POINTWhat you can learn from this article

- In May 2025, Honda achieved cumulative global motorcycle production of 500 million units

- Honda has established production facilities worldwide under the philosophy of “building products close to the customer”

- Honda motorcycles’ brand strength is based on contributing to local communities and building mutual trust

Honda has been focusing on producing models tailored to each market at its Japan-domestic and overseas production sites under the philosophy of “building products close to the customer.” In May 2025, Honda’s global motorcycle production reached the cumulative milestone of 500 million units. In this milestone year, this issue of Honda Stories looks back on the history of Honda’s motorcycle production.

Rooted in every region, producing locally

Honda began full-scale motorcycle production the year after its founding in 1948. In 1949, Honda launched its first motorcycle, the Dream D-Type, marking the beginning of the company’s motorcycle production history. In 1963, Honda established its first overseas complete motorcycle manufacturing plant in Belgium, and subsequently set up production facilities in Southeast Asia, Europe, North America, South America, Africa, China, and other regions, with production rooted in the local markets. In 1997, Honda surpassed the 100 million production milestone, followed by 300 million units in 2014, and 500 million units in May 2025, continuing to deliver motorcycles to customers around the world.

Why are Honda motorcycles globally popular?

Masanori Shimazoe, General Manager of the Kumamoto Factory, which serves as the global hub supporting Honda’s motorcycle and power products production, shares his thoughts:

“Of course, it is essential to produce products tailored to local needs and preferences. However, to be chosen by the local people, it is also necessary to thoroughly understand that country and cultivate a sense of attachment to it.” (Shimazoe)

Masanori Shimazoe, Operating Executive, General Manager, Kumamoto Factory

Masanori Shimazoe, Operating Executive, General Manager, Kumamoto Factory

Shimazoe emphasizes that the philosophy of “building products close to the customer” is important not only because it reduces the lead time from production to delivery from the production country, but also because it allows the company to be accepted by the local community.

For example, Honda considers regions where motorization is just beginning as potential markets with future growth potential. In these markets, infrastructure such as roads, transportation, and legal systems are often underdeveloped, and rapidly realizing mass production or local procurement is difficult. Regions such as Africa and Bangladesh fall into this category, where Honda builds production systems while seeking optimal solutions in line with local laws and regulations. In some country’s case, half the area of chicken farms are used as factories. This is an example of building production systems by effectively leveraging knowledge of how to start production with minimal resources.

“Selling products locally made is not enough to gain trust. It is only by rooting ourselves in the local community and working together that we can gain acceptance. In Honda’s case, motorcycle business has always played a role in market development, and in potential markets, has considered it crucial to collaborate with local governments through building factories and creating jobs. Additionally, rather than simply producing and selling products, long-term investment is needed to contribute to social development and provide freedom of mobility, ultimately earning the trust of the local community.” (Shimazoe)

On the other hand, Honda considers markets such as the Philippines and India as growth markets. Motorization is progressing, and supply is not keeping up with demand, so production capacity needs to be expanded and purchasing and sales networks need to be established. In addition, as localization progresses, improving quality and services will also be an issue.

As markets mature, competition intensifies, and replacement demand becomes the main driver. In such markets, high-quality products that better suit customer preferences need to be developed, and service, and brand strength is vital. Furthermore, rapid response through local production becomes a key source of competitiveness.

Honda is implementing a strategy of leveraging profits from mature markets to make proactive investments in potential markets, balancing its global business portfolio while aiming for long-term growth.

From Kumamoto to the world: A global hub factory that dispatches staff and transfers technology to factories everywhere

Kumamoto Factory acts as global hub for Honda’s motorcycle and power products production

Kumamoto Factory acts as global hub for Honda’s motorcycle and power products production

Kumamoto Factory, Honda’s global hub supporting motorcycle and power products production, has produced a cumulative total of 20.6 million motorcycles since it began operations in 1976. Kumamoto provides support tailored to the diverse challenges faced by Honda plants around the world, including new factory construction, technology introduction, human resource development, new model development, structural reforms, and local procurement. In recent years, Kumamoto has also been focusing on the development and dispatch of specialized staff in the fields of the environment and electrification.

In terms of human resource development, Kumamoto not only dispatches Japanese engineers overseas but has also been inviting management-level associates from over 20 production sites worldwide to Japan for training since 2018. Additionally, it hosts global production managers’ meetings where overseas executives report on country-specific challenges and engage in discussions.

