2.Starting and Expanding Automobile Business

Evolving Sales Based on the Sales Methods

Cultivated in Japan

In its 10th year of operation, AHM undertook automobile sales in the U.S. It began sales of the N600 first in Hawaii in December 1969 and then expanded the sales to the mainland U.S. in May 1970.

Leveraging the motorcycle dealer network it had established by then, AHM began expanding the N600 sales area from three western states, namely California, Washington and Oregon. However, in the U.S., where the foundation of the automobile market was already well established by that time, people had a strong belief that automobiles should be purchased at automobile dealers, which made Honda automobile sales activities an uphill battle.

Gaining momentum from the introduction of the Civic in the U.S. market in 1973, AH began reaching out to automobile dealers to cultivate its own network of dealers who specialized in automobile sales.

AHM sales staff explained Honda’s corporate philosophy and activities to prospective dealers, but most dealers did not take it seriously and said, “We were born and grew up in this country, so we know the market and customers in this country more than anybody.” Many of them didn’t even want to put the Civic on display at their stores. Back then, large-size models had been the mainstream in the U.S. automobile market, and people had the perception that “bigger is better” in terms of the value of automobiles. In such a market, the concept of Honda's small cars, which emphasized a low price and low fuel consumption, was met with strong resistance.

Each member of the AHM automobile sales team had multiple states assigned as their respective territory and made personal visits to each of the automobile dealers within that territory, one by one. As a result of such diligent efforts, the number of dealers who agreed to add the Civic to their lineup gradually increased. That said, the small, low-priced Civic was positioned at the bottom of the dealers’ product lineup, and thus put in a corner of the outdoor display area, or in the area for used cars.

However, the turning point in AHM’s auto sales came rather unexpectedly. It was the first oil crisis that shook the world starting in fall 1973 through the following year, which dealt a serious blow to the U.S. automobile industry and forced a shift in people’s values. American consumers who formerly aspired to own large, luxurious cars began placing value on practicality, including fuel efficiency.

Honda also had the right timing with the launch of the Civic equipped with the CVCC engine, the world’s first engine that met the stringent emissions requirements of the U.S. Clean Air Act of 1970 (the Muskie Act).

Thanks to the lean combustion achieved by the CVCC engine, the Civic was not only low-polluting, but also highly fuel-efficient, rated by the U.S. Environmental Protection Agency (EPA) as the most fuel-efficient vehicle in the U.S. in 1974.

Honda successfully increased Civic sales by communicating the vehicle’s excellence in driving performance, in addition to being the best in the U.S. in terms of emissions and fuel economy. The Civic gained popularity and found its place in the U.S. where there had been no market for small cars.

As was the case with the sales of the Honda 50, the Honda spirit learned from Fujisawa – “If there is no demand, we will create it” – was applied to the startup of automobile sales in the U.S.

Civic (1974) equipped with CVCC engine that passed the U.S. Clean Air Act of 1970.

Earning Trust: The First Step Toward the Emergence of

Exclusive Honda Car Dealers

Even with the success of the Civic CVCC, which featured the world's first low-emission, fuel-efficient technologies, AHM associates were not complacent. Instead, they decided to go back to basics in their sales activities. AHM associates believed that even if their products gain market attention, it might be temporary. Unless the dealers truly understand and can relate to Honda's corporate activities, they would not be willing to sell Honda products on a long-term basis.

Based on this belief, with the help of J.D. Power & Associates, a market research firm, AHM began conducting an annual customer satisfaction survey in 1976. The survey staff visited each and every customer who had purchased a Civic at every automobile dealer that had a sales contract with AHM and collected customer opinions and requests related to their purchases, including the product concept and quality of the Civic, as well as their experience with the dealership where they purchased their Civic.

Customer opinions regarding the product concept and quality were fed back to the R&D Center and production facility, respectively. In the meantime, customer opinions and requests to the dealers were quantified for each individual store, and the AHM automobile sales team members visited each and every store one by one to share the data with the owners. Initially, however, many owners were not so easily convinced of the survey results. Still, the Honda sales staff continued going around to each store and explained, “This is not what I am saying. This is the voice of your customers.” Through these visits, AHM staff and each dealership owner discussed the various improvement measures to be taken before the next year's survey and developed implementation plans.

