POINTWhat you can learn from this article

- Through its modal shift initiative, Honda is working to reduce the environmental impact of freight transportation.

- By shifting EV battery pack transportation to rail, Honda has successfully reduced CO2 emissions by 74.5%

- While rail transport offers significant potential benefits, challenges remain, such as the lack of flexibility in transport schedules.

One of Honda’s key initiatives toward achieving carbon neutrality by 2050 is modal shift, which refers to the transition of freight transport from truck to more environmentally friendly rail and ship-based transportation. Honda has successfully reduced CO2 emissions by 74.5% through its modal shift project. This issue of Honda Stories speaks with the team members who worked on this verification test.

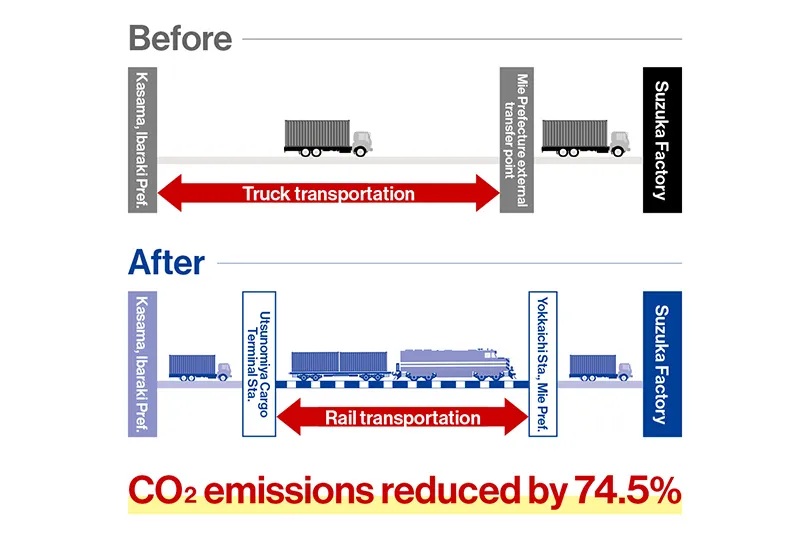

Achieving 74.5% Reduction in CO2 Emissions Through Rail Transportation

As part of its efforts to reduce environmental impact, Honda conducted a verification test to switch transportation of some parts for the N-VAN e:, which was launched in October 2024, from truck to rail.

The N-VAN e: is Honda’s first electric vehicle (EV) in the Kei-car (light car) category. One of the challenges that arose with the start of production was the transportation of parts. EVs have more electrical components than gasoline-powered vehicles, such as batteries and motors. Among these, battery packs are particularly large, heavy, and subject to strict safety regulations during transportation. Additionally, this was the first transaction between Honda and AESC Japan Co., Ltd. (Kanagawa Prefecture, Yokohama City), the supplier of battery packs for the N-VAN e:. At the time, there was no established logistics network to deliver parts from AESC to Honda, requiring the building of a logistics infrastructure from scratch.

TIPS Benefits of modal shift

- The current focus on modal shift stems from the fact that transportation by rail or ship emits less CO2 than truck transportation, thus reducing environmental impact. Additionally, modal shift enables large-scale transportation with fewer staff, which is expected to address Japan’s 2024 driver shortage issue and reduce logistics costs associated with large-scale transportation.

Regarding Honda’s decision to shift to rail transportation, Kengo Hayashi, who was part of the Supply Chain Operation Division’s Suzuka Parts Department (at the time) and led the project, reflects on the process:

Kengo Hayashi of the Supply Chain Operation Division’s Suzuka Parts Department (at the time), who proposed the modal shift for battery packs and led the project.

Kengo Hayashi of the Supply Chain Operation Division’s Suzuka Parts Department (at the time), who proposed the modal shift for battery packs and led the project.

The distance between AESC’s battery factory in Ibaraki Prefecture and Honda’s Suzuka Factory in Mie Prefecture, where vehicle assembly takes place, exceeds 500 kilometers. Over this distance, rail transport offers advantages over truck transport in terms of environmental impact and cost. Despite facing various challenges such as fire safety regulations, quality control tests, and establishing the necessary infrastructure to accommodate rail-specific containers, we confirmed the practical feasibility and obtained approval from relevant authorities, successfully establishing the rail transport system.

