Honda E-Clutch is an electronic control technology that automatically controls clutch operation without the need for the rider to operate the clutch lever*, enabling smooth starting and gear shifting. Developed on the concept of “Take You to the NEXT STAGE,” this new technology was created in pursuit of a high level of sportiness, comfort, and peace of mind. As a result, it delivers an improved riding experience for a wide range of riders who seek the fun of riding.

* Gear shift pedal operation is required to change gears.

Honda E-Clutch electronic control technology expands the fun and freedom of riding a motorcycle

Honda E-Clutch was developed to expand the fun and freedom of riding a motorcycle in a range of riding situations. It allows riders to choose themselves whether or not to operate the clutch lever on manual transmissions, thereby expanding the potential for riders while maintaining the special fun of riding motorcycles.

Honda’s range of large FUN motorcycle models employs a unique dual clutch transmission (DCT) for motorcycles. DCT is an automated gear shifting system that automatically changes gears without the rider having to operate the clutch lever. In comparison, Honda E-Clutch only automates the clutch operation, making it a manual transmission system with the rider always in control of gear shifting. In this way, the clutch and transmission mechanisms are the same as on conventional manual transmission motorcycles.

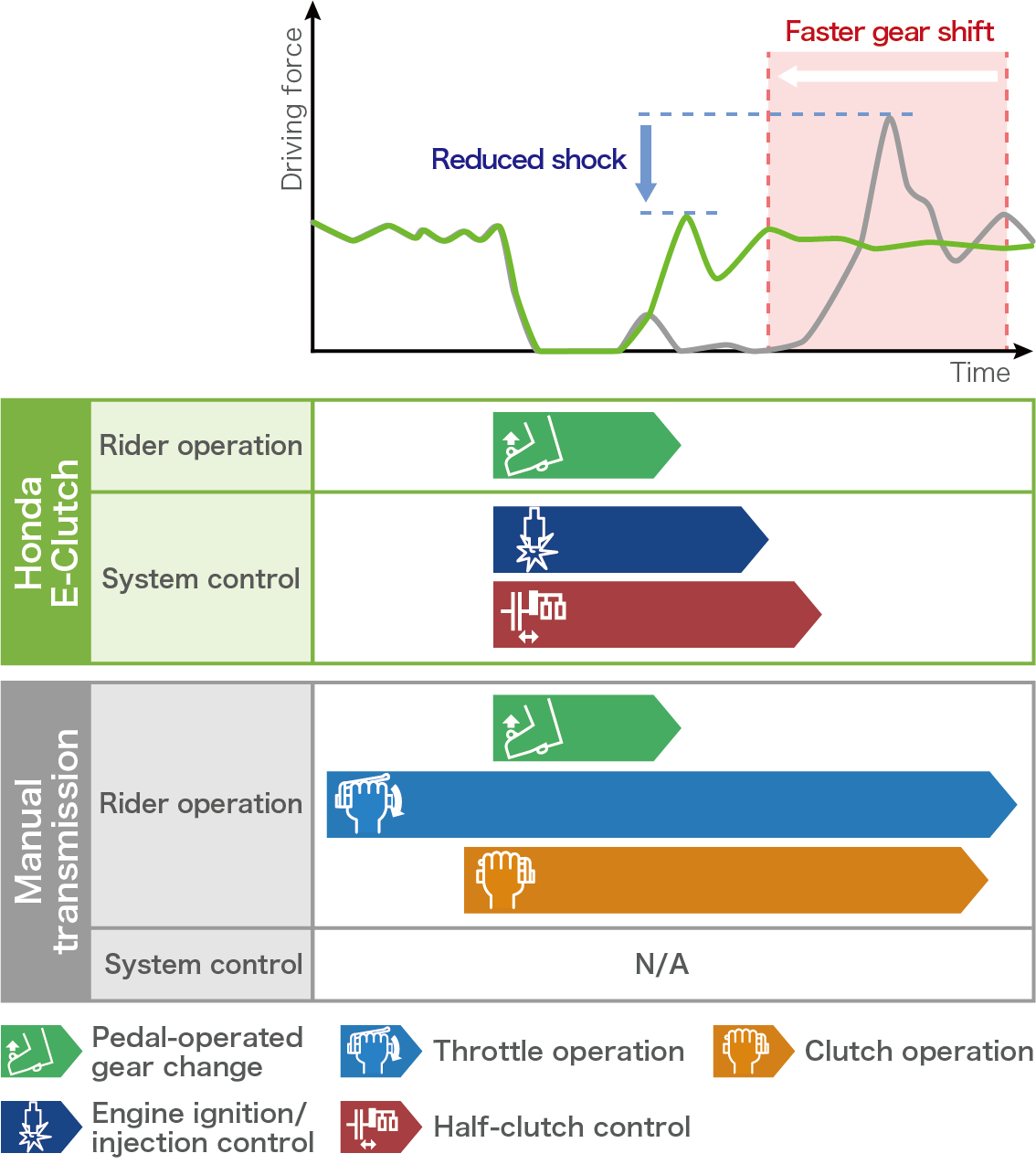

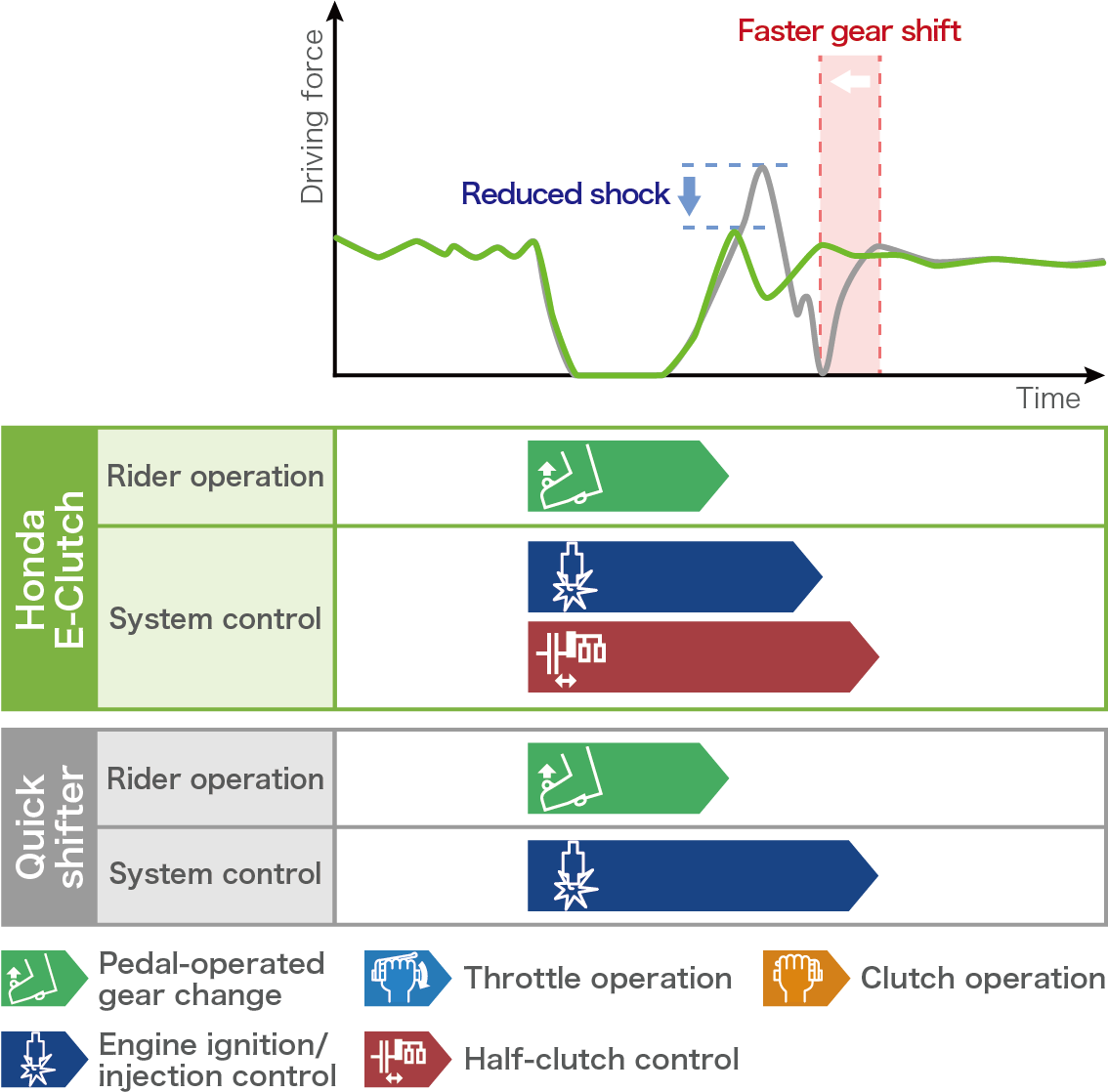

Comparison of operation by clutch type

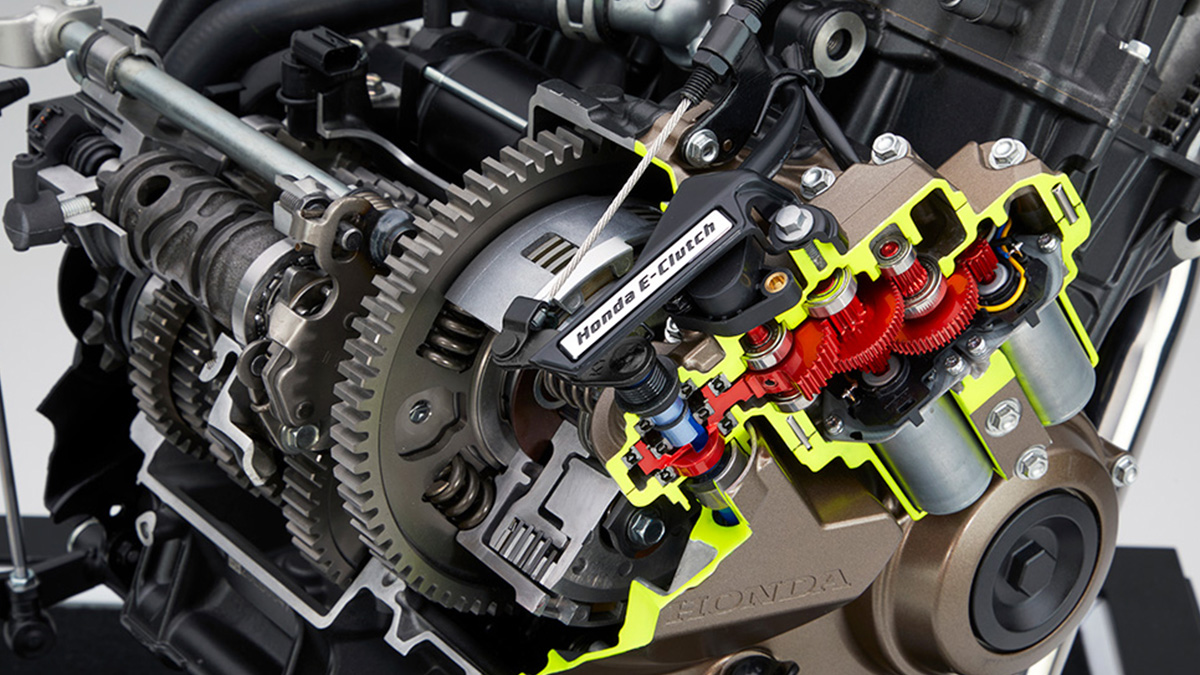

