Design Innovation

Innovation 2

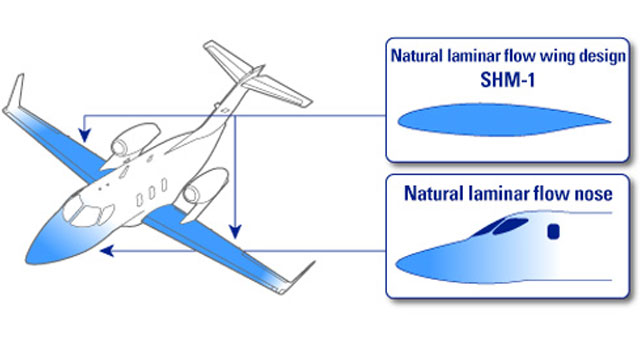

Honda-Developed Natural Laminar Flow (NLF) Wings and Nose

Laminar airflow refers to a condition where airflow on a solid surface such as the surface of aircraft wings (within the boundary layer) is smooth, and it creates significantly less skin friction drag than turbulent flow. Honda independently developed the Natural Laminar Flow (NLF) wings and fuselage nose with shapes designed to maintain a large portion of the boundary layer to have a natural laminar flow even during high-speed flight. This design contributes to HondaJet's outstanding speed and fuel efficiency.

Areas in which natural laminar flow is applied

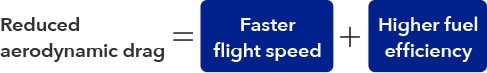

Benefit: The NLF wings and nose contribute to an increase in speed and fuel efficiency by suppressing aerodynamic drag of the fuselage

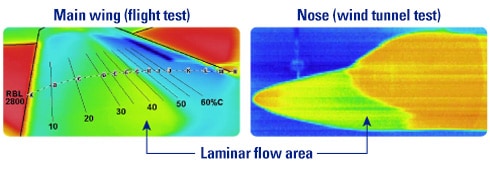

Laminar flow can be easily broken down by even the slightest irregularities on the external panels and rivets. The HondaJet design optimizes the number and positions of rivets and employs a skin (external panels) of integrally machined aluminum for the main wings to reduce surface irregularities to an absolute minimum, which enables the NLF wings and nose to be effective even during a high-speed flight.

Infrared capture of laminar flow area