NC Series: Lower Price, Higher Fuel Efficiency, More Emotion

The new mid-sized concept “NC series,” represented by the NC700 launched in Japan in 2012, attracted attention as an inexpensive and fuel-efficient product among the large models, and even in 2023, the NC750X is still popular as a standard product among Honda’s large fun models. The development of the NC series began with a company mandate to create a “large fun model with a 30% lower price.”

New Mid Series concept began with company order to “create a big fun model with a 30% lower price.”

“The company only wanted us to lower the price, but that was easy to do if you didn’t have to consider profitability,” said Masanori Aoki, then LPL. “But if I was going to do it, I wanted to make sure it was cheap, sellable, and profitable.” At first, the team had a hard time deciding what kind of package they wanted. To formulate the package, the development team gathered 14 large Japanese and imported motorcycles at the Takasu Proving Center test course in Hokkaido, compared them, then spent the evenings at an izakaya (Japanese-style pub) for a “Wai-gaya” (lively discussion).

“We decided to aim for No. 1 not only in price, but fuel economy, when the Engine PL said,’we could use half of the Fit’s 1300 cc engine to realize fuel economy,’ which was the largest factor in making our decision.”

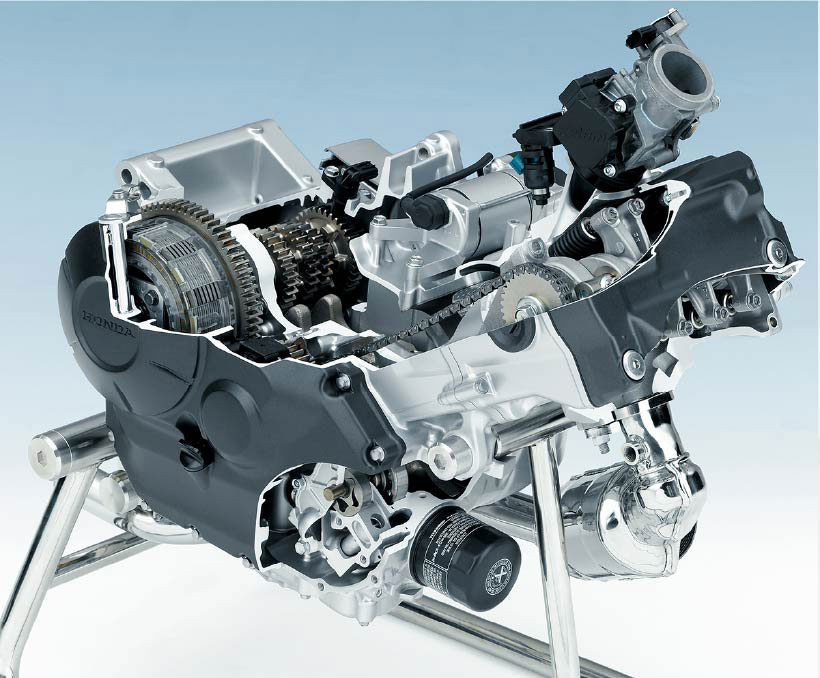

The newly designed engine for the NC series is a two-cylinder 669 cc engine with a maximum speed of 6,400 rpm. The crankshaft was twisted 270-degrees and shaped to create the ideal combustion and pulse, and the camshaft’s timing was similarly shifted from side to side. “At first, however, the company did not approve of the engine. If it is inferior in speed, revs, and horsepower compared to the existing model, which revs at 10,000 rpm, it was practical, and not a big fun model. Fukui, Honda’s president at the time had said, ‘The Nana-han [750 cc] is the king of big fun models in Japan,’ so every development plan we submitted was rejected.”

NC’s engine developed exclusively with the aim of achieving No. 1 fuel economy as well

270° phase twist crank was adopted

The development of the engine was about to be cancelled, but Aoki did not give up. He managed to persuade the company to allow him to build a prototype of the engine, citing the benefits of cost reduction and the low-carbon era. However, he could not get permission for a prototype chassis. He asked the company to let him build only the “jig” to be used on the chassis dynamometer because he wanted to measure fuel consumption at the end of the project, not during a road test.

