Honda Engines

Honda Engines

2025.09.30

B16A: Honda’s Innovative Engine with VTEC World-First Variable Valve Timing and Lift Technology

INDEX

Realizing 100 PS per Liter High Output with a 1.6-Liter Engine

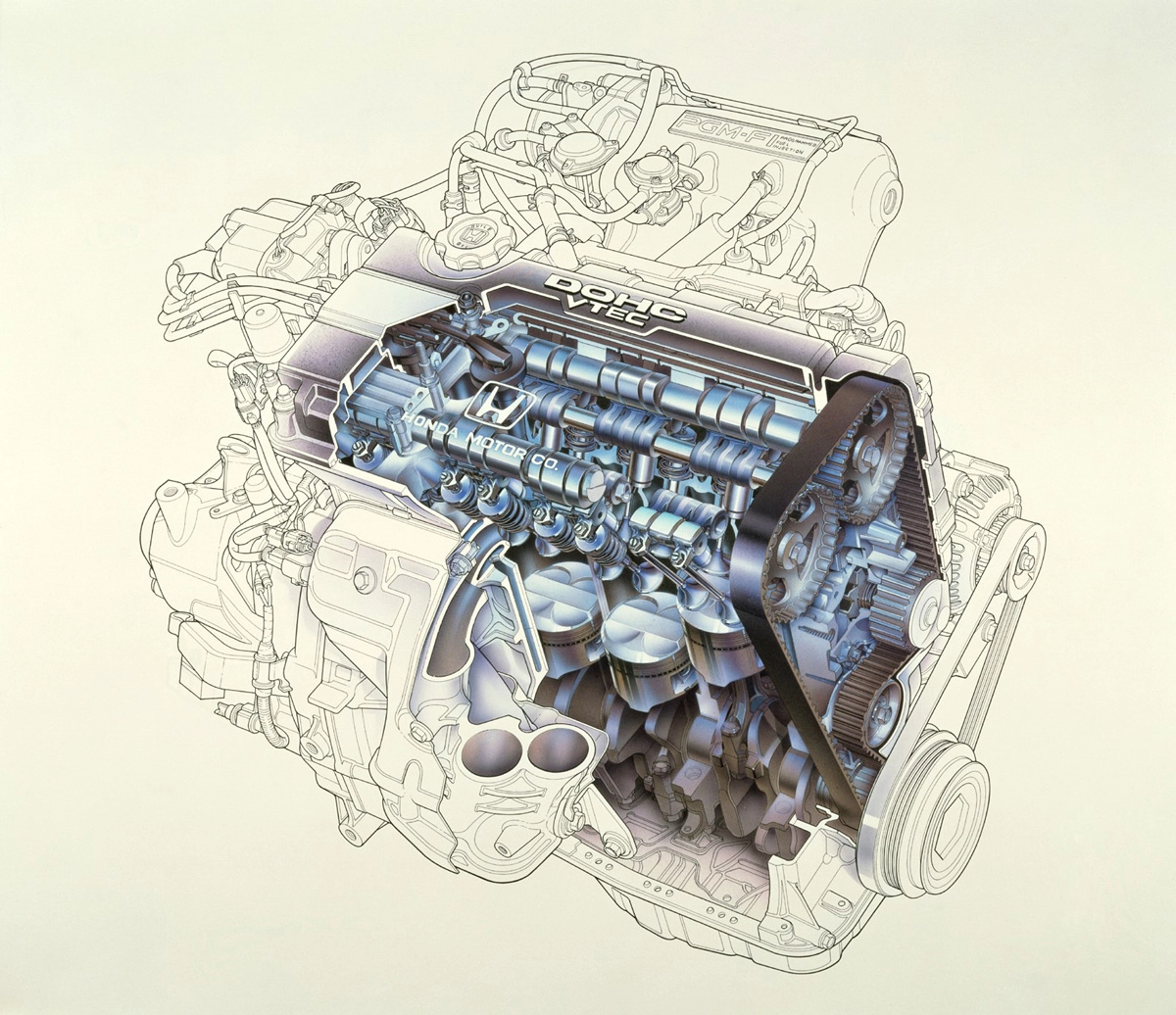

The B16A 1.6-liter inline 4-cylinder DOHC engine is a naturally aspirated engine that made use of the world’s first variable valve timing and lift technology, VTEC, to achieve both a high power output of 100 horsepower per liter (100 PS) and a robust low- and mid-rpm performance. It was incorporated into the Integra model launched on April 19, 1989, and into the CR-X and Civic models launched on September 21 the same year.

