The Birth of Honda’s General-Purpose Engine

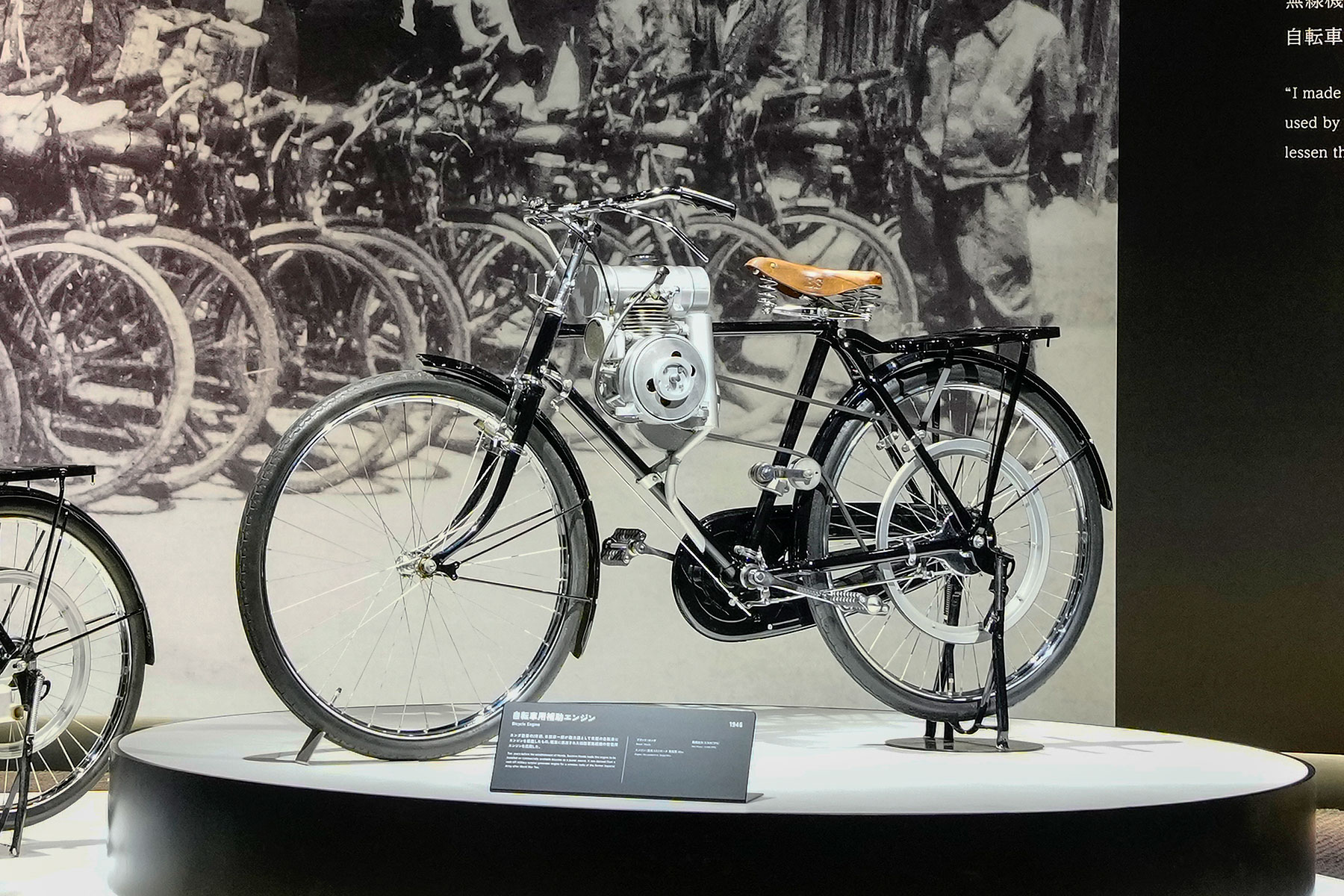

In post-World War II Japan, Honda yearned to make people’s lives easier, and create tools that would be useful in everyday life. This desire eventually led to the development of an auxiliary engine for bicycles, which led to the Super Cub, and ultimately to the birth of Honda Power Products.

“Sachi, see what I made. Try it out.”

In 1946, Honda founder Soichiro Honda brought home a bicycle with an auxiliary engine attached. Sachi was Soichiro’s wife. Concerned that she would be riding the bicycle on a busy street, Sachi wore her “best” Monpe trousers (traditional Japanese work pants), and was seen riding the bicycle with the auciliary engine.

“He claims to have made it because he felt sorry for me having to ride a bicycle to buy groceries, and maybe that was a little a part of it. I honestly think, though, that he just wanted to see if a woman could handle it.” (Sachi)

After riding the bicycle for a while, Sachi said,

“My best monpe is covered in oil. This won't do. Customers will be angry with this.” (Sachi: *01 “Lessons to Hand Down” 50 Years of Challenges)

The reason her Monpe was dirty was the backflow of mixed fuel from the carburetor. Since then, Honda improved the bicycle auxiliary engine (commonly known as in Japan as “Batabata”), and began sales in October as the first product of Honda Technical Research Institute established in September 1946.

