Easing the labor of rural communities

Driven by the conviction that technology should make people’s lives easier, Honda began developing and selling tillers following its general-purpose engines. Amid the harsh post-World War II agricultural environment, Honda’s tillers played a major role in revitalizing postwar agriculture in Japan.

In the early 1940s, Japan was an agriculture-centered nation where roughly 40% of its population of about 72 million people were involved in farming in some capacity.

However, after the war ended, the number of agricultural workers gradually declined, leading to a severe labor shortage in farming.

During the economic growth period of the 1950s, the population exodus to cities accelerated, primarily among younger people. As a result, women and the elderly became the main workforce in agriculture, causing a critical labor shortage. Mechanization became an urgent necessity to reduce the burden of farm work and address the labor shortage.

Amidst this situation, Honda developed the versatile H-Type engine and began supplying it to agricultural machinery manufacturers. Honda contributed to the modernization of Japanese agriculture with versatile engines such as the T-Type and VN-Type agricultural engines.

Furthermore, following the enactment of the Agricultural Mechanization Promotion Act in 1956, Honda established a new Agricultural Machinery Development Division in 1958. At that time, with approximately 6 million farming households, the adoption rate of tillers—the agricultural machinery used for the most labor-intensive task of tilling soil in fields and rice paddies—was a mere 5%.

To alleviate this situation, Honda began developing a tiller accessible to more farmers. The Agricultural Machinery Development Division took on the challenge: “By introducing one Honda engine-powered product per household, we will reduce the burden of labor, increase productivity, and build a prosperous nation.”

