Parts Supply to Gain Customers’ Confidence and Trust

Then Honda president Kiyoshi Kawashima signing a long-term lease agreement for a port site in Ghent.

Then Honda president Kiyoshi Kawashima signing a long-term lease agreement for a port site in Ghent.

Since its beginning, Honda has also focused on supplying genuine parts, which are indispensable for services to gain the confidence and trust of customers, and has established a system to deliver parts quickly and at reasonable prices.

In Europe, Honda Europe (HE), established in 1978, functioned as the European hub for repair parts, but in 1981, local subsidiaries and dealers in Europe complained to HE about slow parts supply and frequent shortages. In response, HE launched a project to improve supply speed and rate, and review the information network. Subsequently, as the number of motorcycles and automobiles sold increased dramatically, HE improved its supply network by establishing a next-day delivery system while building warehouses and starting up new locations.

In Japan, a customer satisfaction survey on parts conducted in July 1987 showed that the speed of supply was not well regarded. In response, Honda shortened delivery times and adherence to schedules by linking the primary delivery service, which supplies parts from the originating parts center to parts distributors, and the secondary delivery service, which delivers parts to distributors via parts companies. To achieve the industry’s top-level distribution network, in 1989, Honda aimed to deliver at least 85% of motorcycle parts and 95% of automobile parts within 24 hours of receiving orders from parts distributors, and exceeded its target at 91% in 1989 (from 73% in 1987) for motorcycles, and 98% (from 94% in the same period) for automobiles (Honda survey). With the exception of some areas in Hokkaido, Aomori, and Akita, the 24-hour supply system was established uniformly throughout Japan.