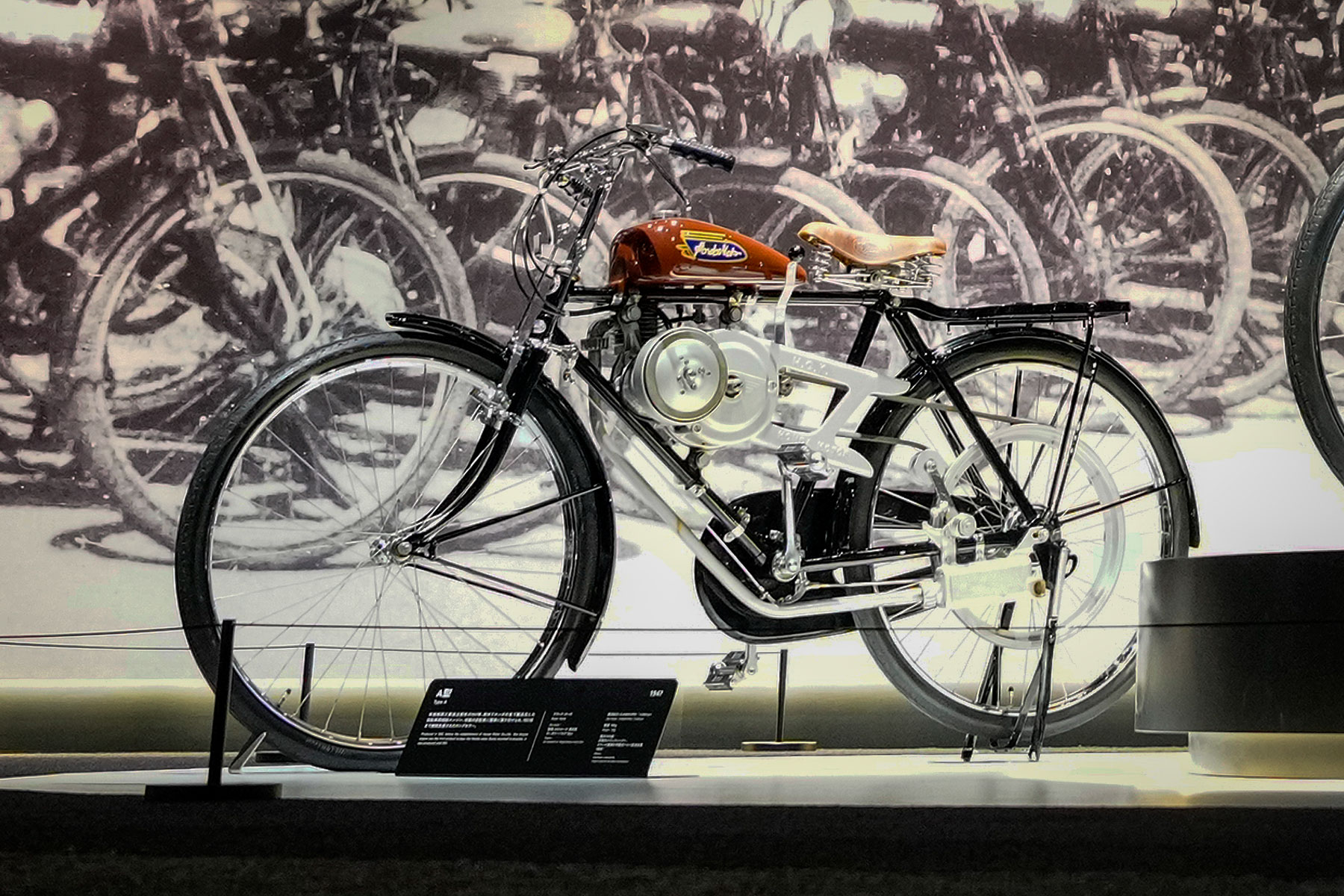

The Honda bicycle auxiliary engine later evolved into the A-Type engine, which launched in November 1947. This was further evolved into the Cub F-Type, which could be mounted on the rear wheel to keep the rider’s clothing comparatively cleaner, and was released in 1952.

In 1953, Kyoritsu Nogyo (now Yamabiko Corporation), an agricultural machinery manufacturer, learned of Honda’s highly reputed A-Type and Cub F-Type engines, and requested the development of a small engine for a backpack spreader. On September 24, 1948, Honda established a new company, Honda Motor Co., Ltd. At the time, Honda’s president, Soichiro Honda, had witnessed the harsh working conditions of people in rural and fishing villages across the country, and was driven by the desire to create tools that could alleviate their labor using Honda’s engine technology and help lift Japan out of poverty. The development of this general-purpose engine provided the perfect opportunity to realize this vision. This was the beginning of what is now known as Honda Power Products.

