Management

Philosophy of “Respect for the Individual” Takes Root in Honda’s Ghana Plant: The Challenges of a Local Manager Supporting West-African Business

In December 2024, Honda’s automobile production plant in Ghana, West Africa, completed its first year of operation. The Ghana Plant began production with the HR-V compact SUV for the West Africa region, which Honda positions as a growth market. This issue of Honda Stories introduces the journey to date, and the local associates’*1 daily challenges and achievements.

*1 Honda calls its employees around the world “associates.”

“SKD production” adopted at Honda’s Ghana plant

Aerial shot of Accra, capital city of Ghana

Aerial shot of Accra, capital city of Ghana

Honda positions West Africa as a growth market, and is developing its automobile business in four key countries: Nigeria, Ghana, Benin, and Cote d'Ivoire.

In 2022, Honda Manufacturing Ghana Ltd. (Ghana Plant), was established as Honda’s second automobile production plant in West Africa, following Nigeria. The Ghana Plant, which began production in December 2023, is an automobile plant with an annual production capacity of around 500 units.

Ghana's population is approximately 34 million*2 as of 2023. With more than 60% of the population in their 20s or younger and a per capita GDP that is among the highest in West Africa, the number of car buyers is expected to increase in the future.

Ghana is also a member of the Economic Community of West African States (ECOWAS) and the African Continental Free Trade Area (AfCFTA). Honda aims to grow its business in West Africa by providing as many customers as possible with the “joy, fun and freedom of mobility and the joy of making changes that make their lives more enjoyable” through production in Ghana, a major country in this economic zone and an ongoing growth market.

*2 Source: “Basic Data of the Republic of Ghana" from the Ministry of Foreign Affairs of Japan website (Japanese language)

