“01 Taikai” Project to Create Flexible Production Structure

that Rapidly Responds to Market Changes

In the 1990s, when Honda expanded its production activities globally and established a four-region system, it faced challenges due to differences in its production structure, such as the specifications of production equipment and production processes at each plant. In Japan, recreational vehicles (RVs), one-box vehicles, and other leisure-oriented vehicles became increasingly popular in the 1990s, but Honda did not have a plant capable of producing these models.

In response, the Saitama Factory’s Sayama Plant and the Suzuka Factory underwent major renovations while the Sayama Plant produced the Odyssey based on the Accord platform, and the Suzuka Factory produced the CR-V based on the Civic platform. However, the difficulty of keeping up with these major market changes became apparent.

The Saitama and Suzuka teams were both providing support even within the same overseas plant, as the support teams from Japan differed depending on whether the model to be produced was manufactured by Saitama or Suzuka.

North American Accord Coupe

North American Accord Coupe

As a result, both the Saitama and Suzuka systems were used even on the same production line. In addition, the domestic factories in Japan had implemented their own structural improvements specific to their production models in order to maximize efficiency, and as a result, production with different systems and processes at each factory had taken root. Overseas plants, which produced both Saitama and Suzuka models on a single production line, needed to have both systems and processes in place.

Furthermore, since the mid-1990s, the production systems and processes had become more diversified, with an increase in the number of models produced in North America, such as the Accord Coupe and Wagon, Acura CL, and Odyssey, which are exclusive for North America, and in Asia, such as the Asia-exclusive City.

In these circumstances, large investments would be required for each new model launch, resulting in a decline in cost competitiveness, and when production increased, each production base would need respond independently, resulting in delays in meeting needs and a decline in market competitiveness. Honda’s future was bleak without a major change in its production structure, which it decided to address on a global basis.

North American Acura CL

Thai City

North American Odyssey

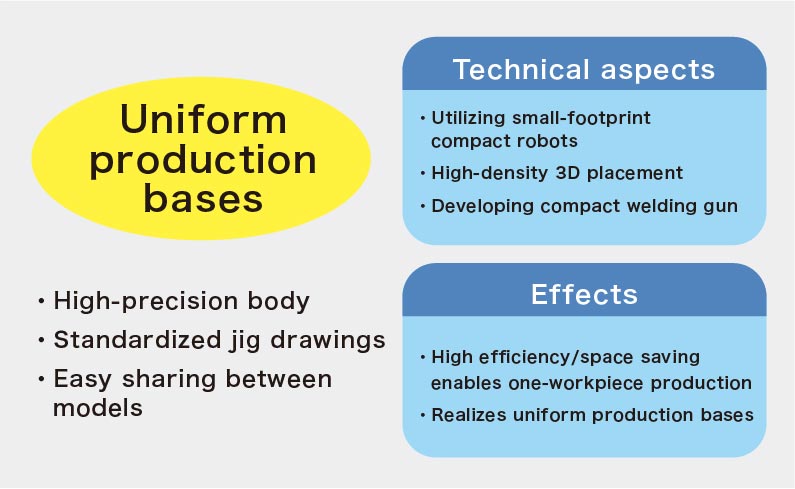

In 2001, the Production Planning Office and Honda Engineering Co., Ltd. (EG), which was responsible for production engineering, launched a joint project, known as the “01 Taikai” [2001 Structure Reform] project. The project aimed to drastically increase versatility and minimize fixed (dedicated) parts of the production facilities (dedicated parts for each model) to accommodate multiple models, and to realize this simultaneously at all worldwide facilities, with the same quality, at one-tenth of the investment cost. The car body welding process, which required heavy and bulky equipment, was in particular need of improvement. The project team targeted the car body welding line, considering three measures to drastically reform its structure:

(1) Shortening the lead time for new models

(2) Reduction of in-house production costs, investment, and expenses

(3) Unified specifications for all four regions worldwide

One idea implemented was the separating of the side panel (sub) joining process from the SMGW (submain general welding machine) process, which is the main process of the welding line. This was a method of separating the high-density TT jig functions (fixed spot welding equipment and jig) to realize light equipment (simplification) and generalization, and to make the robot process highly versatile. Since then, the use of lightweight jigs accelerated.