Based on the experience of working together with the AHM team to improve their sales operations and services, the dealership owners came to put great trust in Honda. Some of them began setting up a dedicated showroom for Honda automobile products and putting more effort into enhancing their services. This trend among automobile dealers eventually led to the emergence of dedicated dealerships that exclusively sold Honda vehicles.

The customer satisfaction (CS) activities that Honda currently conducts all around the world have evolved and expanded from these diligent efforts made by AHM sales team members at the time.

3.Motorcycle, Automobile and Power Products

Starting Local Production in the U.S.

The Company Becomes an Integral Part of Society

Only When its Production Takes Root in the

Local Community

Panoramic view of HAM’s Ohio Marysville plant. The motorcycle plant in the foreground began operations in 1979. The automobile plant is in the back.

In August 1971, the U.S. government announced a new monetary policy in an effort to protect the dollar, which eventually led to a shift from the fixed exchange rate system to a floating exchange rate system. After the announcement, the yen was substantially revaluated, and the Japanese stock market experienced a significant crash. These events posed quite a shock to Honda whose export ratio as a proportion of total sales revenue was reaching 60%, especially with high dependency on exports to the U.S.

Striving to build a corporate structure that would enable more flexibility in dealing with the rapidly changing business environment, in April 1972, Honda launched a company-wide initiative called the “New Honda Plan (NHP).” The NHP consisted of a series of organized activities which were designed to build a total system that would enable Honda to anticipate issues that could happen in the future and take initiatives to prevent such issues before they occur, rather than merely solving issues at hand.

The “Global Production Strategy” was one of the projects discussed and pursued under the NHP. The leader of this project, Kiyoshi Kawashima, then Senior Managing Director, was entrusted by the company founders, Messrs. Honda and Fujisawa, and assumed responsibility as the president of Honda in October 1973. Almost simultaneously, the first oil crisis occurred, spurred by the fourth Middle East War (Yom Kippur War). For Honda, this crisis served as a catalyst for the decentralization of production operations and further internationalization, which would ensure that Honda could secure a stable supply of products regardless of changes in global dynamics.

As represented by “The Three Joys (The Joy of Buying, The Joy of Selling, The Joy of Creating),” which is a part of the Honda Fundamental Beliefs, Honda had a long-standing policy to “building products close to the customer.” In doing so, Honda would contribute to the local communities and their economies by expanding employment opportunities and by paying taxes. Based on these beliefs, Honda began exploring the possibility of realizing local production of motorcycles in the U.S., Honda's largest market in the world.

In fall 1974, under the leadership of Kawashima, the feasibility study for motorcycle production in the U.S. was conducted. The study results highlighted two major concerns: one was profitability, and the other was whether product quality equivalent to that of Japan-made motorcycles could be consistently achieved with local production in the U.S. Due to such concerns, the pursuit of local production in the U.S. was put on hold for the time being.

However, Kawashima knew, “There is no way that one-way exports would last forever. If we only pursue profits, we will never be able to make the decision.” So, he was carefully monitoring the situation and waiting for the right time to make the decision.

The Civic CVCC, which was rated by the EPA as the most fuel efficient vehicle in the U.S. in 1974, was showing strong sales momentum in the U.S. Due to strong sales in Japan and a steady increase in exports to the U.S. and other countries, Civic production at Suzuka and Saitama factories began experiencing capacity constraints. The Board of Directors discussed a proposal to expand the production capacity of Suzuka Factory by adding a second automobile production line. However, Kawashima was not enthusiastic about that proposal.

Kawashima was thinking: “Although the Civic is selling well right now, we must consider that it is currently impossible for Honda to quickly strengthen domestic sales in Japan to match the expansion of production volume. We must also consider burdens related to the addition of a new production line. Honda’s automobile business is finally starting to emerge thanks to the Civic, but I have no confidence that we can outrival the competitors in Japan who have been ahead of us in every aspect including sales capability and financial strength. Moreover, I have concerns in the areas of quality control and cost management as well.”

