Honda Engines

Honda Engines

2025.11.24

C30A: Naturally Aspirated V6 Engine Combining the Most Advanced Technologies of the Time

INDEX

Aiming for the Ultimate Naturally Aspirated Engine

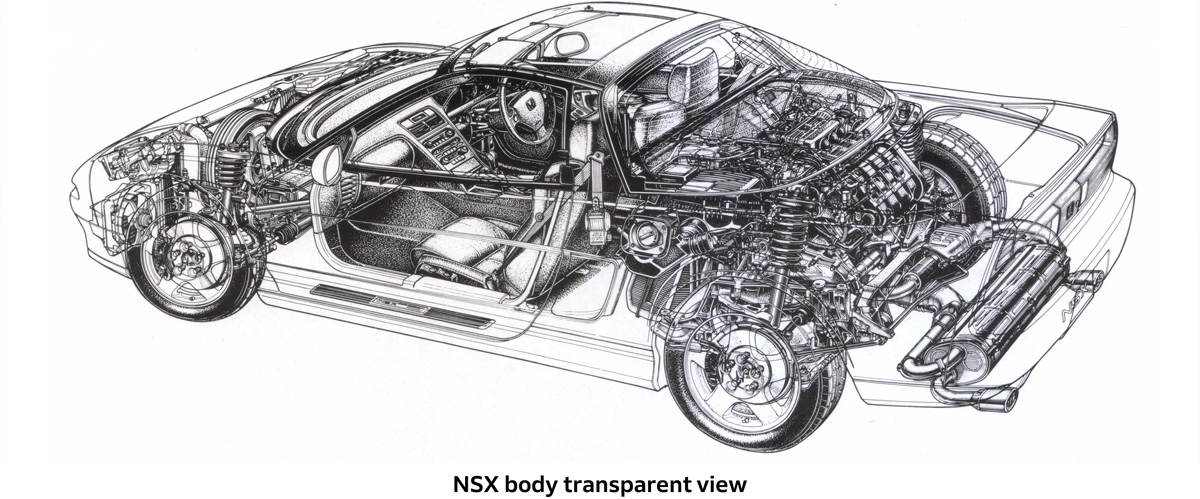

Honda developed the C30A 3.0-liter V6 DOHC VTEC engine exclusively for the NSX midship sports car launched in September 1990. The NSX was developed as a high-performance sports car that pushed the limit for dynamic performance. It was developed with the goal of transmitting full driving torque directly to the road surface and achieving outstanding handling performance through the ideal balance of weight between the front and rear. To achieve this goal, the heavy engine was mounted to the rear of the cabin and close to the center of gravity, and a midship-engine rear-wheel drive (MR) layout was used.

A high-performance engine and lightweight body are essential for improving the dynamic performance of a vehicle. Increasing engine displacement is an easy and effective way of achieving this high-performance engine, but weight and size increases come with any such displacement increase. Increasing engine speed without increasing displacement is another effective way to improve performance, and this can be achieved by increasing the number of engine cylinders. Increasing cylinder numbers, reducing cylinder volume, and reducing piston stroke can be advantageous for increasing engine speed. However, conversely, this method increases the number of parts, thereby increasing engine weight and size in the same way that increasing displacement does.

Yet another way of improving performance is to use a turbocharger or other forced induction device, but with the related increase in auxiliary equipment like intercoolers, the weight and size of the system as a whole increases. Also, compared to naturally aspirated engines, this would require large-scale heat solutions while introducing concerns about a deterioration of drivability due to turbo lag. After such investigations, Honda decided to set displacement at 3.0 liters to achieve a balance between power output and weight, and choose a V6 cylinder format for compact engine design. Likewise, it mounted the engine transversely with a 5 degree lilt to the rear to reduce the longitudinal dimension of the engine, while providing the 5-speed manual transmission (5MT) or 4-speed automatic transmission (4AT) in a side-by-side layout.

