The NV0A features a wedge-shaped seat cowl that looks 20 years ahead of MotoGP. The design with two silencers lined up on each side and sticking out towards the rear is also unique to this machine.

Although the upside-down layout lowered the center of gravity, it also had significant side effects.

The appearance of the NV0A with its cowl removed is genuinely one of a kind. Because the fuel tank occupied the space under the engine, the room available for the radiator and rear suspension was limited, and configuring them required unnecessary effort in a standard machine.

In developing the NV0A's chassis, suppressing wheelies and rear wheelspin was one of the themes, and HRC pursued a low center of gravity. The biggest trick was to place the heavy tank under the engine, which holds 32 liters, approximately 24kg of fuel when full. When comparing the center of gravity height (height of the center of gravity above the ground) of the NS500 and NV0A when loaded with 20 liters of fuel, the NV0A had a lower center of gravity by nearly 30mm.

However, with the NV0A layout in which the fuel tank is placed below the machine's center of gravity, it was also confirmed that the height of the center of gravity rises by more than 30mm when the fuel runs out. The NV0A had the characteristic that as the race progressed and the fuel level decreased, the bike's center of gravity height rose. Another problem unique to this layout was that the center of gravity inside the tank moved away from the bike's center of gravity as the fuel level decreased.

In other words, the NV0A was a motorcycle whose handling and behavior changed to the degree that was not comparable to a typical layout, and it was a machine that required riders to race while adapting to such changes.

Additionally, there was the problem that the fuel moved around a lot in the tank, which hurt handling. They included partitions in the tank and filled it with foam to suppress shaking as much as possible, but Freddie Spencer testified that he could still feel the fuel moving inside the tank during hard braking.

So, is the NV0A a terrible bike? That's not the case. After all, Spencer won three of the five World Grand Prix races he participated in with the same machine. Of course, these results were due to the ability of a genius rider who was at the peak of his powers, but with his riding ability, the NV0A had the potential to win many times at the premier class of the WGP.

On the other hand, at the time, HRC was filled with an atmosphere of pushing forward by constantly trying new things. Therefore, they did not choose to take the time to solve the unique weaknesses of NV0A, and this upside-down layout only lasted for one season.

The Person in Charge of Body Design Is Also the one and only NVOA

Yasuyuki Tsurumi, an engineer known for his motocrosser bodywork, was responsible for designing the NV0A's body. It was the first and last time Tsurumi was accountable for creating a new road racer body. "The work I have the most fondness for was the second-generation aluminum frame for the motocrosser, which I installed for the first time in the 2000 model of the CR250R/125R," said Tsurumi, "I also enjoyed working on the NV0A, though."

One of the points he focused on with the NV0A was the shape of the seat cowl. "This is a design that I thought about only in my head. I wanted it to have a sharp styling. So, I cut paper with hand-drawn line diagrams, assembled them to fit three dimensions, and then created a mold. Everyone at HRC who saw the mold was impressed, saying, "It's so cool!"

In addition to the frame, which has an unusual manufacturing method and shape, the NV0A also has a unique seat cowl shape. This machine's body-related design differs from the NSR500s after NV0B because the chief designer was also One & Only. It is also true that this was a time when, even for top category works machines, the ideas of individual engineers greatly influenced the concept and design.

NV0A Technical Detail Gallery

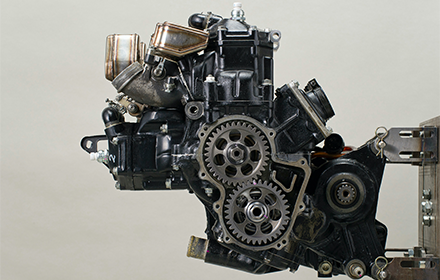

The cover on the left side of the engine has been removed to expose the crank gear, etc. The NV0A's V4 engine had a four-axle configuration:

A reverse-rotating crankshaft (in the opposite direction to the tire rotation when moving forward)

A primary shaft

A main shaft

A countershaft

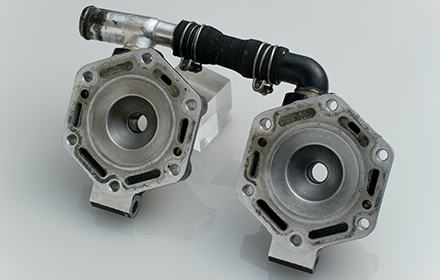

Look inside the cylinder head. The spark plug used was an NV0A-exclusive product with a total length of only 49.6mm.

The four chambers have slightly different shapes due to handling considerations. Still, they are made with the same cross-sectional diameter and cross-sectional shape, all have the same volume, and the diameter of the maximum expansion part is all φ110 mm, which is a fantastic masterpiece born from hard work.

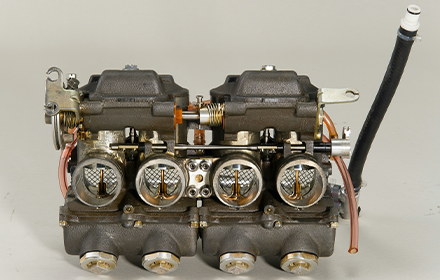

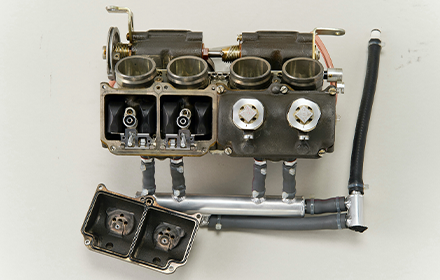

A carburetor unit that combines two cylinders and connects two of them. The supplier is Keihin, and it is a cylindrical valve PE type. The main bore is oval, with a standard diameter of 34mm. The body is made of magnesium.

The NV0A's carburetor was located at the back of the engine, and initially, replacing the main jet required a tremendous amount of effort, as it involved removing the four chambers and the carburetor from the insulator. As a countermeasure, they developed a revolver system with a holder containing four types of main jets that can be set to the desired jet by rotating it with a wrench inserted outside the machine body. It was introduced midway through the season.