After due consideration, Kawashima came to the conclusion: “I want to seize this opportunity to build a motorcycle factory in the U.S., and ultimately build an automobile factory there. I want Honda to compete in the U.S., the world's largest automotive market.” Based on this determination, Kawashima gave instructions to resume discussions toward local production in the U.S.

The previous study concluded that it would be difficult for a Honda factory in the U.S. to become commercially viable by producing only motorcycles. However, Kawashima suggested, “Now that Civic sales got off the ground in the U.S., can’t we reconsider the possibility?” Thus, in November 1975, a study group was formed to explore the possibility of local automobile production in the U.S.

One of the members of the study group was in charge of negotiating the sale of CVCC engine units with Ford. During an in-person meeting with the president of Ford, Lee Iacocca, the member revealed the fact that Honda has been conducting surveys and exploring the possibilities toward local automobile production in the U.S. and requested the opportunity for a factory tour at Ford. Iacocca promptly introduced him to Ford’s vice president in charge of production and the factory tour was arranged on the same day.

On the way back from the meeting and the tour of the highest rated factories among all Ford factories, the study group members came round to thinking that local production in the U.S. could be viable for Honda by using the latest manufacturing technologies developed by Honda Engineering (EG)*2 including technologies that would shorten the stamping process and the welding machines and robots that would enable significant consolidation of welding processes. His logic was that services at hotels and restaurants in the U.S. were highly sophisticated; therefore, the poor production quality of automobiles would not be an issue with the people working at the factory. Most issues related to poor quality were caused by a lack of motivation among workers, which stemmed from the issues of operational structures, and automobile factories would not be an exception.

In addition to cost viability, it was critical to ensure quality equivalent to that of Japanese-made vehicles.

Although Honda had narrowed down the final candidate state to Ohio, none of the sites listed by the research firm or that Honda found on its own seemed suitable. Therefore, as a last resort, the study group decided to request the direct involvement of the Ohio state government in the selection process. The state staff members took the Honda study group associates on a tour of an industrial park in a suburban area, and the group made a stop at the Transportation Research Center (TRC), a full-scale and comprehensive testing facility managed by the state.

Witnessing the dedication of the young test riders working at the center and the vast adjacent flatland introduced by the TRC staff, the study group members felt intuitively that they should look into this surrounding area. After reevaluating several more candidate sites, the team members reached consensus to choose the site adjacent to the TRC.

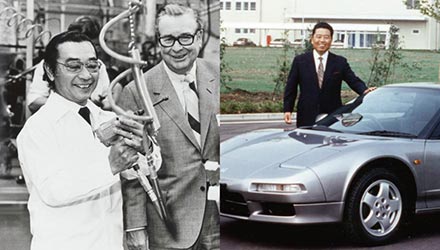

Ground breaking ceremony for the HAM automobile plant. Ohio Governor at the time with second Global CEO Kiyoshi Kawashima