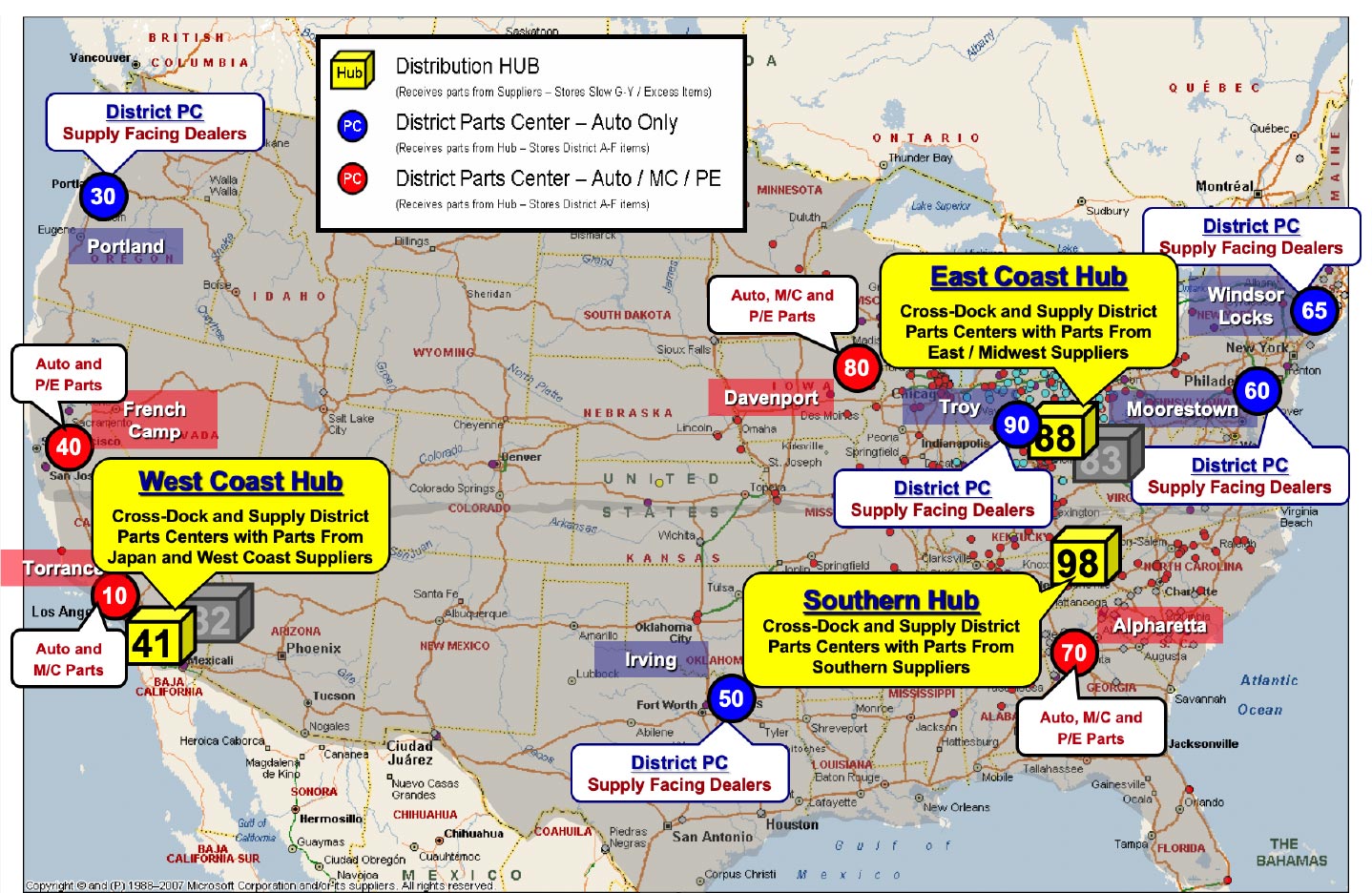

In Asia and Oceania, due to geographical difficulties, such as numerous islands and less developed roads, parts supply in the Asian region was extremely weak compared to that of the Americas and Europe at the time. In 1996, Honda launched the Asian Parts Center (APC) project to strengthen the functions of regional parts headquarters in Asia and to build a warehouse and management system for 310 ASEAN* countries. Next-day delivery was launched in Thailand as operations began in 1998. In the U.S., in 2007, by establishing a supply network based on 3HUB / 9PC, three hub warehouses and nine regional warehouses (parts centers) for parts receiving, storage, and shipping, a next-day delivery system was built and a highly efficient supply system with uniform quality was completed in major regions around the world. In Japan that year, Honda established the Suzuka Distribution Center (HBSL) aiming to achieve a high level of customer satisfaction with industry-leading efficiency. By consolidating, centralizing, and self-supporting logistics bases and improving warehouse operation efficiency, the center was able to deliver parts ordered by 3:30 pm to dealers the next day.

The supply of parts to overseas customers began with exports from Japan, but as local production expanded, it became necessary to go beyond local procurement and intra-regional consumption to global mutual supply of parts across regions and national borders. In 1996, the four-region World Parts meeting, consisting of Japan, Europe, North America, and Asia Pacific, established inter-regional parts supply and pricing rules, and from the following year, 1997, parts supply between the four regions became possible. These meetings were held regularly, and contributed to smooth inter-regional supply by establishing rules (supply period and order confirmation timing) and tools (global tracking system and returnable rates).

In conjunction with the development of globally optimized sourcing including China, beginning with the third generation Fit, direct shipment of repair parts between regions progressed. The number of global parts supplied directly to sales bases around the world from bases other than the major regions (India, China, Vietnam, etc.) increased dramatically, requiring the establishment of export bases and direct delivery routes to ensure stable procurement and worldwide supply of these parts. In addition to evaluating and supporting the parts supply system of new export bases, rules that had been established between major local subsidiaries were substantially revised to clearly establish "inter-regional business guidelines" (global supply and price guidelines), a simple and fair set of business rules that applied consistently worldwide. As a result of applying the same rules to each joint venture company in China from 2018 to 2022, it became possible to reliably supply parts at a fair price to customers from any production country to any sales country. These inter-regional business guidelines are revised in detail at the annual global parts meeting in response to changes in the environment, and have consistently been a clear guideline for the parts business.

On the other hand, there have been failures in enhancing the supply network. Honda’s parts business in India had been handled by Honda’s motorcycle, automobile, and power products operating companies, but by consolidating them under Honda Motor India in 2006, Honda sought to strengthen its cost and logistics structure and build a system to deliver high-quality aftermarket parts in a timely manner. However, when the parts warehouses were consolidated, relocated, and systems changed in response to the explosive increase in motorcycle sales in 2010, warehouses were unable to cope with the rapid changes in the environment and were overwhelmed, requiring two years to recover. Honda learned that in order to ensure the successful establishment of supply networks and bases, which normally takes several years, improving the accuracy of planning by setting globally common KPIs and conducting periodic inspections of warehouse capacity and logistics expenses in conjunction with the local subsidiaries’ mid-term business plans was essential. In response, a Logistics Global Working Group (GWG) was established in 2016 to monitor the warehousing capacity of each overseas subsidiary and continue logistics efficiency balancing activities led by the regions.

