Honda Power Products: General-Purpose Engines (Chapter 2)

Honda General-Purpose Engines Take on the World

Since first appearing in 1953, Honda’s general-purpose engines spread throughout the world, not only for spraying and spreading, but also for use in agricultural and industrial machinery. The desire to help people in need and to assist with laborious work using Honda engines led to the development and sale of Honda tillers and the next generation of general-purpose engines.

Engines to mechanize the work of a million people

Honda’s general-purpose engines evolved steadily from the H-Type in 1953 to the T-Type and then the VN-Type. Lightweight, compact, and easy to handle, these engines offered improved durability, reliability, and power, making them accessible to a wide range of users and capable of assisting with various tasks.

Output quadrupled from 1 to 4 horsepower, expanding its applications. By mechanizing tasks previously performed by people or tools in agricultural work and construction sites, Honda’s steadfast belief, as expressed by its founder, Soichiro Honda, that its engine technology could help lift Japan out of poverty, began to bear fruit.

By the 1960s, Honda not only supplied general-purpose engines to other manufacturers but also launched a series of self-developed products such as tillers, outboard motors, and generators powered by general-purpose engines. These products, which embodied Soichiro’s vision, contributed to the mechanization of many tasks.

During this time, Honda began developing a new general-purpose engine that could compete on the global stage. This engine was known internally as the ME (Million-selling Engine) concept. In other words, it was designed to mechanize the work of one million people.

The Million Engine was designed to be lightweight, compact, quiet, and fuel-efficient, just like the H-Type, T-Type, and VN-Type engines. Development began with the belief that selling one million units would make the work of one million people easier.

-

G150 (left) and G200 (right) developed according to the ME engine concept -

G150 (above) and G200 (below) developed according to the ME engine concept

In developing the G-Type engine, Honda prioritized reliability, durability, and longevity, and began sales of the G150 and G200 in 1977. Four-stroke engines can seize up and break down when engine oil levels drop too low. To address this, the G150 and G200 were equipped with an oil alert mechanism that automatically stopped the engine before oil levels dropped below the specified minimum.

This mechanism, now standard in many engines, prevents major issues by stopping the engine and alerting the user to the need to replenish engine oil before problems occur.

The G150 and G200 engines created a phenomenon in Southeast Asia where they were “red and white engines that sell well without being shown on the storefront.” In Thailand and Indonesia, the number of users who connected the G150 and G200 engines to propellers via long shafts to create longtail boats had surged, contributing to the mechanization of fishing and small vessel transportation.

At the same time, Honda strengthened its OEM sales to agricultural and industrial machinery manufacturers, achieving annual sales of 300,000 units in the first year of release in 1977. By 1982, it reached the ME initiative’s annual target of one million units sold, becoming a global hit product, especially in Southeast Asia.

Honda developed the G-Type engine primarily targeting business use, but to further mechanize the work of even more people, it recognized the need to expand the market with a versatile engine suitable for a wider range of applications accessible to the public. This led to the development of a new engine.

This led to the development of the GX-type engine, which is now the mainstay of Honda’s general-purpose engines. During the development phase, Honda began development with the slogan “ZE” (Zillion, or an unimaginable number), far surpassing the ME Concept.

The concept was to create an engine that was lighter and more compact than the G-Type engine, while also achieving more output, better fuel efficiency, and superior quietness and durability. At the same time, the oil crisis of the 1970s, including the 1979 energy crisis, shifted the focus toward energy conservation, and there was a strong demand for improved fuel efficiency. To achieve this, Honda decided to develop an overhead valve (OHV) engine, which is more fuel efficient, rather than the side valve (SV) engine used in the G-Type engine.

The biggest challenge in developing this engine was to ensure compatibility with the mount dimensions specified by OEM manufacturers, which were based on the SV G-Type engine. The goal was to maximize mount compatibility while adhering to existing specifications.