With a V6 engine, the ideal V-bank angle for regular interval combustion, which carries performance and vibration advantages, is 120 degrees. However, a 120-degree bank angle takes up too much space, which was considered particularly unsuitable for a transverse-mounted engine. A common solution to this issue that achieved regular interval combustion was to use a 60-degree bank angle with a 60-degree offset for the crank pins. This enabled a slimmer engine, but created a taller engine in return.

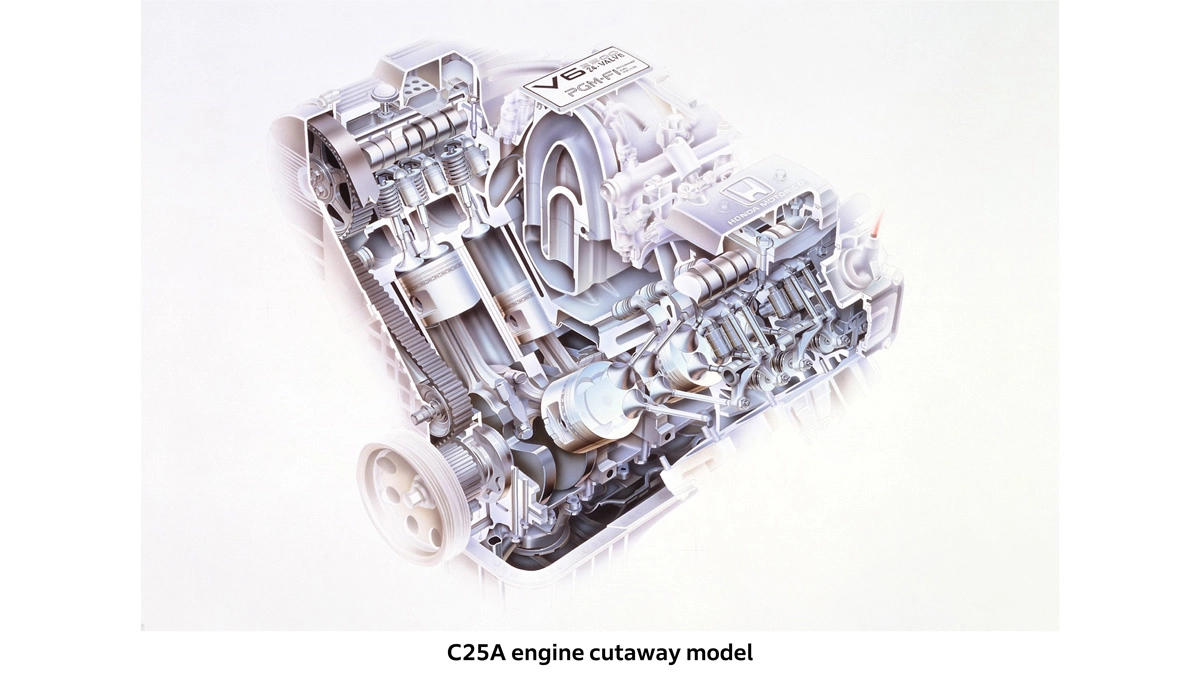

When newly developing a V6 engine for its Legend, launched in November 1985, Honda chose a 90-degree V-bank layout to balance engine width and height. It added a 30-degree offset for the crank pins to achieve regular interval combustion. It also adopted an SOHC cylinder head with a single camshaft driving the four intake/exhaust valves per cylinder of the 2.0-liter C20A and 2.5-liter C25A engines it developed for the Legend.

When developing an engine for the NSX, Honda initially decided to use the C25A as the base model and increase displacement to 3.0 liters. However, in 1989, about a year before the NSX debut, it launched the Integra with VTEC, the world’s first variable valve timing and lift technology. With the new DOHC VTEC technology now available, there were discussions about whether SOHC technology would really be appropriate for a new-generation sports car combining Honda’s cutting-edge technologies. As a result, it was decided to quickly shift from SOHC to DOHC VTEC technology.