While developing a global parts supply network, new challenges emerged due to business expansion. Since its founding, Honda has been committed to delivering necessary repair parts to its customers as long as they used Honda products. However, in the 1990s, the number of parts for discontinued products continued to increase, and it became a major burden for the suppliers to maintain facilities that could accommodate constant production. In light of this, a consulting parts system was first introduced in 1990. This system enabled Honda to make a list in advance of certain parts that were difficult to procure, and upon receiving an inquiry from a customer, it could provide information regarding the time and price required for delivery prior to accepting the order. Subsequently, after carefully studying the trends of other companies, including the availability of parts that are more than 20 years old, a production time limit*4 was introduced in 1992. This allowed suppliers to scrap their molds and equipment after delivering the required number of parts, which was determined by regulations according to the number of units produced, contributing to the reduction of the need to continue producing old parts.

As with its suppliers, Honda’s own parts production plants had reached the capacity limit to continue producing old parts, and they needed to find a new production base. In particular, bases for the stable production and worldwide supply of body parts and bumper parts, which are in high demand, were needed, and Honda gradually developed a consolidated production system for old model parts around the world. First, in 1988, in southern North America, Honda de México S.A. de C.V. (HDM, Mexico) began full-scale production of old-model body parts and bumper parts, to handle the increasing number these parts produced at plants in the region. This was followed in Europe, by Honda Belgium Factory N.V. (Belgium) in 1996, and in Japan by Yachiyo Industry Co., Ltd. in 1998, which began production of body parts and bumpers for repair use. In the 2000s, demand in Asia increased rapidly, and in 2006, Honda established Asian Parts Manufacturing (APM), the first dedicated repair body parts plant for Honda in the Asian region. In 2010, Honda Turkiye A.S. (HTR, Turkey) began production of old models for the European region, establishing a system of integrated production of old model parts in each major region and a stable production and supply system for old model in-house parts.

The consolidated production system for old parts in each region has since benefited Honda in various ways, such as enabling alternative and complementary supply in the event of a disaster or plant closure. When the Thai floods occurred in 2011, APM was damaged and had to suspend operations for four months. Honda was able to minimize the impact on parts supply to its Asian and global customers by using its expertise in centralized production to immediately substitute production and supply at its other three bases, including HDM, Yachiyo Industry, and HTR. In addition, when Honda of the UK Manufacturing (HUM) and HTR were closed in 2021, Honda transferred the old model body parts to be supplied to Europe, which had been produced at HTR, to HDM and APM to continue parts supply, thus minimizing the impact on customer repairs. This global system continues to contribute to the stable supply of parts to the aftermarket today.

APM submerged in the 2011 Thai floods

Honda has also worked to develop products and services to meet a wide range of customer needs. Since its creation in 1959, the Honda ULTRA brand of genuine Honda oil, for which quality is assured through inspection and management equivalent to that of Honda products, has become a standard oil for Honda motorcycle owners in Japan and parts of Asia as a result of continued efforts to appeal to customers together with sales companies. The move to develop genuine oil that best matches Honda vehicles gradually expanded globally. Other oil types apart from engine oil are being developed in Japan, and promoted to regional customers.

- Association of South-East Asian Nations

- Production of old parts continues as long as there is high demand.

Aiming to Exceed Customer Satisfaction

Through Advanced Technology

Each customer uses their car in a different way. Honda would provide the best individualized service to each customer if possible. With this passion, Honda’s history of optimal services tailored to each individual customer began.

In the early 2000s, although Honda planned to provide the owner’s manual on in-vehicle displays and automatic remote updates without a visit to the dealership, the technology and infrastructure necessary were not in place to make this a reality. Then, in the late 2010s, IT technology evolved dramatically. This made it easier to obtain data on each customer’s vehicle, with their consent, while it was in motion, and the idea of “providing optimal services tailored to each individual customer”began to take form. Honda continues to evolve its connected data to visualize the usage status of customers’ cars, updating car software via OTA (Over The Air) without the need to visit the dealer, and providing in-car digital owners’ manuals.

Software update using wireless network

On the other hand, the electronic control mechanisms of vehicles have expanded dramatically since the 2000s, and the mechanisms themselves have become more complex, making it difficult to diagnose and repair problems accurately in a short period of time and the risk of recurrence of problems has increased.