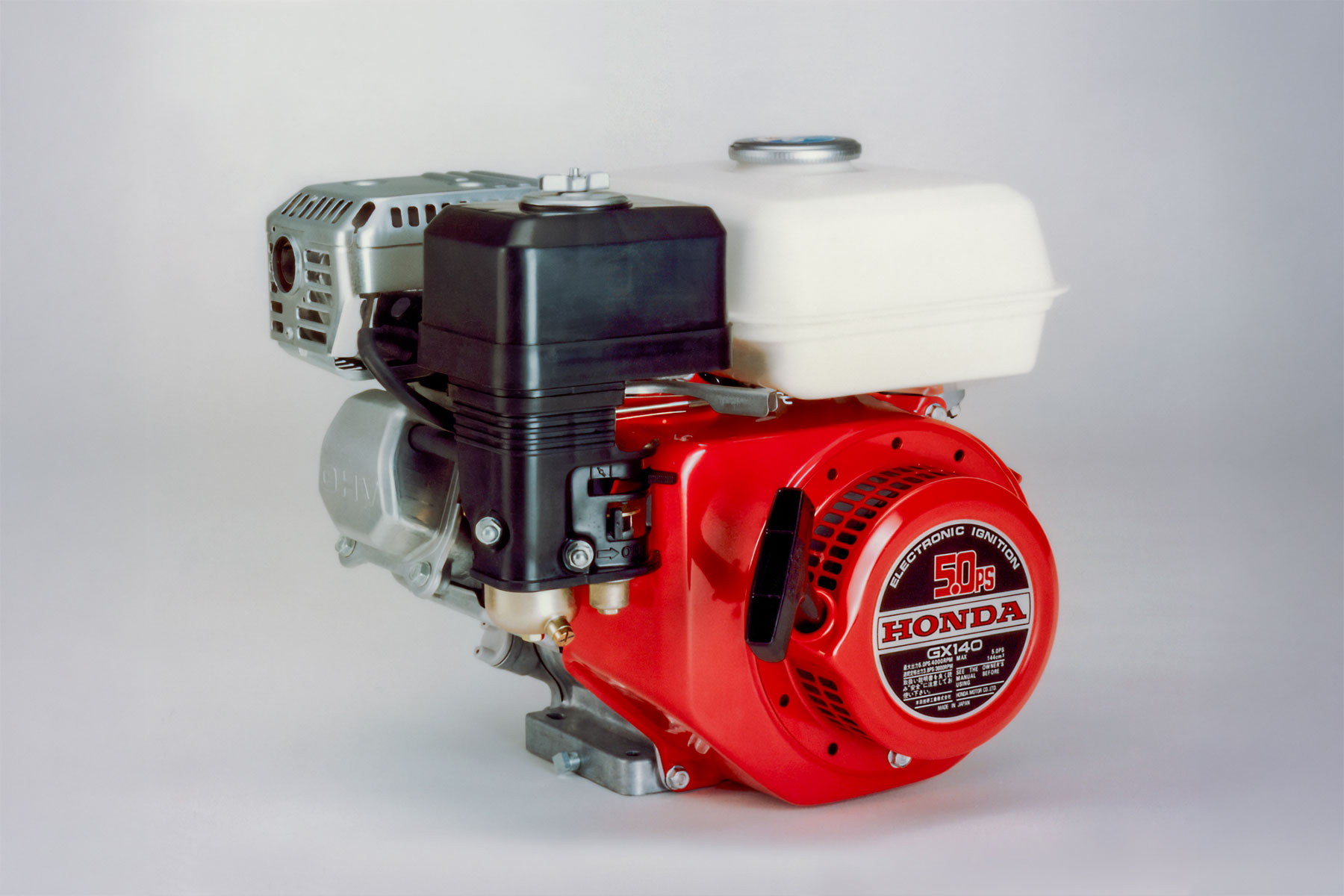

In 1983, sales of the GX110 and GX140 began. Initially, there were doubts about introducing a new engine alongside the already popular G-Type, but as its economic efficiency, lightweight design, and ease of use became recognized, the GX engine established itself as the de facto of general-purpose engines. In fact, many engine manufacturers, starting with China, adopted its OHV mechanism, tilted cylinder, and low center of gravity, leading to the widespread availability of GX-like engines.

-

GX110 (left) and GX140 (right) featuring highly fuel-efficient OHV mechanism -

GX110 (above) and GX140 (below) featuring highly fuel-efficient OHV mechanism

Furthermore, by actively conducting engine matching activities (application engineering) to adjust engine components to meet the specifications of various OEM manufacturers’ products, the GX engine fulfilled its destiny as the “ZE” engine upon its release, and grew into a foundational product supporting Honda’s Power Products business.

Mechanizing even more tasks

Honda did not supply general-purpose engines to OEM manufacturers who sold products that competed with Honda’s own, such as tillers, generators, and lawn mowers. However, based on the belief that removing this barrier would allow more people to be freed from laborious tasks through mechanization, Honda shifted its strategy and began OEM sales to competing manufacturers. This resulted in a significant increase in sales, enabling more people to mechanize their work.