Positive Effects on Domestic Production Through Return to

“Monozukuri” Based on “Three Reality Principle”

Around 2010, the global economy was at a standstill due to the global financial crisis. Japan’s woes were compounded by a strong yen, severely hindering its export competitiveness. For Honda’s domestic automobile business, the key challenge was to achieve self-sufficiency in domestic production capacity through domestic sales. Although the domestic automobile market was shrinking, the majority of this market was dominated by the k-car and small car segment, and demand for k-cars in particular was expected to grow. Competition was fierce among manufacturers, particularly those that focused on k-cars, and Honda was urgently developing a new k-car, the N-BOX.

The development team was instructed by then president Takanobu Ito to move the launch date of the model forward by two months, and was moved to December 2011. This was in response to a strong request from the presidents of the sales companies. On March 11 that year, just as the company was pushing to launch the product, the Great East Japan Earthquake struck. The Tochigi R&D Center was severely damaged.

Masanori Todoroki, who was in charge of the N-BOX at the New Model Center (E-PL) at the time, recalled:

“The earthquake stopped all activities for about a month and a half, and our plan to start up in December was not changed, so we lost a total of about three and a half months.”

Time was not the only thing that was lost. The Tochigi R&D Center was no longer able to produce prototype vehicles. Instead, the Suzuka Factory, handling N-BOX production, decided to build several prototypes.

“We had never built a prototype at Suzuka before, so we were quite anxious about whether we could do it, but considering the situation at R&D, we had no choice. Of course, Suzuka didn’t have the facilities yet, and the engines were all assembled by hand.” (Todoroki)

These new experiences had unexpected effects.

“As a result, we were able to touch, and build the car from an earlier stage than usual. I think it was significant that we could gain experience through some understanding of how the car was built.”

The N-BOX, a project completed through

The N-BOX, a project completed throughface-to-face communication between the development and production teams at the Suzuka Satellite.

In addition, the development team was moved from the Tochigi R&D Center, where they were unable to work, to a satellite office set up at the Suzuka Factory, where development and production were carried out, creating an unprecedented effect.

Yasuaki Asaki, then N-BOX large project leader (LPL) at the Honda R&D Automobile R&D Center, said:

“I have never felt the benefits of proximity so much. Whenever we had a problem, it usually took us a long time to solve it through e-mail or phone calls, but just by meeting face to face on site, we could solve it in an instant, so I realized the importance of face-to-face communication.”

Development speeded up through direct communication, and the N-BOX went on sale in December 2011 as scheduled. This was a reminder of the importance of the “Three Reality principle” of sharing the same place, product, and reality across departmental boundaries.

In April 2012, the Suzuka Satellite developed into the Automobile R&D Center Suzuka Branch (HGT-S). As part of its organization, the DEB (Development, Engineering, and Buying) functions were consolidated on a single floor in Suzuka, and “Kei QCDD Development” was launched, integrating all processes from development to purchasing and production. The “SKI (Suzuka Kei Innovation) Project” was launched integrating quality, cost, and delivery (procurement) in the production area, with the development area, to create a system for speedy commercialization of k-cars. The project was gradually introduced in the development of k-cars following the N-BOX.

Major Reform of Automobile Production System at Overseas

Bases through “Made by Global Honda”

Since its founding, Honda has established production bases in various regions of the world based on the principle of “building products close to the customer.” In the 2000s, this basic production policy evolved into the “Made by Global Honda” (globally optimized production) strategy. It clearly stated that Honda would “utilize its global network to procure and produce parts at optimal locations around the world and supply them to optimal markets” for automobile production. In addition, in order to respond to further expansion of global demand and diverse needs, the regional business operations were developed into a six-region system (Japan, North America, Europe, Asia, South America, and China), and business operations were conducted to meet the market needs of each region through globally optimized production.

