F1 power unit configuration

In May 2013, Honda announced its participation in Formula 1 from 2015 as a power unit supplier in a joint project with McLaren. New power units to be developed would need to be designed and developed with the aim of improving competitiveness of the whole car in a technical collaboration with body developer McLaren.

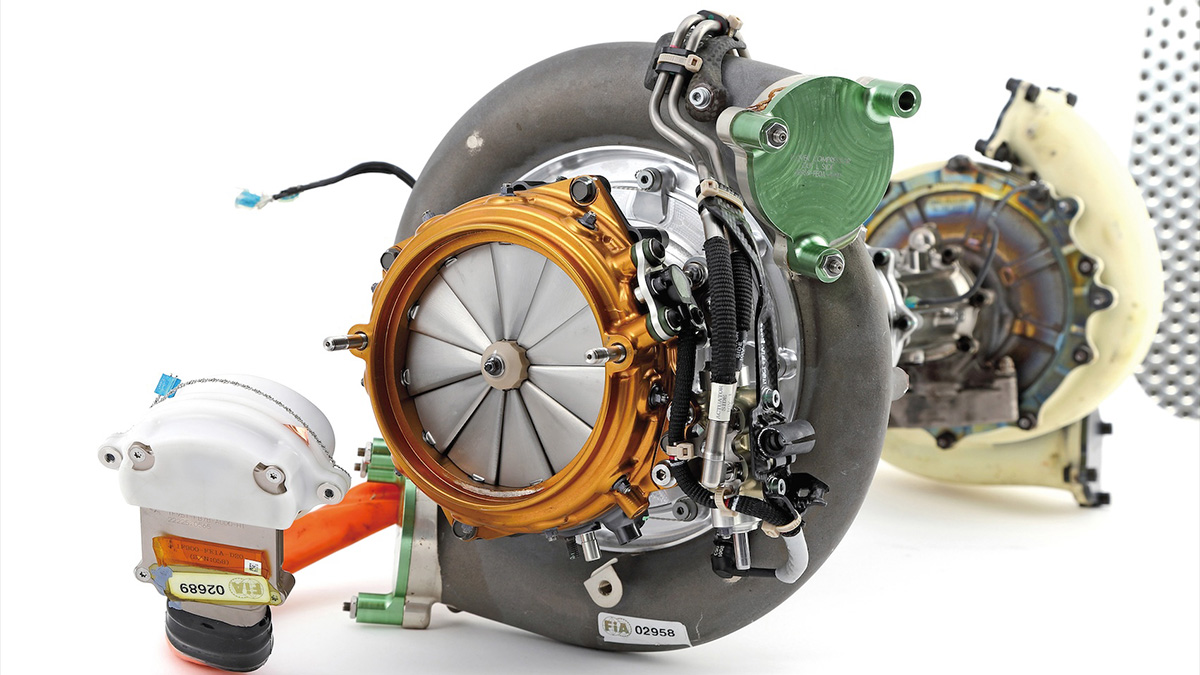

With a significant change in engine regulations introduced in 2014, the previous 2.4-liter V8 naturally aspirated engines were replaced with 1.6-liter V6 turbocharged engines incorporating two types of energy recovery system—kinetic energy recovery and heat energy recovery. The first system included an MGU-K (Motor Generator Unit - Kinetic) for recovery of kinetic energy mainly during deceleration, and the second included an MGU-H (Motor Generator Unit - Heat) for recovery of heat energy from the exhaust gas.

F1 power unit configuration

The new regulations provided detailed specifications, including an engine bank angle of 90 degrees, exhaust to the outside of the bank, maximum bore diameter of 80 mm ±0.1 mm, minimum valve stem diameter of 5 mm, and maximum direct-injection injector pressure of 500 bar. The power unit was restricted to a single turbocharger that had to be arranged in parallel with the crankshaft axis and within an offset of 25 mm, which essentially meant there was no other option than locating it within or to the rear of the two banks.

While the concept up until 2013 was to restrict output to a maximum engine speed (18,000 rpm), the 2014 power unit regulations changed to restricting output to a maximum fuel flow (100 kg/h @10,500 rpm). This meant that development had to focus on how to most efficiently convert the limited energy available in fuel into engine output. Energy management also became an important part of development, with the goal of improving performance by making full use of the two energy recovery systems.