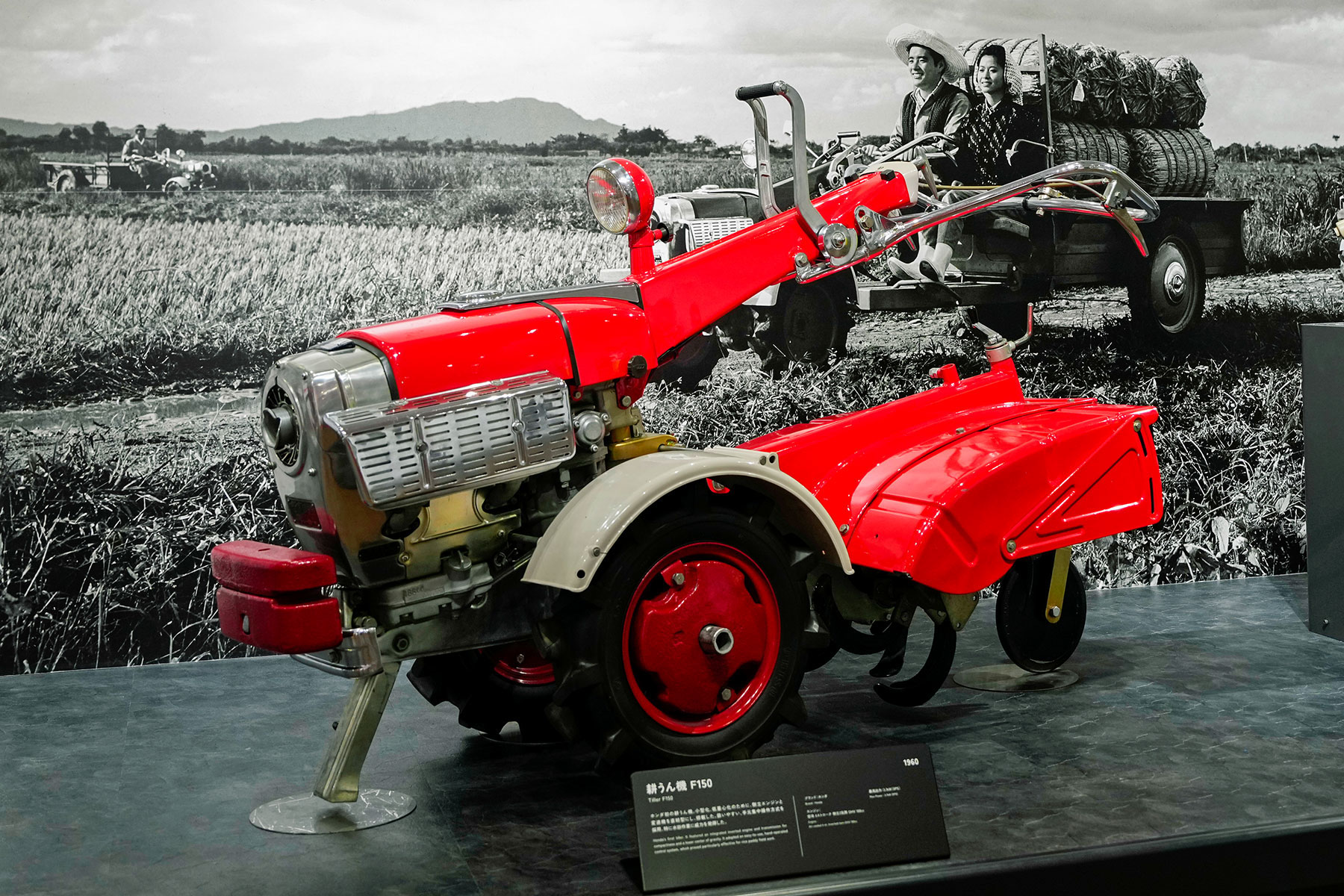

1959: Honda launches its first tiller, the F150

Honda set out to develop a tiller capable of performing all essential farming tasks—tilling, ridging, and leveling—across both dry fields and rice paddies. The development team focused on making it easy to operate, even for women and older farmers, who made up much of the agricultural workforce at the time.

This was because most agricultural machinery at the time was designed for physically strong males, resulting in large, heavy, and complex machines.

Honda began development with the concept of creating a lightweight, compact, durable, and economical tiller that anyone could easily operate. And in 1959, Honda launched its first tiller, the F150.