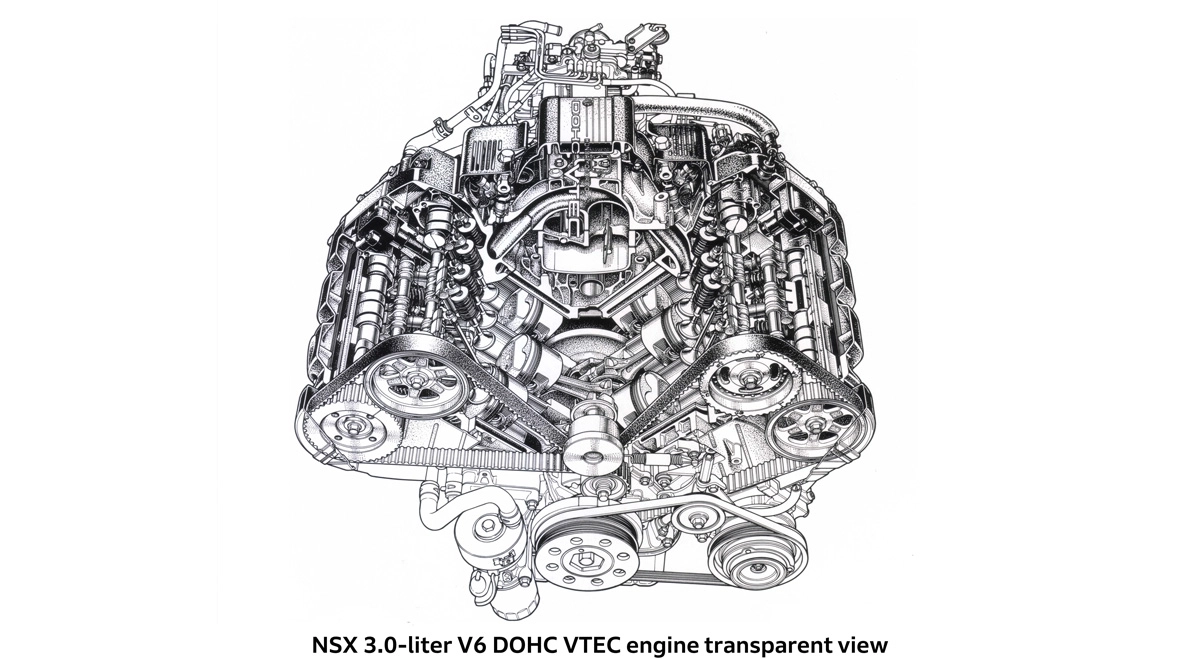

When developing the C30A engine for the NSX, Honda started by choosing DOHC to drive independent camshafts separately for the intake valves and exhaust valves, and setting displacement at 3.0 liters (2,977 cc), which was a configuration based on the C-series 90-degree V-bank layout. It set bore and stroke dimensions at 90.0 mm and 78.0 mm respectively. However, achieving high-power output from a naturally aspirated engine necessitated efficient intake and combustion of large amounts of the air-fuel mixture right through to the high-rpm range. Honda’s choice of a big-bore, short-stroke engine therefore also incorporated the goal of maximizing effective area of the valves.

At the time the NSX was developed, the tendency was for drivers to adapt their driving techniques to the characteristics of the machine to take full advantage of engine performance when driving. However, Honda rejected such conventions and felt that, rather than only being accessible to racing drivers and the like, every owner of an NSX should be able to enjoy the outstanding power performance of the NSX.

Honda believed that straightforward accelerator pedal operation attuned to the driver’s sensibilities and a naturally aspirated engine able to rev up to high rpms without stress, without placing unnecessary tension on the driver, would be appropriate for a next-generation sports car like the NSX.