2015: RA615H

While it fired up its first power unit in the autumn of 2013, Honda actually conducted its first real-world test in joint testing conducted after the Abu Dhabi Grand Prix, which was the last round of 2014. After the third series of joint tests in the new year, the power unit was ready for the first round of the year.

The power unit employed in the 2015 season was named the RA615H in line with Honda’s racing engine conventions, with R standing for racing, A for automobile, 6 for V6, 15 for 2015, and H for hybrid.

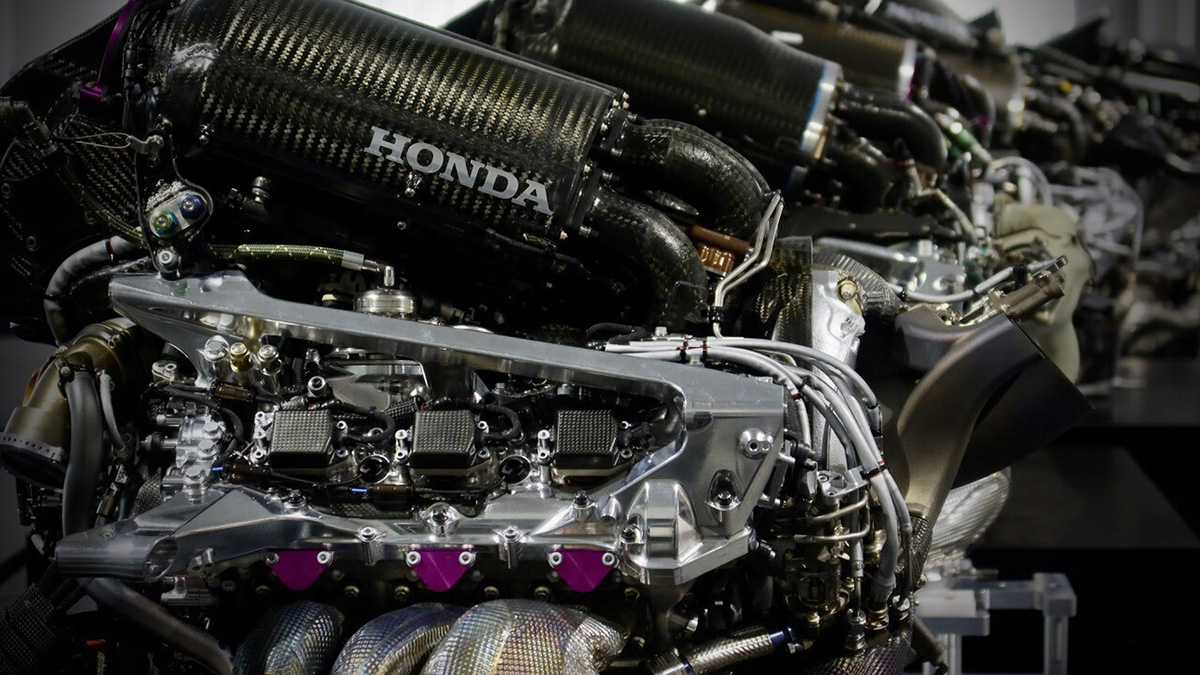

The RA615H was developed with a focus on compactness. With partner McLaren deciding to design its chassis on a “size zero” concept, from the perspective of aerodynamics, there was a need for compactness. While this had some effect, Honda had gone to great lengths on its own initiative to reduce the size of its power unit. A typical example of this approach was Honda’s work on the exhaust manifold.

The basic theory of racing engines is to take an exhaust manifold and tune the diameter and length of pipes, while keeping them an equal length, to maximize the pulsation effect of the exhaust gas and improve engine output. However, with compactness being the priority for the RA615H, a shape with minimal lateral projection was used to carry the exhaust the shortest distance possible from each cylinder to the turbine.

During the season’s competition, it became clear that improving engine performance by borrowing some space from the body side contributed more to overall performance than sacrificing a level of performance to reduce size and improve aerodynamics. At that point, Honda pivoted to a new development approach that focused more on engine performance, changing to orthodox equal length pipes for the United States Grand Prix, the 16th round of the season, and continuing with that concept for the RA616H power unit in 2016.

