level of refinement.

A sketch of the first-generation Accord, featuring a sleek design and extensive glass area

Creating a Car that "Feels Good to Drive"

The team's first project requirement was to achieve "comfortable cruising at 130 km/h." This was a task requiring a thorough review of the suspension, transmission, and other drive components employed in the Civic, to which improvements would be made based on use of the Civic's CVCC powerplant. With regard to the car's suspension, an exhaustive review of the Civic led to various enhancements and the adoption of a four-wheel independent system with Macpherson struts. As for the wheels, the team decided to adopt radial tires, which were characterized by a high degree of dynamic performance.

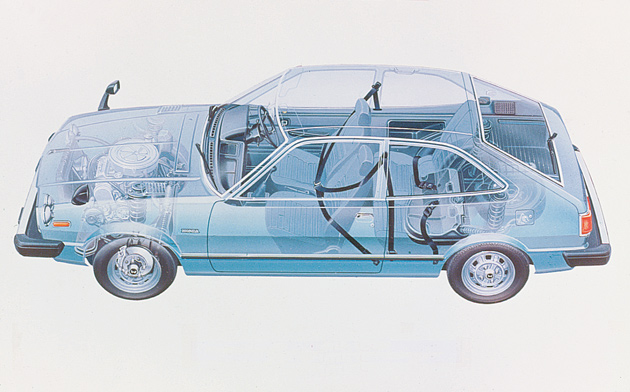

A perspective view of the first-generation, 3-door Accord. Based on the MM philosophy, the layout pursued greater interior space with minimized mechanical space.

However, at the time it was commonly assumed that ordinary cars were fitted with bias tires. Despite their superior performance radial tires were found only on a handful of sports cars. Moreover, they were relatively expensive and associated with reduced ride comfort. To eliminate these drawbacks, the team improved the radial design and created a new suspension mechanism featuring technical advancements obtained through Honda's previous model developments, including the upscale 653 project. It was through these efforts that they secured the levels of comfort and fuel economy commensurate with their design goals.

For the transmission, the team went against the mainstream four-speed, opting for a five-speed with four forward gears and overdrive. The overdrive system, which lowered the engine's r.p.m., helped reduce noise and increase fuel economy. They knew this type of transmission was essential in order for the car to succeed in the U.S., where consumers were at the time placing greater emphasis on fuel economy than speed or power.

The engine displacement was set at 1600 cc, which was the usual specification for upscale compact Japanese cars. However, the team faced enormous difficulties in the process of modifying the Civic CVCC's 1500 cc EM engine. Originally, the EM engine was developed as a 1000 cc unit but was subsequently brought up to the 1500 cc level. To further enhance it to a 1600 cc engine, while ensuring the company's ability to manufacture it using the Civic's production facilities, the piston stroke had to be increased to 93 mm. With its super-long stroke the engine could not maintain quiet operation at high rev ranges, because the engine itself caused significantly more vibration than had been anticipated.

Accordingly, Kizawa asked the management to allow the team to develop a new engine. To his surprise, though, the management team beseeched him to come up with a specification based on the EM engine in order to reduce the amount of investment. Left with no alternative, the team did its utmost to enhance the engine while carrying out thorough reviews on the engine mounts and rigidity of the frame. Finally, the team was able to say it would be feasible for Honda to mass-produce the new car.

"Everyone was concentrating on creating a car that felt good to drive in every respect," Kizawa recalled.

To ensure the car's adaptability to various destination environments, a broad scope of local adaptability tests were carried out. While the Civic also was subjected to similar local tests - performed on-site using test cars shipped from Japan - with the 671, a dedicated test team was organized in order to carry out full-scale testing over an extended period of time. In the arctic regions of Alaska, the team experienced an unexpected incident when the engine belt broke due to the extreme cold of minus 48 degrees centigrade. In Arizona, the team camped out for three months while it carried out extensive durability tests. In Death Valley, California, they thoroughly tested heat resistance, air-conditioning performance, and other functions under heat reaching 50 degrees centigrade extremes.