There are generally two ways to boost engine power. One way is to increase the engine’s workload by increasing its speed. The other way is to compress the intake air using a forced induction device, such as a turbocharger. The amount of fuel burned by an engine depends on the amount of oxygen present in the intake air. The higher the pressure, the more oxygen there will be. Forcing air into the engine has a similar effect to increasing engine displacement and can therefore be used to boost engine power.

At the time, however, the inevitable trade-off for enhancing power output with a turbocharged engine was a delay in engine response, known as turbo lag, which affected drivability. Honda, rather than rely on a turbocharger, decided to go down the path of increasing the speed of a naturally aspirated engine, thereby realizing the smooth, strong acceleration and exhilarating driving experience of a naturally aspirated engine, as well as high power output.

This decision was supported by achievements in racing engine development for Group A vehicles used in the Japanese Touring Car Championship. Honda competed in the Group A category for vehicles under 1600 cc from midway through the 1985 season with a Civic fitted with a ZC naturally aspirated 1.6-liter inline 4-cylinder DOHC engine. The car dominated as a champion machine from 1986 until the series wound up in 1993. Development of the car’s engine enabled Honda to accumulate knowledge about aspects such as valve timing and lift, which was needed to increase engine speed. Honda could now see a path to realizing 100 PS per liter even with a 1.6-liter engine.

VTEC Development Background and Basic Principles

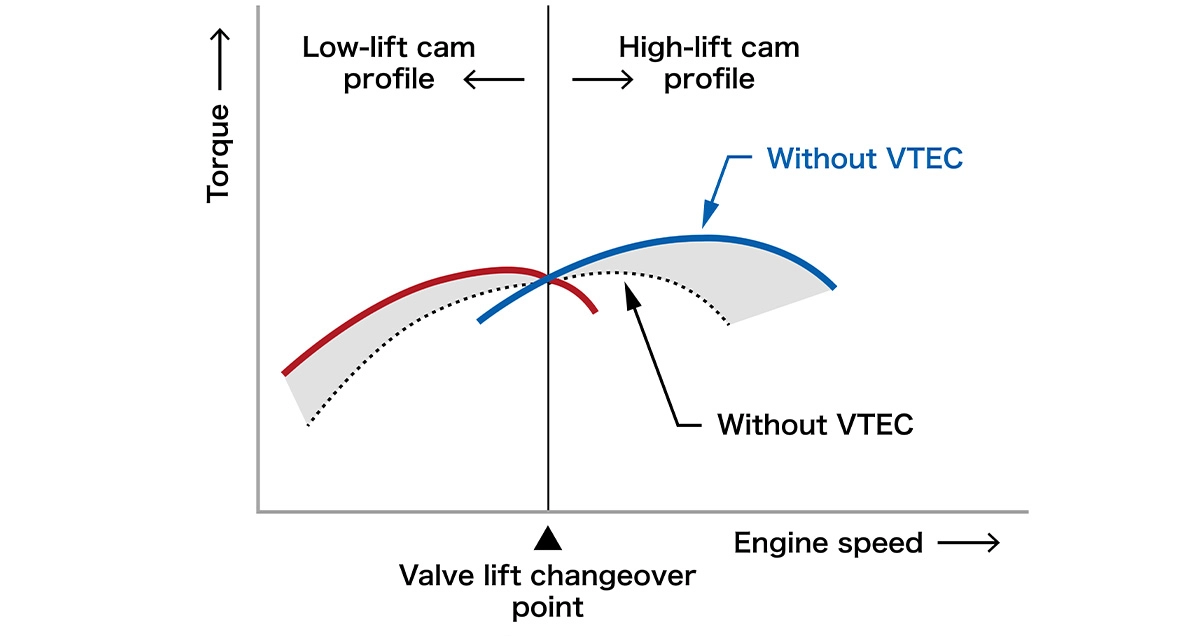

The primary focus when developing racing engines is performance with high rpm and high power output. In the case of passenger vehicles, handling in the low- to mid-rpm range is also important. VTEC, which stands for “Variable Valve Timing & Lift Electronic Control System,” is the technology that fulfills these contradicting requirements.

