Honda General-Purpose Engines Archive

H-Type (launched October 1953)

The H-Type engine developed for agricultural machinery was renowned as a compact, lightweight, and easy to handle engine. Within six months of its launch, production grew to over 5,000 units per month. This first instance of Honda supplying engines to other companies marked the beginning of its OEM (Original Equipment Manufacturer) business.

T-Type (launched December 1954)

Honda announced the four-stroke T-Type engine that increased output from 1 horsepower of the H-Type to 2.5 horsepower. Compared with two-stroke engines, it offered quieter operation, reduced vibration, and eliminated the discharge of burned oil, making it a more user-friendly general-purpose engine.

VN-Type (launched April 1956)

Four-stroke V engine raised output to 4 horsepower.

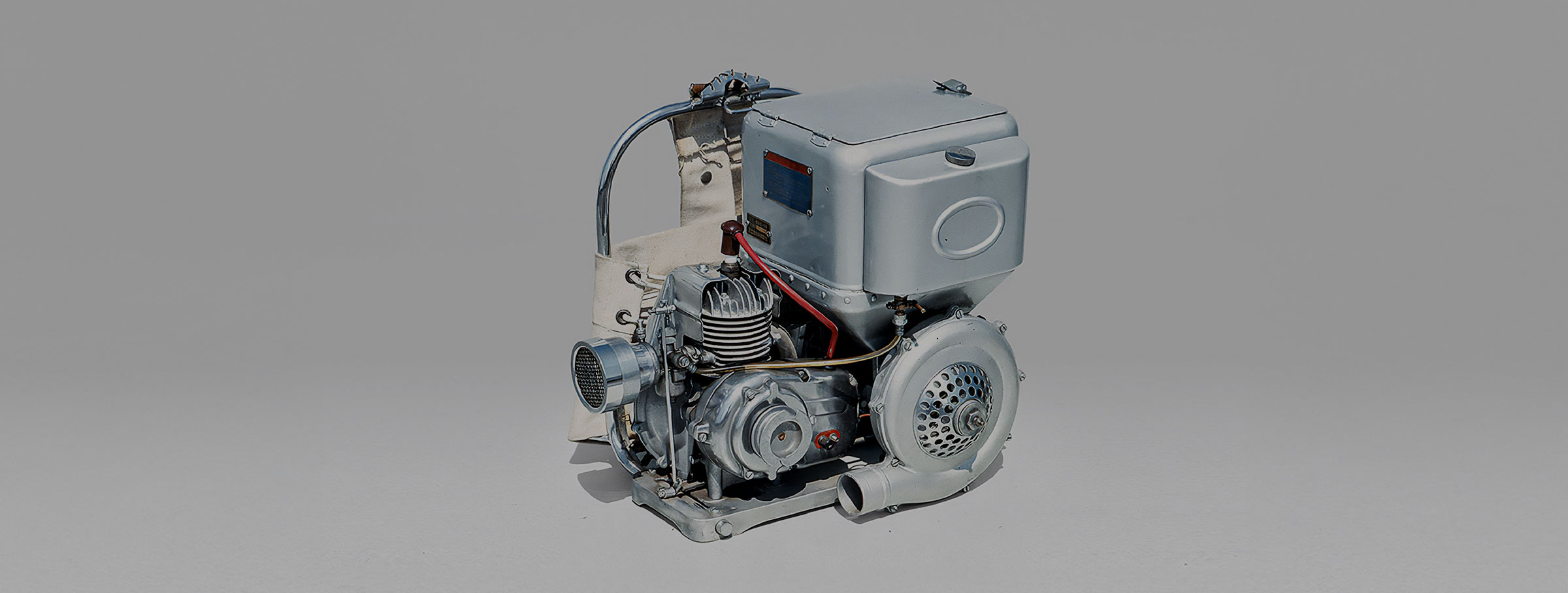

VNC-Type (launched February 1958)

Honda launched VNC- and VND-Type engines with maximum output raised to 5PS.

T10 (launched March 1963)

G20/G30 (launched July 1963)

Sales of the compact and lightweight G20 engine and the versatile G30 engine began.

G45 (launched June 1964)

G21/G25/G40/G65/GD90 (launched November 1966)

GD100 (launched 1967)

G28 (launched March 1969)

The only high-output OHC engine for agricultural machinery, weighing 13.7 kg, the G28 was a compact and convenient power source. It excelled in starting performance and operated smoothly even on slopes. Equipped with a built-in centrifugal clutch, the G28 prioritized ease of handling. It was applied to a wide range of applications: for agricultural use in threshers, sprayers, and water pumps; and for industrial and civil engineering use in belt conveyors and air compressors.

GT50/GT65

The GT50 produced 4 horsepower, while the GT65 produced 5 horsepower. These models were ultra-economical engines that could run on inexpensive kerosene, while solving common kerosene engine issues of starting difficulty and oil degradation.