As a result, we achieved a 74.5% reduction in CO2 emissions compared to truck transportation.

BEFORE: Truck transportation

AFTER: Rail transportation

By switching part of EV component transportation from truck to rail, CO2 emissions were successfully reduced by 74.5%.

By switching part of EV component transportation from truck to rail, CO2 emissions were successfully reduced by 74.5%.

Environmentally Friendly Vehicles Should Be Environmentally Friendly from the Manufacturing Stage

Project members who contributed to the rail transportation project and the N-VAN e:

Project members who contributed to the rail transportation project and the N-VAN e:

With such significant benefits in terms of reducing environmental impact and cutting costs, modal shift for everything seems logical, but there are various constraints and challenges. In fact, switching the transportation of the N-VAN e:’s battery packs to rail took two and a half years of effort.

Unloading container from train to truck

Unloading container from train to truck

While rail transport offers advantages such as the ability to transport large volumes in a single trip, with cargo classified as hazardous materials, restrictions apply on inventory levels at intermediate storage facilities between the station and truck transport, as well as storage capacity within manufacturing facilities, limiting the full potential of rail transport.

Since hybrid vehicle batteries had been classified as hazardous material, there was concern that the battery pack in question might also fall under this category. However, by visiting the Suzuka Fire Department multiple times with AESC to explain the internal structure, the team obtained the battery pack’s categorization as a non-hazardous material as it is not a flammable solid, and therefore does not qualify as a hazardous material.

Furthermore, ensuring quality is vital. The team conducted multiple test runs over the transportation route and thoroughly verified that critical factors such as impact, vibration, and temperature did not exceed the specified standards, confirming there was no impact on quality. JR Freight and Yokkaichi Station staff actively cooperated in this verification process.

We conducted repeated verification tests with team members at Yokkaichi Station under the scorching summer sun. Without access to this location, the quality impact test would not have been possible. We are deeply grateful to everyone involved.

Quality Control department naturally raised concerns, as the team’s mission was to deliver products without issues to the customers. Ultimately, this led to a large-scale verification test involving the R&D and Quality Control departments, logistics company, and suppliers. However, thanks to the assistance of many people and the efforts of the project members, all quality requirements were successfully met.

Quality impact test conducted with full cooperation from Nippon Express and JR Freight

Quality impact test conducted with full cooperation from Nippon Express and JR Freight

Finally at the Starting Point: the Challenge to Achieve Stable Operations Begins

After overcoming the various hurdles and through trial and error, the project team successfully established a method for transporting battery packs by rail. However, since rail transportation has fixed schedules, at the moment it is difficult to respond in a flexible manner to issues that may arise with parts scheduled for transport. There are still challenges in operations, and further efforts are underway to achieve stable continuous operations.

After spending two and a half years to reach the starting point, Hayashi, who led the project, reflects on the journey:

Bringing about change is truly difficult. We constantly considered what requirements must be met and what needed to be changed. I believe that it was because of the challenges of logistics and Honda’s serious commitment to reducing CO2 emissions as a company that we were able to continue promoting rail transportation.

Hayashi emphasizes that rail transportation is not something that can be done alone. This initiative has become a large-scale project involving members of the Suzuka Parts Logistics, R&D and Quality Control departments, suppliers, logistics companies, JR Freight, and even the Suzuka Fire Department. With the hope that this effort will serve as a reference not only for Honda but also for everyone, a new challenge toward the stable operation and expansion of modal shift is about to begin.

The mission of our department, was to promote efficiency in parts transportation. At the time, we often discussed how we could not afford to be indifferent to CO2 reduction in the EV manufacturing process, which is an environmentally conscious product. The transportation costs for battery packs by truck were enormous, and naturally, the environmental impact was significant. Since this was our first transaction with AESC, we had to start from scratch in building the logistics network. We proposed to AESC the idea of using rail for parts transportation, and this marked the beginning of collaborative efforts toward rail transportation.