Torque characteristics comparison between VTEC engine and earlier engines

Torque characteristics comparison between VTEC engine and earlier engines

High-lift cam profiles were the norm for pre-VTEC sports car engines, which sacrificed low-rpm ranges in favor of high rpm. VTEC was the gamechanger, allowing switching between valve lift profiles.

VTEC evolved out of REV (Revolution Modulated Valve Control), a valve deactivation mechanism developed for motorcycles in 1982. The REV system deactivates one intake valve and one exhaust valve on each cylinder (each cylinder has four valves—two intake valves and two exhaust valves) in low-rpm ranges. Applying the basic principles of the REV system, VTEC switches between different intake and exhaust valve open/close timing and lift profiles for the low- to mid-rpm range and the high-rpm range.

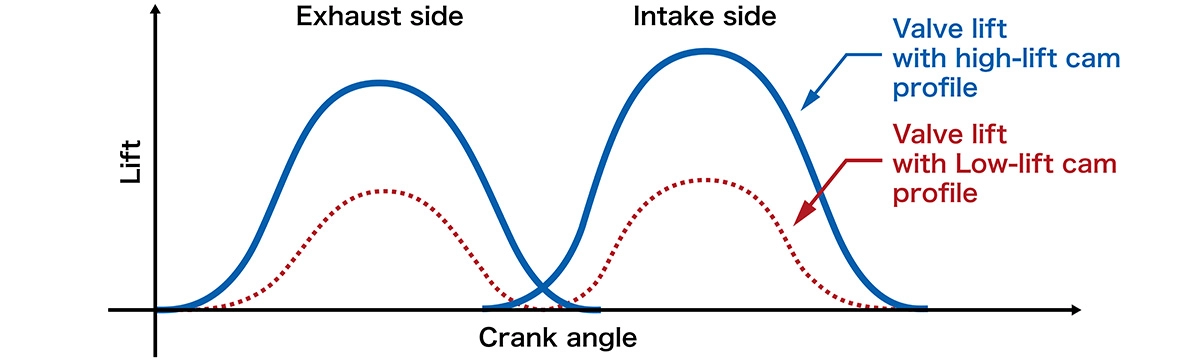

Comparison between high-rpm valve lift (high-lift cam profile)

and low-rpm valve lift (low-lift cam profile)

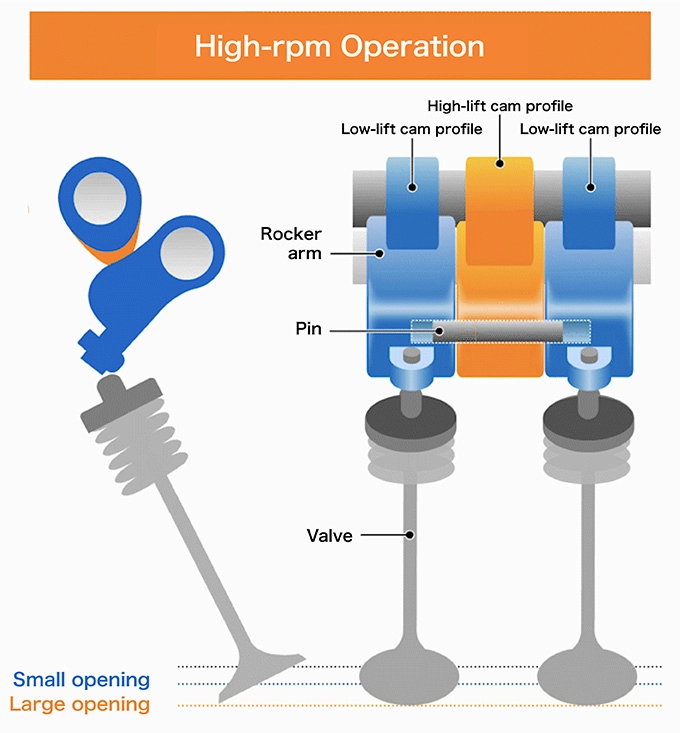

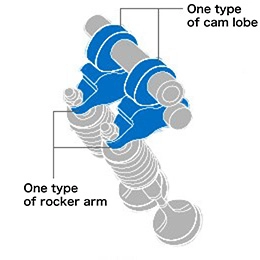

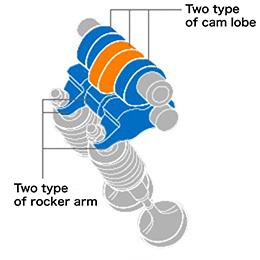

The engine’s intake and exhaust valves are operated by camshafts. As each camshaft rotates, egg-shaped cams attached to the shaft push down mushroom-shaped valves, via a rocker arm, to open and close them. The shape of the cams determines the valve timing, while the height of the cam lobe determines the valve lift.