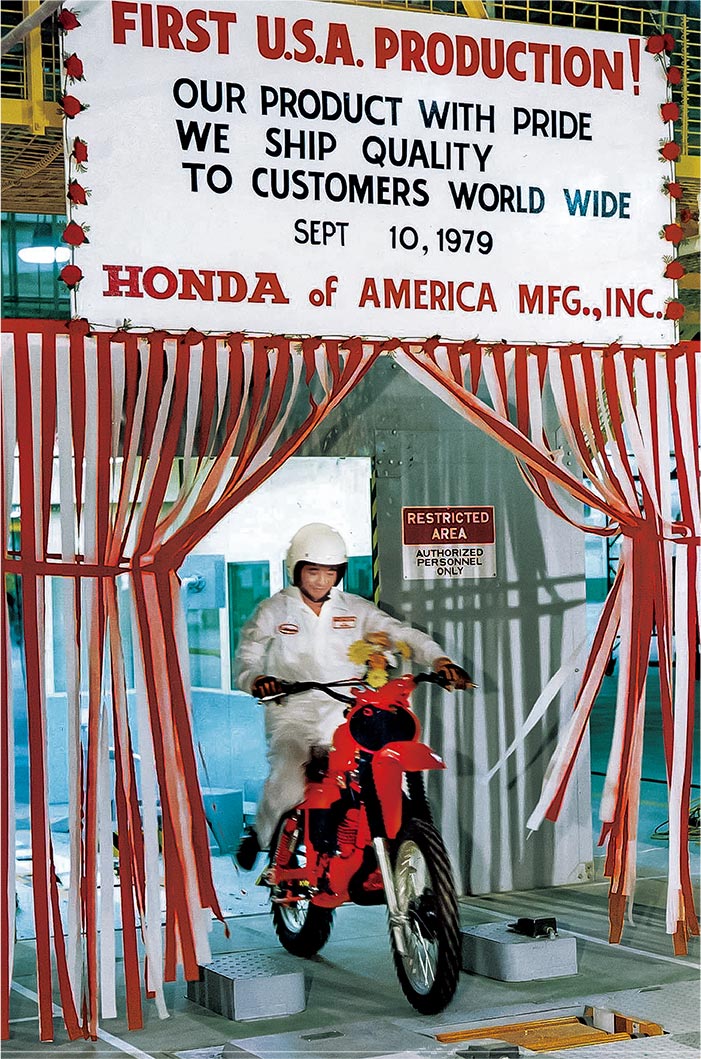

The first CR250R motorcycle produced at HAM rolls off the line in 1979.

Thus, in 1978, Honda of America Mfg. (HAM) was established. HAM started off with a small-scale motorcycle plant and began producing the CR250R, a motocross-type motorcycle model with a relatively smaller number of components. Then, HAM matured its production system and capability step by step, reaching the point where it was ready to begin production of the large-size and more complex Gold Wing GL1100.

At HAM, it was decided that no one working at HAM would be called an employee or a “worker,” which was the common terminology in the U.S. at that time. Instead, HAM employees were called “associates,” emphasizing the idea that they were members of a team working together to achieve a common goal. Even now, this approach remains unchanged and has been one of Honda’s distinctive approaches.

-

Honda Engineering Co., Ltd. (EG) was established in 1974 by consolidating the Honda Machinery and the Production Engineering Division of Honda Motor Co., Ltd. (HM) to play a role in researching and developing production technologies to ensure competitiveness of Honda's manufacturing.

In 2020, some functions in the area of research and development of production technologies were transferred from EG and Honda R&D Co., Ltd. After consolidating its functions of automobile production technology development and equipment manufacturing functions into HM’s Automobile Operations, EG merged with HM.

The first associate at the Ohio plant where the first car was produced.

The Dream of Building Automobiles in the U.S.

In January 1980, Honda announced its plan to build an automobile plant adjacent to HAM's motorcycle plant and thus become the first Japanese automaker to produce passenger vehicles in America.

This announcement brought a breath of fresh air amid a situation where the continuous increase of imports of Japan-made automobiles to the U.S., was being blamed as the core of U.S.-Japan trade conflict issues. Thus, the governments of both countries welcomed Honda’s decision. Moreover, the fact that Honda had voluntarily worked out a plan to produce passenger cars locally in the U.S., even before the onset of trade friction issues, was highly praised by many people including members of the media.

In December 1980, Honda began construction of its first automobile production plant in the U.S. This was when Honda evolved its startup dream of “becoming Japan's best exporting manufacturer” into a new dream of “becoming a member of the local community."

In order to demonstrate its intention to build a plant which would set down deep roots in the U.S. society, Honda proactively adopted production equipment built by local companies, and set a basic policy to build its automobiles using locally sourced raw materials such as sheet steel, plastic and paint. In light of the differences between Japanese and U.S. quality standards at the time, the use of locally procured materials carried significant risk and thus was a challenging initiative. Once people developed a negative perception toward a certain brand due to low product quality, it would be difficult to dispel such an image. Therefore, no mistakes in the area of product quality would be tolerated.

