Initiatives for Automobiles

For its automobiles, Honda has been promoting conventional 3R (reduce/reuse/ recycle) activities as well as ensuring proper processing when disposing of end-oflife products.

The Company will engage in new businesses and services such as horizontal recycling, repurposing, and refurbishing as part of its shift to a recycling-oriented business.

This section describes the resource circulation efforts related to new and used car sales.

Initiatives for Battery Lifetime Management Commercialization (Business Innovation)

For batteries installed in the “N-VANe:” light commercial EV released in 2024, Honda has launched an initiative to maximize battery value by upgrading battery monitoring functions and conducting lifetime management through conversion from on-board use to stationary use.

The battery monitoring function, which determines the state of deterioration of components and other factors, enables efficient use of resources and reduces the economic burden on automobile users.

Link to the news release | https://global.honda/en/newsroom/news/2023/c231012eng.html

Use of Sustainable Materials for Floor Carpet Mats (Circular Design, Circular Value Chain)

Starting in April 2024, Honda adopted a sustainable material, recycled PET material, for the floor carpet mats, a Honda genuine accessory for the N-VAN light vehicle. It is significantly lighter than conventional mats. The use of sustainable materials is an effort to consider recyclability after use and to contribute to a recycling-oriented society in the future. As of the fiscal year ended March 31, 2025, the application of this sustainable material has been expanded to three models: CR-V e: FCEV, N-BOX JOY, and N-VAN e:.

Expanded Use of Recycled Materials from Automobile Bumpers for Parts of New Vehicles (Circular Design)

For the “N-VAN e:” light EV released in 2024, Honda collected and crushed discarded bumpers from Honda vehicles, revitalized them as sustainable materials, and reused them as accessories for vehicle exteriors and other parts.

For the front grille parts, a technology was applied to randomly mix the bumper paint of past Honda models, leaving a rough finish, so that the pattern is unique and attractive.

Launch of Services Related to Refurbishing Used Cars (Business Innovation)

In September 2023, Honda’s Japanese used car business launched “Imakore+ (Plus),” a program to install new Honda genuine accessories to used cars.

In January 2024, Honda launched a new upgrade service for the ACCORD model in its North American used car business, a dealer-installed service that enables the wireless functionality of Apple CarPlay and Android Auto.

Such refurbishing programs for recovering and improving product value, adding new product value, and providing utilization services will lead customers to use up the products to the end, and increase opportunities to collect end-of-life vehicle products, thereby making more efficient use of resources.

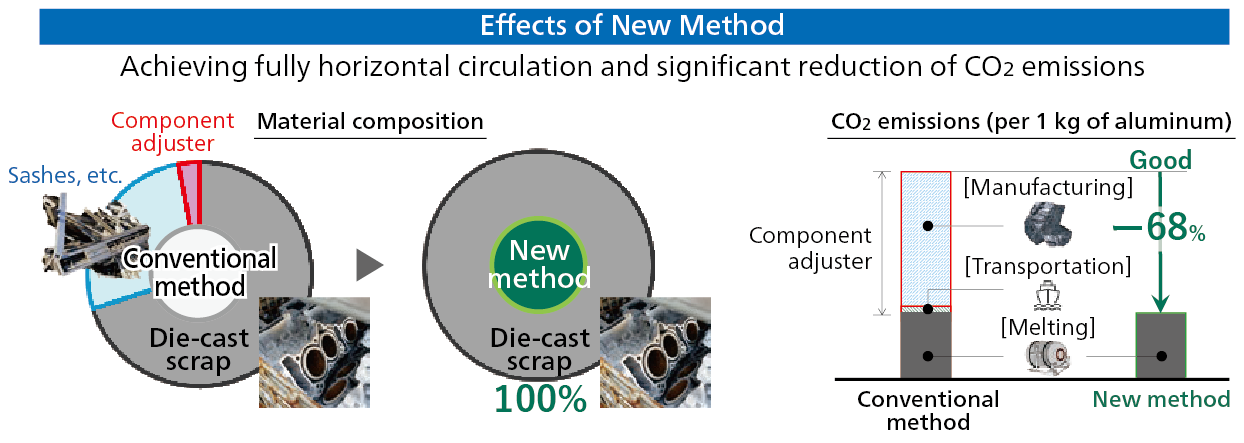

Initiatives to Restructure the Aluminum Circulation (Advanced Recycle)

Starting in November 2024, we initiated horizontal recycling of aluminum die-cast parts for engines at the Saitama Factory Engine Plant.