"By going to these locations and conducting tests there," said Keiichi Mitobe, who was in charge of suspension design as PL, "we experienced many things we wouldn't have otherwise. That meant that we were able to prepare sufficient countermeasures (to the problems identified during the tests)."

"The Steering Feels Heavy" - A Comment Leads to Power Steering

At the S•E•D joint meeting and plan review, several components were identified in order to ensure comfortable cruising through enhanced interior convenience. This comfort equipment included an air conditioner integrated with the instrument panel, tailgate opener, decor-matched interior colors, and power steering. The team worked to minimize the cost of such equipment while maximizing its user-friendliness. The challenge was to think of these things from the users' perspective.

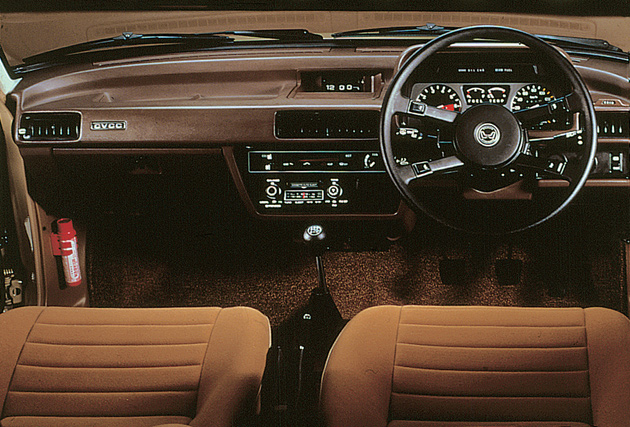

The driver's seat was designed for maximum comfort. The equipment included power steering and a 5-speed transmission.

In those days, air conditioners were commonly known in Japan as "coolers," a term that generally referred to a dedicated cooling device suspended from the instrument panel, separate from the heater. However, by integrating the air conditioner with the instrument panel, subtle temperature adjustments for heating and cooling would become possible. This integrated air conditioner offering a full range of functions was the first of its kind for a car of this class.

At the time, tailgate openers were found only on luxury cars. What prompted the team to install it on the 671 was the complaint a team member heard from a caddie at a golf course: "With a small car, you can't remove a golf bag without asking the customer to open the trunk with his key." However, the openers found on luxury models were electromagnetic, so they were fairly expensive to produce. To lower the cost, the team thought of applying the wire mechanism used for hood openers. They quickly built a prototype and tested it, verifying its smoothness of operation during opening and closing. Contrary to their early expectations, no heaviness was felt during operation because of complex wire routing. Pleased with the results, the team decided to use the wire-type opener, succeeding in furnishing the car with a tailgate opener, and an economical one at that.

Interior colors were rarely a consideration among car models available at that time. With the 671, though, consideration was given to this element of color coordination. After all, if the new car was to appeal to customers upgrading from the Civic, where the design elements were downplayed in favor of utility, the exposed surfaces of painted steel along the pillars and doors would have to be covered. Even the seatbelts, which were black in the Civic, would employ colors that matched the interior tones.

The instrument panel was another area of consideration, where the "cockpit" layout, known to generate a feeling of confinement, was abandoned. Instead, a more open, tray-type design (championed by the Civic) was adopted in order to enhance driver comfort.

As for power steering, which was still limited to large, luxury cars, the team studied its use following a comment by Soichiro Honda during a visit to Wako R&D Center that the steering felt "heavy."

The installation of power steering, however, turned out to be extremely difficult. Although a new power-steering system linked to vehicle speed had recently been developed at Honda R&D during the advance research process, the company had not designed a mass production car with a hydraulically controlled system or power steering. Naturally, there were concerns that the system would be prone to failure. There were also comments that power steering was unnecessary in a small car. Even members of the development staff were polarized by this issue.