VTEC—How It Works

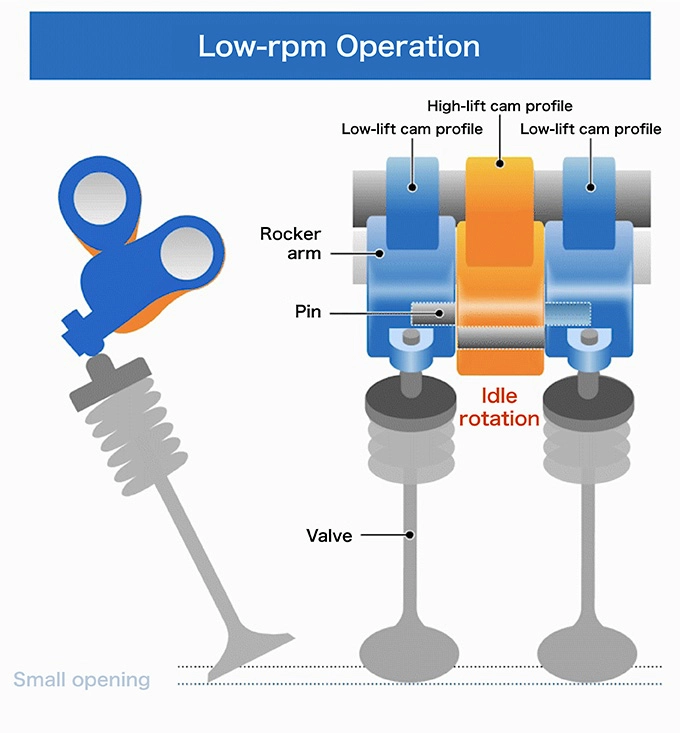

The top diagram illustrates the valves during low-rpm operation. Short cam lobes are used for low valve lift. The cam used for high valve lift, shown in orange, and the rocker arm it touches move as the camshaft rotates, but because the pin inside the rocker arm is not engaged, this is idle rotation (lost motion) with no effect on valve operation. The long pin remains fully inside the high-lift cam rocker arm.

The bottom diagram shows the valves during high-rpm operation. The short pin inside one of the rocker arms touching a low-lift cam lobe (blue) pushes the pin inside the rocker arm touching the high-lift cam lobe (orange) so that the three rocker arms are joined as one. In this state, movement of the high-lift cam lobe is conveyed to the other rocker arms, creating high valve lift. Pins undergo high-precision machining to within 50 μm to ensure proper insertion and removal.

In a VTEC engine, there are not one, but two types of cam lobes and rocker arms used to push down the valves on both intake and exhaust sides. Each cylinder has three cam lobes arranged in a row—low-lift lobes at both ends and a high-lift lobe between them.

Earlier mechanism

VTEC mechanism

Built into the rocker arms, which move when pushed by the cam lobes, are hydraulically operated pins. During low- to mid-rpm operation, the pins are retracted, pushed back by return springs. The three rocker arms are disconnected from one another. The low-lift cam lobes on either side open and close the valves, while the high-lift lobe rotates idly. This is a torque-oriented cam profile, ideal for the low- to mid-rpm range with a small overlap when both intake and exhaust valves are open at the same time and relatively small lift.

When the hydraulic pins are actuated, the three rocker arms become joined. The high-lift cam lobe then controls the movement of all the rocker arms, including the low-lift lobes on either side, making the valves open earlier and close later, and creating more lift. It is the same cam profile as the Group A-specification Civic. The resulting large overlap in valve timing, ideal for high-rpm operation, enhances exhaust scavenging, thereby improving volumetric efficiency during air intake, while the large valve lift facilitates intake and exhaust flow.