G42 (launched May 1973)

The Honda F42 power tiller’s engine was launched as the G42, which output 4.5 horsepower.

GS65

Equipped with a starter motor for easy starting using a switch. Maximum output was 6.5 horsepower.

G35/G80 (launched October 1975)

The 3.5-horsepower G35 was designed for light-duty work across a wide range of applications, while the 8-horsepower G80 featured a high-output mechanism for boosting work efficiency. The G35 powered Honda’s E800 portable generator.

G150/G200 (launched June 1977)

The first model in a series developed to create a universal engine suitable for worldwide use. Featuring a unique rotary breather mechanism that minimizes oil leakage even on slopes, along with a robust design resistant to dust and grass clogging, the G150/G200 served as a power source for everything from agricultural machinery to construction equipment, indeed a versatile engine adaptable to a wide range of applications.

G300/G400 (launched August 1978)

Developed alongside the G150/G200 as a universal engine suitable for worldwide use. The G-series general-purpose engines now comprised four models ranging from 3.5 to 10 horsepower, enabling it to serve as a power source across an even broader spectrum.

G100 (launched January 1980)

The compact G100 general-purpose engine featured a displacement of 76 cc and output of 2 PS, achieving an exceptionally light weight of 8.5 kg (dry weight), surpassing the conventional standards for 4-stroke engines. Leveraging this lightness, it was the ideal engine for powering water pumps, light-duty machinery, and similar applications.

G100 (for seaweed) (launched July 1981)

The G100, Honda’s first four-cycle engine dedicated to seaweed harvesting machines, featured full-scale rust-proofing. Being a four-cycle engine, it excelled in fuel efficiency and durability, delivering stable output characteristics across the entire range from low to high RPM. Moreover, it was quiet and produced minimal exhaust smoke.

GX110/GX140 (launched January 1983)

The GX110/GX140’s OHV mechanism and inclined cylinder design achieved a compact and lightweight construction, resulting in an engine with excellent mountability and portability. Furthermore, the ideal combustion chamber shape and superior intake/exhaust efficiency delivered high performance and outstanding fuel economy (230 g/PS·h).

GX240 (launched January 1985)

The GX240’s OHV mechanism and 25-degree inclined cylinder achieved a compact and lightweight construction while providing an ideal combustion chamber shape and excellent intake/exhaust efficiency, resulting in high performance and outstanding fuel economy (230 g/PS·h).

GX160/GX340 (launched August 1985)

The lightweight, compact Honda GX340 was added to Honda’s general-purpose engine series, widely used as power sources for finished products like generators, tillers, pumps, and snow blowers, as well as OEM products (for small construction equipment manufacturers, pump manufacturers, transport vehicle manufacturers, and agricultural machinery manufacturers). This 11-horsepower general-purpose engine featured a 4-cycle OHV (overhead valve) mechanism known for its quiet operation and durability.

GD320/GD410 (launched June 1988)

The GD320 and GD410 air-cooled, single-cylinder, direct-injection diesel engines offered superior quiet operation and durability, ideal for a wide range of applicatinos. Featuring a highly efficient direct injection system, the combustion injection nozzle employed Honda’s unique two-stage injection method, which injects fuel in two distinct phases.

GX200 (launched February 1995)

The GX200 was a compact, lightweight, fuel-efficient 6.5-horsepower general-purpose engine.

GX22 (launched January 1997)

The ultra-compact, lightweight GX22 (22cc) and GX31 (31cc) engines were the world’s first four-stroke gasoline engines which could be used while tilted at any angle, delivering clean exhaust and outstanding fuel efficiency as power sources for handheld equipment.

GC135/GC160/GCV135/GCV160 (launched April 1997)

The versatile compact four-stroke OHC GC160/135 and GCV160/135 engines achieved top-class lightweight design, quiet operation, clean exhaust, and excellent fuel efficiency, while delivering an internationally competitive price as power sources for small light-duty equipment.

GF160V (launched March 1998)

The GF160V natural gas engine was a versatile power source, running on natural gas, a clean energy source gaining attention at the time, powering a residential absorption heat pump air conditioner.

GXH50/GXV50 (launched June 1998)

The GXH50/GXV50 four-stroke general-purpose engine achieved the world’s smallest and lightest size in the stationary 2.5 horsepower class while delivering clean emissions compliant, or achieving early compliance, with EPA*1 and CARB*2 regulations, along with outstanding fuel efficiency.

*1 EPA: U.S. Environmental Protection Agency

*2 CARB: California Air Resources Board

GX610 K1/GX620 K1/GX670 (launched May 1999)

The GX670/GX620 K1 and GX610 K1 engines featured an OHV mechanism that achieves a high level of balance between low fuel consumption and high output, thanks to an ideal combustion chamber shape and excellent intake and exhaust efficiency. They delivered clean operation and low fuel consumption, while also achieving low noise and low vibration through the 90° V-layout.