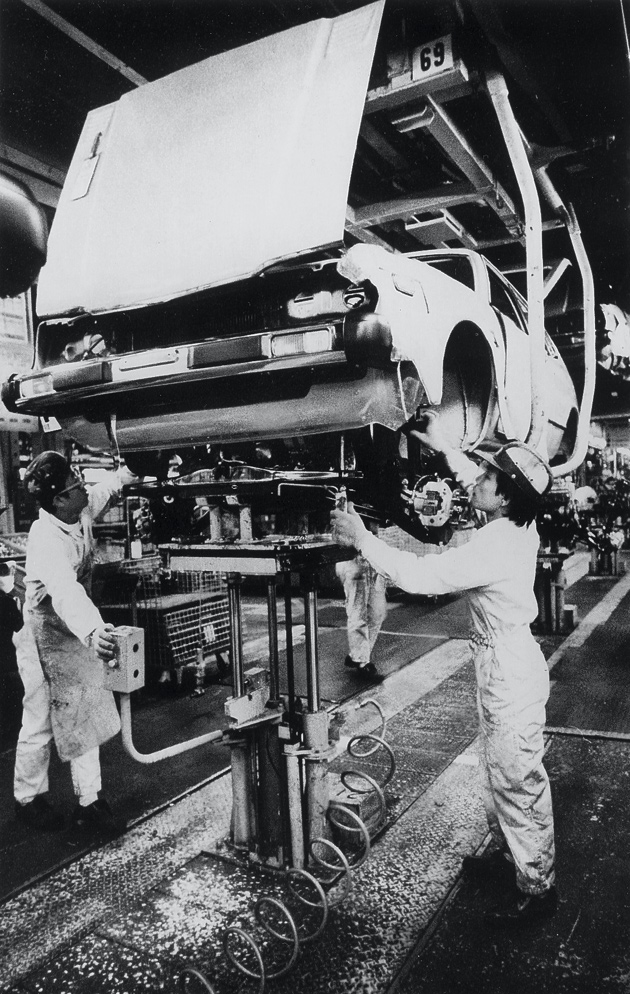

The Accord assembly line at Saitama Factory's Sayama Plant. The installation process of the engine was designed to ensure a better work environment and optimize efficiency.

"I was doubtful whether we should use power steering in a small car," said Kizawa. "But when I actually drove a car fitted with it, I was very impressed with the control it offered. In an FF car with a heavy front end, the power steering definitely improved handling. So, following the test drive I was convinced that power steering was an absolute must."

Having managed to obtain an agreement among the associated departments, Kizawa and his colleagues began developing their specifications for mass production. As development progressed, the initial concerns over quality gradually subsided. The relentless effort by the team had made them confident that the system would be very high in quality.

The Ministry of Transport laid down an unexpected roadblock, however, when it declined Honda's application for certification of the new model. Citing the danger of the power steering in a small car, it was claimed that such a system would lighten the steering beyond an acceptable degree. Kizawa visited officials at the Ministry of Transport in the hope of allaying their fears. When he could not convince them, though, he opted to set up a test drive on the test course of the Japan Automobile Research Institute located in Yatabe, Ibaragi Prefecture. The manager of the Examination Department at the Ministry was invited to this test.

"Once he test-drove the car," Kizawa recalled, "the manager was confident in its performance. He gave us the go-ahead right away, without driving even 100 meters."

Immediately upon its release, the Accord was very well received in Japan and overseas. It would be no exaggeration to say that a key reason behind it was this speed-sensitive power-steering system, which was a first for a car in that size category.

The 671 was introduced as a family of four models representing different grades: namely, the SL, GL, LX, and EX. Radial tires and a five-speed transmission were featured in the LX and EX luxury models, while power steering was found in the EX. Air conditioning was optional.

A new benchmark had been set for the auto industry in Japan, and consequently, more compact car lines began offering the power steering, air conditioner and other creature comforts made popular by the Accord. Today, these features are found even on mini cars.

