In-house Development of New Fuel by Honda

Fuels used in F1 racing cars are strictly regulated in terms of components and properties. However, it is still possible to develop fuels independently within specified ranges.

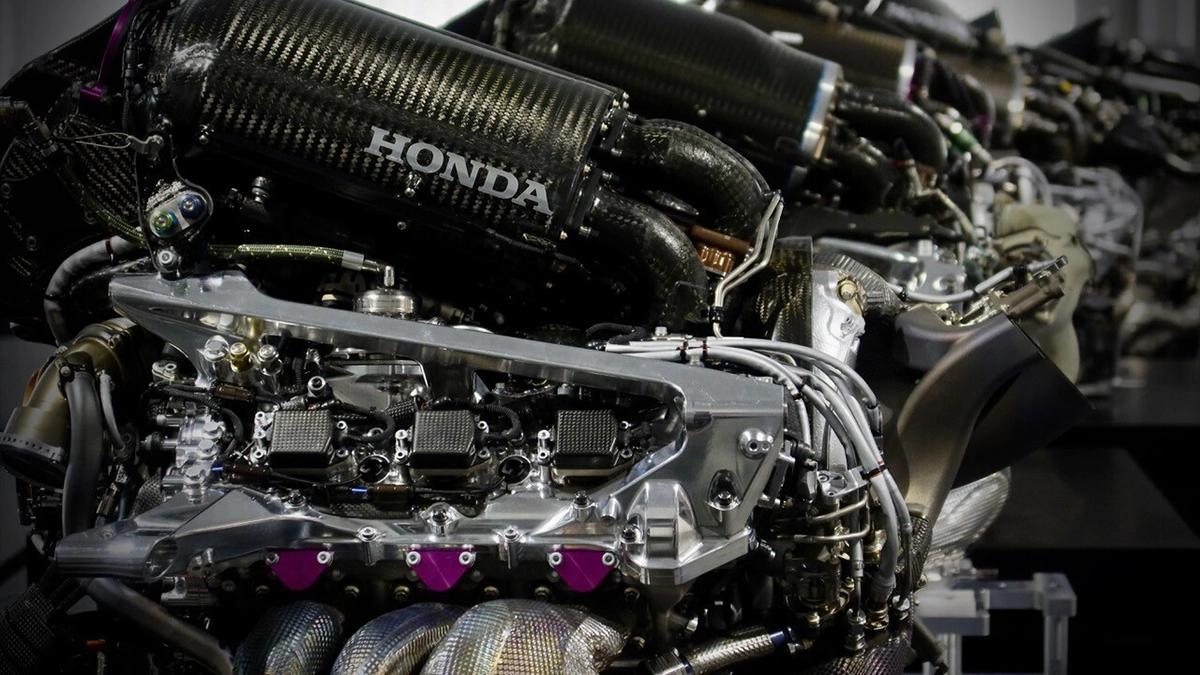

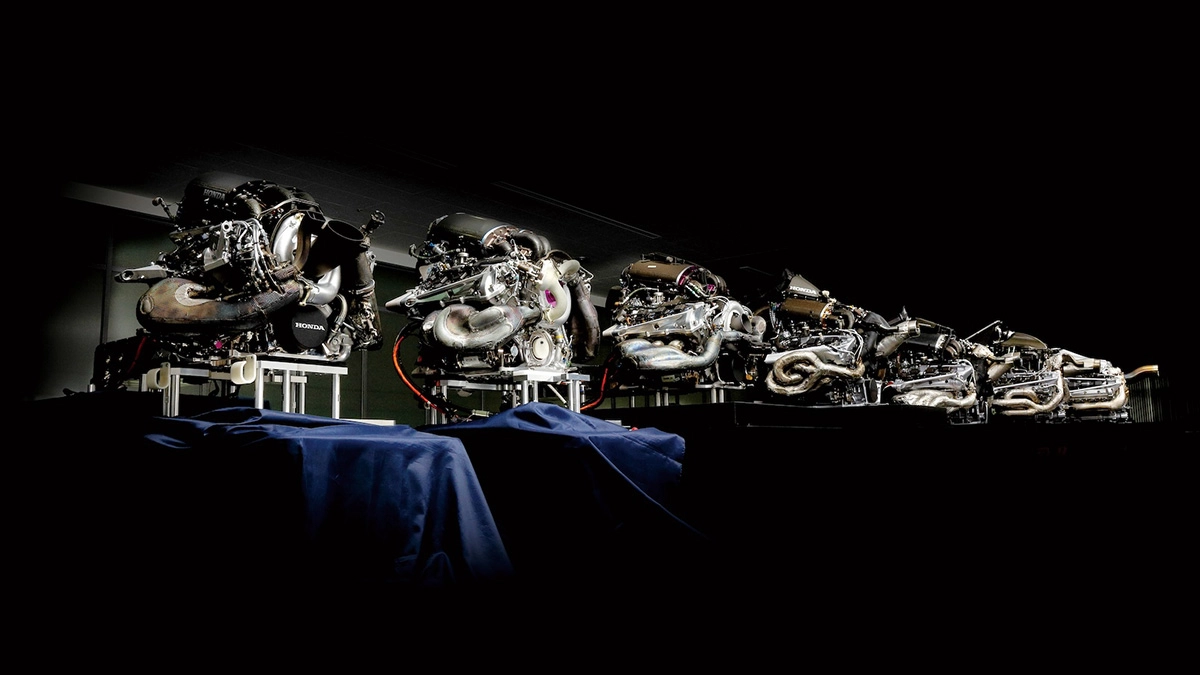

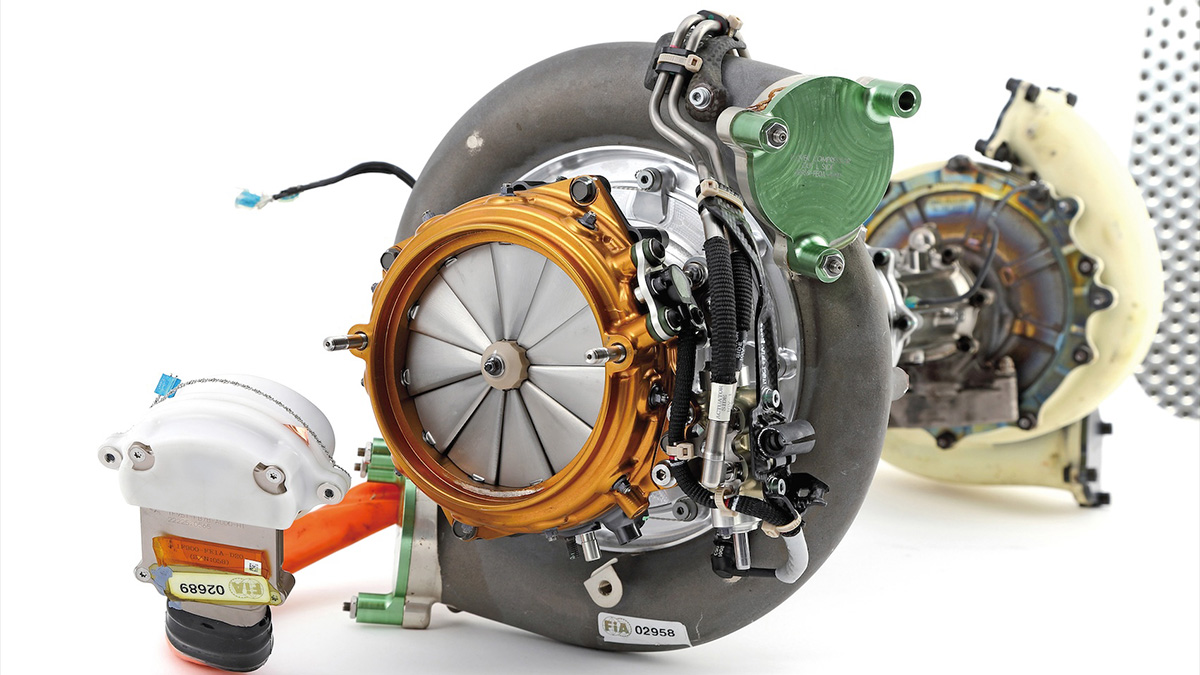

Honda started using rapid combustion from its RA618H Spec 3 power units introduced for the Russian Grand Prix, the 16th round of the 2018 season (Evolution of Technologies Boasting the Ultimate Combustion Efficiency). Conventional combustion technology at the time used a spark from the spark plug to generate a flame that ballooned out from the spark plug electrode. This is known as flame propagation combustion.

