Honda Power Products: General-Purpose Engines (Chapter 3)

World Standard Model and the Future of Honda Power Units

Honda’s Power Products business began in 1953, with the launch of the H-Type general-purpose engine. At its core was founder Soichiro Honda’s passion to contribute to society through technology. Now, more than 70 years later, Honda’s Power Products business is focused on the next generation.

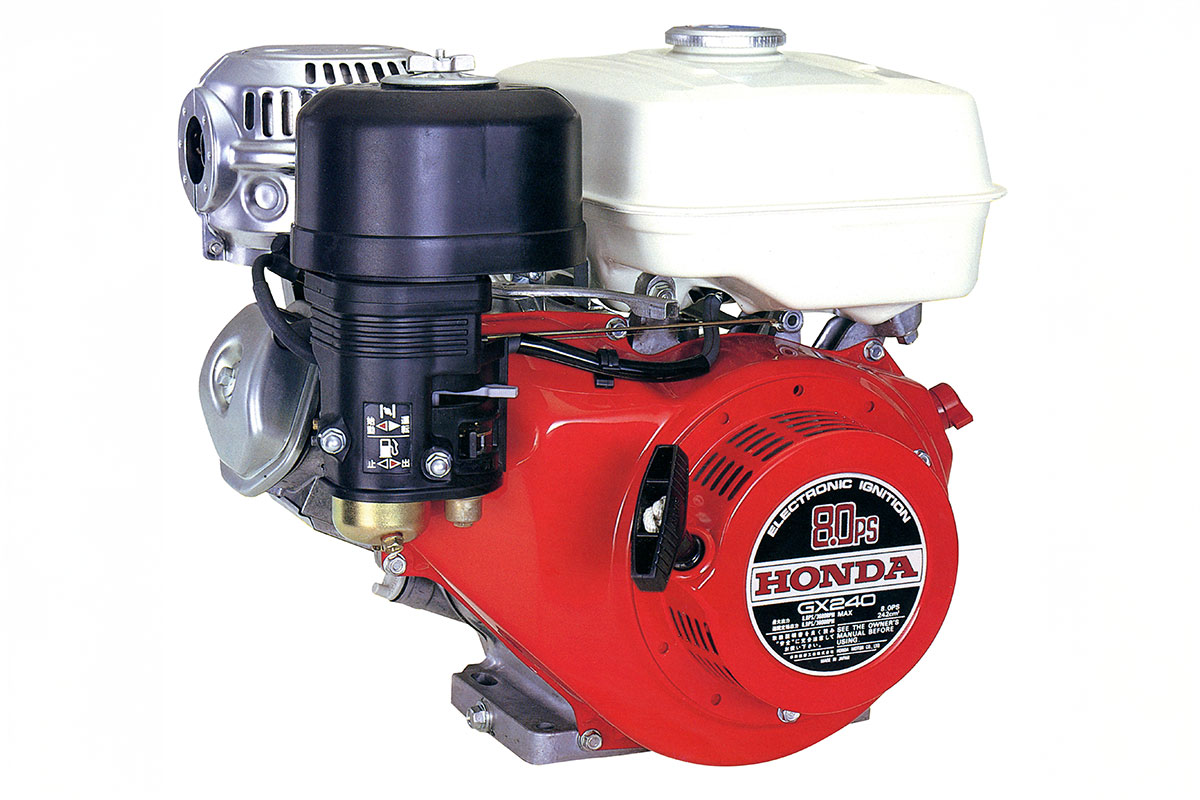

In 1983, the GX engine was launched with the goal of achieving the ZE (“Zillion Engine,” with an unimaginably large number of sales). On release, this engine earned praise throughout the world, and grew into a core product supporting Honda’s Power Products business.

The GX engine was particularly praised for its high durability, lightweight compact size making it easy for anyone to handle, its fuel efficiency offering great economy, and significantly reducing the maintenance burden on users. The defining feature of the GX engine was its shift from the SV (side valve) structure of the preceding G-series engines to an OHV (overhead valve) design. This new configuration delivered higher output, better fuel efficiency, and quieter operation. It also needed fewer parts than the SV engine, reducing manufacturing and sales costs.