After the Civic - The Next Big Thing

The completed 671, designed as a high-class cousin of the Civic, was named "Accord." True to its meaning of "harmony and agreement," it fully represented the concept of this new adult car. Moreover, it made an original statement, aspiring to please the driver and passengers while fostering a new state of harmony between car and society.

The first Accord model with a novel 3-door hatchback design hit the Japanese market in May 1976. At an invitational test-drive held in Hakone, automotive journalists raved about virtually every aspect of the car, from design, interior comfort, and user-friendliness to its ride comfort and quiet operation. The Accord's fundamental concept, too, found immediate acceptance in the market. The car was truly a major hit, establishing some amazing records.

The monthly sales target for Japan, which was initially set at 4,000 units, was doubled to 8,000 units within just three months of the Accord's release. Accordingly, the production volume at Saitama Factory's Sayama Plant was substantially re-outfitted so that eventually its 8,000-unit monthly goal was adjusted to 11,500. Yet, despite the increase in production, public demand continued to exceed the planned production and sales volumes by a considerable margin. Consequently, domestic sales during the first year, over a nominal six-month period, reached 53,752 units.

The Accord had provided an eager market with a combination of concept, specifications, and equipment simply not found in previous compact models. As a result, the Accord was awarded the 1976 Japan Car of the Year Award by Motor Fan magazine.

The Accord's stunning popularity was boosted even further with the introduction of the four-door sedan introduced in October 1977. That year, the Accord line of three- and four-door models sold 83,941 units.

The Accord four-door sedan attracted the gaze of visitors at the 22nd Tokyo Motor Show, held in 1977.

Honda premiered its new 1800 cc model in September 1978, featuring a few minor improvements, and with that, the Accord's domestic sales volume grew again, reaching a one-year total of 94,986 units. Thanks to the Accord, an industry newcomer was able to consolidate its foothold in Japan's compact-car segment.

In a move designed to cultivate a market in the U.S., Honda began exporting the three-door hatchback in May 1976, right after the car's introduction in Japan. That year, the Accord sold 18,643 units in the U.S. Sales volume experienced dramatic growth the following year, with sales totaling 75,995 units.

"When we brought the Accord evaluation car to American Honda (AH)," Kizawa said, "Mr. Munekuni [in charge of sales as corporate director of AH] and the engineering staff raved about the car, saying it would be the next big thing after the Civic." However, the plan to export the four-door version had to be postponed following a decision at the evaluation meeting that the 1600 cc engine was not powerful enough for American four-door sedan buyers. Subsequently, a new model was developed, providing better dynamic performance with increased displacement of 1800 cc. Honda began exporting the upgraded sedan in September 1978, winning considerable praise from U.S. customers. As a result, combined sales of three- and four-door Accords grew rapidly, reaching 120,841 units in 1978.

The Accord thus began its evolution as the standard compact car for the American market. In fact, it was soon so popular that people did not really mind having to pay a little extra for it. Thanks to the Accord's success, Honda's market grew steadily in the U.S., and the company cemented its position overseas as a premier auto manufacturer.

A Mainstay Model for the Times

The Honda Accord - first introduced in 1976 as a three-door hatchback - has, in the intervening 23 years, produced a series of six outstanding model generations. The key theme in its development, however, has always been the same; to ensure harmony between the car and society.

The second-generation Accord family introduced in September 1981 incorporated model changes reflecting Honda's shift in emphasis toward the 4-door sedan. This was because the first-generation 4-door model had, upon its market introduction, received high marks comparable to those of the preceding 3-door model. Although sales growth had been a bit more gradual, the sedan was demonstrating steadily increasing sales. In fact, it was already outselling the hatchback. Therefore, the decision was made in view of these figures, proving that the Accord had established its position in the 4-door market both in Japan, as well as the U.S.

The Vigor 4-door sedan was introduced to the Japanese market as a sister model upon the release of the second-generation Accord. Moreover, the release of these new models was timed to the introduction of Honda's new three-channel sales system. Subsequently, the third-generation Accord was introduced in 1985, and here, the new three-door Aerodeck with extended roofline was added for sale in Japan and Europe, rather than the familiar 3-door hatchback. The fourth generation released in 1989 saw a further expansion in the model line, with the Accord Inspire, Vigor, and Ascot debuting together. The expanded variations were in line with increasingly diverse and sophisticated market needs.