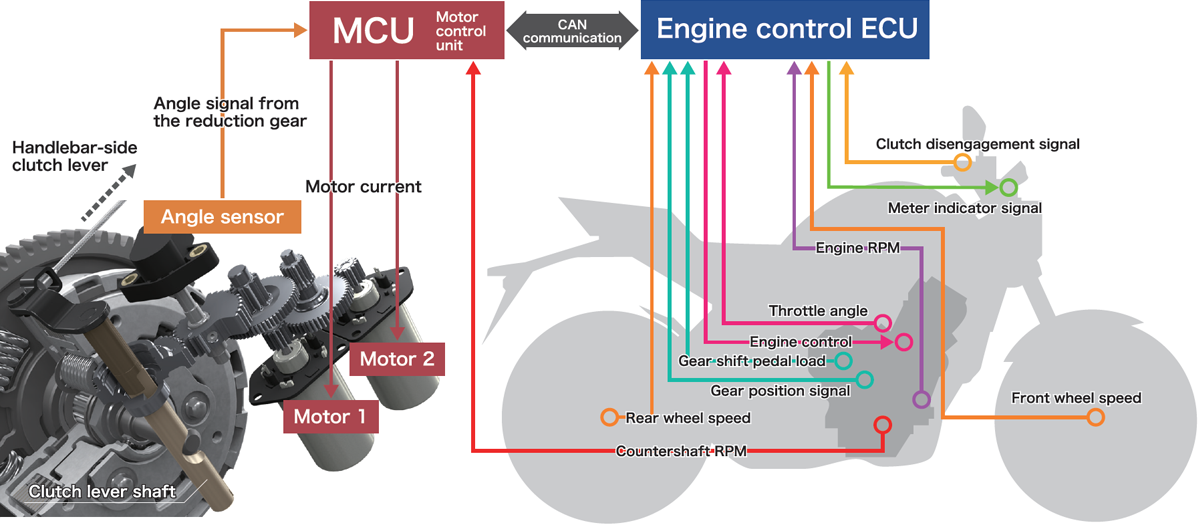

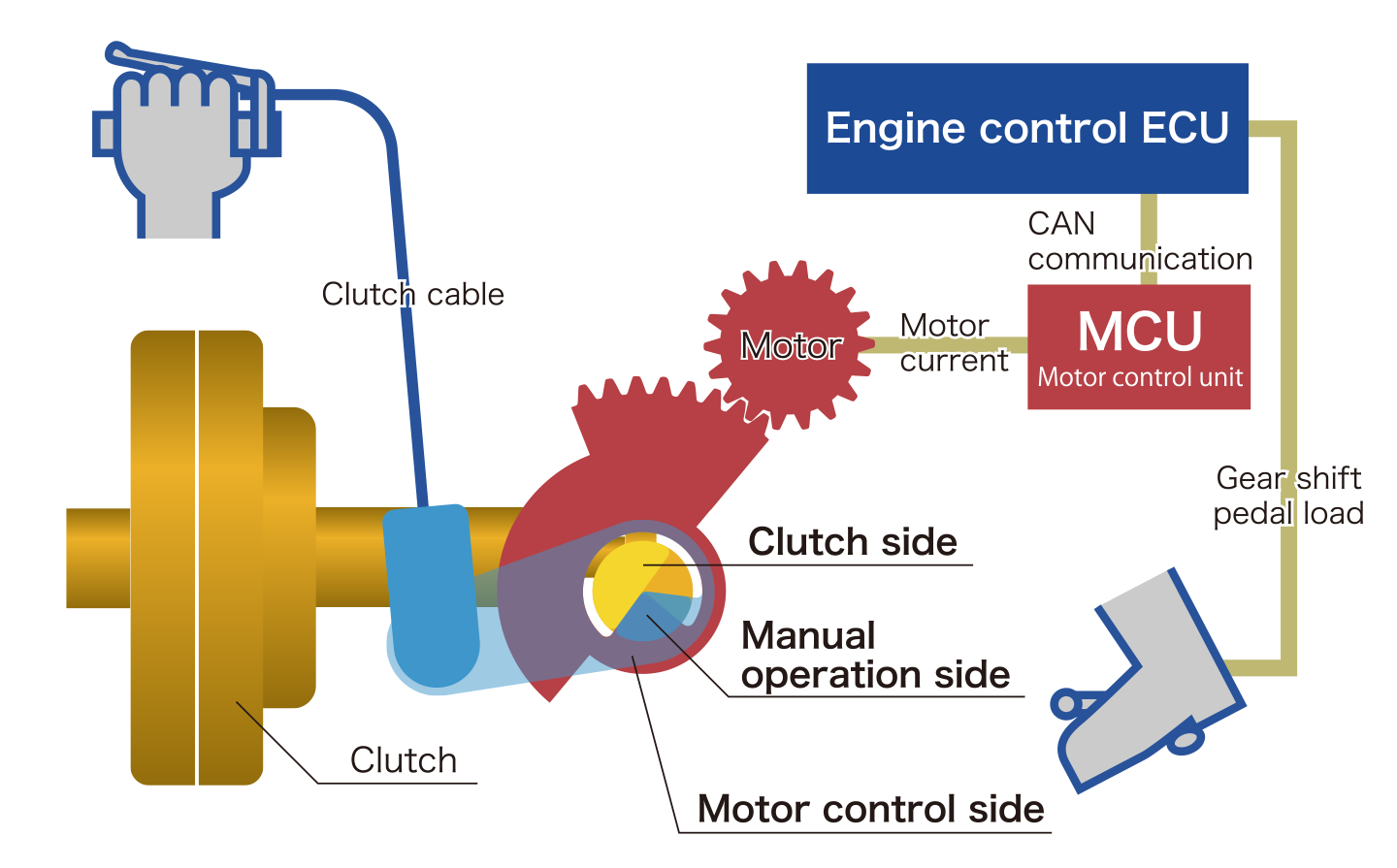

At the heart of the Honda E-Clutch system is a drive unit and motor control unit (MCU) comprising two small motors and gears, and a three-part clutch lever shaft for moving the clutch lifter piece. The system itself is made up of an engine control electronic control unit (ECU) that operates in conjunction with the MCU in response to data sent from various sensors.

System overview (illustration)

Automatic clutch control parameters use many different signals, including engine RPM (crankshaft), throttle angle, gear position, gear shift pedal load, clutch disengagement, meter indicators, and front and rear wheel speed. Referencing and cooperating with computations from the engine control ECU, the system then applies appropriate clutch control.

Clutch control is effected through MCU control based on information received from the engine control ECU. This design has led to the following technology, creating a new world of riding experiences.

(1) A light, compact system unit suited to motorcycles

(2) Faster clutch control than is possible through human operation

(3) Clutch control appropriate to the riding state (starting, gear shifting, and stopping)

(4) Ability to manually operate the clutch even during automatic control, and to switch the system on or off, according to rider preferences

The two MCU motors are small 32-millimeter diameter motors positioned side by side to deliver the required torque while keeping system size to a minimum, resulting in a compact system unit suited for use on motorcycles.