“Since the purpose of this ‘jig’ was to measure fuel consumption, we could not make any other parts for running the bike. So, I gathered up parts that were left over for testing and managed to make it into a form that could move. For some reason, it had tires, blinkers, and a seat, but it was still a ‘jig’ frame.” (Aoki)

Of course, there were no test parts conveniently lying around. Aoki found parts that could be used and asked his team members to pick them up. This was such a bold and brilliant tactic that he decided to make a prototype called the “jig frame bike” and blend it in with the test bikes for the board members to test ride.

Jig frame model highly acclaimed at the executive test ride

“I had to get the president to ride it, so I slipped it into the Takasu test course at the last minute and laid it out on the line trying to look as innocent as I could. Then, when the president, Ito, rode the bike, he said, ‘This engine has an unprecedented feel, and it is very fun to ride. This is the best one I’ve ridden today.’”

In a reversal of fate, the decision was made to develop the bike for mass production. Since absolute performance was not required, parts using expensive materials and manufacturing methods were not necessary. Although existing components could be used while reviewing specifications in line with the development concept, it became clear that this would inevitably affect the selling price. This led the team to procure parts from overseas on an unprecedented scale. Aoki himself led the procurement department and the development team to visit parts manufacturers and procured parts from more than a dozen companies. In the end, 40% of the complete unit was made up of parts procured from overseas. For example, frame materials were procured in India, processed in the Philippines, and assembled in Kumamoto.

“Normally, purchasing is the Procurement department’s job, but I had gained experience in local procurement when I developed the Gold Wing (GL1800) in North America and the Devil in Spain, so it was faster and more reliable for me to do it myself. In procurement for the NC series, we went door-to-door to most of the suppliers, mainly in the Asian region, but only about 1/4 of the 100 companies we visited were able to fulfill our orders. There were some suppliers we visited, and decided to leave 10 seconds later.” (Aoki)

The NC series was not only characterized by low cost and low fuel consumption. The fuel tank, which was downsized for low fuel consumption, left space that could be used to store a helmet. It was important that it was not obvious, so the rider be surprised when they opened the lid.

Inconspicuous helmet storage space

“Just saying it has good fuel economy would not resonate with customers who ride large fun models. A helmet could be stored because the fuel tank is smaller thanks to its higher fuel efficiency. You had to point this sort of thing out to resonate with customers. What I had in mind was to create the No. 1 product at a reasonable price, and since we were making something that would be ridden, I wanted to create something that would be exciting to ride and that would convey our feelings.” (Aoki)

Aoki said the three important elements for the complete bike were “number one,” “reasonable price,” and “our message,” and to achieve this, it was important to go to the site and see the bike for themselves, that it was always necessary to meet the users and feel the atmosphere.

The NC series was launched in February 2012 and became a big hit. It also had the biggest engine production volume at the Kumamoto Factory for six consecutive years, a bright spot in a production volume that has been suffering from the economic stagnation since the global financial crisis.

NC700X

Africa Twin

Going Anywhere, On- or Off-Road

In 1986, Honda introduced the NXR750 factory bike in the Paris-Dakar Rally, which won the rally for four consecutive years until 1989. The Africa Twin (XRV650) was launched in 1988 as an adventure sports model inheriting the technology of the NXR750. It embodied the equipment and image of the NXR, including dual headlights, a large fairing, a big 24-liter fuel tank, and an aluminum swing-arm, and was powered by the same liquid-cooled 52° V-twin 583 cc SOHC 3-valve 2-plug engine as the Transalp 600V.

Africa Twin (XRV650) with technology from Paris-Dakar winning NXR750

In 1989 and 1990, Honda France (FH) organized the Objet Dakar, in which riders from the public were invited to compete in the Paris-Dakar Rally on the XRV650, and the XRV650 won the championship in the unmodified production motorcycle category for two consecutive years, expanding its popularity, especially in Europe.