2016: RA616H

The RA616H power unit in 2016 changed to a more performance-focused design in areas where compromises were previously made when too committed to compactness. Used to regulate the flow of air into the engine, the plenum chamber on the RA616H was located 30 mm higher than on the RA615H. This was done to reduce bending of the air intake pipes between the plenum chamber and cylinder head to facilitate air flow into the combustion chambers.

For the British Grand Prix, the 10th round of the season, Honda changed the variable induction system (VIS) within the plenum chamber. The basic premise of the VIS is to optimally adjust air intake pipe lengths to the engine speed to maximize utilization of the dynamic effect of intake air, so longer pipes are used at low revs and shorter pipes are used at high revs. The greater the variability of length, the greater the rpm range that can be accommodated.

To make the overall RA615H power unit more compact, the variable funnels were positioned opposite each other in the horizontal space available. With the RA616H, the funnels were repositioned opposite each other in an inverted V shape, allowing less bending of funnels that were previously bent at 90 degrees. At the same time, the variable range was increased to enable optimization to a wider range of engine speeds.

Also for the purpose of compactness, the MGU-H assembly had been sandwiched between the turbine and compressor since the RA615H. With the RA616H, the compressor was increased in size, as much as possible within the V-bank, to increase recovery capacity.

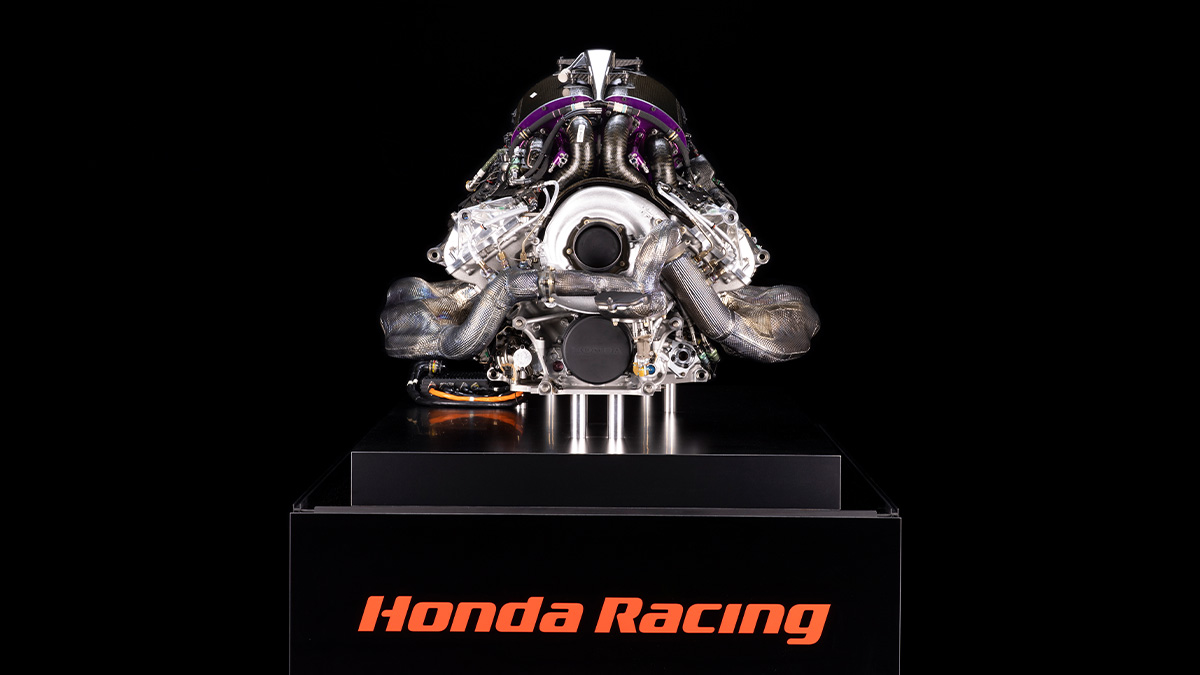

2017: RA617H

With the RA617H in 2017, the design was changed dramatically. Instead of being enclosed within the V-bank, the compressor was moved to a forward-projecting position, followed by the MGU-H, and with the turbine projecting rearward of the engine. Freed from the space restrictions within the V-bank, the compressor and turbine could then be increased in size. Also, with the compressor and turbine located outside the V-bank, the shaft could be relocated to a lower position, thereby lowering the MGU-H assembly mounting position and significantly lowering the center of gravity. With this layout change, the RA617H had a center of gravity more than 25 mm lower than the RA616H.