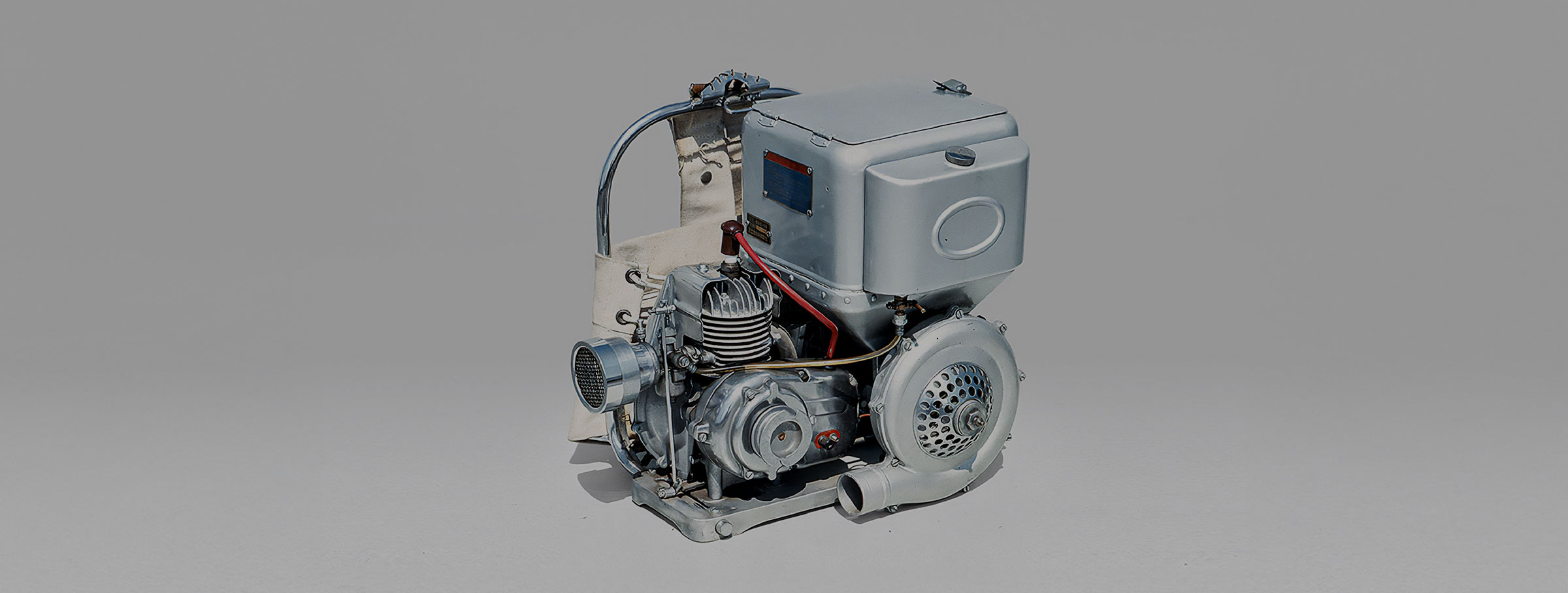

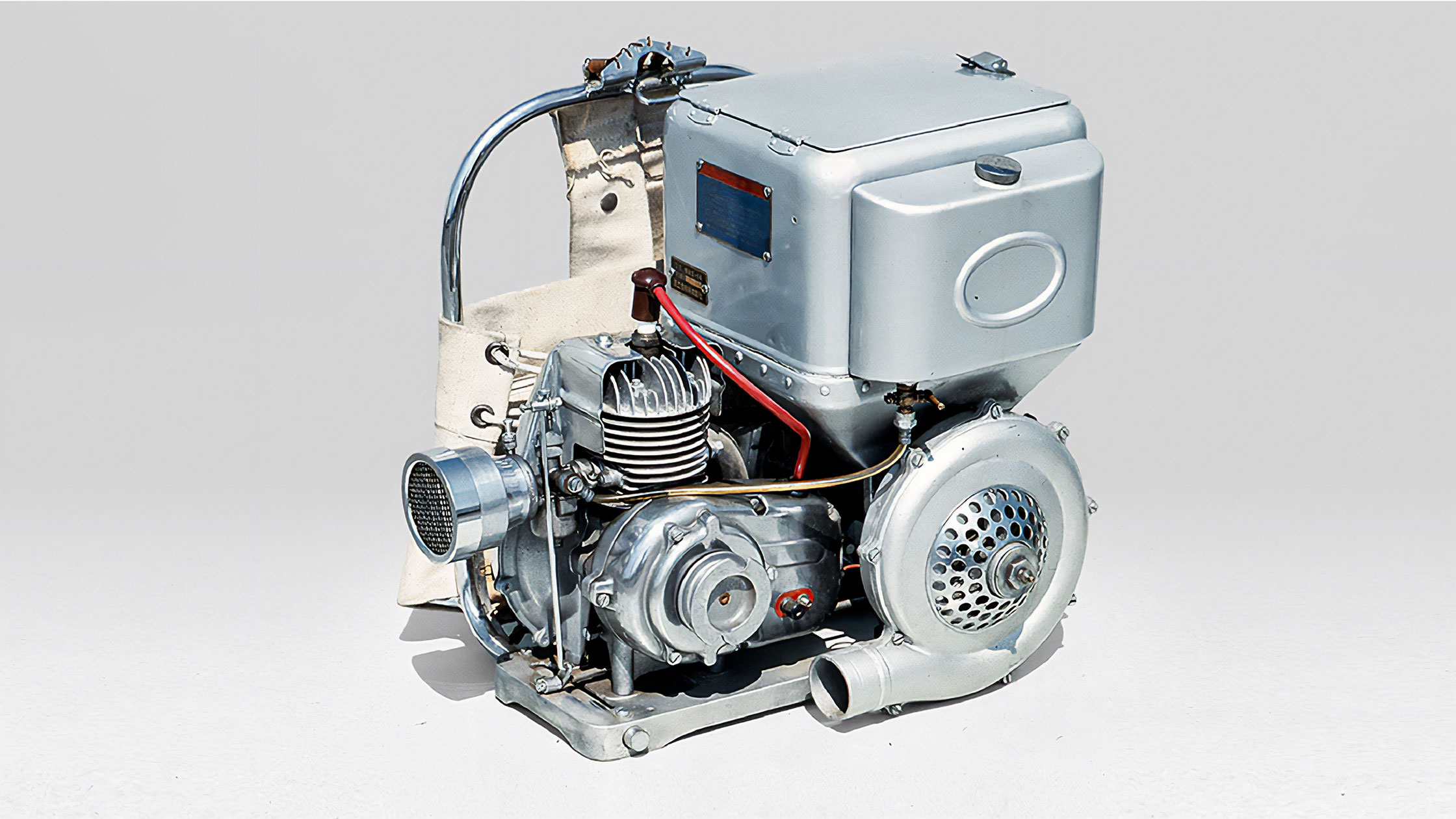

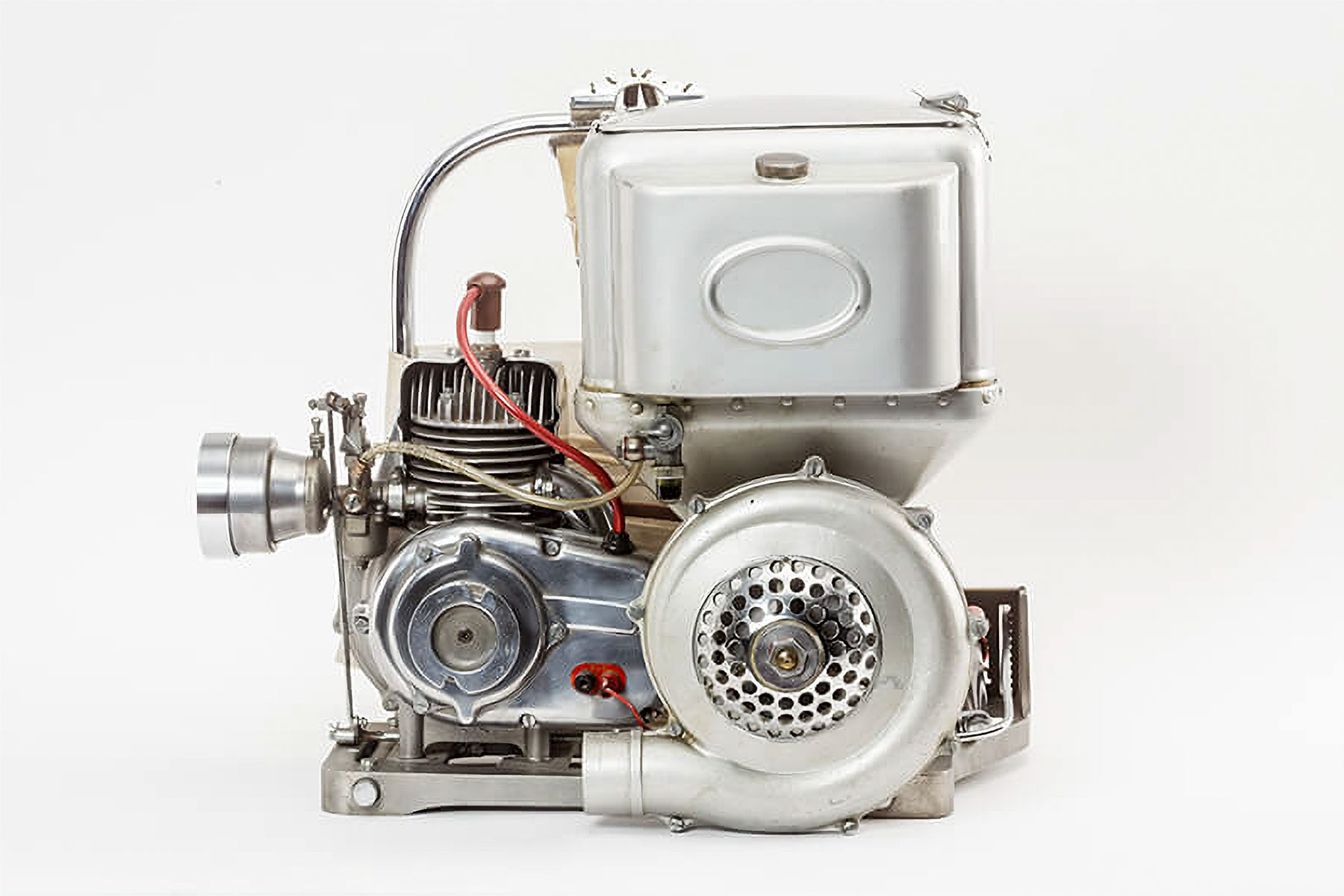

Backpack spreaders became agricultural machines in high demand during the post-war period as Japan sought to mechanize its agriculture, alongside tillers and threshing machines. Honda began development using the basic layout of the Cub F-Type’s two-stroke engine launched the previous year in 1952. The resulting H-Type engine, launched in October 1953, gained a positive reception for its compact size, lightweight design, and ease of use, reaching monthly production of over 5,000 units within six months of its release. This was Honda’s first foray into engine supply to other companies; the beginning of Original Equipment Manufacturer (OEM) production.