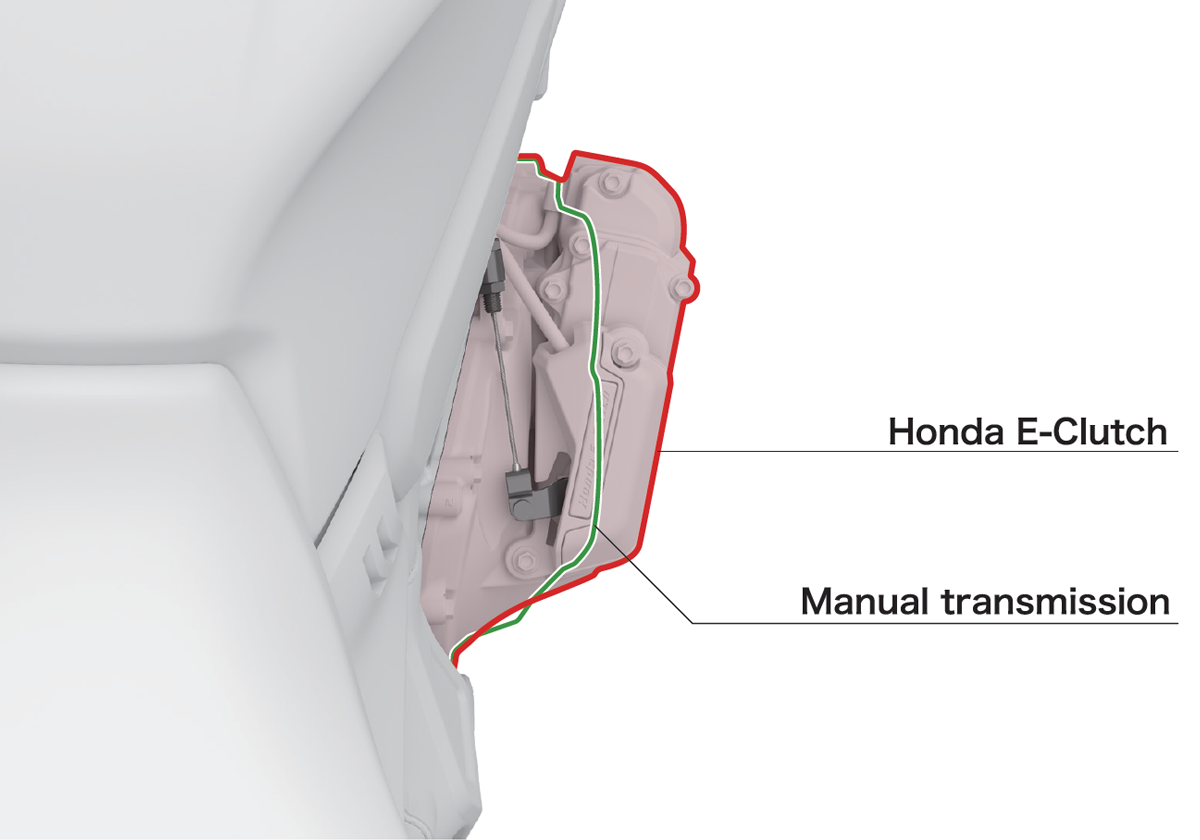

Projection from the engine side cover (comparative illustration)

Manual clutch operation and automatic clutch control, providing greater comfort and the choice to concentrate on the fun of riding