With rapid combustion, on the other hand, flames are even generated around the circumference of the combustion chamber, where they are triggered by the pressure shock from jet flames injected from the pre-chamber. While the jet flames spread out to the circumference from the center of the combustion chamber, the other flames spread from the circumference toward the center, so combustion proceeds rapidly. Rapid combustion, therefore, is the result of jet flames triggering self-ignition at the circumference of the combustion chamber.

With the combustion method being different from the past, the fuel used also needs different properties. One of the good things about flame propagation combustion is that it is resistant to knocking, which is not necessarily the case with self-ignition-based combustion. On the other hand, easy ignition is also not necessarily better. It is a fuel property optimized to rapid combustion.

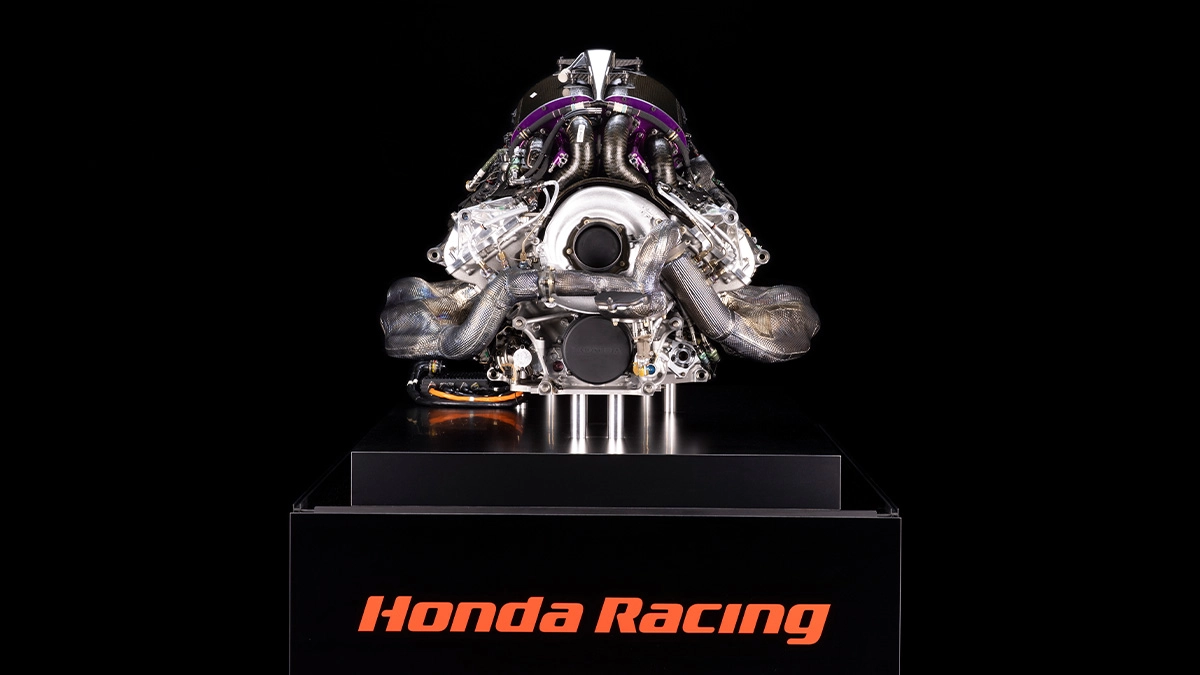

Just like with its turbocharger and cylinder bore coating technologies, Honda is applying a company-wide approach to development of power units, utilizing all of its resources rather than just those within its F1 power unit development division. When developing fuel, it enlisted the support of Innovative Research Excellence, Power Unit & Energy, its center for research and development of power unit and energy technologies that will help achieve a zero environmental impact society.