In response, Honda has thoroughly analyzed electrical system failures, and developed these strategies:

(1) Strengthen the self-diagnostic function of ECUs.

(2) Improve reproducibility of failures by storing control information when failures occur that cannot be self-diagnosed.

Until now, self-diagnostics required additional diagnosis even if a failure code DTC (Diagnostic Trouble Code) was displayed when a failure occurred, taking time to determine the true cause of the failure. However, by subdividing the ECU’s self-diagnostic function, one DTC is set per detected failure, greatly reducing the time required for diagnosis by the dealer’s service staff. In addition, for symptoms such as stalling and starting failure, OBS (On Board Snapshot), a time-series record of ECU data, is kept in the ECU’s memory, allowing the control state at the time of the failure to be determined.

In addition, the storing of diagnostic data at the time of failure has been greatly enhanced by renewing the diagnostic equipment, improving reproducibility and diagnostic capability in the event of failure, and making it easier to pinpoint the true cause of failure and reducing repair time.

The use of ECU memory for reproducibility of failure diagnosis in order to achieve these goals was extremely difficult to implement because it was necessary to gain the understanding and approval of developers who wanted to utilize memory to improve vehicle performance.

However, Honda persistently explained to the designers how the use of memory for reproducibility of failure diagnosis would lead to customer satisfaction and discussed increasing the amount of memory, which led to the implementation of the new system.

In addition, detailed design data, which is key to diagnosing failures based on recorded control data, was proactively provided to dealers and others as new advanced diagnostic service data, leading to a reduction in the time required for repairs when a failure occurs. In addition, the ability to reliably determine what, how, and why a failure occurred had improved the success rate for reliable repair in a single visit to the dealership. These improvements have led to improved convenience for customers and reduced workload for dealers.

In addition, the new diagnostic equipment introduced allows the Japanese service department to collect self-diagnostic data from defective vehicles via an online network with dealers around the world, and feed this data to the design department, contributing to source improvement.

i-HDS diagnostic system for inspection and maintenance, using advanced technologies for cars

Although it had become easier to collect vehicle data since the new Fit in 2020, only a limited number of quality department personnel were able to retrieve and analyze the connected data stored on the server. In order to enable effective use of this data in the field of service from FY2022, Honda developed a BI (Business Intelligence) tool which could visualize connected data, and service departments and the STC (Honda R&D’s Service Technology Center) collaborated and began to study whether the tool could solve problems in the market. Although trials are still ongoing as of 2023 to determine under what circumstances connected data can be utilized in the service field, it has become possible to visualize the state of the vehicle at the time of malfunction (failure, accident, malfunction, or mishandling) and to accurately grasp and analyze the circumstances. Furthermore, it is now possible to check whether a failure occurred and whether the failure continued to occur for each operation after the DTC occurred.

Through the widespread use and experience of smartphones, people can now routinely update data and applications themselves, and the need for OTAs to update vehicle software through wireless networks has become very high.

Service updates through OTAs began in North America with the 2018 model year. Initially, this was limited to entertainment display audio and navigation systems, and the service department created an OTA management system and distribution server. Next, in order to increase the number of ECUs to which the system was applied, from 2019, personnel from the service department entered the development department and engaged in joint research as part of Honda R&D’s development theme, “Development of a software update system using OTA.” Then, the OTA technique for the engine and other main control system ECUs was developed and applied to the 2023 Accord model year.

In the OTA development of the control system from the 2023 model year, Honda worked on a wide range of development projects and obtained patents, including control of tens of thousands of software distributions, compliance with software update regulations, software download and installation methods, and user interface design. In addition, in order to ensure the performance and quality of the system, the service department conducted long-term and multiple on-site verifications over more than six months before the mass production of vehicles in the U.S., the country of launch, and was able to complete the system. Honda is now working with related divisions to formulate and promote future plans, aiming to expand the value of the system from OTA to fix defects, to adding functions through software updates, and to improving security.

Honda’s service division has been working to provide the best possible service at the point of contact with customers, the dealers’ service sites, aiming to deliver the “joy of buying” to customers around the world, which has been Honda’s philosophy since its founding. The essence of this desire and activity will remain unchanged.