On the other hand, approximately 200 technical support staff are dispatched from Japan annually. They provide support in both technical and human resources aspects for tasks such as technology introduction and establishing new plants.

How can these plants align with Honda’s global standards while adapting to local environments and needs? Establishing a production plant requires constant ingenuity and innovation. Honda’s basic approach is to start small and grow big where there is demand. Honda begins with small-scale, handmade production and gradually considers automation of conveyor systems as production volumes increase, growing the operation incrementally. If the market grows rapidly, Honda takes proactive initiative; if not, it waits and observes until the timing is right. This ability to adapt in a flexible manner is a key strength of Honda’s motorcycle business.

Building Honda factories around the world together with local associates

Honda’s motorcycle business often involves establishing production plants in locations where parts procurement, sales networks, and production facilities are not yet fully developed. Additionally, teaching motorcycle production methods to associates*¹ with no prior manufacturing experience is no easy task. Despite these challenges, in recent years Honda has achieved local production in numerous locations and expanded its global market share. This success has been driven by expatriates and local associates who have dedicated themselves to the pillars of localization (people, materials, money, and management) as their mission, as well as the ongoing support from Japan. Honda Stories spoke with local expatriates to learn about the realities of local production.

*1 Honda refers to every employee working at Honda facilities around the world as an associate.

About the factory

- Annual production capacity: 35,000 units (as of end of March 2025)

- Location: Africa / Nairobi, Republic of Kenya

- Start of operations: March 2013

――The Interview:

Tetsuya Miyamoto, Power Unit Manufacturing Technology Manager, Production Planning Division, Motorcycle and Power Products Operations. Stationed in Kenya from 2022 to 2025.

Tetsuya Miyamoto, Power Unit Manufacturing Technology Manager, Production Planning Division, Motorcycle and Power Products Operations. Stationed in Kenya from 2022 to 2025.

――Why did Honda establish a production facility in Kenya?

“We implemented Honda’s philosophy of ‘building products close to the customer.’ By local people manufacturing Honda products, we believe we can become a company deeply rooted in the local community.” (Miyamoto)

In Kenya, the government's policy of promoting local production and procurement significantly supported the establishment of local production facilities.

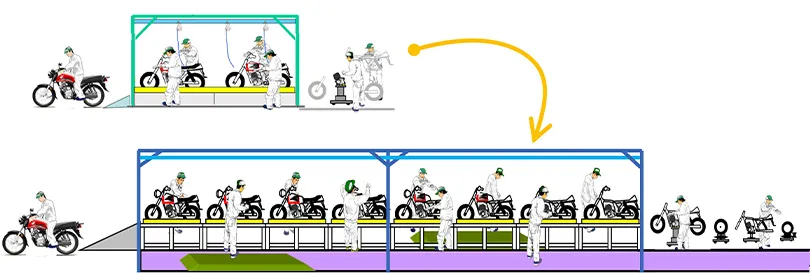

As the first step, Honda adopted the concept of “starting small and growing big”, leading to the creation of the minimal production line “Simple, Anywhere, Pack (KDP: abbreviation of Kantan-Dokodemo-Pack in Japanese).” KDP was first introduced at Honda Motorcycle Kenya (Kenya Plant). The Kenya Plant, following Nigeria, became the second production plant in Africa and began operations in 2013.

――What is KDP?

KDP was designed to enable swift local production in potential markets with minimal resources. It is a simplified assembly method that allows production even in limited infrastructure environments, using only the minimum tools required for assembly and the necessary documentation for quality checks. In Kenya, production began by installing a manual conveyor line (instead of an electric conveyor) in a rented warehouse, effectively realizing the KDP concept. By manually pushing motorcycles through each assembly stage, the process can be completed by just three to four people. Additionally, by extending the manual conveyor line as sales expand, the plant can be scaled up to produce 200 units per day.

KDP was developed as a method for exploring potential markets by minimal factory setup. Its key feature is the use of a manually operated line instead of electric conveyors, enabling simple production

KDP was developed as a method for exploring potential markets by minimal factory setup. Its key feature is the use of a manually operated line instead of electric conveyors, enabling simple production