The XRV650 became the Africa Twin (XRV750) in 1990 with a larger displacement of 742 cc, and in 1993 a new frame and fairing were designed, eventually being sold until the 2000 model year. Later, the market for adventure models, especially in Europe, became so large that it surpassed that of road sports models, and ironically, BMW, which once competed against Honda in the Paris-Dakar Rally, reigned supreme. It was no surprise that fans around the world were clamoring for a new Africa Twin from Honda, the originator of the large fairing adventure model.

The new generation Africa Twin was announced in 2015 as the CRF1000L Africa Twin. Since many of the development team members were fans of the old Africa Twin, they were well aware of what users wanted from the new model. Although the engine is now a 998 cc inline 2-cylinder unicam 4-valve engine, its all-around performance, from long tours to winding tours to hard off-road riding, was a big step up from the old Africa Twin.

CRF1000L Africa Twin

“In reality, 90% of our customers ride their bikes mainly on-road, but there is a big difference between the feeling of being able to, or not being able to, ride off-road. The ‘Africa Twin’ moniker was deified by fans, so we had to make the new model more versatile than the old one, including off-road performance,” said Tetsuya Kudo, who was in charge of handling and safety tests and continued development up to mass production. He took charge just before the end of the preliminary development.

“I was told that the bike was almost ready, and it was all up to me until mass production started, but when I rode it with my testing colleagues, they said, ‘This is no good at all.’ The chassis was too stiff for off-road riding, and more suited to on-road riding. However, the Africa Twin is also designed to be ridden at high speeds on highways, so the most difficult part was to find the right balance.” (Kudo)

In general, frames for on- and off-road bikes require different elements, and prioritizing one tends to sacrifice the other in a trade-off relationship. In the case of the Africa Twin, for example, if the frame is designed to handle the high loads required for high-speed cruising with a full load, it would be too sensitive to disturbances off-road and become extremely unstable. Turning is another example. The challenge was how to make the 21-inch front wheels, which enhance off-road rideability, have a kind of handling characteristic that would be hard to make comfortable on-road.

CRF frame tuned for rigidity balance with 6 engine mounts

CRF frame tuned for rigidity balance with 6 engine mounts

After repeated trial and error with his colleagues, Kudo realized that the strength of the engine and number of engine mounts may have an effect on the flexing of the frame. Kudo and his team therefore made prototypes of various shapes of engine mount plates to confirm the results.

“Increasing soft engine mounts was the answer to realizing both off- and on-road performance. Six engine mounts are used to tune the rigidity balance, so that at relatively slow off-road speeds, the frame flexes, and the engine area flexes with a delay. When the speed range is high and a large load is applied all at once, as in on-road riding, the entire frame moves instantly. This is not a theory, but I happened to notice it. That’s why the Africa Twin frame has a special configuration, with M8 and M6 mounting bolts instead of the usual larger M12 and M10.” (Kudo)

As those who have ridden it can easily understand, the frame achieved its intended on- and off-road characteristics remarkably, and its all-rounder characteristics, which cover everything from highways to motocross courses, are outstanding even among adventure models.