The VIS structure changed dramatically as well. While the variable funnels were positioned laterally and opposite each other until the RA616H, they were positioned in the longitudinal direction in the RA617H. Variable range was increased further again with this structural change.

Adopting a new layout, the RA617H changed to a pre-chamber ignition (PCI) system that made significant progress from the combustion perspective (Evolution of Technologies Boasting the Ultimate Combustion Efficiency). Also called pre-chamber combustion, PCI technology encloses the spark plug electrode of each cylinder within a small pre-chamber, and jets of fuel are injected into the main chamber from small orifices in the pre-chamber wall to rapidly combust the lean air-fuel mixture.

2018: RA618H

The RA618H power unit, developed for the 2018 season in collaboration with new partner Scuderia Toro Rosso (rebranded to AlphaTauri in 2020 and to Visa Cash App RB in 2024), employed rapid combustion, developed from PCI combustion, from Spec 3 introduced for the round 16 Russian Grand Prix.

With rapid combustion, self-ignition of the air-fuel mixture around the circumference of the combustion chamber is triggered by the jets of fuel injected from the pre-chamber. The flame then propagates from both the pre-chamber side and the chamber circumference toward the center of the chamber, achieving instantaneous combustion (Evolution of Technologies Boasting the Ultimate Combustion Efficiency). This achieved even faster combustion than the PCI system, which was already fast. Adoption of rapid combustion enabled significant increases in the compression ratio and specific heat ratio, dramatically improving engine output.

2019: RA619H

From 2019, Honda partnered with Red Bull Racing in addition to Scuderia Toro Rosso, resulting in it supplying power units for two teams and four cars. The RA619H inherited and continued to improve upon the basic concept of the RA618H to further draw out the advantages of the rapid combustion system.

For the round 8 French Grand Prix, Honda updated the compressor. Collaborating with HondaJet gas-turbine engine developers at its Wako R&D Center, it was able to improve compressor efficiency by improving its aerodynamic performance. This made the Honda cars more competitive at the round 9 Austrian Grand Prix, at 750 meters above sea level, enabling Max Verstappen, driving Red Bull’s RB15, to get Honda’s first win since it rejoined the F1 competition.

With increased understanding of rapid combustion, combustion pressure had been increased since rapid combustion was adopted with Spec 3 in 2018. However, as combustion pressure increased, piston forces, or more specifically piston ring forces, on the cylinder walls also increased, resulting in greater damage. With the resulting severe abrasion of the surface treatment, sealing properties also deteriorated, leading to loss of combustion energy and therefore loss of output.

2020: RA620H

To solve this problem, Honda worked with its Kumamoto Factory to develop a cylinder plating method that could withstand damage from the piston rings, and it applied this technology to the RA620H power unit in 2020. As a result, the engines could produce higher outputs for extended period of time.

A 3D-printed (additive manufactured) turbine housing made from Inconel was also used from 2020. With the ability to manufacture complex shapes, which were difficult with conventional technologies, 3D printers were able to easily create structures with an optimal balance of weight, strength, and rigidity. They were therefore used to manufacture the MGU-H housing and steel pistons, which had complex shapes. Application of 3D printing technology in this way enabled the creation of pistons with ribs and indentations in places that were not possible when forged and machined.

2021: RA621H

The RA621H in 2021 underwent a complete redesign and adopted a new layout. With increased output from a better understanding of rapid combustion, it became obvious that the layout used continuously since the RA617H had reached its peak in terms of performance, reliability, and durability. This enabled Honda to adopt specifications optimized to rapid combustion. In addition to creating a cylinder head shape with optimal combustion chambers for rapid combustion, the cylinder block was also changed from a conventional sand mold cast block to a machined aluminum alloy block to achieve the strength to withstand the high combustion cylinder pressure.

A narrow valve included angle was used to match the higher compression ratio, but it was also intended to contribute to body-side design. In particular, by minimizing exhaust-side projection from the outside of the body, it was possible to contribute further to aerodynamics. Therefore, while V-shaped ribs were used to ensure rigidity of the cylinder head cover, the exhaust-side ones were removed to create a slimmer profile.