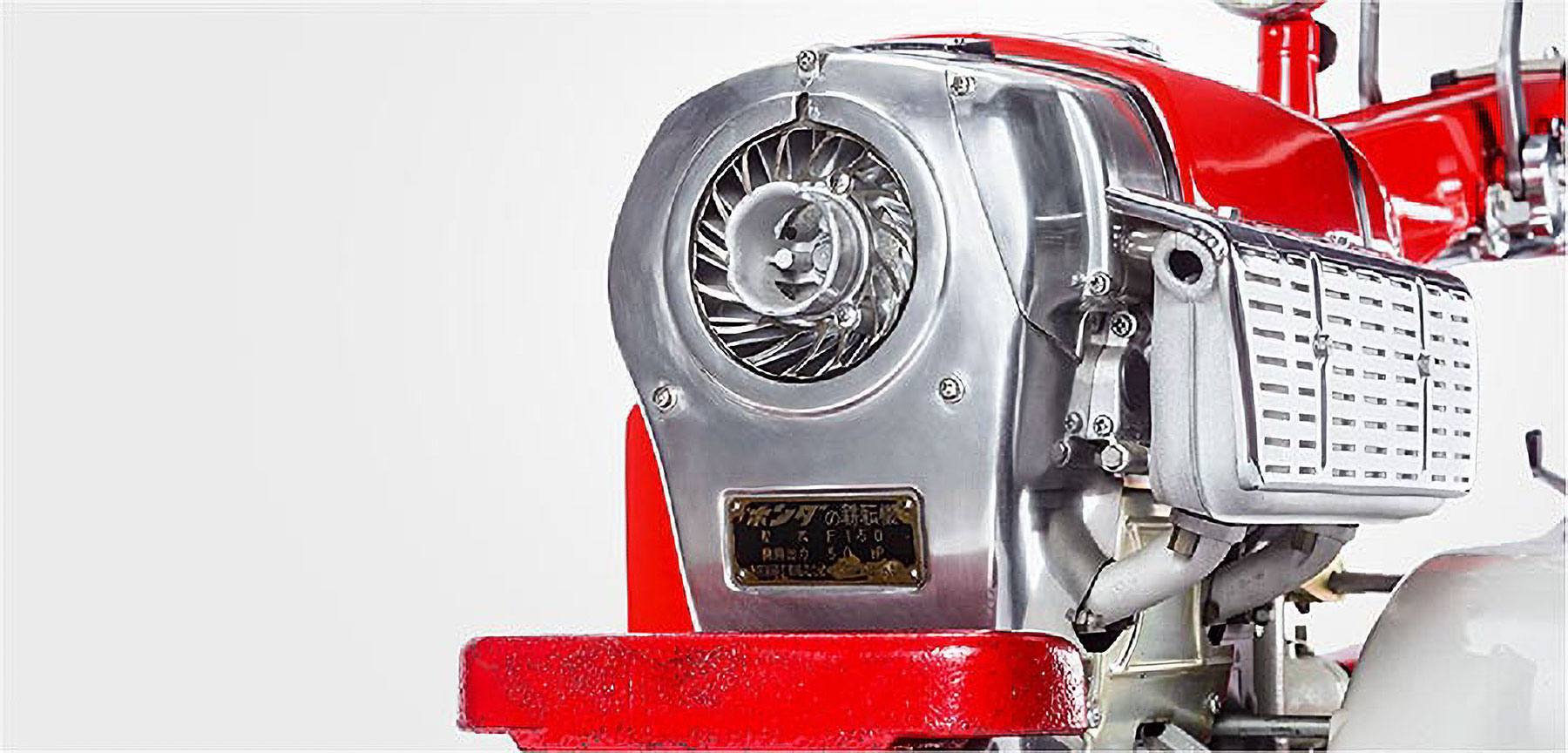

The F150 achieved a low center of gravity by mounting its 154cc air-cooled two-cylinder engine in an inverted position. This design considered the engine’s top-heavy structure, placing the heavier components lower to improve handling. Furthermore, the inverted layout positioned the air intake at the top, making it effective for rice paddy work where the machine’s lower sections could be submerged.

The engine adopted the world’s first OHV (Overhead Valve) configuration for a tiller. It replaced the then-common belt-driven direct drive with a system featuring an automatic centrifugal clutch, a 3-speed forward / 1-speed reverse transmission with an auxiliary gearbox. This 6-speed forward / 2-speed reverse configuration eliminated power loss due to slippage inherent in belt systems, achieving high driving performance. The automatic centrifugal clutch, also featured on the Super Cub C100, required no lever operation to change gears. Consequently, in this era of low automobile penetration, the F150 was frequently seen being used as a tow vehicle.