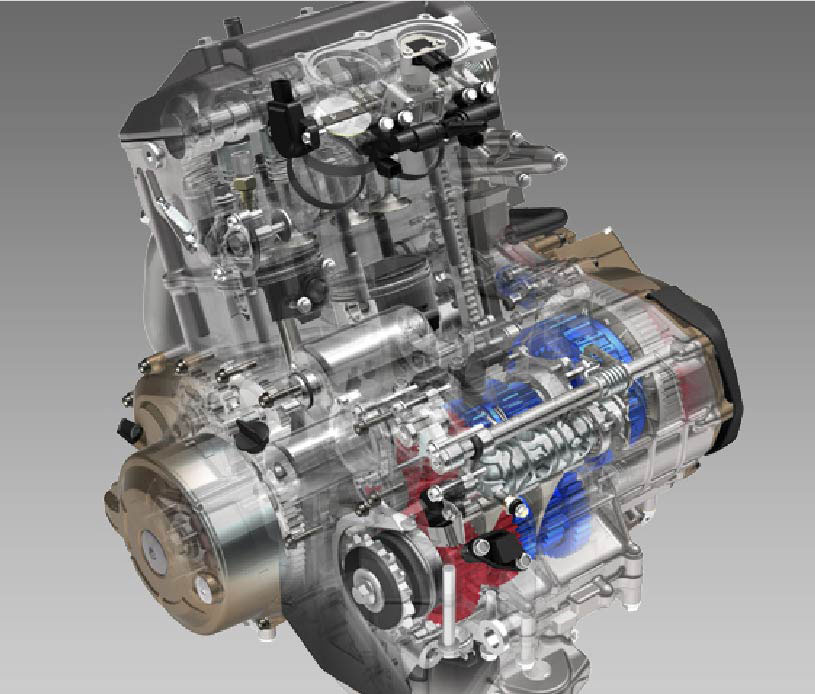

In addition, the availability of a DCT version and electronic power control are major features of the Africa Twin.

“The DCT and electronic control make off-road riding friendly for beginners, and to satisfy skilled riders as well, the DCT has a finely tuned half-clutch and a "G switch" (Gravel switch) in the drive mode to allow the rider to have fun to their heart’s content. I always ask myself where the customer’s heart is, and how far I can put myself in the customer's shoes. A senior member of the test group at that time always said to me, ‘[motorcycle manufacturing] is about the self and others being inseparable.” (Kudo)

CRF1000L engine with DCT

DCT model equipped with G Switch to satisfy novices and experts alike

In 2018, Adventure Sports was added to the Africa Twin series, with a big 24-liter fuel tank, long stroke suspension, and other features, and in December 2019, the Africa Twin was completely revamped with the Adventure Sports ES, with increased displacement to 1100 cc, and the first model with a fully electronically controlled suspension. In February 2020, the Africa Twin and Adventure Sports were launched, and the Africa Twin still sets itself apart from other adventure models.