Honda also accelerated local development and production in order to supply products optimized for each region in a timely manner, while promoting the “01 Taikai” [2001 Reform] in the production area. However, this response to the diverse needs of each region led to confusion on the production floor and a decline in business efficiency by the mid-2010s.

When starting up mass production of a new model at a production plant, “product maturation” (quality maturation) is carried out through a series of stages of setup, quality, and mass production confirmation, according to product specifications, production processes, and production facilities. At the beginning of its expansion of production bases, the process was Japan (the originating country) initiating mass production, and sharing production knowhow with secondary production countries to shorten the product maturation period. However, the increase in the number of derivatives of global models and region-specific models due to regional optimization had significantly increased the man-hours required for product maturation, and the conventional process had become difficult to handle. As a result, new models overseas were not launched as planned, and after coming off the production line, modifications were required, which increased costs and the burden on associates. In addition, there was a lack of support members from Japan with the skills to apply production requirements to the product maturation process for the launch of models and specifications that were not produced in Japan, and human resource development became an urgent issue.

To solve these issues, Honda announced that in 2019, as a company-wide initiative, it would introduce a development method called the “Honda Architecture” to increase development efficiency and the percentage of standardized parts. This was to be adopted starting with the development of the global model Civic (to be launched in 2021), as the amount of jig reconfiguration work required for each change in parts and equipment on the production line could be reduced, and speedy and flexible production complementation between regions would be possible. With this, production management began measures to achieve standardization of product specifications, production processes, and production facilities. This was also an initiative of the “Global New Model Quality Maturity Skills” improvement activity, which started in 2017 to train Japanese support members.

As an example, a simple structure and specification with the least variation was developed based on CAE (Computer Aided Engineering) analysis data, so that the welding structure of the front body frame could be easily standardized for deployment at each production base. A data box was newly established so that the content of product maturity data developed in Japan, the originating country, could be shared with other bases, and through close communication, the status of setup at each base could be confirmed and local problems could be addressed.

Meanwhile, as a measure to train local associates for region-specific models, a detailed quality maturity manual was developed and trials were conducted at two production bases in North America. Having completed verification and confirmation of the manual’s effectiveness, it was deployed from Japan to five production bases in North America, one in South America, and three in Asia and Oceania, and a unified quality maturation system was established for the launch of new models in 2023 and beyond.