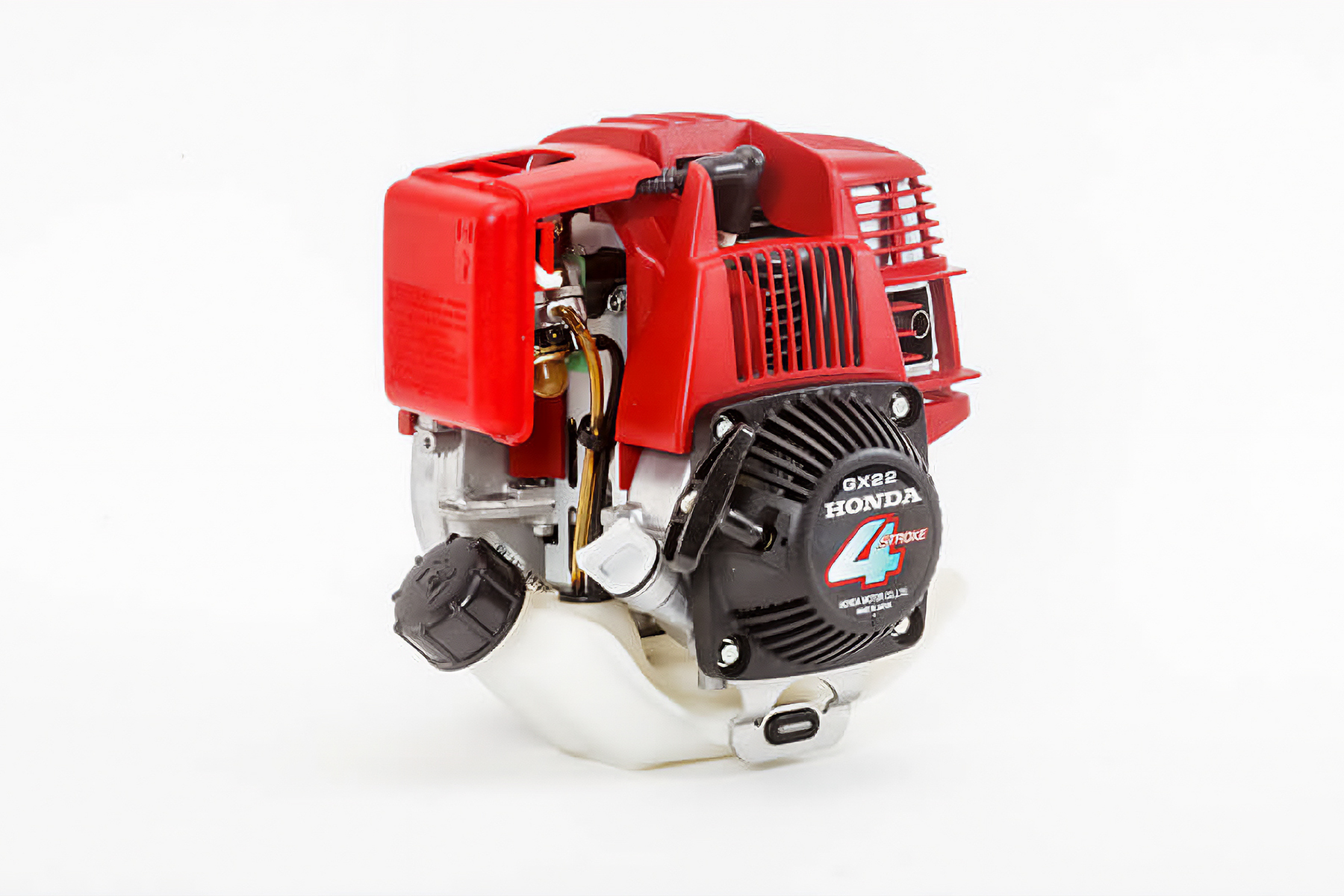

In 1997, Honda began sales of the GX22 and GX31 engines. These engines, internally referred to as the M4 (Mini 4-Stroke), were developed as small-displacement 4-stroke engines for handheld power tools such as brush cutters.

At the time, most products in the handheld market were powered by lightweight, easy-to-handle 2-stroke engines. However, 2-stroke engines burn lubricating oil along with fuel, not only resulting in exhaust gases containing burnt oil, but loud, high-pitched engine noise, poor starting performance, and the inconvenience of preparing a mixture of gasoline and engine oil.

In contrast, 4-stroke engines offered superior quietness and cleaner exhaust emissions. Handheld products, however, often require operators to move the machine at various angles while working, making it difficult to maintain a consistent lubrication path for the engine oil. Additionally, 4-stroke engines, which have more parts and are heavier than 2-stroke engines, were considered unsuitable for handheld products.

To overcome these issues, Honda developed a rotary slinger pumping lubrication system unaffected by engine tilt. By adopting this mechanism in the GX22, Honda achieved stable engine operation at any angle, giving birth to the world’s first lightweight 4-stroke engine capable of 360-degree operation.

The GX25 which followed further achieved a more compact and lightweight design by adopting an oil-immersed timing belt OHC structure. This technology has been adopted not only in Honda’s handheld products but also by many OEM manufacturers, contributing to comfortable working environments.

Honda’s passion, that began in 1953 with the development of a general-purpose engine to mechanize work and make people’s lives easier, has been inherited by the GX-series engines.