CRF1000L developed to be outstanding both on- and off-road

Africa Twin Adventure Sports ES Africa Twin Adventure Sports ES

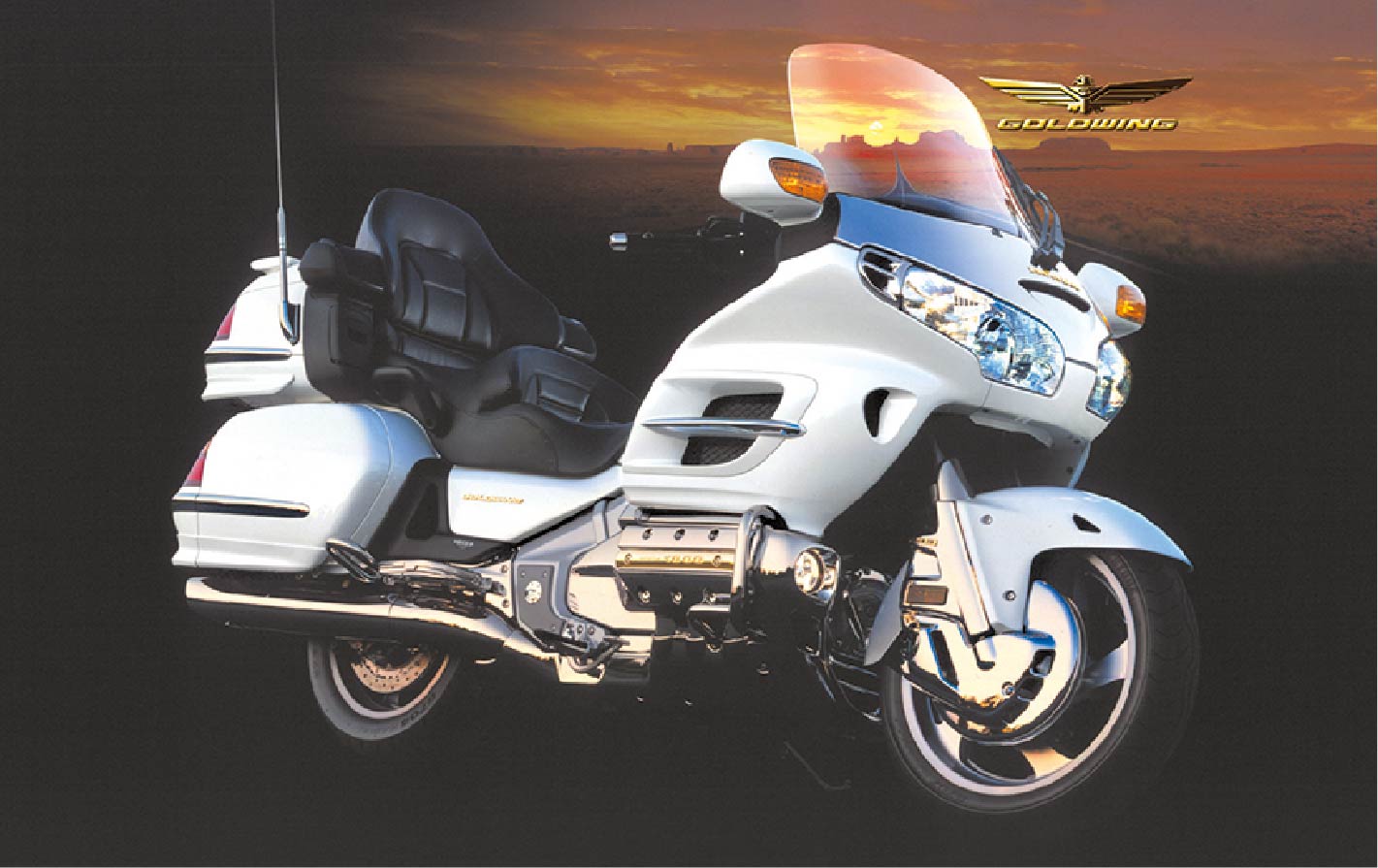

Gold Wing

What The King of Grand Tourers Pursued

The starting point for the Gold Wing was to achieve an unparalleled presence as The King of Motorcycles. The first model, the GL1000, launched in 1975 for the North American market, adopted a liquid-cooled, horizontally opposed 4-cylinder 999 cc engine, the largest displacement of any Honda production model at the time. It was priced at about $3,000, about twice that of the CB750 FOUR, but was highly acclaimed as a grand tourer, especially in North America.

The GL1000, the Gold Wing’s starting point

Later, while expanding its displacement to 1200 cc, Honda added the Interstate with a large fairing, panniers and top case, and the Aspencade with a full audio system as standard equipment and an air suspension with an electric compressor for ride height adjustment, reflecting the needs of North American users, to keep products competing with the Gold Wing at bay.

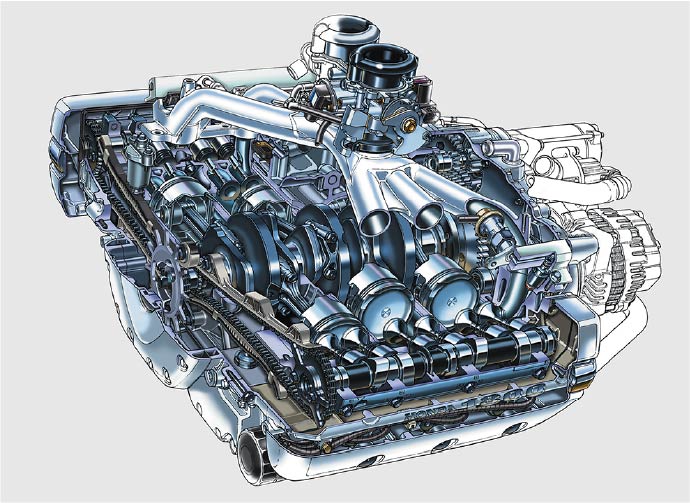

In 1988, to strengthen its market competitiveness, Honda launched the GL1500 with a horizontally opposed 6-cylinder 1,520 cc engine. The GL1500 featured a completely redesigned chassis and equipment, including an electric reverse system. It was the first large-sized motorcycle to be sold in Japan since the abolition of voluntary restrictions on the sale of motorcycles over 750 cc in Japan.

In 2001, Honda launched the fifth-generation Gold Wing, raising its displacement to 1,832 cc and adopting an aluminum twin-tube frame and Pro-Arm swingarm, the same configuration as supersport models. It was a unique grand tourer, unseen before. Masanori Aoki, who had been the LPL of the NSR250R until then, was assigned to the U.S. to develop this new Gold Wing.