The H-Type engine was not limited to use in sprayers for orchards and fields but also powered spreaders and water pumps, and even found widespread use in coffee plantations as far away as Brazil.

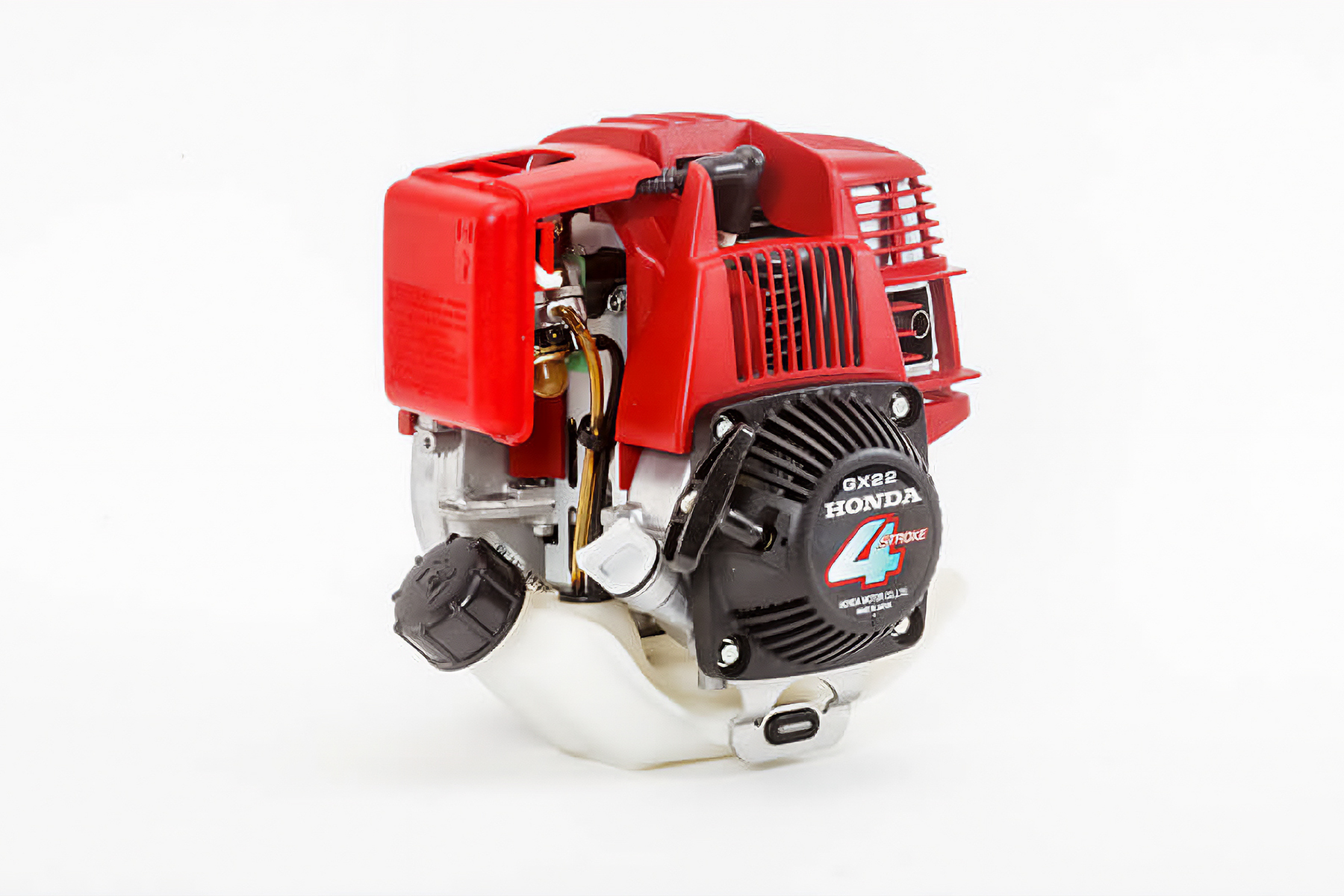

H-Type engine users praised the engine, while also providing feedback for improvements. In response, Honda began developing a lightweight, dirt-resistant, high-output 4-stroke general-purpose engine in August 1954. Four months later, in December 1954, Honda unveiled the 4-stroke T-Type engine with output increased from the H-Type’s 1 horsepower to 2.5 horsepower. This compact engine achieved exceptional fuel efficiency, consuming only approximately 0.54 liters of gasoline per hour of continuous operation. Despite its high output, the T-Type continued to operate even when used in various angles, such as backpack or shoulder-mounted configurations. Compared to two-stroke engines, the T-Type featured quieter operation, reduced vibration, and lack of burned engine oil, making it a user-friendly general-purpose engine.

Honda’s History (※02) published in 1955 stated, “When the T-Type engine was introduced in December 1954, its outstanding performance, including gasoline consumption of just three cups per hour of continuous operation, 2.5 HP output, complete waterproofing, manual rope-starting, no vibration, and no stalling even when tilted at any angle, made it a coveted item for farmers.”