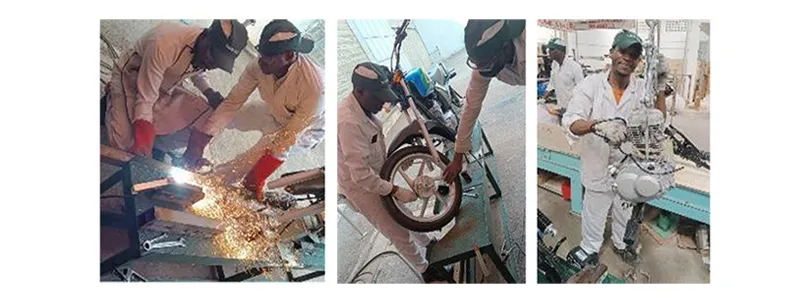

The Kenya plant has a DIY spirit, with painting and welding processes done by hand. It embodies the “if you want it, make it” philosophy

The Kenya plant has a DIY spirit, with painting and welding processes done by hand. It embodies the “if you want it, make it” philosophy

――Challenges during factory setup

“KDP means minimal investment as well. For example, we purchased only a welding machine and used scrap materials from parts packaging to create workbenches and shelves we made ourselves. By pooling our knowledge and creativity and working together with local associates, we naturally developed a sense of unity. We believe that these efforts will help us become a company deeply rooted in the local community.” (Miyamoto)

Production line at Kenya Plant

Production line at Kenya Plant

――Memories of Kenya

“The local associates in Kenya are all highly motivated to learn, and eager to absorb new knowledge, making it easy to work with them. On the other hand, unforeseen challenges arose daily, such as customs officials taking extended leave, causing import delays: situations unthinkable in developed countries. Despite these challenges, we worked together as a team, turning hardship into opportunity and overcame obstacles.” (Miyamoto)

A relaxed atmosphere at a new model launch celebration party

A relaxed atmosphere at a new model launch celebration party

About the factory

- Annual production capacity: 1.4 million units (as of end of March 2025)

- Location: South America / Amazonas, Manaus City, Federal Republic of Brazil

- Start of operations: 1976

Aerial view of Manaus Plant (within yellow lines)

Aerial view of Manaus Plant (within yellow lines)

――The Interview:

Katsuaki Iwamoto, Manager, Regional Planning Department, Production Planning Division, Motorcycle and Power Products Operations. Stationed in Brazil from 2016 to 2021.

Katsuaki Iwamoto, Manager, Regional Planning Department, Production Planning Division, Motorcycle and Power Products Operations. Stationed in Brazil from 2016 to 2021.

――What is Manaus like?

“At night, when you fly in, even as the plane begins to descend, the ground remains pitch black and you cannot see anything. Just as you start to worry where the airport is, a sudden flash of light appears right before landing. It is truly an isolated island surrounded by jungle.” (Iwamoto)

Manaus was once a thriving city thanks to natural rubber, but its economy declined as production shifted to Southeast Asia. To revive the economy, a Manaus Free Zone tax incentive program was introduced. In 1976, Honda began establishing a local production plant in line with this trend. Moto Honda da Amazonia (Manaus Plant) developed into a core plant in South America and, with government support, advanced localization and in-house production of parts. As a result, “we can now manufacture parts equivalent to those previously imported from five suppliers at the Manaus plant.” (Iwamoto)

The Manaus Plant is equipped with a state-of-the-art water purification facility and is environmentally conscious. This photo illustrates the process of mixing chemicals into wastewater in a tank to remove pollutants.

The Manaus Plant is equipped with a state-of-the-art water purification facility and is environmentally conscious. This photo illustrates the process of mixing chemicals into wastewater in a tank to remove pollutants.

Treated water flows through fish ponds and returns to nature.

Treated water flows through fish ponds and returns to nature.

For details of the Manaus Plant’s SDG initiatives, see here

――Challenges during factory setup

There were simply no parts suppliers in Manaus. Honda approached Japanese manufacturers to establish bases in Manaus, and supported local companies to grow, eventually developing the operation to its current scale.

――Honda rooted in Brazil

Since the plant was established in 1976, until the introduction of the local currency (Brazilian Real) in 1994, Brazil was plagued by hyperinflation.

“While motorcycle sales were stagnating, competitors were withdrawing from Brazil. But Honda did not leave. We wanted to do everything possible to preserve the jobs of our local associates.” (Iwamoto)

With the introduction of the Real and the stabilization of the exchange rate, living conditions improved, and demand for motorcycles surged. By the time competitors rushed to re-enter the market, Honda had successfully secured the top market share.