The GL1800 developed as a grand tourer

A bigger, 1,800 cc horizontally opposed 6-cylinder engine

A bigger, 1,800 cc horizontally opposed 6-cylinder engine

Aoki began by getting to know the Gold Wing and the U.S. by riding one from Anchorage, Alaska, south along the Alaska Highway to Seattle, covering approximately 4,000 km in seven days on the North American continent. He conducted thorough research during his two-year stay in the U.S., visiting motorcycle events and festivals around the country on weekends to talk to users.

“I knew what I wanted to create. After living in the U.S. for two years, I realized that in many families, the wives have the strong opinions, so I needed two elements: a keyword that would allow wives to encourage their husbands to buy a new motorcycle, and a phrase that would resonate with the rider’s ego, that their bike was the best in the world. We asked for various customers’ opinions, which became the supporting data to start the development process.” (Aoki)

That led to the concept “More power and better handling for Dad, a first-class seat for Mom.” In addition to aiming for a compact body size and improved sportiness, hospitality for “wives who hold the purse strings” was also an emphasis.

“One day, I went to a ‘Wing Day’ (owners’ meeting) where Gold Wing owners from all over the U.S. gathered, and I thought, ‘If we build a new Gold Wing and put it here, and the customers see it and decide to buy a new one, we win. It will sell like hotcakes.’ So, I decided to persuade the company by showing them only the convenient parts of the data I had collected, so that they could proceed with the development based on what I had thought. But I didn't lie to them, though.” (Aoki)

It was fair to say that the increased displacement, aluminum twin-tube frame, Pro-Arm swingarms, and mono-shock absorbers were essential for this purpose. In particular, the aluminum frame, which had been used on the NSR250R, was the key to realizing Aoki’s vision. However, there were many objections.

Aluminum twin tube frame, similar to supersport models

GL1800 with Pro-Arm swingarm

“First of all, the production side was all against it because of the lack of a track record. At the time, the Gold Wing was manufactured in the U.S., but the aluminum frame had only been produced in Japan, so there was no manufacturing base. So, we looked in the yellow pages phone book and called every company that handled aluminum to find a supplier that could produce a prototype frame. The most difficult part of the process was searching all over the U.S. for three months. Thanks to that, I was able to make an advanced prototype on my own initiative.”

At first, no-one understood the merits of aluminum frames, no matter how much Aoki and team explained it. He decided to ‘Let them ride it,’ and made an advanced prototype, to which Americans who rode it thought it was great. Aoki realized something very important during the development of the Gold Wing GL, including the aluminum frame and local procurement:

“It means the LPL must be able to manage everything from development to production in order to create products that sell. The roles of procurement and sales are also important, but it is important to have an environment where the LPL can take responsibility and speak his mind. In order to sell a product and make a profit, the price must be at a reasonable level acceptable to the customer. No matter how great the product is, it will not sell unless the price is affordable. The cost is determined by the design, so we need a system that allows the designers to control the cost and a development team that can realize it. That is what we did with the GL1800.”

That said, its development was not as easy as it sounded. Aoki went to the U.S. in 1993 and returned to Japan in early 1996, but it took about five years before production was launched in 2000. Around 1999, just before the start-up, the final hurdle awaited him.

Reports came in from customers whose bodies still could not fit into the larger, more comfortable rear seats. Many of the U.S. customers were larger than the development team had anticipated. So, when development was nearing completion, the rear area was redesigned to increase the seat size. Both the rear suspension and tires also had to be revised.

“We took the completed model to Wing Ding, and when I was told by a large-set lady that she thought the best part was the seats, I was overjoyed.” (Aoki)

After all, Aoki had secured large testing staff for this purpose. The GL1800 was a huge hit, selling 20,000 units in North America in its first year. After the 2010 model, production was transferred from the Ohio Plant to the Kumamoto Factory, and in 2018, the GL1800 became the sixth and current generation. The Gold wing will continue to be The King of Motorcycles, made by Honda.

The Gold Wing generations