Motorcycles Technology

A Frame Designed for Flexibility

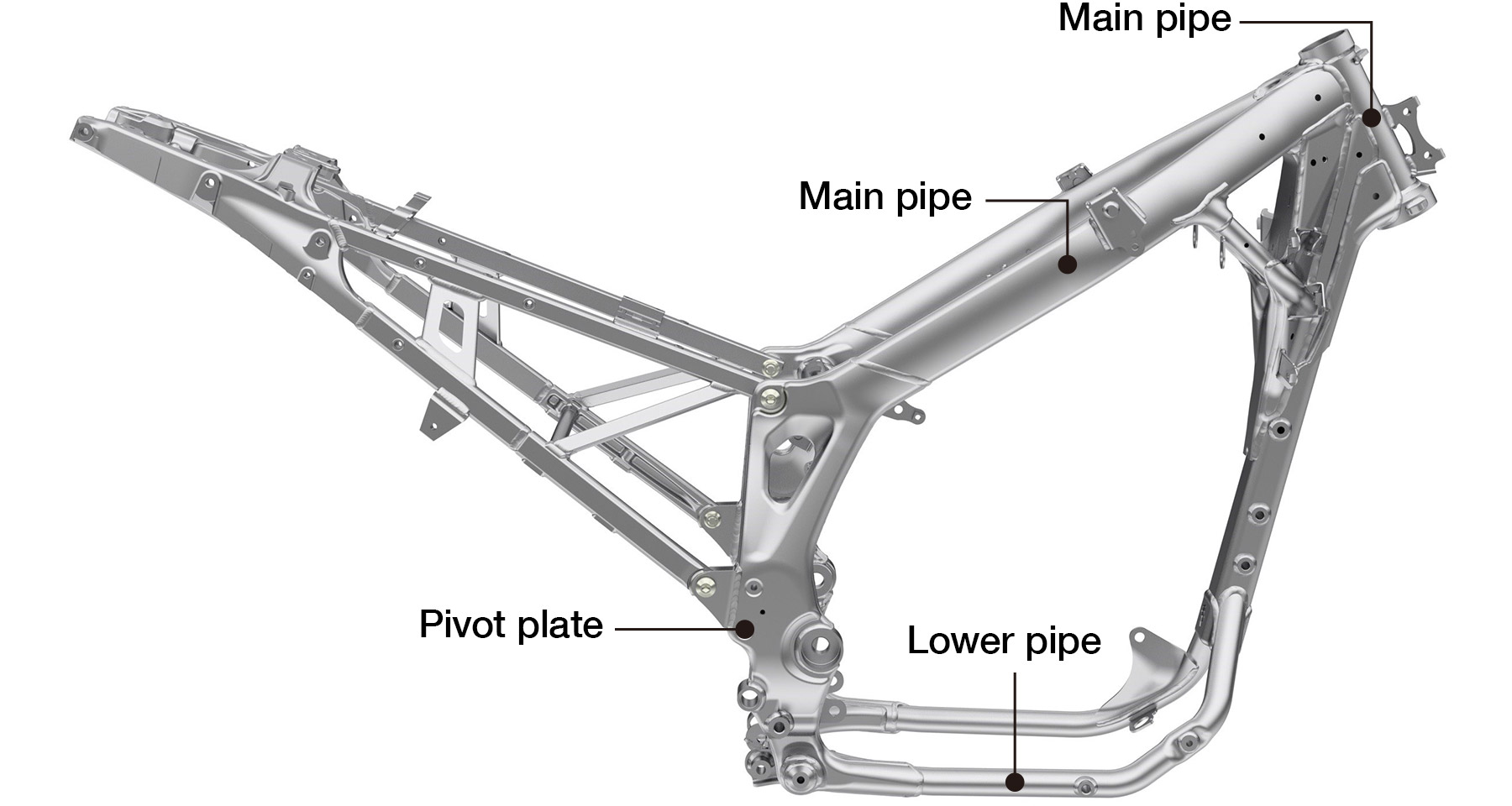

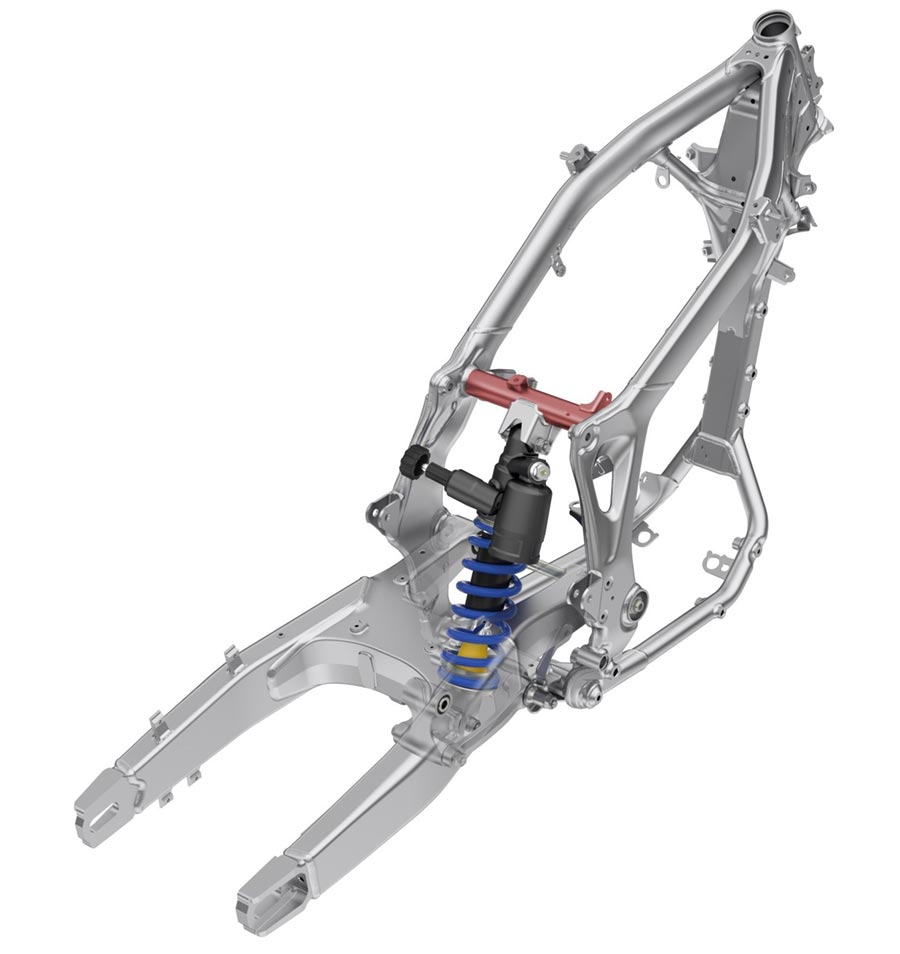

The semi-double cradle structure used in the Dakar Rally entry model, CRF450 RALLY, and the first-generation Africa Twin, XRV650 Africa Twin, has been adopted.

By adopting an atypically shaped elliptical main pipe material and optimizing the placement of various stiffeners, the new model achieves excellent running performance in a wide range of situations, including both tough off-road driving and high-speed driving with a full load of luggage.

The Engineer Talks

-It doesn’t seem that the exterior has changed much.

“Maybe it doesn’t. But it is not an exaggeration to say that almost everything has been updated.

Our goal with the new Africa Twin was to inherit the basic performance of the previous model while making it lighter.

But what was more important was to make it feel 'light' when you actually ride it. To achieve this, we needed to make it “flexible”.

-Why is "flexibility" important?

“In order for the rider to feel that they can control the bike with ease as they want, certain qualities are required: a sense of ground contact and security regardless of the road conditions, as well as a gentle change in behavior when crossing a gap.

To achieve this, a moderate amount of "flexibility" is necessary.

Even for on-road use, if the stiffness is too high or in other words, too “hard”, you will feel that the vehicle responds with too much agility, which may cause fatigue for the rider”.

-What are the difficulties in pursuing "flexibility"?