“We are grateful to the senior staff who worked hard during that time, as it is thanks to them that we have our current plant.” (Iwamoto)

――Memories of Brazil

“I was stationed in Brazil during the tough times following the 2008 global financial crisis. We went through a difficult period with repeated revisions to production plans and personnel adjustments. To return the plant to profitability, we worked closely with local associates to analyze Honda’s production methods, efficiency, and quality control techniques at other production sites, and applied the insights to improve and optimize our own plant. This allowed us to reorganize the factory into a more efficient operation with minimal investment. As a result, the plant returned to profitability, and production volume, which had dropped to 650,000 units at its lowest point, has now recovered to 1.4 million units.” (Iwamoto)

In this challenging environment, Iwamoto was supported by local associates and the people of Manaus.

“When I suddenly had a high fever for reasons unknown, the associates tried to station a nurse stay at my home as I was ‘invaluable’ to them, and on my birthday, they surprised me with a party. Thanks to the warm and family-like support of the Brazilian people, I was able to endure my solo assignment.” (Iwamoto)

About the factory

- Annual production capacity: 35 thousand units (as of end of March 2025)

- Location: South America / Iquitos City, Loreto Region, Republic of Peru

- Start of operations: October 2007

――The Interview:

Teruyoshi Yoshida, New Model QCD Coordinator, Vehicle Assembly Plant, Kumamoto Factory Motorcycle and Power Products Operations. Stationed in Peru from 2019 to 2024.

Teruyoshi Yoshida, New Model QCD Coordinator, Vehicle Assembly Plant, Kumamoto Factory Motorcycle and Power Products Operations. Stationed in Peru from 2019 to 2024.

――Why establish a production plant in Peru?

Since 1961, Honda’s motorcycles have been imported to Peru as CBUs (Completely Built-Up: complete vehicles) and sold by local distributors. In 1974, Honda established Honda del Peru (HDP), a 100% subsidiary, and began importing and selling motorcycles. Starting around 2005, there was growing interest in establishing a motorcycle production facility in Peru, a member of the Andean Community*² with strong motorcycle demand. The Peru plant project was launched, and with support from the Manaus plant in Brazil, the Honda Selva del Peru Production Plant (Peru Plant) began operations in 2007. Even after operations began, efforts continued to focus on training technicians with support from the Manaus plant.

*2 An economic community comprising Bolivia, Colombia, Ecuador, and Peru. In the Andean countries, motorcycles are a crucial mode of transportation, and tariffs on motorcycles and motorcycle parts between member countries are either exempt or subject to preferential treatment.

――What is Iquitos like?

As Iquitos, an isolated city surrounded by jungle, has no land connections to other cities, many of its people spend their entire lives without visiting another city. Within the city, there are no buses or trains, and the main mode of transportation is shared buses (vehicles modified from used trucks). Shared buses pick up people from the roadside who raise their hand, but there are no designated stops, and travel times are long. Motorcycles play a vital role as a means of transportation for people who want to shorten travel times or “buy time with money.”

――Challenges during factory setup

At the time, the only way to transport CKD parts (Complete Knock Down: a method of exporting products as parts and assembling them in the destination country) to Iquitos, an isolated landlocked city, was by air or via the Amazon River. There were no cargo planes, so CKD parts were transported in the cargo hold of passenger planes. However, this method was expensive, and if there was no available cargo space, parts could not be transported at all, making production highly unpredictable.

Starting in the 2000s, waterway transportation began to be utilized on a large scale. First, 40-foot containers are unloaded in Lima, then transported by land to a port on the Amazon River. From there, the parts are packed into steel cases loaded onto the deck of a passenger ship, unloaded at Iquitos Port, and transported by truck to the factory. However, the transportation environment in the Amazon was harsh. The jungle was humid, and pirates roamed the rivers. In addition to quality issues, security risks were high, necessitating rigorous packaging with thick plywood to prevent rust and theft. Furthermore, during the dry season, water levels dropped, causing the shoreline to shift significantly. As a result, there were instances where steel cases weighing 200–300 kg had to be carried by four to five people over distances of 10-20 meters.

――Honda rooted in Peru / Memories from Peru

“South America is a world of ‘amigos’ (friends). We relied on the local management’s network and connections with Japanese expatriates deeply rooted in the community to introduce us to local business leaders, while exploring ways to improve operational efficiency,“ (Yoshida)

There were no science and engineering faculties in Iquitos’ universities, so technical staff were primarily recruited from the capital, Lima. However, many urban-born associates struggled to adapt to life in the jungle, and returned to Lima after a few years.