VTEC Enables 8,000 RPM Red-Zone Driving

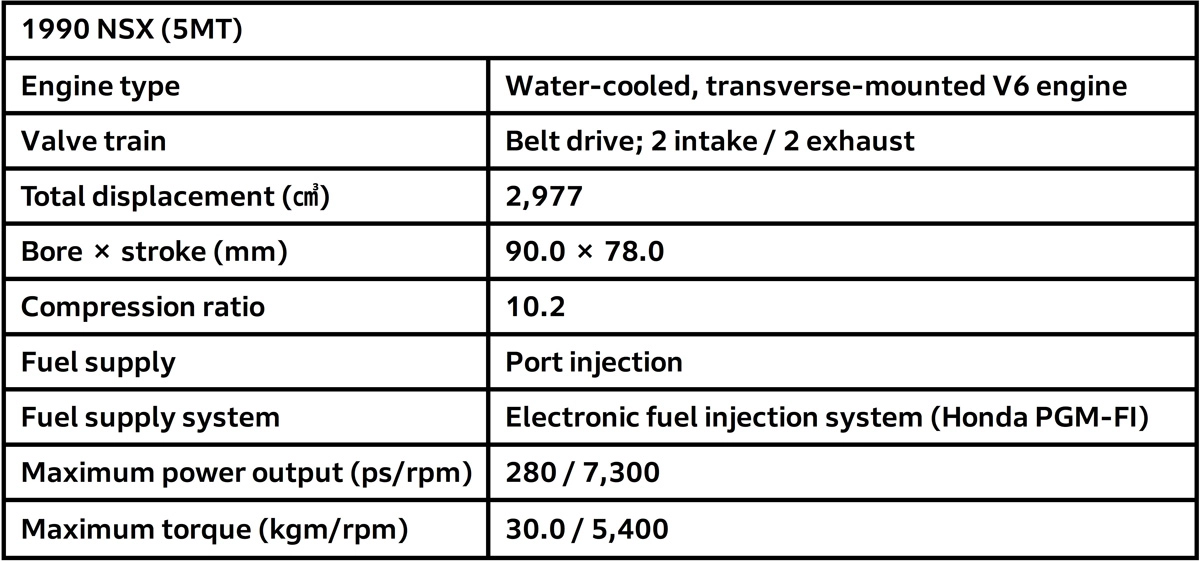

The C30A was designed to generate maximum output power of 280 PS at 7,300 rpm (for 5MT vehicles, while 4AT vehicles generated 265 PS at 6,800 rpm), and maximum torque of 30.0 kg·m at 5,400 rpm, which were class-leading achievements for a 3.0-liter naturally aspirated engine at the time. The red zone for the manual was set to start at 8,000 rpm, and for the automatic at 7,500 rpm. DOHC VTEC, adopted at the last minute, was one of the technologies that helped achieve this performance.

When pursuing high-rpm, high-power output equivalent to a racing engine, performance can easily become unstable in the low- to mid-rpm range. Conversely, focusing on performance in the low- to mid-rpm range can make it more difficult to achieve high power output. The VTEC technology was able to achieve a balance between the conflicts of ease of handling in the low- to mid-rpm range, and high-rpm, high-power output performance. It was a system for switching between optimal valve open/close timing and lift profiles for the low- to mid-rpm range, and optimal valve open/close timing and lift profiles for the high-rpm range. (Refer to “B16A: Honda’s Innovative Engine with VTEC World-First Variable Valve Timing and Lift Technology” for more information on VTEC.)