Reviewing Global Automobile Production with a View to

Electrification, and Evolving Global Manufacturing Technology

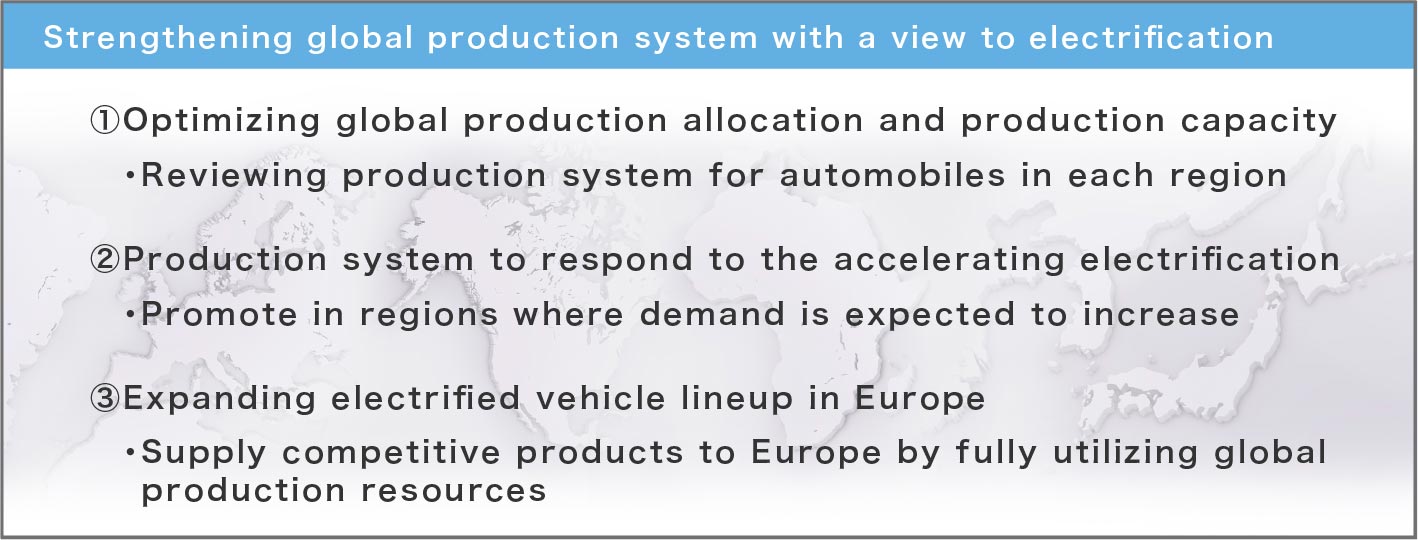

In the latter half of the 2010s, the global trend toward electrification began in earnest, and the automotive industry entered a major transition period that is said to occur only once every 100 years. Honda had already been working on electrification technologies, not only for motorcycles and power products, but also for energy, with a focus on automobiles. In anticipation of the ever-accelerating demand for electric vehicles, Honda decided to build an automobile production system for electric vehicles centered on Japan, the U.S., and China under the policy of “optimization of global production layout and production capacity.” In Europe, however, while electric vehicles needed to be strengthened, Honda determined that production of electric vehicles within Europe would be difficult from the standpoint of competitiveness among other factors. Based on its concept of strengthening cooperation among regions under “Made by Global Honda,” the decision was made to review the business foundation by utilizing global production resources, such as sharing product lineups with China, which had similar environmental regulations and directions to those in Europe.

As a result, in February 2019, Honda announced that it intended to end production of complete vehicles at HUM by the end of 2021 with the Civic Hatchback. On the same day, Honda also announced that production of the Civic sedan at Honda Turkiye A.S. (HTR), an automobile plant in Turkey, would also end during 2021.

In July 2021, the last Civic produced at HUM rolled off the line, bringing an end to 35 years of production activity, although HUM had played an important role in Europe with the largest production of the Civic since its establishment, producing approximately 2 million units and more than 400,000 engines as of 2020.

In Japan, Honda announced in October 2017 that the Saitama Factory’s Sayama Plant would be integrated into the Yorii Plant, which is equipped with the latest production technology for future electrification, and in December 2021, the Sayama Plant would cease production of complete vehicles. In June 2021, Honda also decided to close the Powertrain Unit Manufacturing Department (Moka City, Tochigi), and consolidate operations into multiple production bases aiming to close the facility by the end of FY2024.