Approximately 300 experts and veteran engineers were sent to the U.S. from the Sayama Plant of Saitama Factory, which served as the mother plant*3 that supported the startup of HAM auto production. In addition, some local Honda associates who had experience in HAM’s motorcycle production were transferred to the auto plant, and they demonstrated leadership as the core of the newly hired associates. The mass production trial was also conducted at a rapid pace, leading to a smooth startup of mass production at the new plant.

On November 1, 1982, the first unit of Accord rolled off the production line. HAM started off its auto production while placing the first priority on quality, and gradually increasing the production volume, which put it on track for full-scale production.

The first Accord, the first locally produced vehicle in the U.S. by a Japanese automaker, rolls off the line.

In April 1986, the second production line became operational, and HAM auto production moved on to a new stage with annual production volume of 300,000 units. Moreover, AHM began exporting some of the products made at HAM to various countries around the world, including Japan.

“If we had failed in the U.S. market, Honda would have lost its biggest market, that would have put Honda in a disastrous situation. In that sense, I was thinking that Ohio would be Honda's lifeline,” said Kawashima, then the president of Honda.

Kawashima's words reached the ears of associates working at the spot and became a driving force that inspired them to persevere to achieve their goal by overcoming any difficulties and hardships.

In June 2009, based on the decision to focus HAM on automobile production, the last unit of Gold Wing rolled off the line at the Marysville Motorcycle Plant, concluding HAM’s history of motorcycle production that spanned 30 years.

- The mother plant supports local Honda plants in other regions as needed.

Starting Automobile Production in Canada

Honda of Canada Manufacturing automobile plant

In order to secure a stable supply of automobile products for the Canadian market, which was growing into the second largest market after the U.S., it became essential for Honda to have an auto plant in Canada.

In June 1984, Honda announced the establishment of Honda of Canada Mfg. (HCM), the second auto plant in North America, which began production of the Accord in November 1986. Then, in 1998, HCM carried out the so-called “Maple Project” – constructing a new building to establish a second production line and start mass production of the North American version of Odyssey. This expansion solidified HCM’s foothold as an important production operation in North America.

Odyssey (North American specifications, 2002 model)

Establishment of HPE, Production of

Honda Power Products in the U.S.

HPE exterior (1987)

Mower line off at HPE North Carolina plant

Mower line off at HPE North Carolina plant

For Honda, the U.S. also has been the largest market for its power products. In particular, the U.S. was a huge market for lawnmowers with annual industry-wide sales volume of approximately 5 million units in the early 1980s. Honda’s lawnmore sales in the U.S. started with models imported from Japan. However, as with motorcycles and automobiles, based on the Honda approach to “building products close to the customer,” Honda Power Equipment Mfg., Inc. (HPE) was established in the state of North Carolina in 1983.

Lawnmowers, then the best-selling power products in the U.S., were not an immediate success for Honda upon entering the market. Honda lawnmower products faced some performance issues in terms of how well they can mow different types of grass.

Different countries and regions had different types of grass used for lawns, and their speed of growth, hardness of stems, density and other characteristics varied depending on the type of grass. Therefore, in order to understand how people actually use lawnmowers in different places, Honda formed a working group consisting of associates from the R&D center, factories and divisions related to services and quality assurance. Since 1990, the working group started collecting customer opinions and complaints from each market and developed maps, with photographs and illustrations, which visualized how people use power equipment, including how people use lawnmowers to get their lawn cut nicely.

Unlike motorcycles and automobiles, it was rare for Honda associates to become regular users of most Honda power products; therefore, these maps served as a useful tool for those who were involved in the development, production, sales and service of Honda power products to understand how power products were actually used in the market.

This resulted in the design of products such as lawnmowers and trimmers being adapted to the needs of local customers and increased production of a variety of power equipment products bein produced in North Carolina.