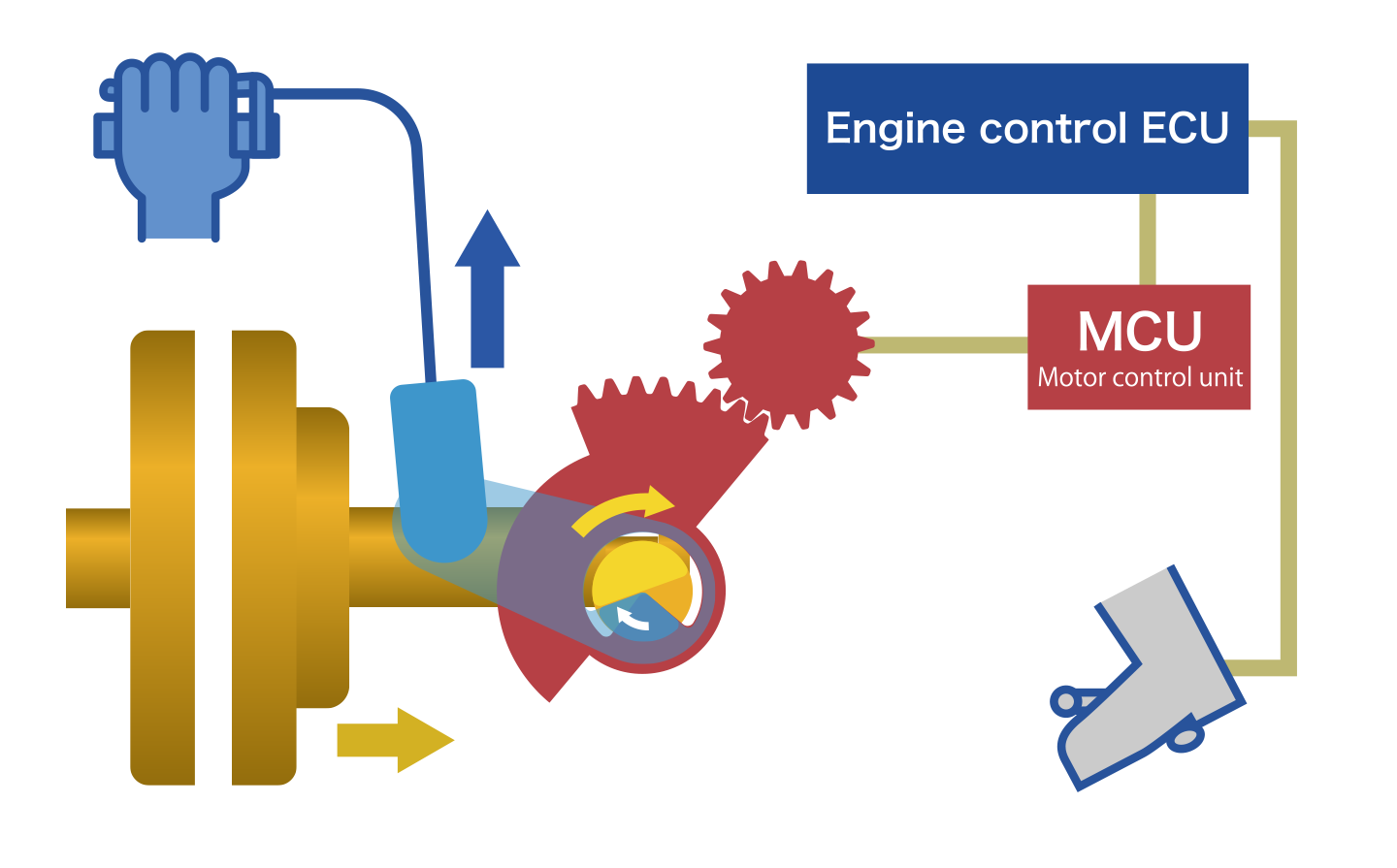

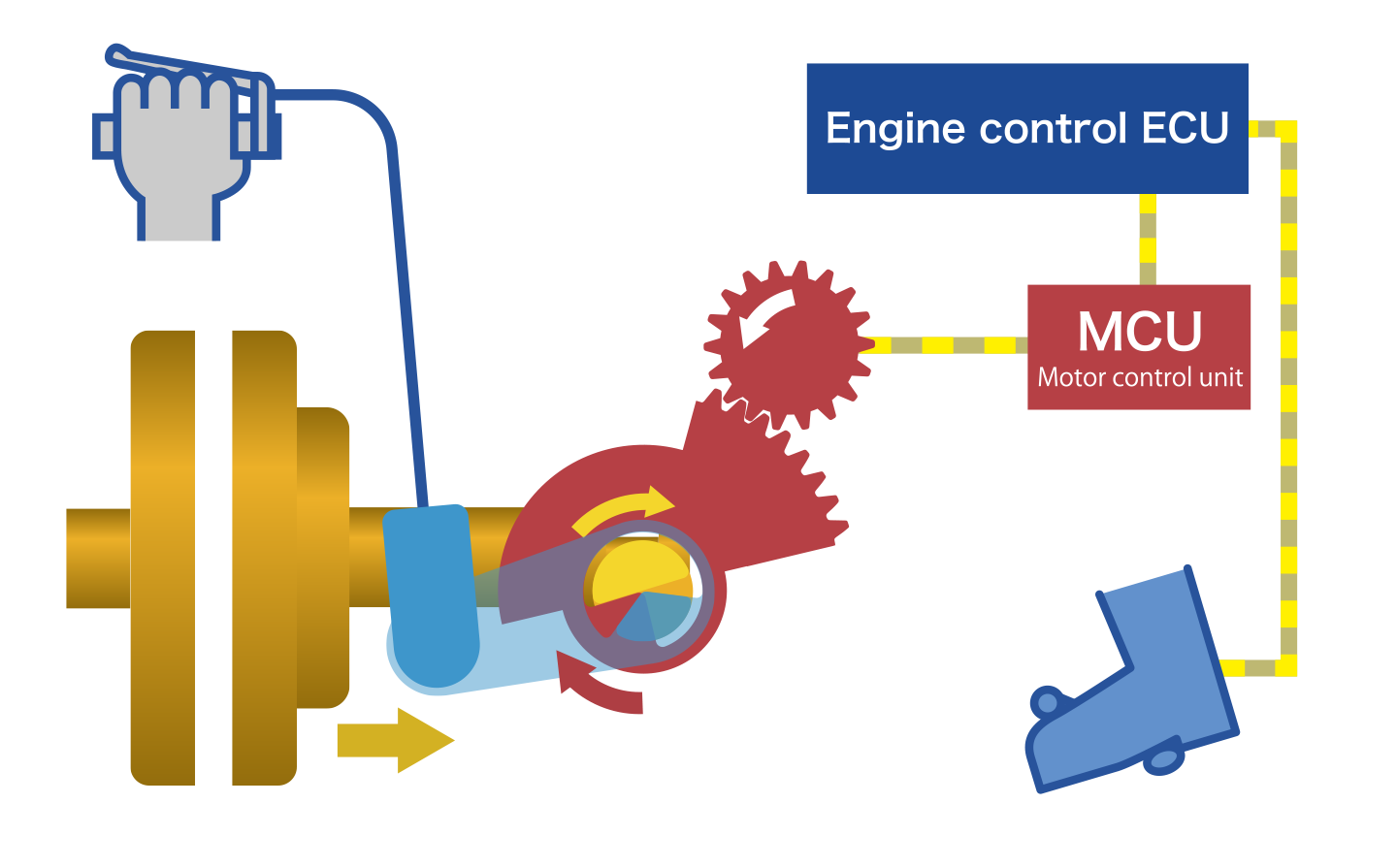

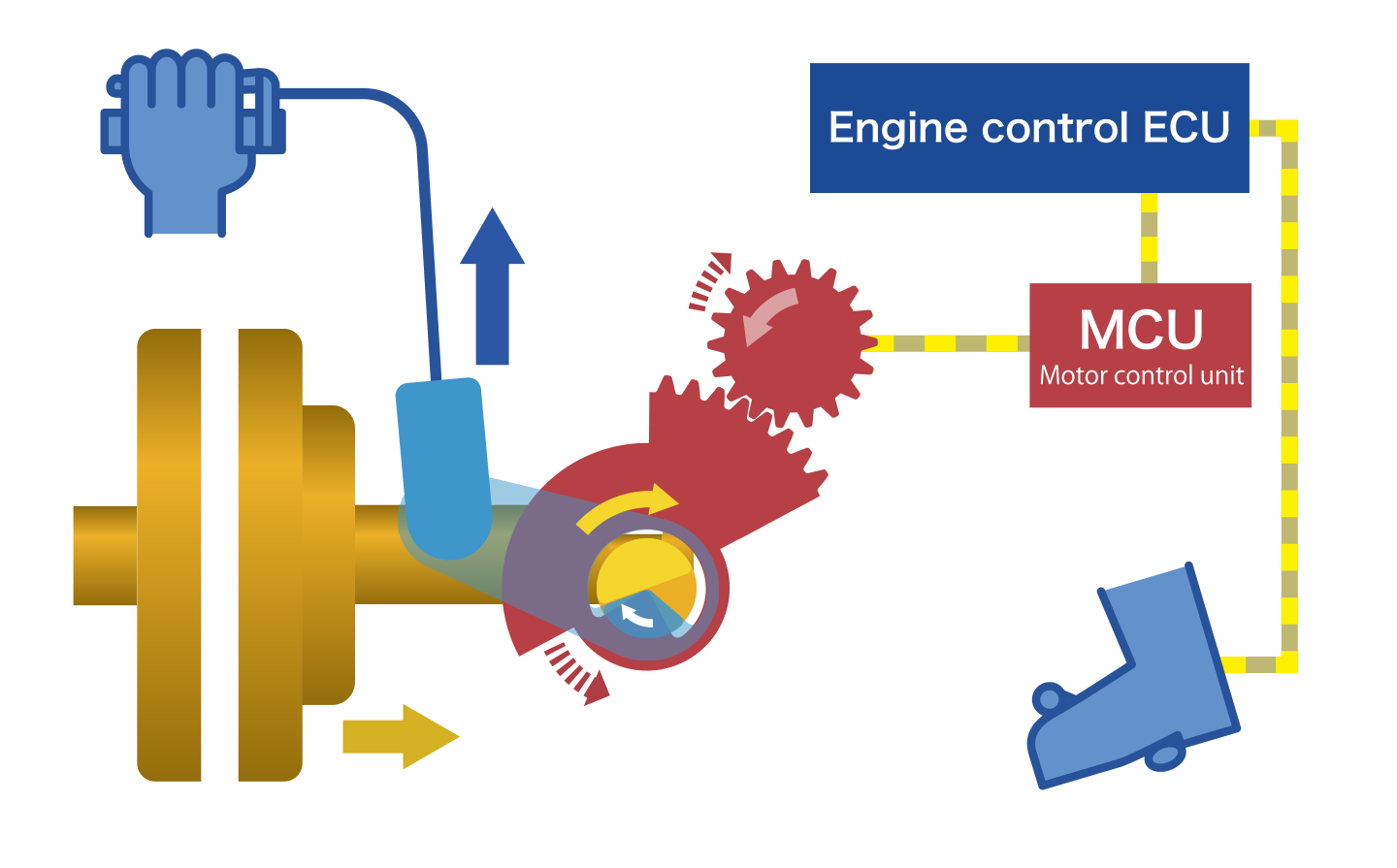

The innovative feature of Honda E-Clutch is a structure that offers independent actuation from either manual clutch operation using the handlebar-side clutch lever or automatic clutch control using the motors. The three-part clutch lever shaft is a structure of three parts; the clutch side that engages with the clutch lifter piece, and the other side that comprises a manual operation side (top) and a motor control side (bottom) situated on the same axis. Even during motor control, manual operation is possible via an override. By operating the clutch lever with the left hand, riders can disengage the clutch whenever they wish.

Clutch control overview (illustration)

When a gear shift change is detected, the motor controls the clutch.

When clutch lever operation is detected, motor control is cancelled.

This new design enables two different movements from a single shaft, which makes it possible to mount the system with a minimum number of changed or additional parts and without any major changes to the conventional manual transmission engine structure. The structure also has minimal impact on the rider’s foot space.

The system can be turned on or off. When the system is on, it automatically controls clutch operation and no clutch lever operation is required from the rider (excluding manual mode as explained below). Only throttle operation is required when starting, only gear shift pedal operation is required for gear shifting, and clutch lever operation is not required when stopping. When