Honda’s new fuel, developed in-house, was used for the first time at the Japanese Grand Prix in 2019, the 17th round of the season. Because fuels are supplied under contract with chassis constructors and fuel suppliers, it is actually the fuel suppliers that develop and manufacture fuels and then supply them to teams. Therefore, Honda had to propose a composition for the new fuel to a fuel supplier. For its part, the fuel supplier accepted the proposal and optimized it by blending it with other components.

Making fuel carbon neutral

The next challenge was to make the high-performance components of the new fuel carbon neutral without impacting performance in any way. In October 2020, Honda declared its aim to realize carbon neutrality. Then in April 2021, it established the goal of creating a circular economy with zero environmental impact, announcing that “Honda will strive to realize carbon neutrality for all products and corporate activities Honda is involved in by 2050.” Behind these efforts was the Paris Agreement, adopted at the 21st Conference of Parties to the United Nations Framework Convention on Climate Change (COP 21) in 2015, which proposed to keep average global temperature increase to 1.5 degrees Celsius by reducing CO2 emissions.

In the process of achieving carbon neutrality for the high-performance components of its fuel in 2021, Honda started by acquiring green hydrogen (produced without CO2 emissions) from the Fukushima Renewable Energy Research Center of the National Institute of Advanced Industrial Science and Technology (AIST). The hydrogen was then reacted with carbon from wood biomass to produce carbon neutral methanol. In turn, the methanol was reacted with second-generation biochemicals, based on wood and other non-food raw materials, and other chemical products to produce the high-performance components.

As of 2021, 58.5% of these high-performance components were carbon neutral, and Honda has confirmed that it is technically possible to achieve carbon neutrality for 100% of the components. Honda is manufacturing its carbon neutral high-performance fuel components in Japan and sending them to a fuel supplier for formulating into fuel and supplying to the teams by the supplier.

Combustion reaction model

The above image shows a combustion reaction simulation for isooctane (C8H18), as an example. Calculating reactions with a range of substances, the simulation shows when ignition will occur and what will happen with cylinder pressure under ICE temperatures and pressures. Good components were selected from these results and confirmed by testing.

With a regulation change in 2022, it was decided to use fuels mixed with 10% ethanol from the perspective of promoting carbon neutrality, with cars required to use 100% carbon neutral fuel from 2026. Also returning to F1 as a power unit supplier from 2026, Honda is working through Honda Racing Corporation (HRC) to develop fuel alongside the new-regulation power units to be supplied from 2026.

Compared to traditional gasoline, carbon neutral fuels are difficult to vaporize, so it is important that development of fuels focuses on ease of vaporization. On the other hand, there is also a need to develop technologies that facilitate combustion of fuels that are difficult to vaporize.

In-house development of power units and carbon neutral fuel is one of Honda’s strengths. The technologies that it is refining through development of F1 carbon neutral fuel can be transferred to other racing in Japan where carbon neutrality is being promoted, while application to production cars in the future is also within sight.

Carbon neutral fuels produced from green hydrogen undergo a distillation process that is similar to gasoline purification before becoming different types of fuel. While the light components after distillation can be used as gasoline substitutes, the heavy components can be used as jet fuel, making it possible to use them in testing of electric vertical take-off and landing (eVTOL) aircraft, which employ gas turbine hybrid technology, and for sustainable aviation fuel (SAF). For this reason, Honda is developing carbon neutral fuel concurrently with F1 power units in the hope of making significant contributions to society.