“Since this is an off-road bike, we need to take into account the impact that will occur when jumping and landing. The bike must have a certain degree of softness to handle gap, but also be strong enough to withstand large impacts. How far can we go to achieve both of these goals at a high level? This is the point that we focused on to the fullest in order to realize the unique ride quality of the Africa Twin.”

The section that connects the head pipe to the pivot plate is called the "main pipe".

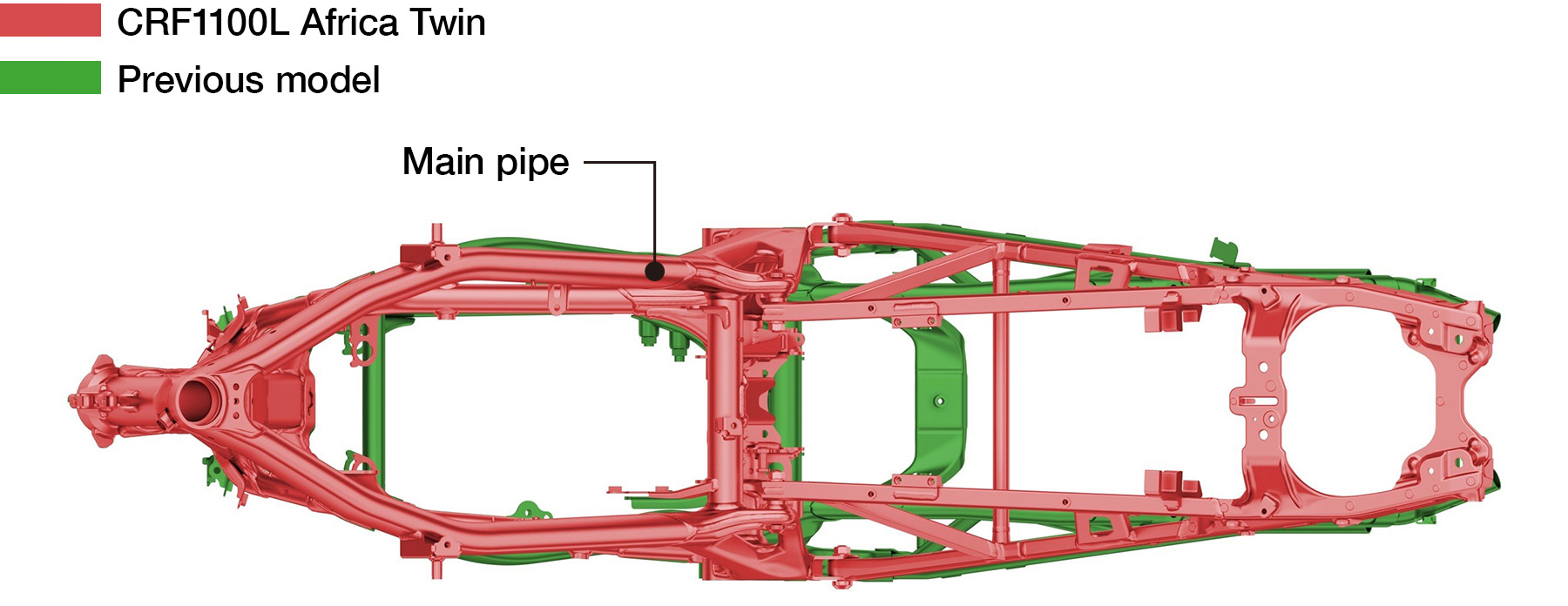

Compared to the previous model, what has visibly changed is that the cross pipe that crosses the main pipe from left to right has been eliminated.

On top of that, the new model features a straighter line of body than the previous model.

The Engineer Talks

-Why the elimination of the cross pipe?

“Of course, we eliminated the parts to create the “flexibility” in the frame.

Since the reinforcing parts that were designed to take large impacts from the road are removed, the frame itself moves softly.”

-That’s quite a bold change.

“We have tried drilling holes, changing the thickness, and trying many other ways of modification.

However, we were unable to get the outcome we were hoping for.

Then, the test team suggested "Let's get rid of this pipe!" and we agreed on it.

