Initiatives for Motorcycles

From the perspective of reducing environmental impact, we have undertaken efforts in motorcycles, including reducing material usage through lightweight design, adopting recycled materials, and designing structures with recyclability in mind.

In addition to using recycled materials such as iron and aluminum, which can reduce land alteration during raw material extraction and CO₂ emissions during material production, we are pursuing new initiatives by applying bio-based materials and recycled resins that contribute to reducing the extraction of fossil resources.

Application of Recycled Automobile Bumper Materials to Motorcycles (Circular Design, Circular Value Chain)

We have previously utilized recycled materials made from discarded bumpers of Honda vehicles collected from dealerships, applying them to undercovers and other parts of automobiles.

Through design optimization, we have successfully applied recycled bumper materials from automobiles—previously challenging to use in motorcycles—to components such as the luggage box of the NC series* sold in 2024.

This initiative leverages Honda’s distinctive strengths, including the diversity of our sales products and our established recovery scheme.

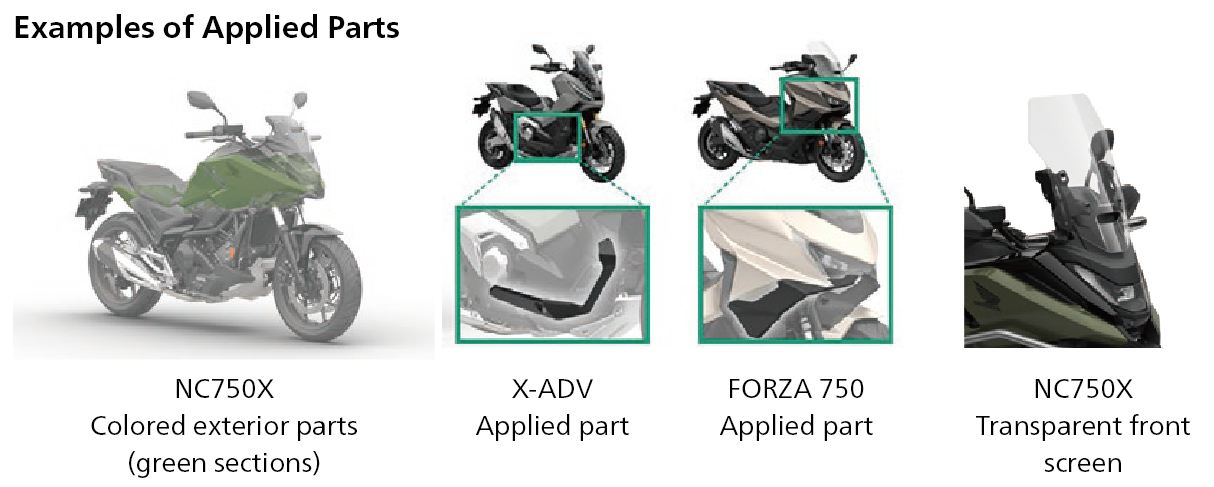

Applicable Models: NC750X, FORZA 750, X-ADV

Application of Pre-Consumer Recycled Materials to Products (Circular Design)

As part of our efforts to expand the use of recycled resins, we applied pre-consumer recycled polypropylene materials*1 to the exterior parts of the NC series sold in 2024.

Pre-consumer recycled materials, due to their known material properties, allow for physical property adjustments equivalent to virgin materials while mitigating the risk of regulatory chemical substance contamination.

We will continue to apply pre-consumer recycled materials to other models in the future.

- Pre-consumer recycled materials are derived from scraps generated during the manufacturing or molding processes of products such as automobiles and home appliances.

Application of Bio-Engineering Plastics to Products (Circular Design)

As part of our efforts to expand the use of the bio-engineering plastic “DURABIOTM”*2, we applied it to the colored exterior parts of the NC series sold in 2024, marking the first such application in motorcycles.

By using colored DURABIOTM with high aesthetic quality, painting becomes unnecessary, contributing to CO₂ reduction.

Additionally, following the world’s first*3 adoption of DURABIO for the transparent front screen of the CRF1100L Africa Twin, launched in March 2024, we expanded its application to the X-ADV (launched in Europe in September 2024), as well as the NC750X and XL750 TRANSALP, with plans to apply it to other models in the future.

- DURABIOTM is a registeredtrademark of Mitsubishi Chemical Corporation.

- Based on Honda’s research (as of October 2023).

Application of Recycled Aluminum Materials (Circular Design)

We have been applying small-diameter wheels, which are made from market scrap using the High-Pressure Die Casting (HPDC) method to compact models, such as scooters and Cubs in Vietnam, Thailand, Brazil, and China.

Meanwhile, large-diameter wheels, which had previously been difficult to apply due to technical challenges, have also begun to be applied to large models produced in Japan and released from 2024 onward.

With this application to large models, wheels made from recycled materials are now used across our entire product line, from compact to large models.

We plan to continue expanding the use of recycled aluminum wheels to global models in a phased manner.