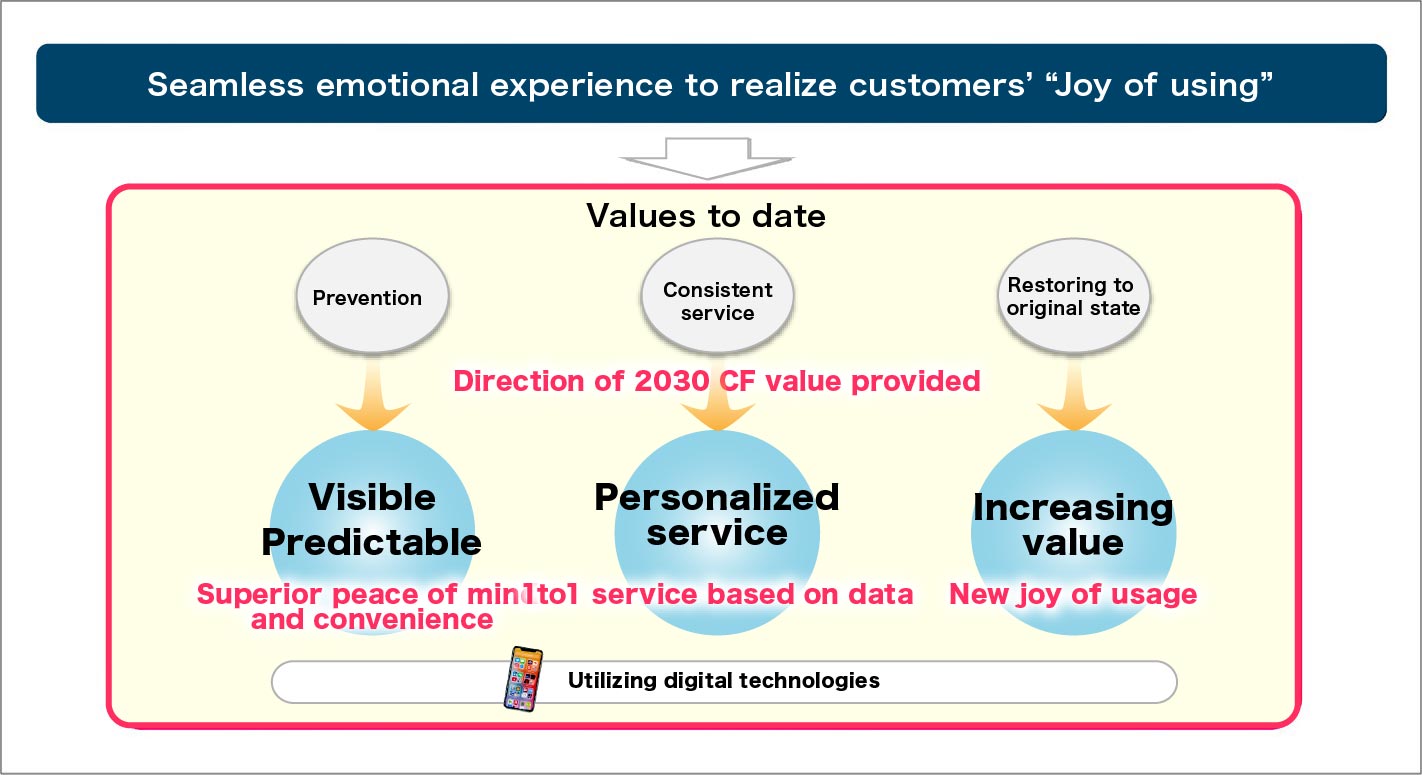

Honda, however, anticipates changes in the business environment as it aims to become carbon neutral and achieve zero fatalities in traffic accidents involving Honda motorcycles and automobiles by 2050, as well as the diversification of customer needs and dramatic changes in values that will accompany the shift to electrification. The service and parts departments, which are needed throughout the customer’s vehicle ownership, must create new service value to ensure that customers continue to use the products they have purchased for as long as possible, and further, to provide the services created directly to individual customers by fully utilizing digital technology, in addition to providing services through dealerships, as has been done in the past. Honda aims to build a seamless relationship with its customers by providing these services directly to each customer through the full use of digital technology, in addition to the services it provides through its dealers. In order to achieve this, Honda needs to expand the points of contact with each and every customer and strive to create new “joy of use” so that it can provide an emotional experience to each and every customer.

To achieve this goal, Honda will make maximum use of digital technology, strengthen its ties with the global Honda group engaged in service and parts, and actively collaborate with external companies to take on the challenge of speedy change.

Building a seamless relationship with each and every customer, utilizing digital technologies.