As engineers in charge of designing, we often get suggestions and requests that make us shout “Come on! That’s just too much to ask!”, but this kind of drastic proposal is rather common in Honda's development. ...... (laughs)".

-How did it turn out?

-What parts of the frame body will be affected?

We have succeeded in drastically reducing the weight to the point where we thought "Why haven't we tried this until now?

Of course, we couldn’t have made it happen had we applied the same method as with the previous model as it included the pipe as an essential element of the body.

Therefore, we decided to consider how we could make it a viable specification based on the premise that the ride quality without the cross pipe is "proper".

“The cross pipe had the effect of creating high rigidity by forming a triangle at the point where the large impact comes in.

By removing this, the main pipe will be deflected significantly.

In particular, we needed to make it possible for the frame to endure a heavy load since such an amount of load was to be placed on the frame joints.

Simply making the frame sturdier would result in a loss of flexibility, so we had to ensure that the entire frame could share the load, rather than any particular part of the frame taking it.

We needed to think outside the box.”

The lower pipe is located under the engine.

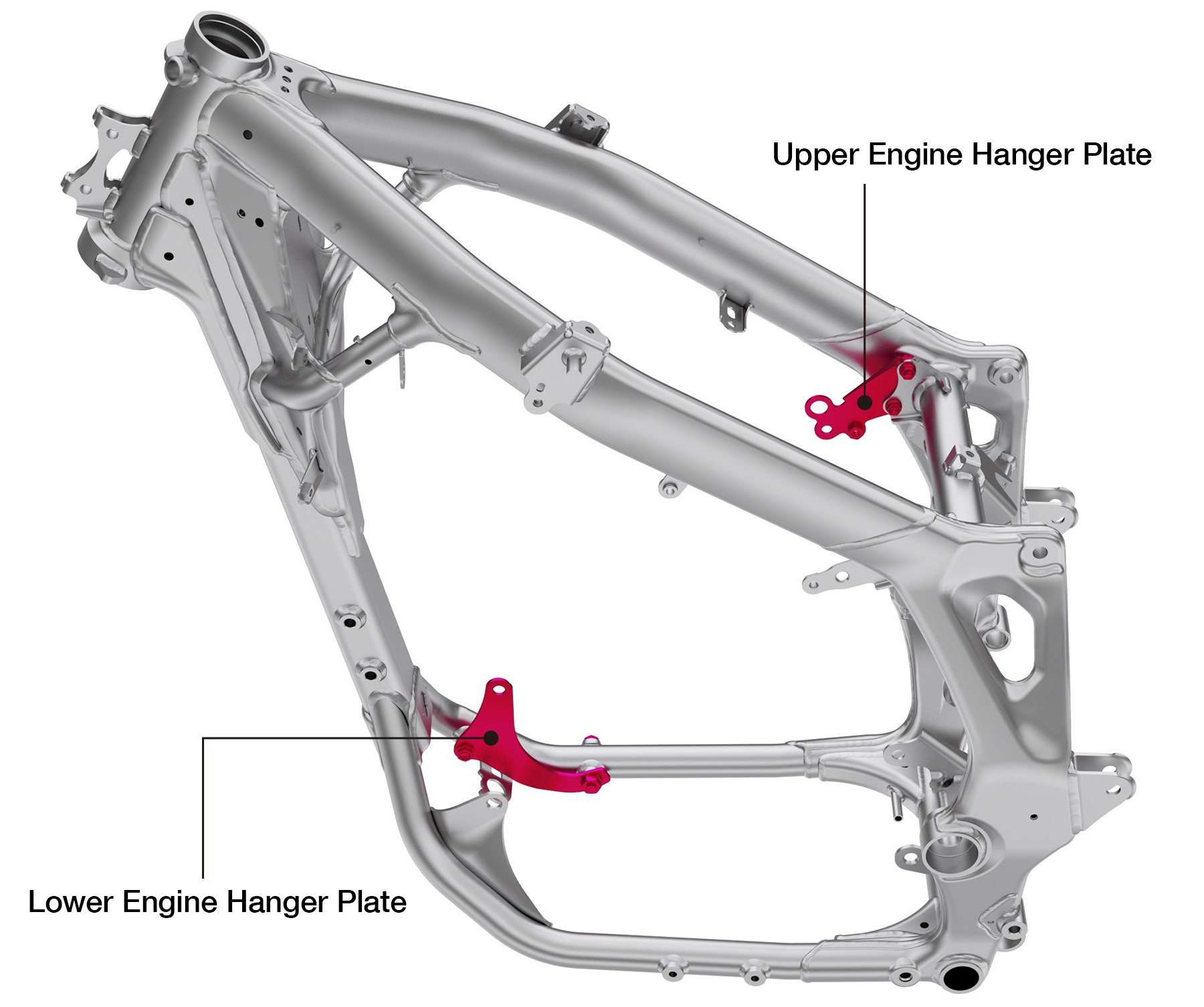

In the previous model, the right side of the lower pipe was a separate bolt-on structure to make it easier to mount the engine during manufacturing, but in the new model, it is a welded integrated structure.

The right-side lower engine hanger plate and the right-side rear upper engine hanger plate have been separated to ensure the same level of engine installability as before.

The Engineer Talks

-What was the purpose of changing the structure from the previous model?

“This is also to make it easier for the rider to comprehend the bike's behavior in hard riding situations.

In the past, one side of the frame was welded and the other side was bolted, which inevitably resulted in a slight difference in the flexibility of the left and right sides of the frame.

It was surely designed to minimize the effect, but we decided to make some changes in this part to take it to the next level.”

-If the change is possible this time, couldn't it have been done before?

“In hindsight, yes.It would have been possible. However, since we are starting mass production of bikes from scratch and have not yet accumulated enough knowledge, we cannot take things too fast.

If the difficulty of assembling increases, it will affect the quality of the bike. This time, we have been able to install the engine in a new way because we have acquired technological insights over the three years since 2016.

We will continue to improve the technology and update it as we continue production.”

