Resource Use and Circular Economy

Environmental Impact of Mining Scarce Resources Associated with Product Electrification

Our lives involve production, consumption, and disposal, relying on various resources. Driven by global population growth and economic development, the demand for resources continues to rise, and extensive resource extraction has become a societal issue.

Electrification of products is an effective means of reducing CO₂ emissions during product use. However, compared to traditional internal combustion engine vehicles, electric vehicles use larger amounts of scarce resources such as copper, nickel, cobalt, lithium, and rare earth elements. The extraction of scarce resources not only involves substantial energy consumption and significant CO₂ emissions but also affects natural capital such as biodiversity and water through land alteration. To move away from these environmental impacts caused by resource consumption, “resource circulation (efficient utilization of resources)” is crucial.

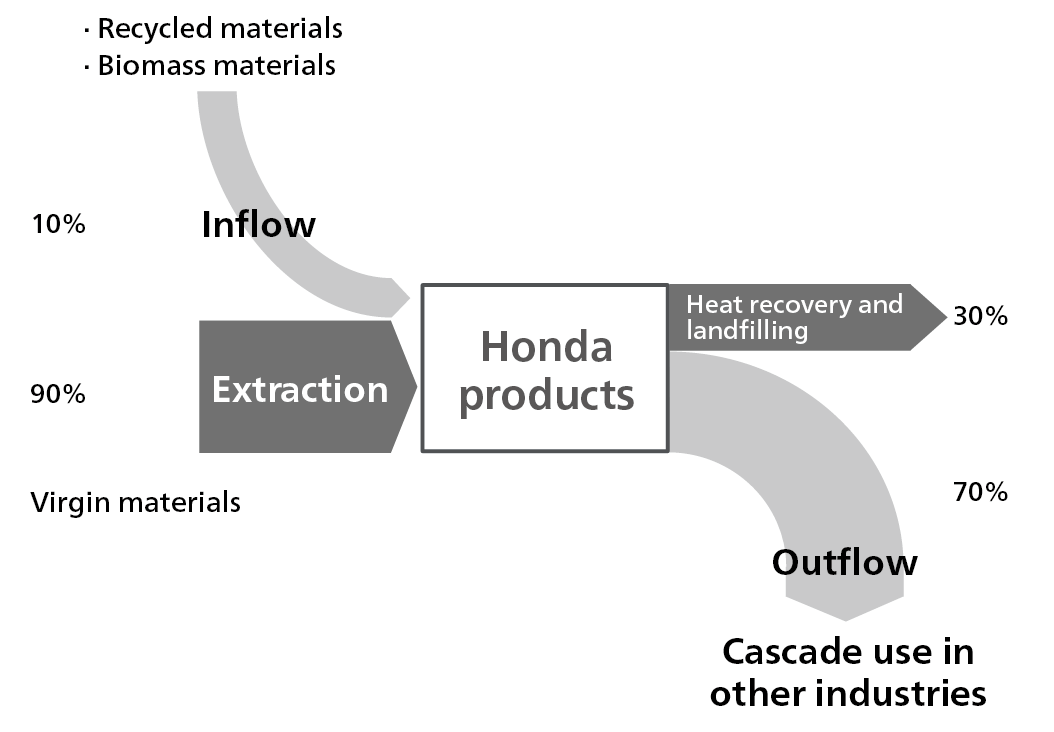

Currently, approximately 90% of the resources used in new car manufacturing rely on newly mined materials. Although about 70% of the resources from dismantled vehicles are recycled and reused, they are often subjected to cascade use*in other industries, with the remaining 30% either incinerated for heat recovery or landfilled. Advancing the electrification of products increases the demand for scarce resources, leading to potential risks of rising resource prices and supply constraints, which could affect the availability of products and services. In addition, since the quality requirements for materials in today’s automobiles are high, using recycled materials increases costs. Therefore, it is essential to implement resource circulation initiatives with economic feasibility to make recycled materials more viable.

- Cascade use: A method of using resources and energy in stages to maximize their use while allowing for a decline in quality