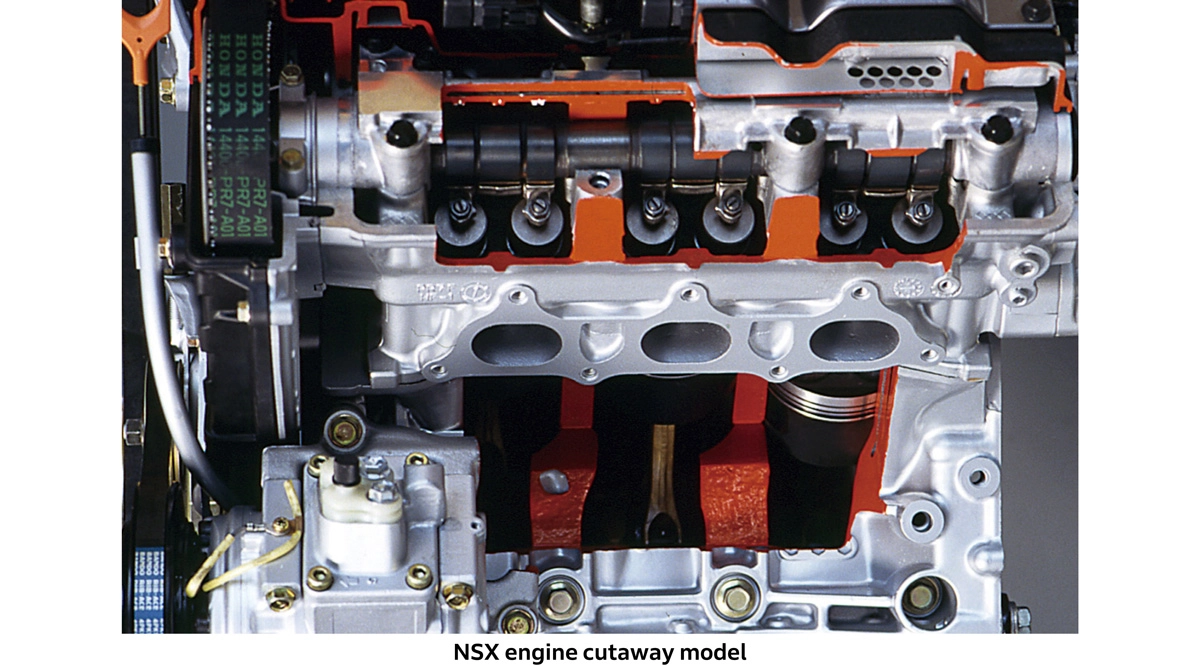

Normal DOHC engines with four valves per cylinder employed two rocker arms and cam lobes per cylinder on each of the intake-side and exhaust-side camshafts. VTEC, on the other hand, employed a third rocker arm and cam lobe. The two outside cams in the line provided low-lift cam lobes (primary and secondary) for the low- to mid-rpm range, while the center cam provided a high-lift cam lobe for the high-rpm range. By switching between these two cam types according to operating conditions, the system provided optimal valve timing and lift for both the low- to mid-rpm range and the high-rpm range. In this way, it was able to create both high-rpm, high-power output characteristics, and high-torque characteristics for the low- to mid-rpm range.

In the C30A engine, timing for the switch from the low-lift cams to the high-lift cam was set at 5,800 rpm. Valve lift for the primary lobe on the intake-side, controlling the low- to mid-rpm range, was set at 8.7 mm, and the secondary at 8.3 mm. The secondary side was set to open slightly later than the primary side and to close earlier to create an intake air swirl effect (laterally rotating vortex) to mix the fuel spray and air well. Valve lift for the high-lift cam lobe was set at 10.2 mm. While these settings were for the manual transmission configuration, automatic transmission specifications were set for slightly lower rpms.

Nevertheless, it was not possible to cover all engine speeds from the low- to mid-rpm range to the high-rpm range of 8,000 rpm, even with VTEC, and a torque dip was created. Honda therefore developed a resonance chamber volume switching intake manifold system (temporarily accumulating air) to eliminate any dips in torque. Using the resonance effect and inertia effect of the naturally aspirated engine, the system switched between them according to the speed of the engine to draw in larger amounts of the air-fuel mixture into the cylinders.

The resonance effect is the creation of a resonant sound when a specific frequency is received, maximizing the vibration amplitude of the air. Pressure amplified by this resonance returns to the intake port, which improves volumetric efficiency as pressure rises at the front of the intake valve during the intake stroke to draw in large volumes of air into the cylinders. With this resonance effect being particularly strong in the engine’s low- to mid-rpm range, it increases torque at these speeds.