To achieve the optimal dynamic effect of intake air at low revs, which are used when starting or exiting low-speed corners, the VIS was redesigned to also use the charge air cooler (CAC) pipe, which connects the air-cooled intercooler with the plenum chamber, as part of the air intake pipes. This change stabilized combustion when starting, which tended to be unstable previously, and created the optimal starting conditions.

Over the seven racing seasons from the RA615H in 2015 to the RA621H in 2021, Honda’s power units achieved an increase in output of over 100 kW. Achieving such an increase in output under fuel flow regulations meant Honda dramatically increased thermal efficiency.

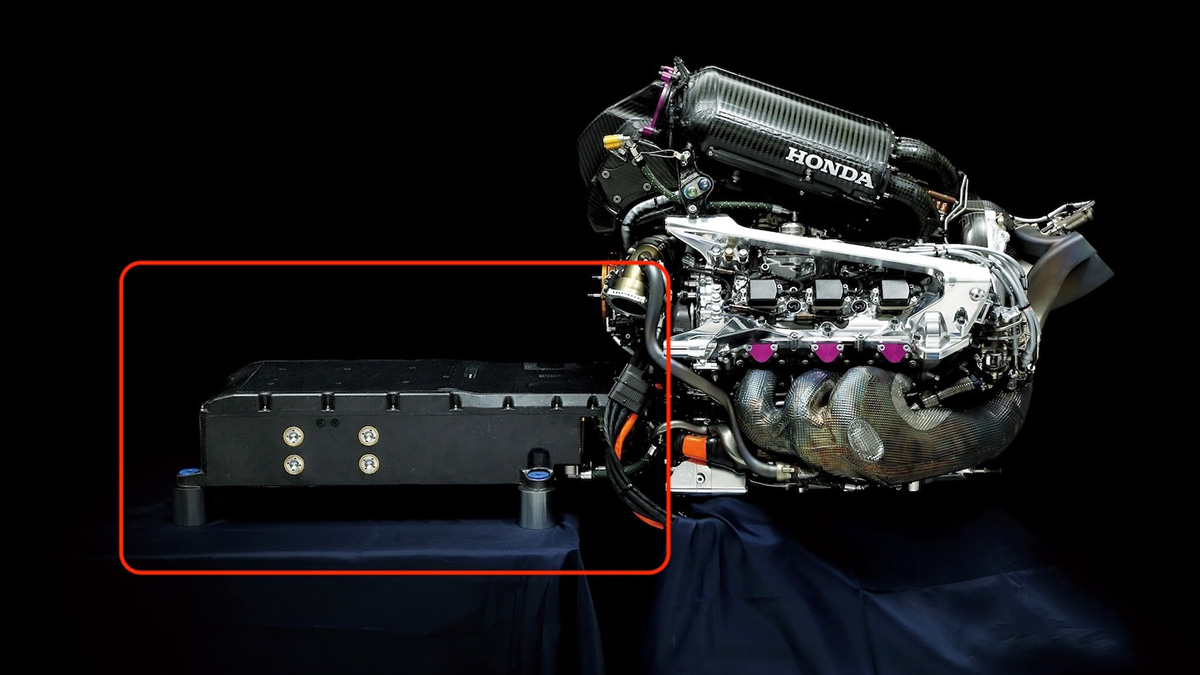

Changes in power unit dimensions

Relocating the compressor and turbine to project to the front and rear of the V-bank enabled the MGU-H assembly shaft mounting position to be lowered. This freed the compressor from the space restrictions within the V-bank and enabled it to be increased in size. (The diagram depicts the final specifications for each year listed.)

While the RA615H power unit was designed with a commitment to compactness, it was actually the RA621H, with considerably more output, that was more compact. Comparing the old and new power units, it is clear that a lower compressor mounting position enabled use of a larger compressor to deliver the larger air amounts needed for improving efficiency and output.

The RA621H is a high-performance power unit using a new layout designed for rapid combustion. Driving Red Bull’s RB16B, mounted with the RA621H, Verstappen became Driver's Champion with 10 wins out of 22 races. After a drought of 30 years since Ayrton Senna in 1991, driving a McLaren, Honda had again contributed to creating a racing champion.