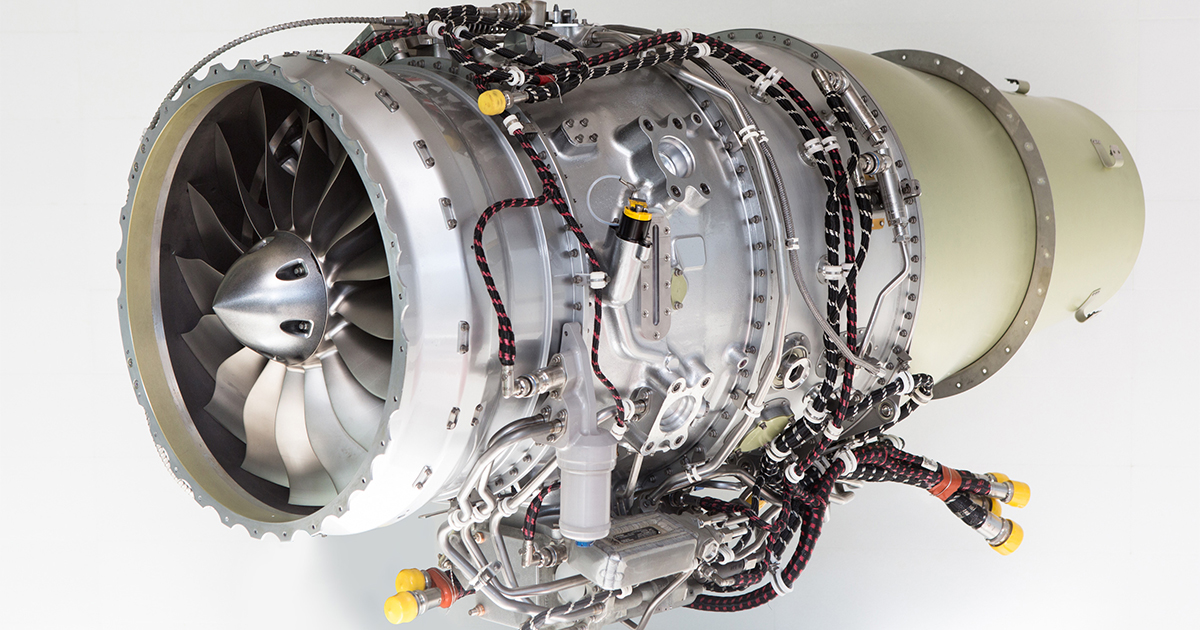

GE Honda Aero Engines Completes Testing of HF120 Engine Using 100% Low Carbon Sustainable Aviation Fuel (SAF)

ORLANDO, FL, October 17, 2022 - GE Honda Aero Engines (GE Honda) successfully completed testing of its HF120 engine using 100% Sustainable Aviation Fuel (SAF), a synthetic jet fuel. Currently, the HF120 engine can operate on approved SAF blends up to 50%, and this successful test demonstrates the capability of the engine to run on 100% SAF.

The purpose of this test was to assess the performance of the engine technology with 100% SAF compared to Jet A / A1. Ground testing was performed on an HF120 engine over several days at GE’s Peebles Test Operations using HEFA-SPK*, the most widely available SAF, produced from plant-based used cooking oil, waste fats, and greases. Test results are very favorable, with engine performance equivalent to Jet A fuel during the SAF run.

“As our testing shows, the HF120 engine can operate on approved SAF today and in the future. Our customers can be confident that the HF120 engine can help them meet their sustainability goals to reduce CO2 emissions in flight, thanks to the HF120’s innovative design features,” said Melvyn Heard, president of GE Honda.

“We are excited to share one of the steps GE Honda Aero Engines is taking toward carbon neutrality based on our belief that reducing our impact on the environment is not just an initiative, but an obligation,” said Shinji Tsukiyama, executive vice president of GE Honda. “In addition to HF120’s best-in-class fuel efficiency, future use of 100% SAF on HF120 will further contribute to environmental sustainability.”

GE Honda’s parent companies are both part of distinct international efforts that seek to standardize industry specifications and ensure the safety of SAF.

The HF120 has already demonstrated to be the most fuel-efficient engine in its class representing decades of research and development. Innovative aerodynamic designs, such as unique air blast fuel nozzles that yield superior fuel-to-air combustion, minimizing fuel burn, and laser drilled combustor liner holes that enable optimum transfer of compressor energy to the turbine. GE Honda is striving to unlock new possibilities and soar above the standard in reducing carbon emissions and is on a journey to lead the future of sustainable operations for business jets in its class.

* Hydroprocessed Esters and Fatty Acids Synthetic Paraffinic Kerosene

■About GE Honda Aero Engines

GE and Honda formed a 50 / 50 joint venture in 2004, called GE Honda Aero Engines, based in Burlington, North Carolina. The joint company integrates the resources of GE Aviation and Honda Aero, Inc., a Honda subsidiary established to manage its aviation engine business.

March 2022 - GE Honda Aero Engines surpassed 200,000 flight hours since entering service in 2015.

June 2022 - GE Honda Aero Engines marked production of its 500th engine since the start of production of the HF120 in 2013.

For additional information about GE Honda, please visit GE Honda’s official website at https://www.gehonda.com

or Honda’s official website https://global.honda/en/products/aeroengine.html.