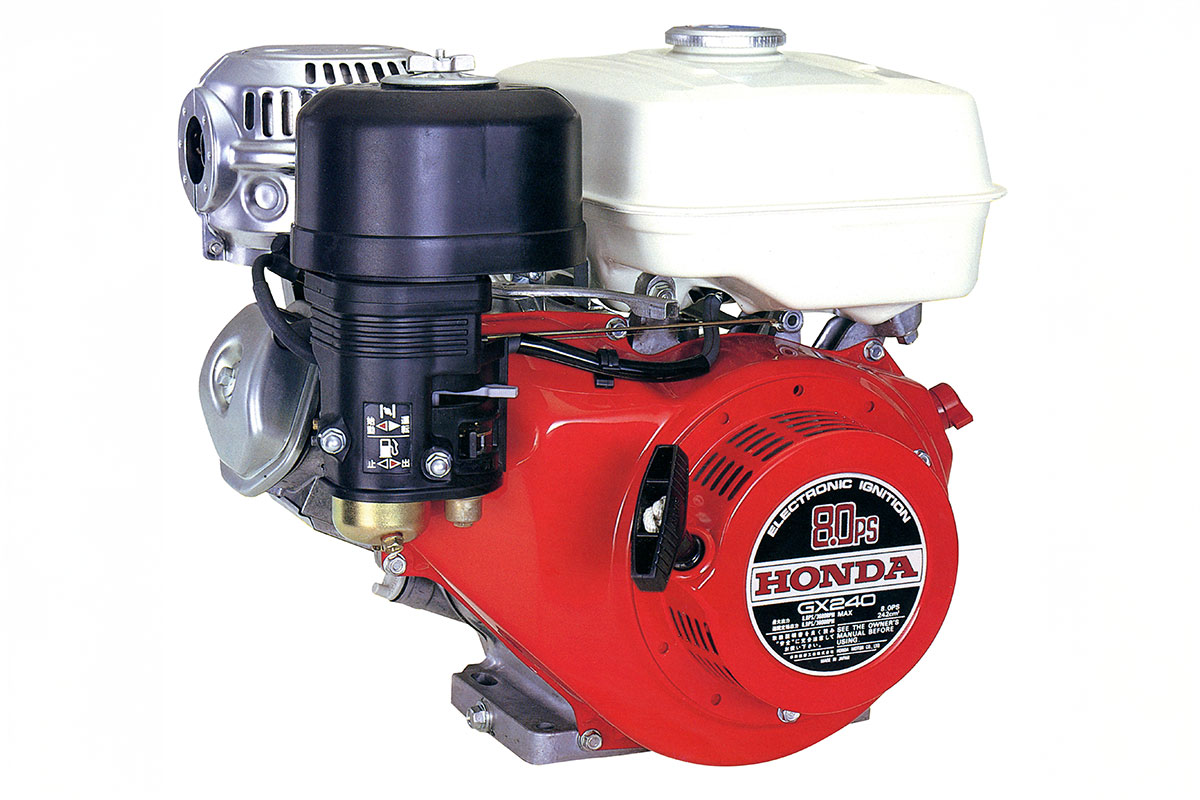

Following the development and sale of the T-Type engine, Honda’s general-purpose engines expanded beyond their original applications, spraying and spreading, to be used in various fields such as power cultivators (agricultural machinery for weeding and soil cultivation), tillers, construction machinery, and generators.