Furthermore, the GX engine incorporated numerous new mechanisms enhancing its performance. These included mechanical decompression for easier starting and a maintenance-friendly, point-less transistorized magneto ignition system. For installation compatibility, the engine was successfully downsized by approximately 30% compared to the initial development target, enabling seamless integration into existing products originally equipped with conventional engines, fulfilling a key development objective. These technological challenges led to the GX series engines earning such high acclaim that they became known as the “industry standard” for general-purpose engines.

Sales of the GX engine grew immediately after release, coming within striking distance of the annual target of 3 million units. It gained high acclaim not only in the largest markets, North America and Europe, but also in Southeast Asia.

However, the downside was that the GX engine’s core design concept—the OHV mechanism with inclined cylinder—was adopted by general-purpose engine manufacturers worldwide. This forced Honda into a new competitive landscape. Consequently, Honda pursued continuous product improvements to enhance performance while also implementing cost reductions, enabling expansion into emerging markets in Southeast Asia and Africa.

Honda’s approach to emerging markets involved deploying service caravans in rural and fishing villages. This introduced the concept of after-sales service—regular repairs and adjustments—to these regions.

This approach, adjusting poorly performing products and repairing those with issues, could not be matched by competitors focused solely on low prices. Emerging low-cost manufacturers rapidly growing at the time priced their products so low that customers could simply buy a new unit if problems arose, and even included replacements for easily breakable parts in the package.

Consequently, Honda’s reputation for high durability, rapid parts supply, and robust service systems elevated its brand value. This after-sales service philosophy was a continuation of the approach Honda had followed since its founding for both motorcycles and automobiles.