Since aluminum die-cast alloy scrap contains attached iron components, it was necessary to dilute the scrap with high-purity aluminum scrap to reduce the iron concentration in the alloy.

By developing a technology to remove iron components from molten aluminum alloy, we achieved 100% horizontal recycling of scrap of the same material (ADC12 series).

This has enabled us to reduce the use of high-purity aluminum scrap materials, leading to a reduction in CO₂ emissions and manufacturing costs.

This initiative not only promotes the horizontal recycling of low-grade scrap, but also provides an opportunity to review the utilization of high-grade scrap that has traditionally been used for cascade recycling. This is expected to lead to a higher level of resource recycling, as high-grade scrap is reused while maintaining its quality. Furthermore, we believe that this will provide an opportunity to reconsider the entire material flow of aluminum resources and contribute to the realization of a sustainable circular society.

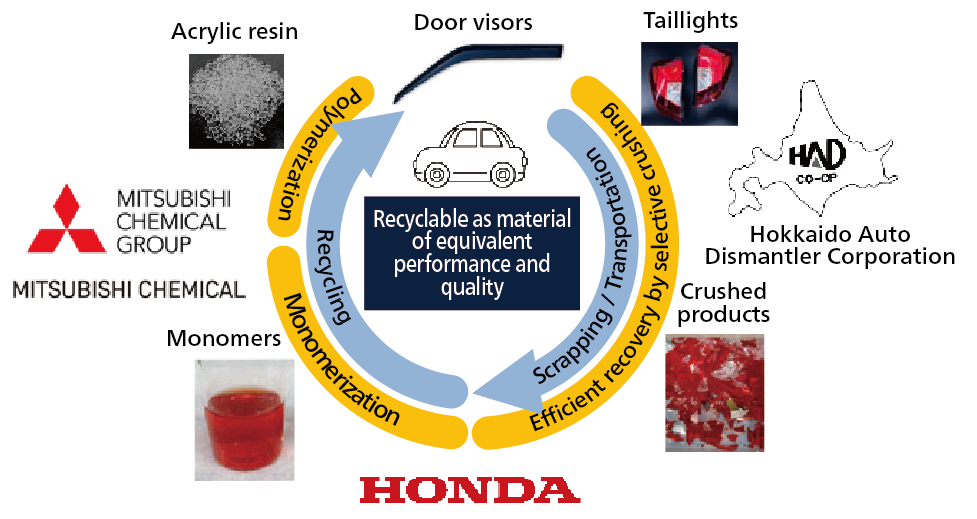

Mass Production of Horizontally Recycled Acrylic Resin from ELVs*1(Circular Value Chain, Advanced Recycle)

We will begin applying horizontally recycled door visors, which are made from acrylic resin recovered from ELVs, to its automobile products scheduled for launch in 2025.

Conventionally, the majority of resin derived from ELVs has been used for fuel and other purposes due to the technical challenges of sorting and recycling, and has not been recycled into products.

Honda, in collaboration with Hokkaido Auto Dismantler Corporation and Mitsubishi Chemical Corporation, conducted a demonstration experiment on the horizontal recycling of acrylic resin (from August 2021 to February 2022), establishing an efficient scheme for the entire operation.

Through this experiment, we developed a recovery method that prevents contamination by foreign materials and a regeneration technology equivalent to virgin materials, paving the way for the world’s first*2 mass production of horizontally recycled products.

This initiative will enable a reduction in the use of virgin materials and a 50% reduction in CO₂ emissions during the production and disposal of acrylic resin.

Moving forward, we will continue to research and develop advanced recycling technologies that support the creation of value chains and sustainable resource recycling to realize a circular society, and work with partner companies to implement these technologies in society.

- ELV: End of Life Vehicle

- Based on Honda’s research (as of April 2025)

Realizing Resource Circulation through Co-Creation with Customers

To realize resource circulation, Honda has been conducting activities to communicate and promote resource circulation at regional environmental events since the launch of N-VAN e: in October 2024, with the aim of promoting customer understanding and empathy for the initiative.

At the events, in addition to showcasing products to which sustainable materials are applied, we introduced services for product use based on resource circulation principles and our upcycling initiatives that effectively utilize repair parts scheduled for disposal. We also explained that products and services that make efficient use of resources not only reduce environmental impacts through waste reduction but also lead to new value provision.

Honda sees this initiative as an opportunity to encourage customers to consider how products should be handled after use. By fostering understanding and empathy for Honda’s resource circulation philosophy and initiatives, as well as deepening mutual understanding between our customers and Honda, we aim to realize a sustainable society based on resource circulation.