With multi-cylinder engines, each cylinder takes advantage of a pressure wave generated during the intake stroke of the preceding cylinder. This increases pressure at the port opening immediately prior to the next cylinder’s intake valve closing, which improves volumetric efficiency during air intake.

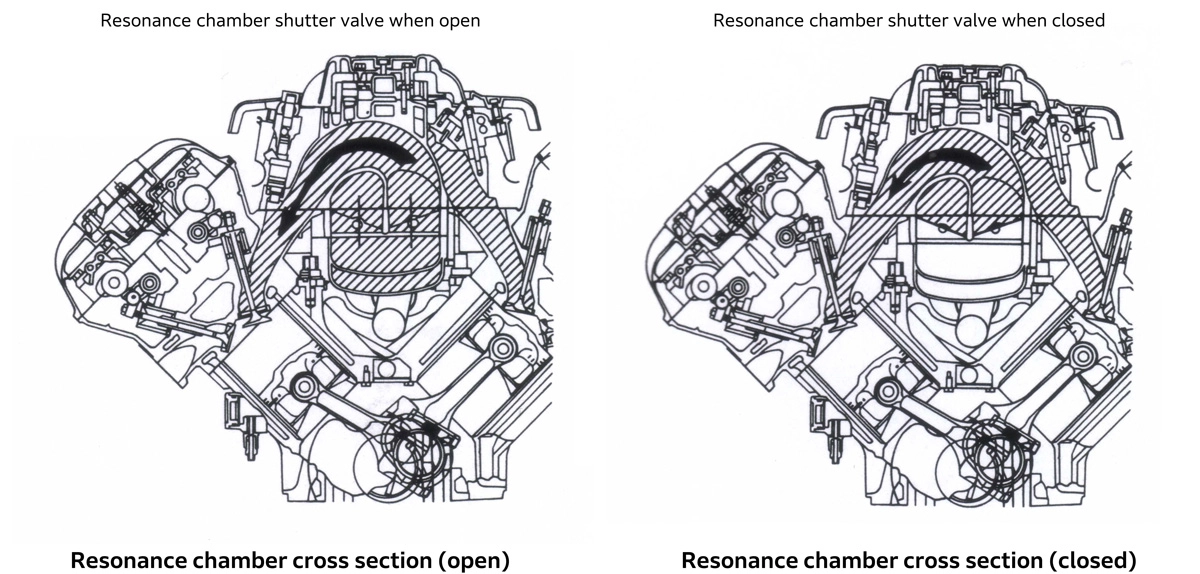

The C30A was equipped with a chamber with six shutter valves (three integrated valves per bank) located within the V-bank. In the low- to mid-rpm range, the chamber’s shutter valves closed to create a resonance that increased volumetric efficiency of the air intake and increased torque. In the high-rpm range, on the other hand, where intake airflow momentum builds and inertia increases, the shutter valves opened to take advantage of that inertia and increase both volumetric efficiency and power output.

The shutter valves were set to open at 4,800 rpm. As a result, the VTEC’s low-speed cams took advantage of the resonance effect up to 4,800 rpm and the inertia effect from 4,800 rpm to 5,800 rpm, and then the high-speed cams took advantage of the inertia effect from 5,800 rpm and higher. In this way, the C30A combined VTEC with the resonance chamber volume switching intake manifold system to realize linear engine characteristics, without any dips in torque, across the entire speed range.