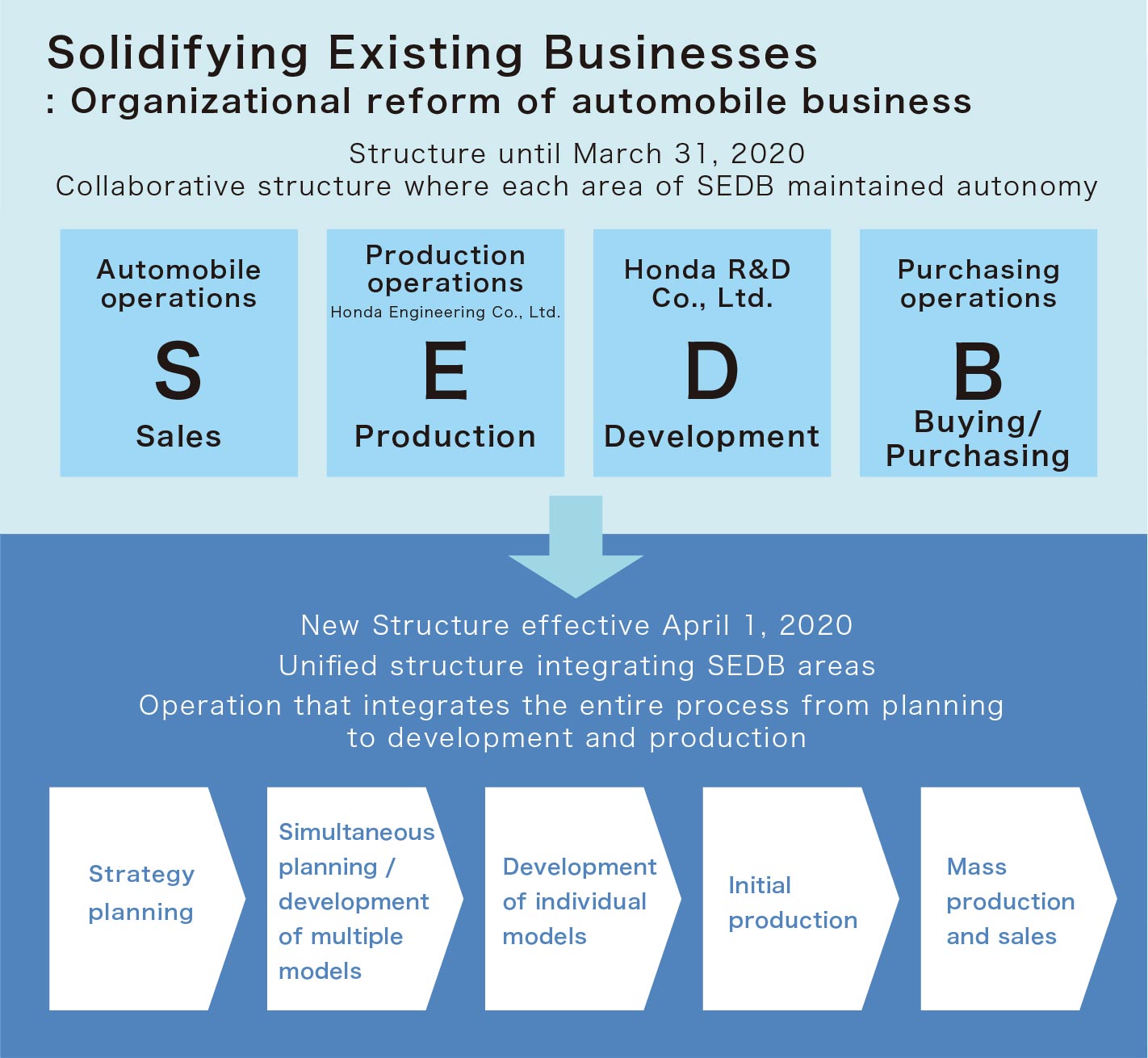

In 2020, the head office’s automobile business operation was significantly revised. Sales (S), Production (E), Development (D), and Purchasing (B) were integrated into the Automobile Operations to create a unified management structure. The aim was to strengthen strategic planning, build a manufacturing base that is highly competitive, and realize a strong automobile business.

In the area of production, management and achieving a high level of production quality on a global scale gained importance. In order to ensure the quality of automobiles with advanced technologies including electrification, Honda decided to verify at each production site through DEB the manufacturing technologies and whether the site could begin manufacturing, while introducing a global manufacturing technology functionality at each site to increase competitiveness.

The required manufacturing technology functions were based on the process and process design defined by global standards, and the production, manufacturing, and quality technologies that would serve as the basis for the new functions, were consolidated into manuals and know-how collections utilizing manufacturing DX technology, and procedures were defined.

On September 17, 2020, the Global Manufacturing Technology Building was established in the Yorii Plant as a base to realize stable production while ensuring the high quality and highly intelligent safety functions of electric vehicles. This marked the beginning of a manufacturing initiative that integrates development and production in a speedy manner.

SEDB from cooperative structure to integrated operations

Associates Gave Their Best Until the Final Unit

HUM Closed

When the ending of HUM’s production activities was announced in February 2019, a message from Takahiro Hachigo (then Honda president) and Jun Nishimoto (then HUM president) was distributed to all associates at HUM, and talks between management and associates began.

The status of the discussions was disclosed as needed, and care was taken throughout the process, such as providing feedback on questions raised by associates as needed. To ensure that all associates felt secure, efforts were made to provide retirement packages and outplacement support, and internal events such as social gatherings and awards were held to maintain motivation and an environment in which associates could concentrate on their work until the end of production.