GX100 (launched February 2001)

The GX100 3-horsepower four-stroke OHC gasoline engine was ideal for powering small construction equipment like compact concrete mixers and rammers, as well as portable generators. Simultaneously with its release through Honda power products dealers, Honda also began OEM sales to various work equipment manufacturers.

GX25 (launched April 2002)

The 2.78 kg, 25cc GX25 was the world’s lightest* 360° tiltable four-stroke engine, and an ideal power source for handheld equipment. Honda simultaneously began OEM sales various equipment manufacturers as well its release through its power products dealers.

*As of April 2002

GCV190 (launched 2002)

GX35 (launched August 2003)

The GX35 35.8cc four-stroke engine with 360° tilt capability was a power source for handheld equipment. It powered tools such as brush cutters and was also available for purchase by equipment manufacturers.

GSV160/GSV190 (launched 2003)

iGX440 (launched April 2005)

The next-generation general-purpose engine iGX440 (15 horsepower, 438 cc) featured the world’s first* electronic speed control technology for a single-cylinder general-purpose engine. The iGX440 was sold to work machine manufacturers.

* Honda internal research

GXH50/GX120/GX160/GX200/GX240/GX270/GX340/GX390/GX25/GX35/GX100/iGX440 (launched July 2007)

GX630/GX660/GX690/GXV630/GXV660/GXV690 (launched 2009)

GX240/GX270/GX340/GX390/iGX240/iGX270/iGX340/iGX390 (launched October 2010)

The new iGX series (with electronic governor) and new GX series (standard specification) general-purpose engines addressed more complex and advanced applications, enhancing output, environmental performance, durability, and reliability.

GX120/GX160/GX200 (launched February 2012)

The GX series of general-purpose engines, acclaimed for high mounting compatibility and durable reliability, saw minor improvements to three models*1. While maintaining the popular compact unit’s extensive mounting compatibility, low noise and vibration*2 were enhanced, achieving class-leading low emissions and fuel efficiency while also improving operability and durability.

*1 GX120 (118 cc, max output 2.6 kW), GX160 (163 cc, max output 3.6 kW), GX200 (196 cc, max output 4.1 kW)

*2 GX160

GXR120 (launched 2013)

GCV145/GCV170/GCV200 (launched June 2018)

The GCV*1 series was completely revamped and was made available for European work machine manufacturers.

The new GCV series expanded from the previous two models (GCV160 and GCV190) to include three models: the GCV145 (145cc), GCV170 (166cc), and GCV200 (201cc). While maintaining excellent fuel efficiency, improvements in combustion technology, including changes to the combustion chamber design, achieved class-leading*2 output and torque. Simultaneously, enhanced starting performance and reduced vibration prioritized ease of use as a power unit for work equipment intended for general household use.

*1 GCV160 (160cc, max output 3.3kW (4.4PS)) and GCV190 (186cc, max output 3.8kW (5.1PS))

*2 140cc-150cc, 160cc-180cc, 200cc-210cc displacement ranges. Honda internal research (as of end of May 2018)

GX50 (launched February 2019)

The newly developed a 50cc-class GX50 engine achieved maximum output of 2 horsepower. This engine features the acclaimed 360° tiltable four-stroke engine, popular as a power source for handheld equipment like brush cutters. Despite its displacement of 47.9cc, it achieves maximum output of 2 horsepower. Through downsizing and weight reduction, it achieves a power-to-weight ratio comparable to that of a 2-stroke engine.

iGX800/iGXV800/iGX700/iGXV700

The new V-Twin series adds four models to the versatile iGX engine, featuring proprietary electronic speed control technology.

The new iGX V-Twin series*1 incorporates electronic governor*2 (STR*3 Governor) electronic speed control technology where the ECU (Electronic Control Unit) constantly controls the throttle to precisely maintain the operating and idle speeds required by the attached work machine, electronic fuel injection, and DBW*4 remote control. This allows it to handle more complex and advanced applications while delivering excellent fuel efficiency and high work efficiency.

*1 iGX800 (Horizontal mount, 779 cm³, maximum output 18.6 kW (25.3 PS)), iGXV800 (Vertical mount, 779 cm³, maximum output 18.6 kW (25.3 PS)), iGX700 (Horizontal mount, 688 cm³, maximum output 16.5 kW (22.4 PS)), iGXV700 (Vertical mount, 688 cm³, maximum output 16.5 kW (22.4 PS))

*2 Governor: Speed control mechanism (maintains rotational speed regardless of load fluctuations)

*3 STR: Self Tuning Regulator.

*4 DBW: Drive By Wire

GXE2.0H/GXE2.0S (launched May 2021)

eGX electric (DC) power unit was released as a power source for compact work machines.

The eGX electric power unit inherits the reliability and mounting compatibility of the versatile GX engine series for use as a power source in various commercial work machines. It also offers excellent compatibility by maintaining identical flange mounting holes and shaft dimensions to the GX series*1. Furthermore, it is available in two configurations, integrated and separate, enabling installation in a wide range of work machines.