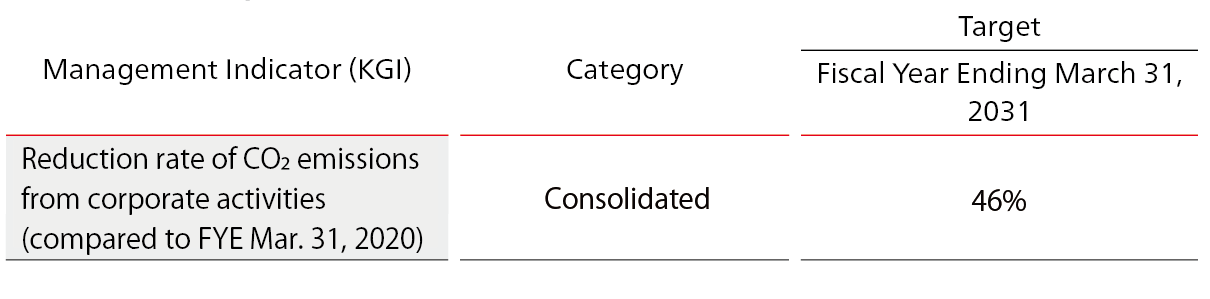

Reduction of CO₂ Emissions from Corporate Activities

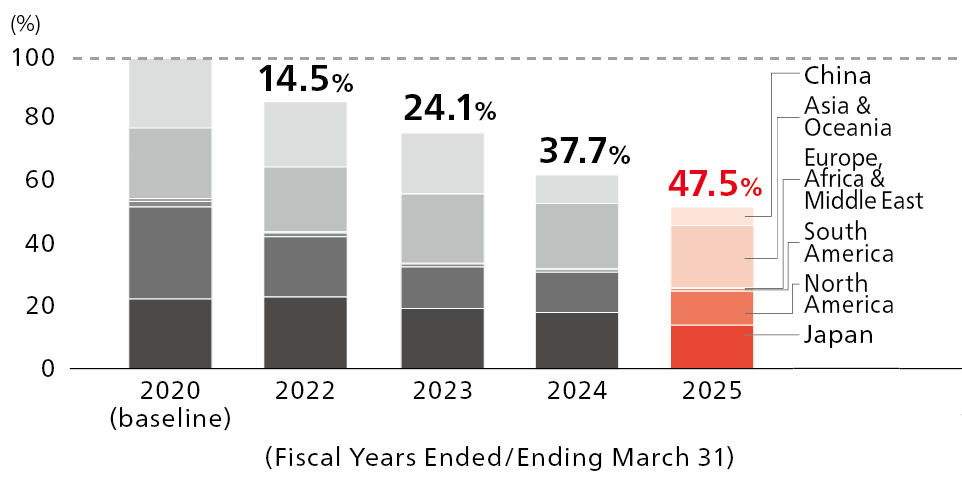

CO₂ emissions from corporate activities (Scope 1 and 2) primarily result from direct CO₂ emissions during product manufacturing at production sites and indirect CO₂ emissions from the use of fossil fuel-based energy in the manufacturing and processing phases. We aim to reduce these emissions by improving production efficiency, electrifying equipment, and substituting energy sources with renewable energy.

Key Initiative 3: Expansion of Carbon-Neutral Factories

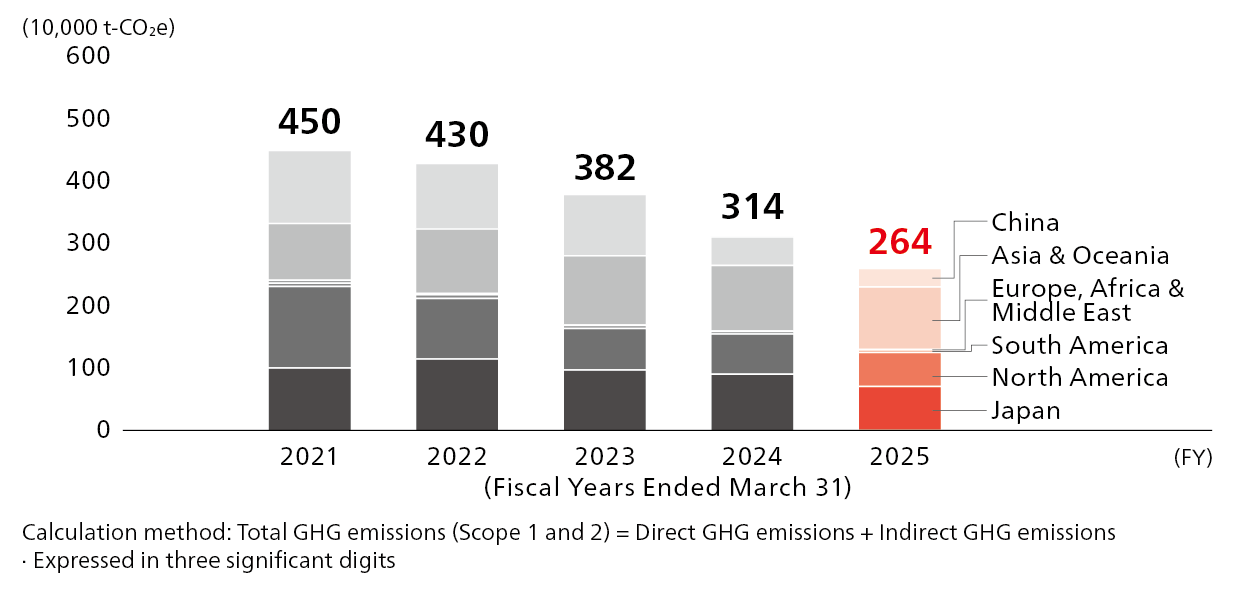

The starting point for reducing CO₂ emissions lies in improving production efficiency and implementing energy-saving measures.