Despite this, Honda provided an environment where associates could learn while working, which Yoshida describes as “akin to a ‘Honda University.’” While some associates have left to work for other local companies after gaining business experience, Honda has prioritized development of associates nonetheless, as in the long run they ultimately contribute to Peru. Although retaining technical staff has been challenging, Honda has placed a strong emphasis on social contribution through human resource development.

About the factory

- Annual production capacity (Taicang Plant): 1.1 million units (as of end of March 2025)

- Location: China / Jiangsu Province, Taicang City

- Start of operations: August 2018

――The Interview:

Takayuki Nakanose (left), General Manager, Production Planning Division, Development and Production Unit, Motorcycle and Power Products Operations. Stationed in China from 2014 to 2023.

Takayuki Nakanose (left), General Manager, Production Planning Division, Development and Production Unit, Motorcycle and Power Products Operations. Stationed in China from 2014 to 2023.

――How was Sundiro Honda Motorcycle Co., Ltd. established?

Since the 1980s, Honda has been producing motorcycles in China through three joint ventures*³, beginning with a technical partnership with Jialing Machinery Factory (now Jialing Industry). The motorcycles produced were highly regarded for their advanced technology and high quality, particularly in the mid-to-high-end segment. To better meet the growing needs of customers, Honda decided to fully enter the Chinese motorcycle market. As a result, the motorcycle division of Hainan Sundiro Motorcycle Co., Ltd. (formerly a state-owned enterprise in China) was merged with Tianjin Honda Motorcycle Co., Ltd., a Honda subsidiary with advanced engine technology, leading to the establishment of Sundiro Honda Motorcycle Co., Ltd. (Sundiro Honda) in 2001.

*3 In China, foreign companies were not permitted to establish motorcycle production companies solely with foreign capital, and a joint venture with a local manufacturer was required, with the equity ratio limited to 50% or less.

Honda e-cai 125cc scooter satisfied local needs

Honda e-cai 125cc scooter satisfied local needs

――Challenges during factory setup

“At the time, Sundiro was producing and selling products that closely imitated Honda motorcycles. Starting around 2010, they began producing motorcycles nearly identical to Honda’s and selling them under the Sundiro name, which caused Honda significant headaches.” (Nakanose)

At the time, the Chinese motorcycle market was estimated to be around 25 million units, and Honda’s strategy was to establish a joint venture with this company to produce and sell genuine Honda motorcycles and capture the market. Under the condition that the production and sale of the previously manufactured imitation products would be halted and involvement in core components such as engines, frames, and bodies would be restricted, establishment of the new company was finalized. For Sundiro, partnering with Honda, the world’s largest motorcycle manufacturer, undoubtedly presented significant potential.

――Memories of China

“I'll never forget the COVID-19 pandemic.” (Nakanose)

Nakanose was assigned to Shanghai in 2014 to oversee the construction of a new factory for Sundiro Honda, whose existing facility was aging. He later served as vice president. During the COVID-19 outbreak in 2020, China implemented a zero-COVID policy, leading to city-wide lockdowns and mandatory stay-at-home orders. As the number of infections increased, lockdown areas expanded, and Shanghai also entered lockdown.

“Even in such circumstances, since Sundiro Honda was responsible for overseas production, we held daily operational (production planning) meetings to decide how to secure parts, which production lines to halt, and how to operate the plant.” (Nakanose)

Nakanose negotiated with the Chinese government and local authorities to secure special permits, stayed overnight at the plant, and overcame the unprecedented pandemic through various hardships.

Operational meeting during the pandemic. Every day was filled with tension as Sundiro Honda scrambled to respond to the rapidly changing production situation.

Operational meeting during the pandemic. Every day was filled with tension as Sundiro Honda scrambled to respond to the rapidly changing production situation.

Honda's motorcycle business has grown alongside the efforts and hardships of such expatriates and local associates. Regarding the current state of the business, Shimazoe, the General Manager of Kumamoto Factory says:

“The world is changing by the minute. In markets where Honda does not have a share, foreign manufacturers such as China and India are emerging, and it will become increasingly important to focus on the sites, circumstances, and products, rather than relying solely on data. To advance the localization of ‘people, products, capital, and management’, we must establish a co-leadership system where local associates and Japanese employees collaborate, leveraging diversity to compete effectively.” (Shimazoe)

Honda’s strength in the motorcycle business lies in its consistent efforts to build the reasons why it is chosen worldwide. Additionally, contributions to local communities and the trust that has been built are the foundation of Honda’s motorcycle brand strength.

500 million units is merely a milestone. Honda will continue production where there is demand, and provide products that meet the needs of customers worldwide.