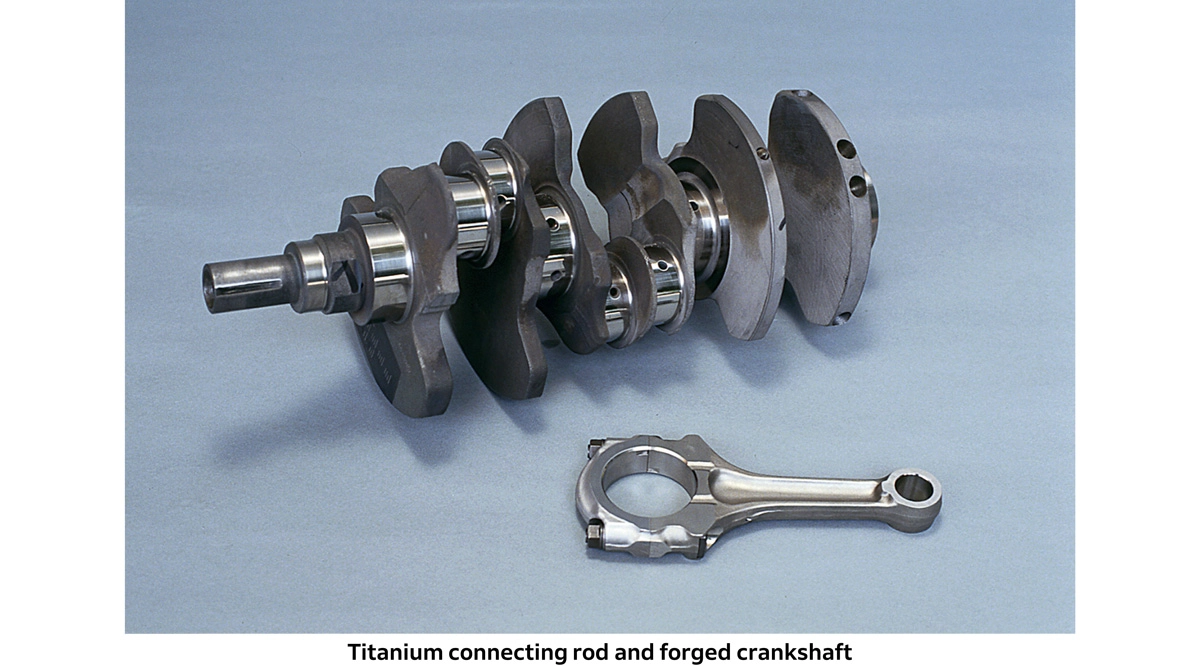

Extensive Adoption of Lightweight, High-Performance Materials and Processing Technologies

The C30A produced 280 PS of output power, which was a class-leading achievement for 3.0-liter naturally aspirated V6 engines at the time, and a high engine speed of 8,000 rpm (for the manual transmission). These high engine speeds were largely achieved due to the use of lightweight titanium connecting rods. Inertia forces generated by pistons and connecting rods, as reciprocating movement parts, increase in proportion to the square of the speed. In other words, inertia forces increase at an accelerating pace as engine speeds increase, which increases pressure on the crank pin pressure-bearing surfaces and leads to reduced thickness of the oil film between crank pins and connecting rod plain bearings. Because peripheral speed also increases, the seizure resistance of parts (bearing margin) declines. Conversely, reducing the weight of connecting rods lowers these inertia forces, which increases the thickness of the oil film between crank pins and connecting rod plain bearings and improves seizure-resistance limits. This in turn enables higher engine speeds.

Titanium has a lower specific gravity than iron and it exhibits excellent tensile strength. Tensile strength and durability are closely related. It was understood that changing conventional steel connecting rods to titanium alloy rods leads to dramatic reductions in weight and improvements in durability, but the change brings difficulties in terms of forgeability and machinability due to the characteristics of the material. Also, because there were no surface hardening technologies suitable for mass production, the application of this alloy to mass-production parts had been extremely rare, excluding special applications such as racing engines.