Honda is actively working to reduce direct emissions (Scope 1) and indirect emissions from energy use (Scope 2) in corporate activities.

CO₂ Emissions Reduction through Three Key Technologies / Experience and Expertise:

1) Improving production efficiency and implementing energy-saving measures

2) Electrification of production equipment

3) Procurement and utilization of renewable energy

In the production process, Honda prioritizes improving production efficiency through process enhancements and implementing energy-saving measures. Additionally, the electrification of factory equipment is actively pursued during equipment upgrades or automation.

Furthermore, to address CO₂ emissions from the use of fossil fuel-based electricity, we are working on reductions through the procurement and utilization of renewable energy, including the installation of solar panels on factory premises.

In the fiscal year ended March 31, 2025, the Company achieved a reduction of 47.5% compared to the fiscal year ended March 31, 2020, resulting in CO₂ emissions of 2.64 million t-CO₂e.

Achieving Carbon Neutral at Saitama Factory Automobile Plant by the Fiscal Year Ending March 31, 2026

Honda is implementing CO₂ emissions reductions from its corporate activities using three key technologies / experience and expertise and defines production sites that have effectively achieved zero CO₂ emissions as “carbon neutral factories.”

Honda has designated its Saitama Factory Automobile Plant as a leading facility for carbon neutrality and applied three key technologies / experience and expertise. By advancing these initiatives, the Company aims to achieve Honda’s first carbon-neutral factory in the fiscal year ending March 31, 2026. The technologies / experience and expertise accumulated through these efforts will be shared across other sites and expanded to achieve carbon neutrality tailored to regional characteristics. Honda will work towards realizing carbon-neutral factories at all its automobile production sites worldwide by the late 2030s.

Technologies/Experience and Expertise 1: Improving Production Efficiency and Implementing Energy-Saving Measures

Honda believes that the key actions for reducing CO₂ emissions from its corporate activities are improving production efficiency and implementing energy-saving measures. To enhance production efficiency, we are reviewing production processes and reducing the number of steps and procedures involved in production.

For energy-saving measures, we are implementing practices such as theutilization of surplus heat, among other strategies, to reduce energy consumptionsand lower CO₂ emissions.

For example, we are advancing efforts to recover and utilize waste heat generated in the painting process in other equipment. These efforts are not limited to the painting process and are continuously applied across various processes.

Technologies/Experience and Expertise 2: Electrification of Production Equipment

Electrifying equipment is an effective measure to reduce CO₂ emissions from production processes. For example, we have electrified gas-burning equipment used for drying, which has helped reduce CO₂ emissions from the process.

Additionally, by substituting the electricity used for electrified equipment with renewable energy sources instead of fossil fuels, we are achieving further reductions in CO₂ emissions.

Going forward, we will continue to focus on electrifying equipment tailored to the characteristics of our production processes.

Technology/Experience and Expertise 3: Procurement and Utilization of Renewable Energy

Honda is actively installing solar panels on buildings and parking lots within itspremises.

To make the most of the renewable energy generated by these installations, we are also implementing stationary battery storage systems. This approach aims to minimize the Company’s own CO₂ emissions from its operations and enhance its reduction efforts.

Additionally, in regions such as Japan and North America, Honda is also advancing the procurement of renewable energy sourced from external suppliers.

As a case example in Japan, Honda has signed a Virtual Power Purchase Agreement (PPA) with Rusutsu Wind LLC in September 2024, and plans to acquire the non-fossil certificate (environmental value) from the fiscal year ending March 31, 2026.

Honda is actively promoting the use of renewable energy sources such as solar and wind power generation on a global basis.

More specifically, the Company has installed solar panels on parking lots, factory roofs, regulating reservoirs, and other locations.

Going forward, to further facilitate and expand the use of renewable energy, the Company is promoting the introduction of lithium-ion storage batteries and will continue to use renewable energy matched to the conditions of each region on a global basis.

-

Kumamoto Factory -

Saitama Factory Automobile Plant -

Hosoe Outboard Engine Plant -

Boiling Springs Wind Farm

■Use of renewable energy power (global)

2,835 GWh (increase of 47.1% from the previous year)

Utilization of Carbon Credits

Honda is implementing various strategies and innovations to reduce and mitigate CO₂ emissions. However, even with these efforts, we anticipate that achieving complete zero CO₂ emissions may still be challenging. Therefore, we consider the use of high-quality carbon credits, among other options, as part of our strategy to achieve net-zero emissions.