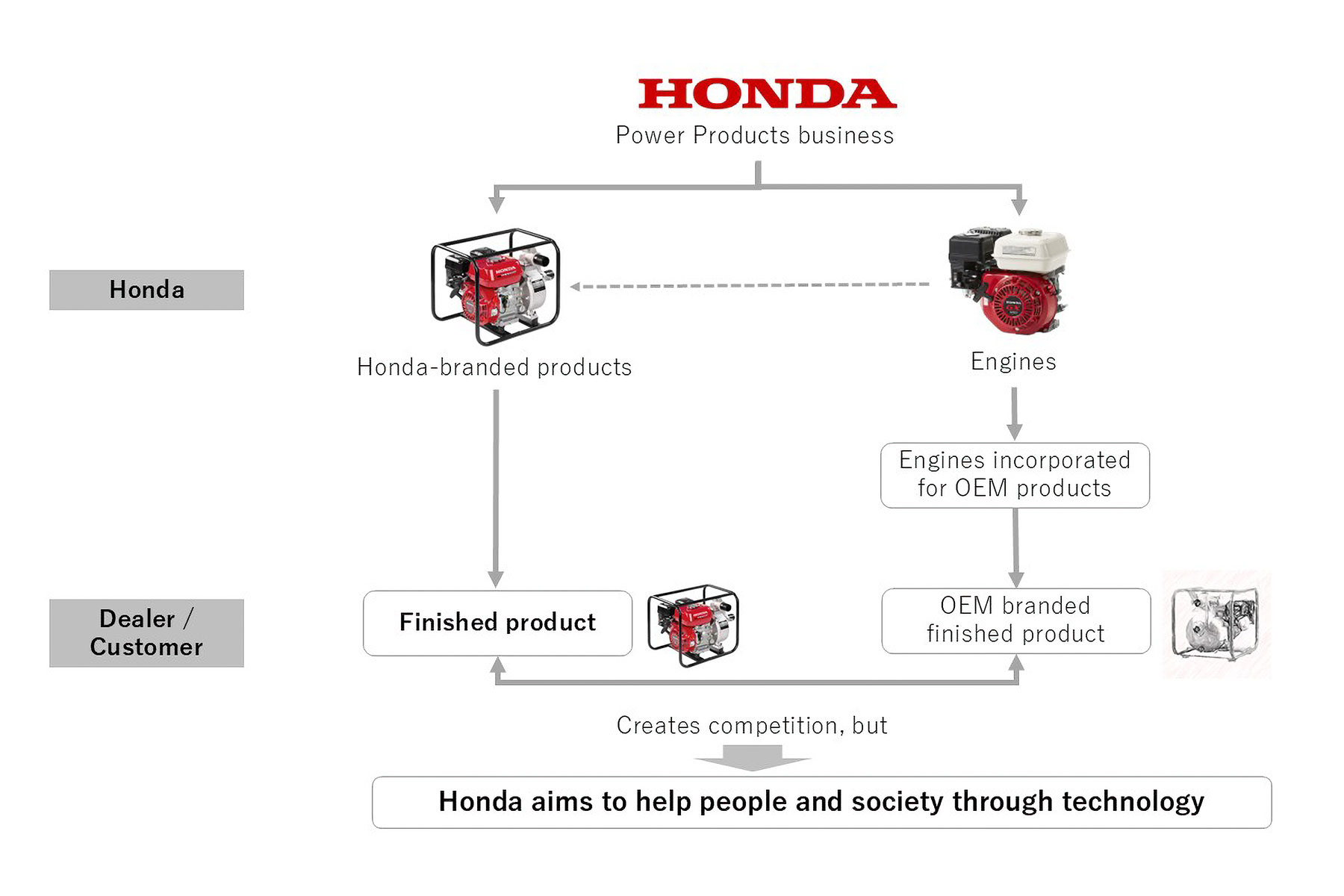

The reputation of the GX series engines also influenced Honda’s OEM sales of general-purpose engines to other manufacturers. While OEM sales typically avoid supplying products to competitors, Honda supplies its general-purpose engines even to manufacturers that compete with its products. Honda sells various products like lawn mowers, snow blowers, water pumps, and tillers, yet it also supplies general-purpose engines to manufacturers that produce and sell similar products.

This approach reflects the philosophy of Honda’s Power Products business. Honda believes that while selling finished power products brings happiness only to those customers, OEM sales increase the number of products powered by Honda’s general-purpose engines. This, in turn, creates greater potential to bring happiness to more people. This philosophy can be directly attributed to Soichiro Honda’s passion to “help people and society through technology.”

Furthermore, Honda’s general-purpose engines are adopted by various construction machinery manufacturers as power sources for equipment used in the construction industry. As a result, Honda’s OEM sales volume globally accounts for just under 70% of its Power Products business. Honda’s current OEM supply network now spans over 50 countries and exceeds 2,000 companies worldwide.

Honda’s general-purpose engines are now entering a new era. This involves adapting to new demands, such as environmental performance and carbon neutrality.

In 2005, Honda introduced the iGX engine, featuring the world’s first*1 newly developed electronic governor system (engine speed electronic control technology) Honda’s newly developed battery-free electronic speed control technology to constantly monitor engine speed and throttle position to maintain constant engine output. For example, even when grass becomes entangled in the rotating blade during use, increasing engine load and causing RPM to drop, this technology maintains the set engine speed.

*1 Honda internal research as of 2005: World-first as a single-cylinder general-purpose engine

This iGX engine achieved emissions reductions exceeding the world’s strictest EPA (U.S. Environmental Protection Agency) and CARB (California Air Resources Board) regulations by approximately 30%. It met stringent emissions standards not only in the U.S. but also in Canada, the EU, Australia, China, and elsewhere, achieving world-leading environmental performance. Furthermore, compared to competing manufacturers’ products, it improved fuel efficiency by approximately 15% per hour* and reduced noise by approximately 4 dB.

* Fuel efficiency based on EPA mode operation; noise based on EU noise regulations/generator measurement mode.

Regarding carbon neutrality, Honda has produced and launched the eGX, a power unit that combines a battery and motor. By cooling the basic structure of the battery and motor, which houses precision electronic components, to a level higher than that of an engine, and designing the unit to withstand dust and vibration, conditions engine-powered units could not operate under, Honda achieved zero emissions, taking the first step toward preparing for the carbon-neutral era.

eGX began OEM sales to finished machine manufacturers in June 2021, and launched leasing in 2022. In March 2022, Komatsu announced its electric compact excavator PC01E-1 powered by eGX. As various implementations progress, Honda expects to help solve issues like noise and exhaust emissions in residential area construction and nighttime work.

It is, of course, unlikely that small construction machinery and agricultural equipment, which have lower environmental impact compared to automobiles and motorcycles, will immediately face stringent emissions regulations. However, Honda is preparing for that time to come.

More than 70 years have passed since Honda developed its first universal H-Type engine for agricultural sprayers in 1953, just five years after the company’s founding. Today, Honda’s general-purpose engines power not only Honda’s own products but also a wide range of work machines worldwide, serving as the driving force for agricultural machinery, construction equipment, and more. As the times change, power sources are expected to evolve from engines to electric and other power units. However, Honda’s belief, of helping people and society through technology, will continue to support people’s lives.