The head pipe is located at the end of the frame. The center of torsion has been lowered by revising the gusset, and the rigidity has been optimized to achieve both weight reduction and stability.

The pivot plate to which the swing arm is attached inherits the same structure of two steel press plates overlapping each other as in the previous model, but the inner part is made of 600 MPa class high strength steel to reduce the thickness of both the inner and outer plates to achieve weight reduction. The suspension is placed at the center of the vehicle body so that the load from the suspension can be equally transferred to the pivot plate on both sides.

The Engineer Talks

-The head pipe and pivot plate are important parts of the frame design, aren’t they?

“Yes, they are. Because the impact from the tire is transferred to the frame via the head pipe and pivot plate first. The head pipe receives the load impact from the front fork while the pivot plate receives the load impact from the rear cushion.

How to connect these two points is the key to frame body design.”

-What kind of modification has been applied?

“First, the head pipe. We have reviewed the frame design thoroughly, but the most significant change is the elimination of the cross pipe behind the head pipe, which makes the bike more "flexible".

However, if the cross pipe is simply eliminated, the rigidity to withstand braking and jumping will be lost, and the movement of the head pipe during suspension operation will cause the suspension to lose its operability. In order to compensate for this loss, we reviewed the surrounding areas. As a result, we have achieved a flexible and nimble handling setting that gives the rider a sense of security.”

-What about the pivot plate?

“There is a center cross pipe that connects the pivot plate to the left and right, and that is where large impacts from the rear cushion are received. In the previous model, the rear cushion was slightly offset to the right side, but for the new model, we reexamined the placement of various parts from scratch and placed it in the center again.”

-What kind of effect do you expect?

“As with the lower pipe, this is to ensure that the impact to the frame is equal on both sides. If the impact is unevenly distributed to one side of the frame, the frame has to be "stiffened" and if the frame is stiffened, the ride quality becomes heavier.

We need to ensure that the load will be shared and distributed through the entire frame, even if only a little, which is the concept of effect that we expect can be achieved through our effort.”

New Items Adopted in the CRF1100L Africa Twin

A More Powerful Engine

The DCT in Closer Harmony with the Rider’s Feeling

Suspension for variable characteristics

Electrical Systems for Greater Adventure