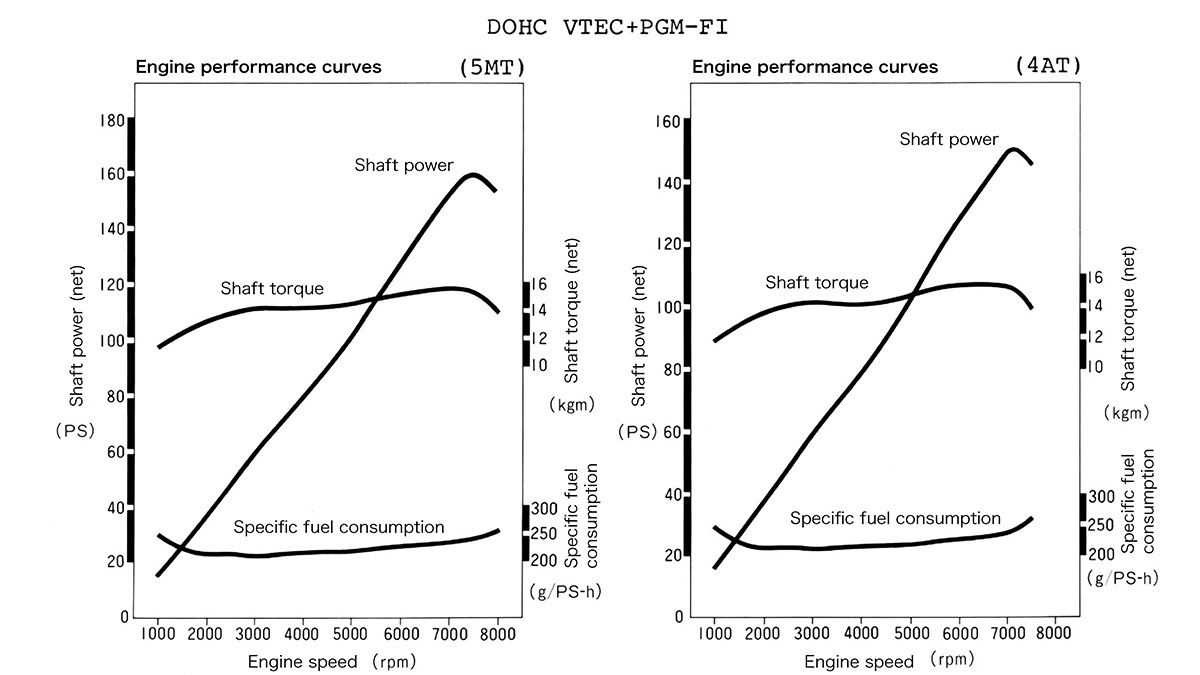

Switching between cam profiles is controlled according to the operating conditions at the time, with the engine control unit (ECU) sensing inputs such as engine speed, engine load, and vehicle speed. Switching occurs around the 4,800–5,200 rpm range. By incorporating VTEC technology, the B16A engine was able to exhibit the sharp response characteristic of a naturally aspirated engine, and not easily achieved with a turbocharged or other forced induction engine, while also realizing a maximum power output of 160 PS, or 100 PS per liter.

No compromise was made on torque characteristics in the low- to mid-rpm either—the engine revs quickly to 8,000 rpm in the red zone. There is a clear change in engine sound when switching the cam profile from low lift to high lift that both exhilarates the driver and announces the switch. This became an unintentional feature of the VTEC-incorporated B16A alongside high-rpm performance. The rocker arms, which move pins hydraulically to change the valve open and close timing and lift, required ultra-high-precision processing and high-precision adjustments.