-

Traditional Material Flow

-

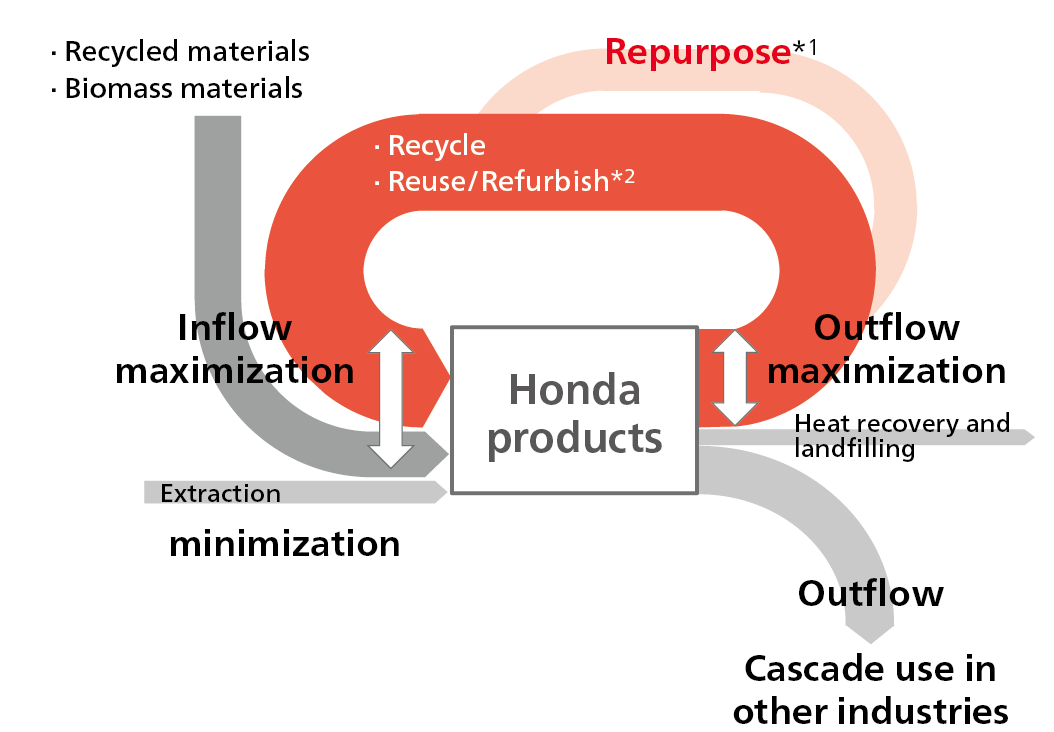

Ideal Circular Material Flow

- Repurpose: Secondary use of own products for other purposes after primary use

- Refurbish: To add new value to used vehicles by improving performance and service through the latest updates

Achieving Horizontal Recycling by Maximizing the Use of End-of-Life Products

Honda aims to achieve resource circulation through horizontal recycling*, which maximizes the use of End-of-Life Vehicles (ELVs). This approach requires the development of a new “circular value chain.” To build this value chain, Honda is working to acquire capabilities beyond its current corporate activities. The insights and technologies gained from this effort are expected to support new businesses and products designed with a circular economy in mind, as well as the innovative technologies to achieve them. Consequently, we focus on transforming our business from a mass consumption model to a circular one.

Horizontal recycling: Recycling used products back into resources and using them again for the same purpose

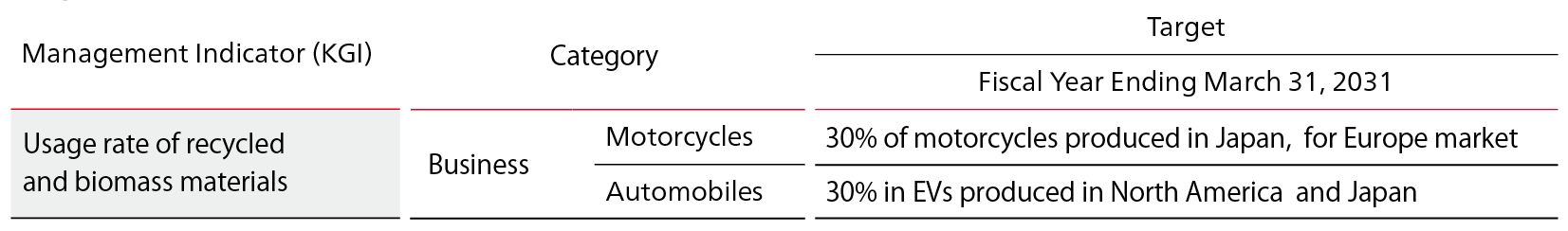

Setting New Targets with a View to 2050

To maximize the inflow, we have set the new management indicator (KPI) “usage rate of recycled and biomass materials.” For motorcycle models produced in Japan for the European market, and for automobiles (EVs) produced in North America and Japan, in the Fiscal Years Ending March 31, 2031, we will aim for a target of 30%. To achieve this new target, we will further collaborate with suppliers of materials and parts in the upstream processes and apply recycled and biomass materials.

Management Indicator and Targets

To maximize the outflow, we will advance the establishment of horizontal recycling, which maximizes the use of end-of-life vehicles (ELVs). For the high-efficiency recycling of ELVs, it is crucial to incorporate “circular-oriented materials and design” into the products.For the products currently under development, we are advancing the replacement of materials with those designed for circularity, integrating material types, and adapting material specifications and manufacturing methods to accommodate the use of recycled materials.Additionally, we are working on designs that facilitate easy disassembly of ELVs and are aiming to transform components made of multiple materials into structures that allow for easy separation into single materials, avoiding the inclusion of contaminants during the recycling process.

In addition to incorporating these strategies into product design, we will also focus on expanding future horizontal recycling efforts. To achieve both environmental sustainability and economic viability, we are working with our partners to develop advanced recycling technologies, including those for dismantling, shredding, sorting, and reprocessing materials.