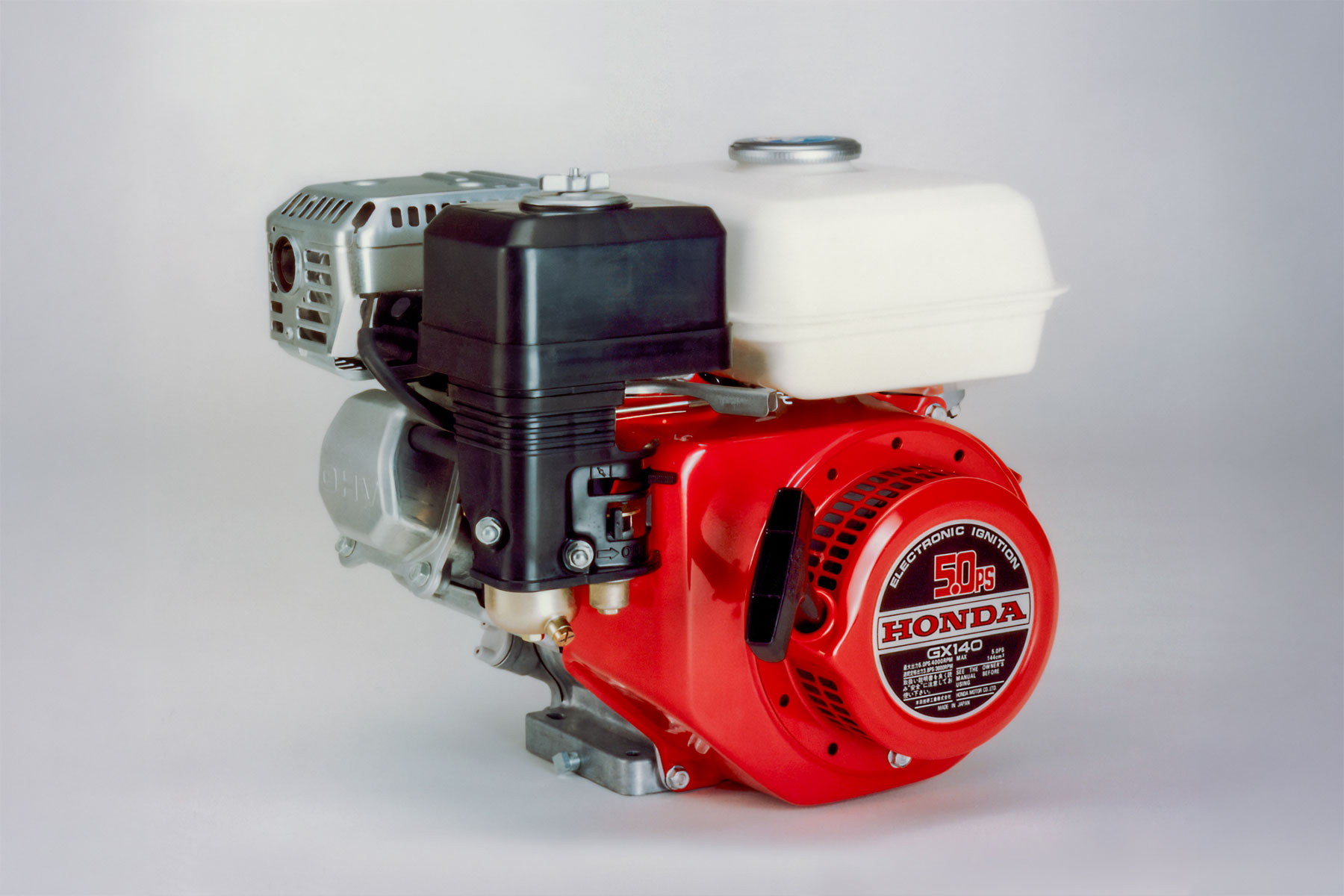

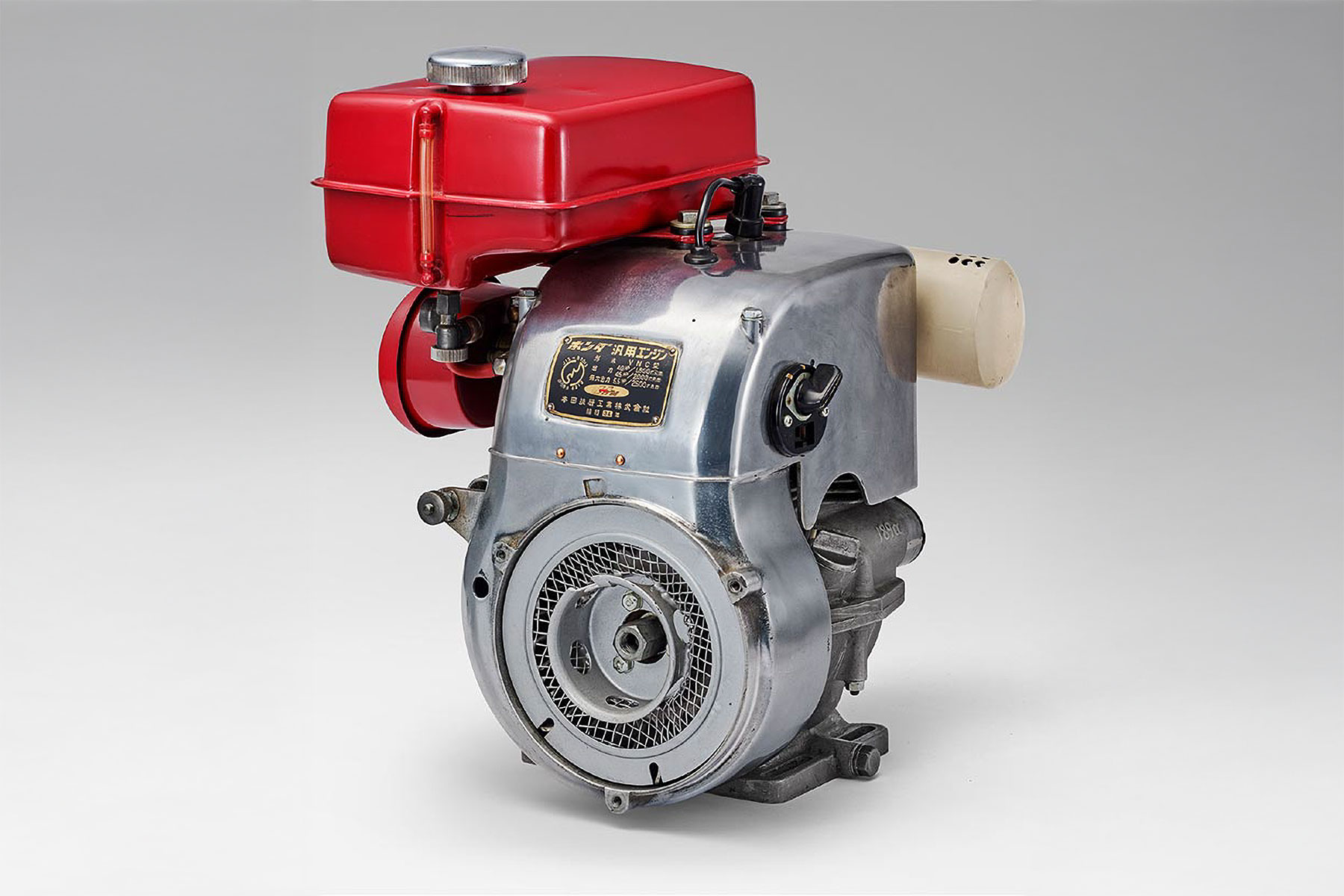

As a result, Honda followed up the T-Type with the introduction of the four-stroke V-Type engine in 1956, increasing output to 4 horsepower. In 1958, Honda launched the improved VNC-Type and VND-Type engines, further increasing maximum output to 5 PS.