A Host of Technologies Contributing to Later Engines

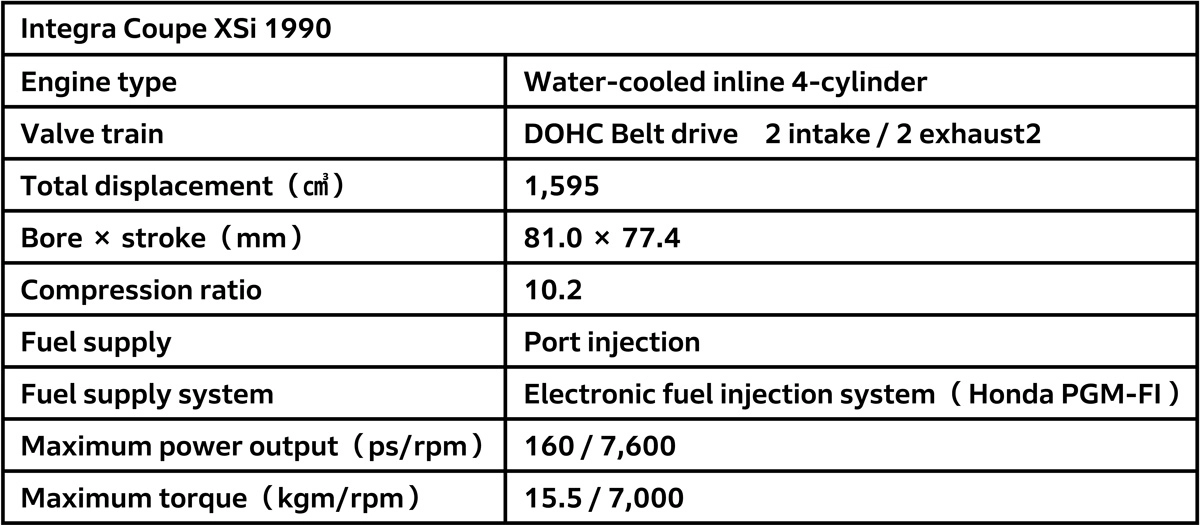

The B16A engine’s maximum power output was 160 PS at 7,600 rpm. Maximum torque was 15.5 kg·m at 7,000 rpm (with manual transmission). This contrasts with the 120 PS at 6,300 rpm and 14.5 kg·m at 5,500 rpm of the earlier ZC engine. Dimensions were also very different. Whereas the ZC is a long-stroke engine with a bore × stroke of 75.0 × 90.0 mm, the B16A is a short-stroke engine, measuring 81.0 × 77.4 mm, suitable for high rpm. A larger bore diameter allows the use of wider intake and exhaust valves. The B16A’s intake and exhaust valve diameters were 33 mm and 28 mm, respectively, contrasting with the ZC’s 30 mm and 27 mm. The valve angle is 56 degrees, enabling a compact pent-roof combustion chamber. A near-straight intake manifold was used, allowing higher airflow efficiency.

The cylinder block is made of aluminum alloy and has cast-in iron liners. To support high performance, the water jacket has deep grooves. Cooling efficiency was also improved by integrating the main oil gallery into the cylinder block. Oil jets were employed in the main gallery to spray the undersides of the pistons when oil pressure is high, such as in high-load, high-rpm situations.

The cylinder head, like the cylinder block, is also aluminum alloy to make it as light as possible. Whereas the ZC engine had a compression ratio of 9.1:1 (designed for regular gasoline), the B16A was designed for premium gasoline, realizing a high compression ratio of 10.5:1. The engine has both a knock limit improved by VTEC’s exhaust scavenging effects and a flame propagation distance shortened by having a compact combustion chamber.

The throttle body has wide bores for efficient airflow. To prevent an over-sensitive torque response at the beginning of accelerator depression, when the pedal stroke is small, the throttle employs an eccentric drum. This allows for smoother throttle opening relative to the pedal stroke when the accelerator pedal angle is small.

Pistons and connecting rods were made lighter to reduce the reciprocating mass. Crankshaft surfaces underwent lapping with an ultra-fine grinding stone to minimize friction. Camshafts, operated by high-strength timing belts, were cast using a new high-carbon, high-chromium steel alloy. Valves were made from a new material containing molybdenum and titanium. This allowed thinner stems, thereby realizing both reduced weight and improved heat-resistance strength.

Integra Coupe XSi (1990)

CR-X SiR (1989)

The B16A engine, while inheriting the 1.6-liter displacement of the ZC engine introduced in 1984, achieved both high-rpm, high-power performance and utility in the low- to mid-rpm range through the application of VTEC variable valve timing and lift technology. All the various components, including moving parts, the intake and exhaust systems, the cylinder head, and the engine block, incorporated technology optimized for high rpm and high power. After initial adoption for Integra, CR-X, and Civic models, as well as the NSX in 1990, VTEC became the centerpiece of Honda’s engine technology.

Specifications

TechnologyHonda EnginesB16A: Honda’s Innovative Engine with VTEC World-First Variable Valve Timing and Lift Technology