In a survey of associate awareness of “motivation to work, pride in work, and workplace satisfaction” conducted in February 2020, one year after the announcement, around 80% of respondents said they were “proud to work for HUM” and about 70% said they would “give their best until the end.” They protected the Honda brand until the plant closed in July 2021, working with pride until the last vehicle rolled off the line.

Although HUM’s production activities had ended, a Honda Heritage Park was landscaped at the northeast end of the plant site with a memorial tree, and the Civic TYPE R, the last major model, was donated and displayed at the British Automobile Museum, forever marking the legacy of HUM on British soil.

Doing What Can Be Done in an Age of Anxiety

Social Contribution Activities During COVID-19

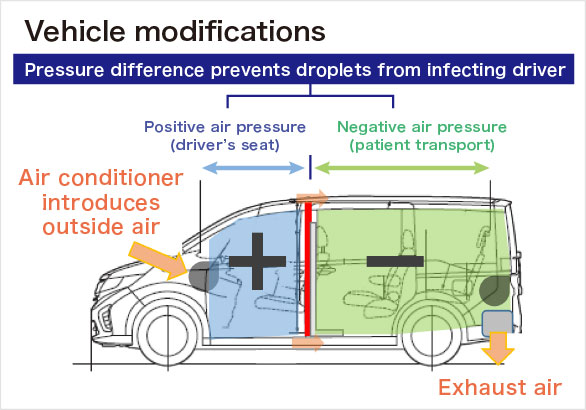

As the COVID-19 pandemic spread, an associate of the Saitama Factory’s Sayama Plant proposed the creation of a vehicle to transport infected people, and in an extremely short time, Honda developed a vehicle with partitions between the driver’s seat and the rear seats, and other measures to prevent the driver becoming infected. Odyssey, Step Wgn, and other vehicles were produced at domestic plants and provided to local governments.

Subsequently, sales companies in various regions also modified vehicles which were provided to local municipalities. A total of 168 vehicles had been provided to 26 prefectures since April 2010, including the installation of partitions on vehicles used by local governments.

When this initiative was posted on a video sharing site, it caught the attention of officials in Michigan and Detroit in the United States, who commissioned Honda R&D America (later to become Honda Development and Manufacturing of America, LLC. (HDMA)) to provide similar vehicles. In collaboration with the engineers at the Saitama Factory’s Sayama Plant, HDMA prepared ten vehicles in two weeks, which were lent to the City of Detroit to transport infected patients.

Evolving Production Activities in Response to

Times and Circumstances

Honda’s approach to its production activities has changed as its business evolves to meet the needs of the times. It is a history of the company’s continuous pursuit of how to efficiently and competitively manufacture products and exceed customer expectations, while effectively utilizing existing resources and ensuring quality.

Kensuke Oe, Managing Executive Officer and Head of Production Unit, Automobile Operations, reflected on Honda’s production activities:

“It was essential to review our structure, system, and operations in a timely manner in accordance with the times. We have continued to evolve by making changes in a flexible manner without being bound by the past, and through our efforts, we have put into practice our company principle of providing high quality products at reasonable prices from a global perspective for the satisfaction of our customers around the world.”

Oe also says that the driving force behind the future evolution of Honda’s production activities lies with the awareness of each and every Honda associate.

“In order to continue to be a company that society wants to exist, we need to go return to the starting point of Honda’s philosophy, to always think about how to respond to the times that are changing second by second, to proactively face the challenges of our own work and the challenges of our organization, and to continue to take on the challenges of finding solutions. As Monozukuri [the art of making things] professionals, we have always set high goals and boldly tackled challenges that defy stereotypes and common sense. There is no doubt that all the activities of each and every one of us are the source of Honda’s next generation. Honda, which has grown as a manufacturing company, is now on the verge of transforming itself into a mobility company and a key player in the circular economy that enhances the value it provides through the fusion of hardware, software, and services. We need to recognize that ‘not to change is a risk,’ and boldly rethink the way we do our jobs. Innovation comes from there.”