In the early 1980s Honda had moved to localize production in the U.S., in keeping with the philosophy of "building products in the markets where they are sold." Subsequently, Honda of America Manufacturing (HAM) turned out the first locally made second-generation Accord in November 1982. In fact, this was the first car Honda produced in the U.S.

Along with production, Honda also promoted the localization of research and development activities by reorganizing the R&D branch in California and establishing Honda Research of America, Inc. (HRA) in September of the following year. The Accord two-door coupe, for which production began at HAM in 1988, became the company's first locally developed model, with the entire design process performed by HRA. Following the two-door coupe, Honda developed a five-door Accord wagon in 1991 - again through the efforts of HRA - thus extending the Accord family in the U.S.

Honda began exporting the HAM-manufactured Accord Coupe to Japan in 1988. As the first Japanese nameplate U.S.-made car imported to Japan, the move was reported in a sensational manner by the world's media. In the first year alone, more than 10,000 U.S.-made Accords were imported and sold in Japan. The U.S.-version Accord wagon, which began importing to Japan in April 1991, also became a popular model, due in part to the new RV (recreational vehicle) boom in Japan. Accordingly, sales of the wagon variant far exceeded the initial target of 5,000 units per month.

In Europe, Honda of the UK Manufacturing (HUM) in Britain began producing the European-version four-door Accord sedan in November 1991, while in Asian Oceania, Honda was already conducting knockdown assembly production in several countries. This was a process begun in Indonesia in 1978. Through such efforts, Honda was truly achieving worldwide production.

The birth of the sixth-generation Accord family was celebrated in September 1997 via the simultaneous launch of local-specification Accord models designed exclusively for Japan, the Americas, Europe, and the Asia Oceania. Honda had been working to establish a system in which it could more effectively tailor products to the needs of customers in various regions, based on an original "Global Flexible Platform*1." The company's strategic move, highlighted by the launch of these new Accords, signaled the arrival of an automotive production system that was driven by autonomous regional operations. It was the very type of system that Honda had been promoting under its four-polar global operations system.

The history of Accord engines is equally noteworthy. In 1985, Honda replaced the conventional CVCC engine with new SOHC and DOHC (single overhead and dual overhead cam) engines having displacements of 1800 cc and 2000 cc, respectively. Adopting electronic engine management and a three-way catalyst, the new powerplants offered significantly better performance. In 1989, a 2200 cc SOHC unit was added to the series. Further expansion came in 1993, when the VTEC engine was introduced. In 1997, Honda introduced the low emission vehicle (LEV) specification, which offered the benefit of reduced environmental impact. In all, the evolution of Honda's Accord engines reflects a continuing effort to respond to the needs of the times.