riding, however, hand operation of the clutch lever can move the system into manual mode temporarily, which requires the same clutch lever operation as a normal manual transmission. When the system is off, it operates like a normal manual transmission, which requires clutch lever operation in all riding states (starting, gear shifting, and stopping).

In combination with the state of the motorcycle and quick shifter control, clutch disengagement/engagement is controlled electronically to support a range of riding situations. There are a range of situations where a rider would want to avoid aggressive clutch operation that may lead to things like stalling or tipping over the motorcycle when starting or stopping, fatigue in traffic congestion, slipping when motorcycle behavior is disturbed in gear shifting, or even when touring long distances. In these situations, not having to operate the clutch lever can help to reduce rider fatigue and provide peace of mind. Entrusting clutch operation to the Honda E-Clutch system on winding roads allows the rider to concentrate on throttle, brake, and gear shifting operations, and on controlling motorcycle behavior. And in circuit racing and other sports riding scenarios, in addition to conventional quick shifter control, the system can also instantly half-clutch to provide control appropriate to the motorcycle state, which can be better than a quick shifter in reducing changes in motorcycle behavior due to gear shifting.

Time-based comparison of operations and rear wheel driving force when shifting up

When using a manual transmission, the time taken for driving force to stabilize after initial drop-off, and the shock created when re-engaging the clutch and opening the throttle, depend on the skills of the rider.

When using a quick shifter, anyone can quickly change gears through pedal operation alone, whereas with Honda E-Clutch, the addition of half-clutch control as well helps reduce changes in motorcycle behavior.

A unique and creative Honda technology that takes advantage of generations of technical knowledge in areas such as DCTs

The knowledge of years of research and development into drive system technologies, including DCTs and quick shifters, is clearly evident in Honda E-Clutch. It is the drive system control technology, based on this knowledge, that has created the riding experience that riders want.

Another factor behind this unique and creative Honda technology is the company’s history of technological pursuit in a wide range of fields. One such field is robotics technologies, as typified by the ASIMO humanoid robot that embodies the challenge of how to technically reproduce human movement in action and speed. These technologies have also been used in the Honda E-Clutch system to instantaneously provide appropriate clutch control through a simple and easy structure that delivers precise electronic control.

With Honda E-Clutch, the ability to choose whether or not to use clutch lever control delivers an even higher level of peace of mind and comfort in city riding, and the fun of riding to also allow the rider to concentrate on sports riding. Bringing great versatility to motorcycles, this simple and compact system is expected to be included in a wide and varied range of models going forward.