The further evolved VNC-Type and VND-Type engines were compact and lightweight, yet featured automatic centrifugal clutches and recoil starters for improved starting performance, and adopted aluminum fan covers to enhance quietness.

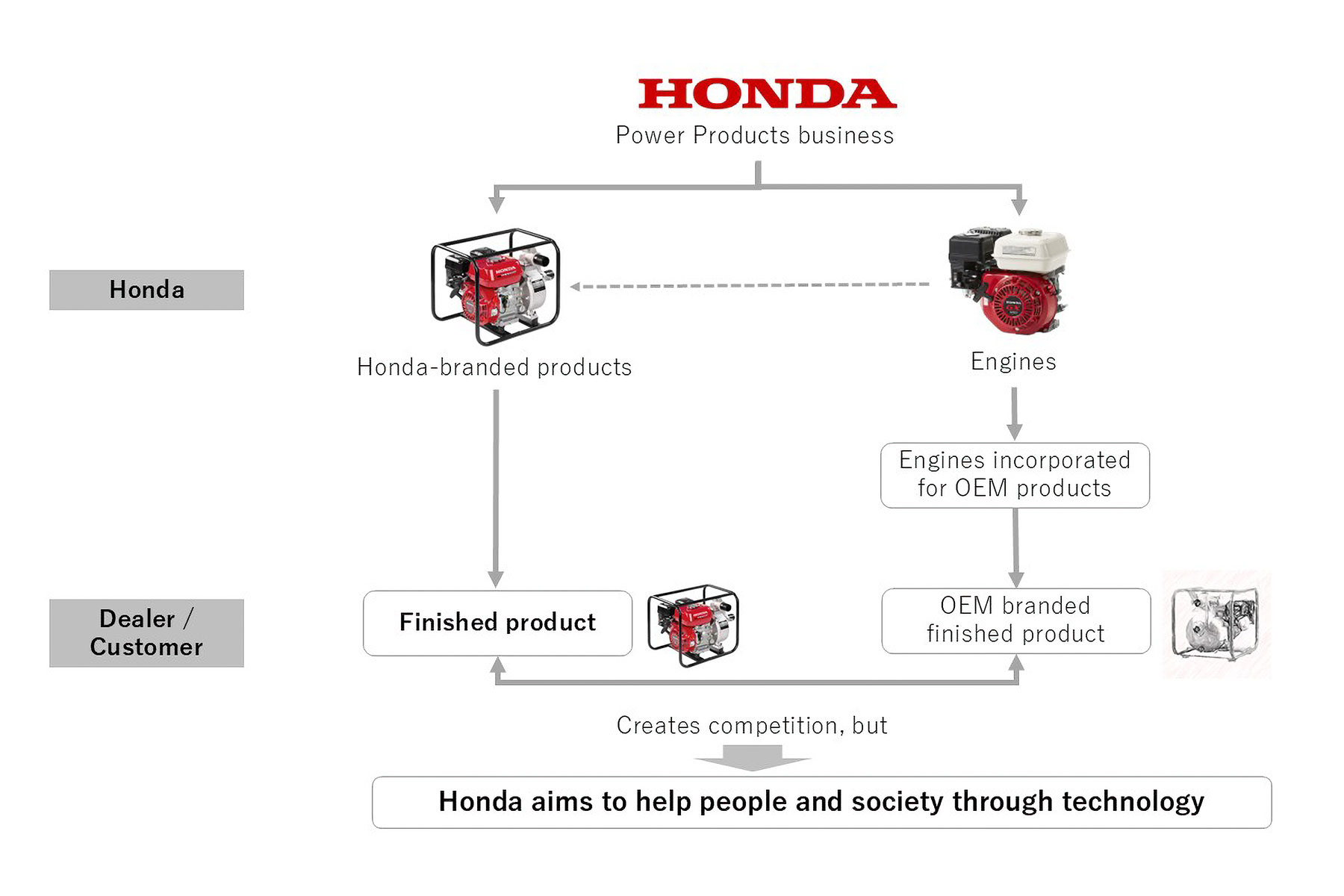

Honda’s power products business, which began in 1953 shortly after the end of World War II with the development of a general-purpose engine commissioned by an agricultural machinery manufacturer, expanded beyond the agricultural sector to supply general-purpose engines to manufacturers in a wide range of industries, including construction. Honda continued to play a significant role in various fields worldwide, with general-purpose engines at the core of its operations.

References

*1 Honda Motor Co., Ltd. (1999) “Lessons to Hand Down” 50 Years of Challenges (Japanese language only)

*2 Honda Motor Co., Ltd. (1999) Honda Motor Co., Ltd. History (7-Year History Reprint) (Japanese language only)