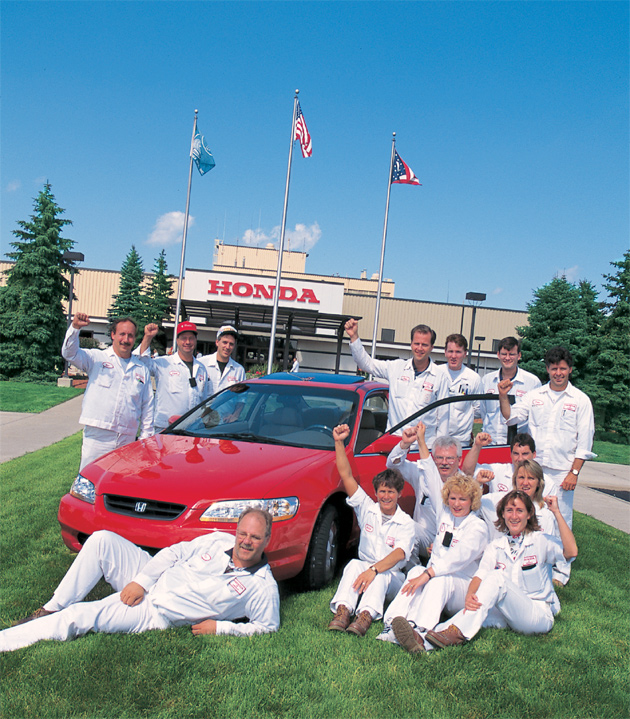

The promotion of four-polar global operations saw the simultaneous 1997 launch of Accords produced to local specifications. In the picture, associates at HAM surround the new Accord coupe, which was launched mainly through the efforts of Honda's American operations.

In June 1998, Honda's President Kawamoto visited 10 Downing Street, the official residence of British Prime Minister Tony Blair. He introduced the new European-version Accord (manufactured by HUM) to Prime Minister Blair (right) and Trade and Industry Minister Beckett.

The Accord model line has, through its various generations, demonstrated a constant process of evolution; a process of refinement reflected in model lines, engines and displacements, comfort equipment and more. These elements, all of which were developed in keeping with the times, have contributed to the realization of the Accord's unique identity. Ultimately, it is a car that inspires a state of harmony between the driver and the surrounding world. This evolutionary theme has earned high recognition in every market region.

Note:

*1 Global Flexible Platform refers to a base frame that forms the foundation of the car. It ensures a high level of rigidity while being flexible enough to adjust efficiently to different vehicle sizes. The term also indicates the use of this frame as a basis for producing cars with optimal body dimensions and vehicle shapes, thus meeting the needs of different regions.

A Car that Maintains Trust

The Accord has received high honors on three occasions in Japan. After winning the 1976 Car of the Year award, the Accord was named the Japan Car of the Year for the 1985/86 period and again for the 1993/94 period (both given by the Japan Car of the Year Executive Committee). In contrast, domestic sales continued to decline after reaching the all-time high of 94,986 units in 1978. Sales for 1998 ended at 59,040 units. One reason behind the shrinking sales is the growing popularity of RVs in the domestic market, a presence that has eroded the sedan market.

Nevertheless, the Accord has received consistently high marks overseas. For example, it won the 1977 Car of the Year Award in the under-$5,000 category from Road Test and Car & Driver magazines. The Accord has also been a favorite of Car & Driver in its Ten Best awards, which began in 1983. Including its 1998 selection, the Accord has received twelve top awards in sixteen years.

As for its sales history in the U.S., the Accord has consistently sold in the neighborhood of 400,000 units, annually, since its 1976 release. The car sold 18,643 units in its initial year, hitting an all-time high of 417,179 units in 1990. Cumulative sales volume over the 23-year period is approximately 6.47 million units. The Accord even outpaced the Ford Taurus to become the top-selling model in sales volume (passenger-car category) for three years in a row, beginning in 1989. Moreover, the Accord has been routinely named among the top performers in various car rankings.

Today, the Accord is produced at factories in twelve countries and sold in more than 140 countries around the world. At the end of 1998, cumulative production volume exceeded 10.22 million units worldwide. This remarkable achievement only proves that the Accord is more than a world-class car. It has become a world standard: A car that is accepted, trusted and loved by drivers around the world.

"One thing that we must remember with the Accord," said Kizawa, who oversaw the car's development, "is that when developing a new model the engineers must thoroughly understand the vernacular of the times and the market in which they are selling. It is important that they do not indulge in development for the sake of self-satisfaction.

"Another important aspect is that future model generations must remain first-class. By that, I mean a car that satisfies the expectations of the person who purchases it. I don't think any car that fails to satisfy those expectations will ever sell successfully. In that sense, the Accord must remain a car that satisfies those expectations to the greatest possible degree."

Accord owners around the world are an important asset to Honda. Therefore, it is the task of future Accord offspring to maintain that asset while continuing to evolve in response to changing customer expectations and maintaining harmony with the times.