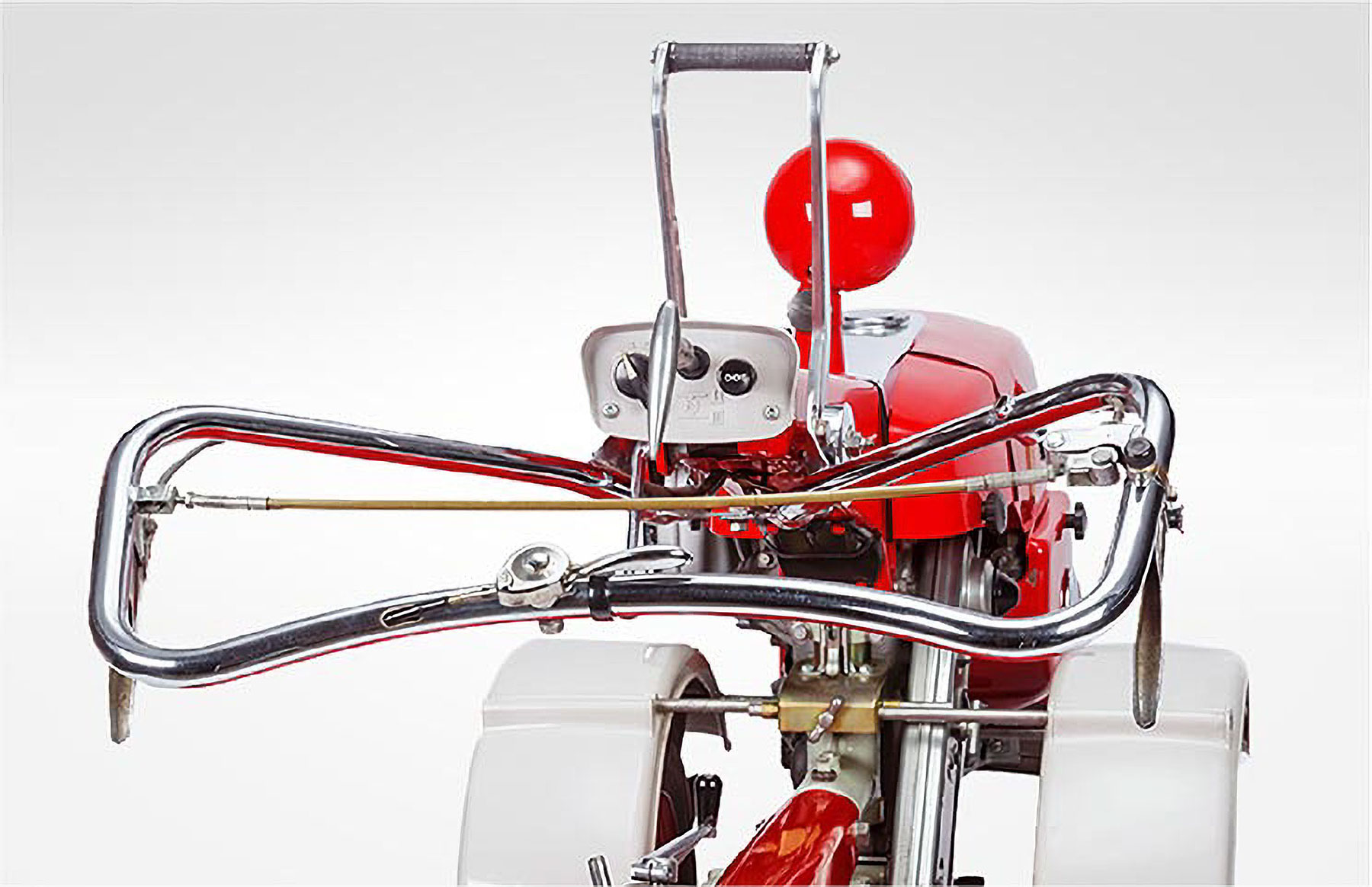

Furthermore, the F150 replaced the conventional recoil starter—previously the standard for starting the engine by pulling a rope—with a convenient push-button starter on the handlebar. All major controls, including forward/reverse shifting and throttle operation, were centralized around the handlebar, allowing the operator to manage nearly all functions by hand.

Additionally, the handlebar was mounted on dampers. This minimized engine vibration transmitted to the operator’s hands, reducing fatigue during long work sessions. Moreover, while many tillers exposed their engines and moving parts, the F150 covered both with a protective shielding. This enhanced safety while also refreshing the image of tillers, which were often dark colors such as black, with its bright red, stylish body color. It was hailed as the “Honda whirlwind turning fields bright red” and changed the world of agricultural machinery.

Honda then priced this F150 for 120,000 yen. This price was 50 to 100 thousand yen cheaper, far cheaper than competitors selling for 170,000 to 220,000 yen. Riding the wave of Honda’s heightened national recognition, boosted by the Super Cub launched the previous year, the F150 recorded massive sales upon release. In an era where the tiller market was only a few thousand units, it achieved annual sales of 20,000 units. Its popularity was so overwhelming that some dealers would drive trucks directly to the Hamamatsu Plant to pick up freshly completed F150 units. These machines then began operating nationwide, gradually creating the familiar sight of red tillers working the fields.

Six years after developing its first general-purpose engine in 1953, Honda entered the agricultural machinery field in 1959 with the F150 tiller, its second finished machine following motorcycles. It all began with Honda’s conviction, rooted in the social context of the time, to use technology to make people’s lives easier.