Efforts to Reduce Lifecycle CO₂ Emissions

Advancement in Aggregating Corporate GHG Emissions

While the expansion and adoption of electric products are advancing the reduction of CO₂ emissions from product use (Scope 3 Category 11), CO₂ emissions associated with the manufacturing of materials and components required for these electric products (Scope 3 Category 1) are expected to increase if current trends continue.

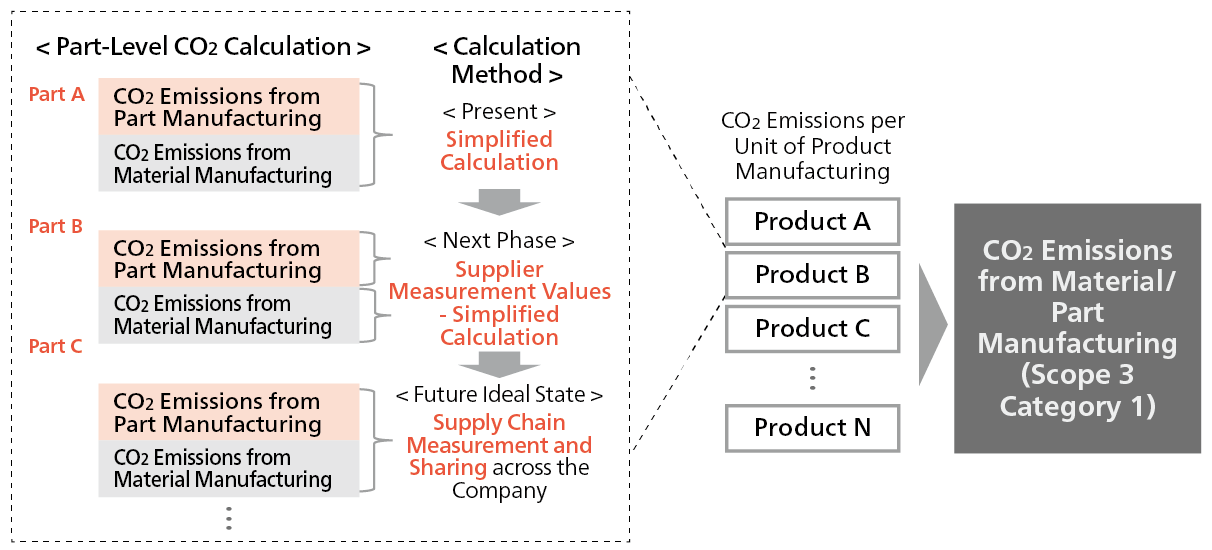

To identify the major sources of CO₂ emissions (hotspots), Honda has developed and implemented a method for calculating CO₂ emissions for each component by breaking down approximately 20,000 parts into about 50 types of constituent materials.

Currently, CO₂ emissions during the manufacturing of materials and components are calculated using simplified methods based on industry averages. However, moving forward, it will be possible to more accurately assess CO₂ emissions reduction efforts by measuring the actual energy consumption during the manufacturing process.

On the other hand, it is the suppliers who can accurately calculate CO₂ emissions during the production of materials and components, as they are directly involved in the manufacturing process. As an ideal approach for the future, we aim to share CO₂ emission data calculated by our suppliers along the supply chain. This will enable us to more accurately assess the CO₂ emissions of Honda products and, based on this assessment, collaborate with our suppliers on further reduction efforts and initiatives.

Based on the belief that accurate assessment of CO₂ emissions enables more effective measures, we are advancing the implementation of a system that can aggregate and analyze CO₂ emissions data across the entire Honda value chain, including not only our own corporate CO₂ emissions (Scope 1 and 2) but also Scope 3 emissions.

Based on the analysis results obtained, we will utilize them to enhance strategies and measures for further CO₂ emission reductions, aiming to achieve carbon neutrality.

Scope 3 Category 1 Aggregation: Concept Diagram

Efforts to Calculate Product Carbon Footprint

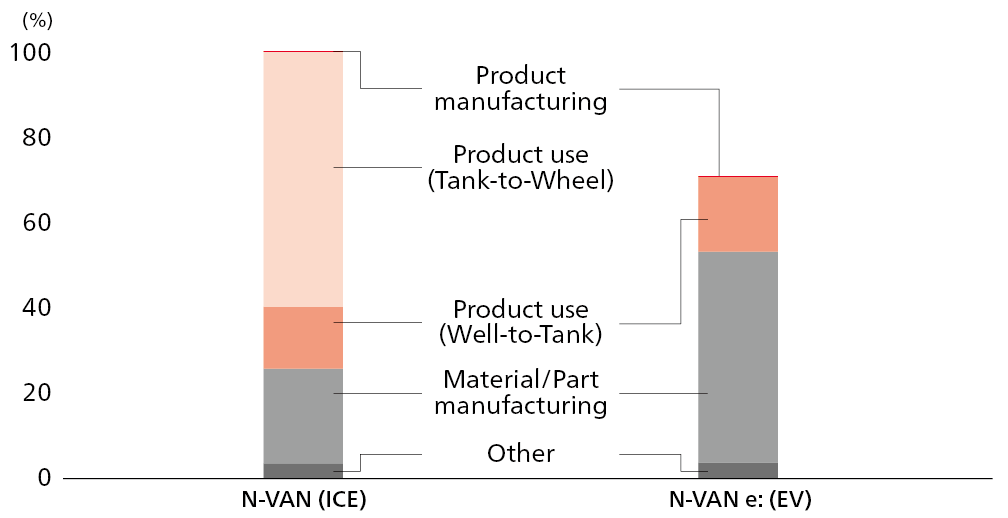

To achieve carbon neutrality by 2050, we are focusing on effective CO₂ emission reductions through product electrification and striving for more sustainable, environmentally friendly manufacturing.

To this end, we are quantifying the product carbon footprint across the entire lifecycle and examining areas such as material and component manufacturing, which may result in higher CO₂ emissions compared to traditional products. We are also developing technologies and improving product specifications to enable CO₂ emission reductions associated with product electrification.

Moving forward, we will incorporate the findings from our carbon footprint assessments into the early stages of product design and development processes, continuously promoting our activities for a lower carbon future.

Carbon Footprint Comparison of N-VAN (ICE) and N-VAN e: (EV)

Initiatives for Internal Carbon Pricing (ICP)

Honda has started operating ICP system from 2023 to further accelerate the reduction of CO₂ emissions at its Japanese business sites. (Carbon price: 15,000 yen per metric ton of CO₂)

The amount of carbon reduction is converted into a monetary value that can be used as one of the factors when making capital investment decisions.

At overseas sites, Honda has selected representative sites in each region and begun trials mainly in the area of production.