When developing the C30A, Honda set about developing these titanium alloy connecting rods as a technology for achieving high rpms and high power output. This led to the development of a new titanium alloy (Ti-3Al-2V) with improved forgeability and machinability. It was further able to apply the technology to mass-production parts through a range of measures, including the establishment of a surface hardening technology (CrN PVD coating) that could guarantee reliability and durability of the parts. Compared to conventional steel connecting rods, the technology reduced weight by approximately 190 g per rod, or roughly 30 percent less weight. The reduction in reciprocating inertia force due to this lightweighting also had the effect of raising the engine’s maximum speed by approximately 700 rpm.

The C30A engine’s cylinder heads were made from aluminum alloy, as was the cylinder block, which had an open deck structure with cast-in-place cast iron liners. A magnesium alloy with lower specific gravity than aluminum was used for the intake manifold chambers, cylinder head covers, and top cover. Finally, high-strength NC43VC material was used for the crankshafts and the plain bearings were polished to an ultra-high gloss mirror finish.

The C30A’s included valve angle was set at 60 degrees, with intake and exhaust valves angled at 30 degrees each. Intake valve diameter was set at 35 mm, exhaust valve diameter at 30 mm, and valve stem diameter at 5.5 mm. Considering that the valve stem diameter on the B16A 1.6-liter inline 4-cylinder DOHC VTEC engine, installed on the Integra and other models, was 6.6 mm, these settings made the C30A a more aggressive design. Honda was able to achieve such narrow diameters through innovations in material and manufacturing technologies. The narrow stems led to reduced weight of the valve themselves. It also reduced the reciprocating inertial mass and delivered advantages in terms of higher engine speeds and reduced losses. It also had the effect of reducing resistance of intake and exhaust air when passing through the ports.

The camshafts had a solid structure on the intake side to ensure rigidity where lift was higher. On the other hand, they had a hollow structure on the exhaust side to reduce weight. In addition, valve springs were made from high-strength material to support higher engine speeds. Silicon was added to the aluminum alloy pistons to increase strength, while a molybdenum coating was added to the piston skirts to reduce friction.

As compression ratios increase, maximum pressure during combustion also increases, which enables higher power outputs. With the C30A, Honda used pent-roof combustion chambers with the plugs located at the center, enabling outstanding combustion efficiency, and set the compression ratio at 10.2. The engine was designed exclusively for use of RON100* fuel to provide high knocking resistance. An additional knocking control technology was also used to prevent knocking by detecting the state of ignition through signals sent from two sensors located inside the cylinder block. This technology had the effect of increasing both power output and torque.

* RON stands for Research Octane Number, which is an indicator of engine knocking resistance as calculated using the research method. The higher the number, the higher the resistance to knocking. Japanese Industrial Standards (JIS) stipulate that regular gasoline must have an octane number of at least 89.0, expressed as RON89, while high-octane gasoline must have an octane number of at least 96.0 (RON96). In Japan, the actual rating of high-octane gasoline is around RON100.

The C30A used platinum spark plugs, with platinum center electrodes and ground electrodes for good thermal load and vibration resistance. Instead of the conventional method of sending high-voltage current from the distributor via high-tension leads to the plugs, it used a direct ignition system with compact ignition coils attached directly to each spark plug. This method provided more powerful and stable ignition.

In this way, Honda applied a range of detailed high-rpm, high-power output technologies to the C30A, developed exclusively for the NSX. This resulted in good low-speed torque in the practical driving range and the ability to quickly rev up to the high-rpm range. As a naturally aspirated high-rpm, high-power output engine with high performance across the entire speed range, it was truly worthy of a next-generation sports car. In addition to reducing inertial mass to contribute to high engine speeds, Honda also focused on lightweighting the engine as a whole to contribute to improved vehicle dynamic performance.

To support more extensive driving in the high-rpm range for the NSX Type R that it launched in November 1992, Honda implemented thorough quality control, on par with its racing engines, to improve the precision of crankshaft balance and piston/connecting rod weight. As a result, the car delivered smooth and powerful acceleration without affecting maximum output power or maximum torque specifications.

Specifications

TechnologyHonda EnginesC30A: Naturally Aspirated V6 Engine Combining the Most Advanced Technologies of the Time