Through the maximization of inflow and outflow, we are striving to achieve a 50% usage rate of recycled and biomass materials in our next-generation models in the future.

Creating Economic Viability in Resource Circulation

Fully utilizing the value of products and parts during their lifecycle and highly efficient recycling of used products while ensuring economic viability throughout a product are both vitally important for resource circulation.

To fully utilize the value of products and components, we will focus on reusing and repurposing them.

We will also utilize data to “visualize value” throughout the product lifecycle, facilitating regulatory compliance, proper transactions of products and components, and promoting their effective use.

To efficiently recycle used products, it is crucial to incorporate “circular-oriented materials and design” into the products. For the products currently under development, we are advancing the replacement of materials with those designed for circularity, integrating material types, and adapting material specifications and manufacturing methods to accommodate the use of recycled materials. Additionally, we are working on designs that facilitate easy disassembly of ELVs and transforming components made of multiple materials into structures that allow for easy separation into single materials, avoiding the inclusion of contaminants during the recycling process.

In addition to embedding these approaches into products, we will also focus on expanding future horizontal recycling efforts. For this purpose, we are working with our partners to develop advanced recycling technologies, including those for dismantling, shredding, sorting, and reprocessing materials, all aimed at balancing environmental impact reduction and economic viability.

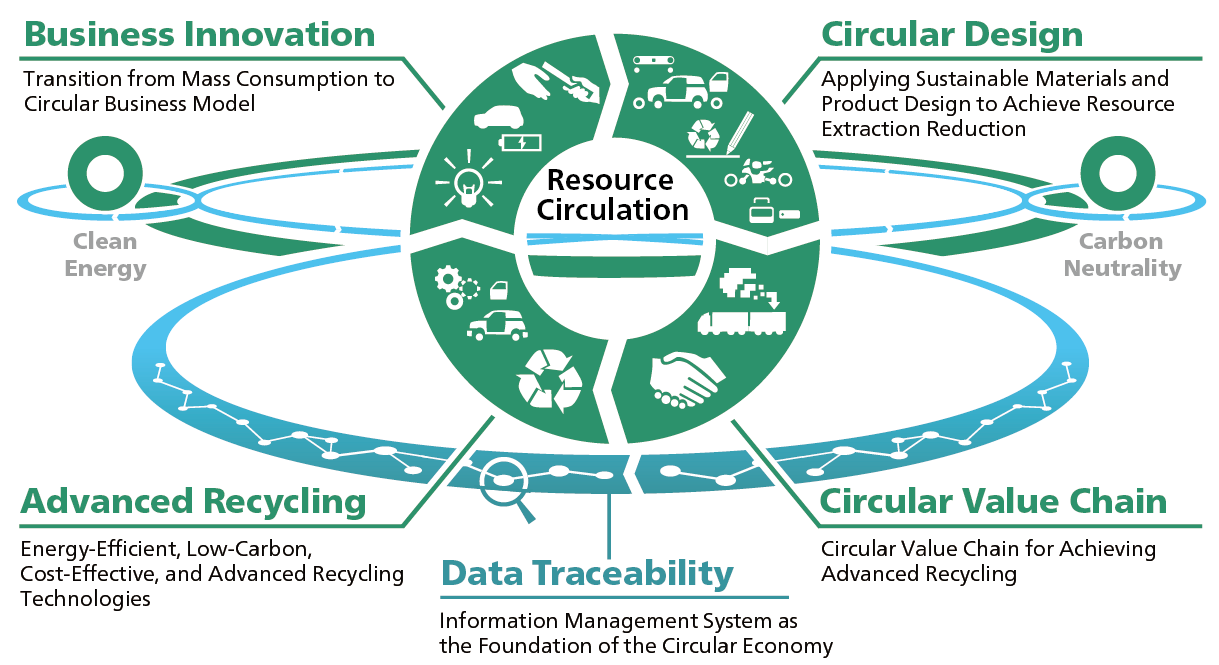

Five Key Principles of Resource Circulation

Resource Circulation Concept Diagram

-

Business Innovation

Honda is committed to shifting to a recycling-oriented business that uses up products and parts throughout their entire life cycle and recycles them with high efficiency.

Advanced Recycling

Honda is committed to the research and development of advanced technologies that enable energy-saving, low-carbon, and low-cost recycling.

Data Traceability

Honda will work on visualization of social values such as lifecycle CO₂ emissions and recycling rate to prove compliance with laws and regulations and to promote appropriate trade and use of recycled materials. The Company is committed to proving maintenance history and improving resource recovery rates through the extensive use of digital technologies.

-

Circular Design

Honda is committed to creating a system premised on recycling, which includes the selection of materials suitable for recycling, easy disassembly and separation design that enables the removal of high-quality scrap, and stable procurement of recycled materials.

Circular Value Chain

Honda will work on optimizing specifications across the entire supply chain involved in resource circulation, including material manufacturers and dismantling and shredding industries, to build a circular value chain that maximizes economic efficiency.