https://www.mofa.go.jp/mofaj/area/ghana/data.html

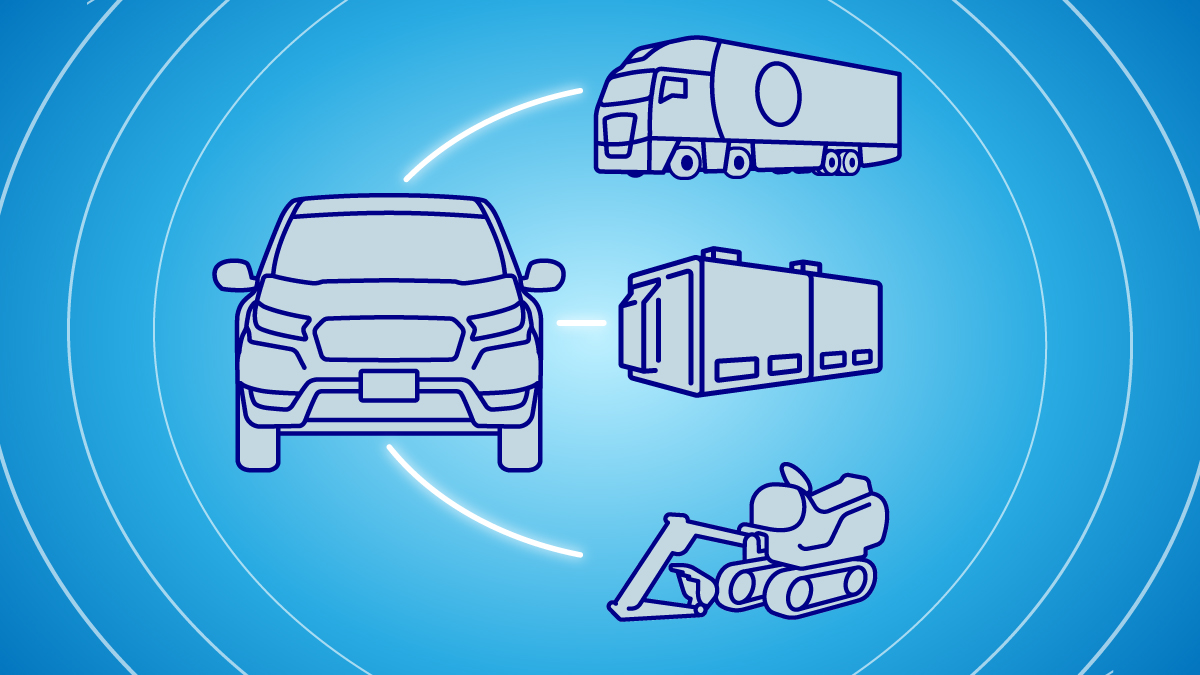

A main feature of the Ghana plant is its Semi Knock Down (SKD) production system, in which major automobile parts are imported in partially assembled form and final assembly is performed locally. Compared to CKD (Complete Knock Down) plants, which require large-scale production facilities, SKD plants can produce cars with smaller facilities and systems.

TIPSThe differences between CBU, CKD and SKD

- CBU (Completely Built-Up): Completed vehicles produced at the originating country are imported as-is: Vehicles are transported to the country of sale after being fully assembled at the factory.

- CKD (Complete Knock Down): Complete vehicles are exported in a “disassembled” state and are then re-assembled at the local factory: Vehicles are disassembled into components such as the engine, body, chassis, and other necessary parts, packaged, and transported for assembly at the local plant. Transportation costs are often lower for CKDs than CBUs.

- SKD (Semi Knock Down): Vehicles are transported in a partially completed state, and final assembly is performed locally. For example, the engine and chassis are already assembled, and the final assembly is done at the local plant. Compared to CKD, this method requires less local assembly work, manufacturing costs, time and personnel. In addition, local tariff exemptions may be available depending on the country, and total costs are lower to a certain extent than CBUs.

SKD factory production line in Ghana. Imported parts are assembled, including painted body panels, complete engine and transmission units, and interior and exterior component

SKD factory production line in Ghana. Imported parts are assembled, including painted body panels, complete engine and transmission units, and interior and exterior component

Honda has been importing and selling CBUs through local wholesale distributors in the Ghanaian automobile market for over 20 years. Ghana’s economy has grown remarkably during this period, backed by political stability. When the Ghana Automotive Development Policy (GADP) related to Semi-Knocked Down (SKD) kits*3 came into effect in 2022, Honda decided to produce locally in Ghana based on the idea of “producing where the demand is.”

*3 The Ghana Automotive Development Policy (GADP) related to Semi-Knocked Down (SKD) kits allowed SKD local production to receive a partial exemption from import duties on parts, and a certain amount of exemption on CBU imports. The reduced tariffs allowed both produced and imported vehicles to be marketed at more reasonable prices.

Completing the Ghanaian HR-V: Local manager shares the project’s challenges

The Japan-Ghana collaboration project was launched in October 2021, and preparations began for the plant’s launch and commencement of production. In September 2022, the Ghana Plant of Honda Manufacturing Ghana Ltd. (HMG), a local subsidiary for automobile production, was established.

Despite difficulties in communicating with local authorities and procuring production machinery, Honda recruited and trained local associates for two years after the project was launched, and in December 2023, began local production of the HR-V, Honda’s first vehicle to be made in Ghana.

Preliminary verification at a Nigerian subsidiary, where the SKD plant was established prior to Ghana in West Africa. “Business in Africa is a series of irregularities, and our common sense doesn’t always apply. It was a great experience for me to be involved in the project to set up the plant working hand in hand with local associates,” says Saori Sakurai (right), formerly in automobiles sales (now in motorcycle sales), who was involved in the Ghana SKD plant start-up project.

Preliminary verification at a Nigerian subsidiary, where the SKD plant was established prior to Ghana in West Africa. “Business in Africa is a series of irregularities, and our common sense doesn’t always apply. It was a great experience for me to be involved in the project to set up the plant working hand in hand with local associates,” says Saori Sakurai (right), formerly in automobiles sales (now in motorcycle sales), who was involved in the Ghana SKD plant start-up project.

One local associate hired during this start-up period was Angela Ackon. Before joining Honda, Angela worked for a foreign electrical engineering company in Ghana, where she was in charge of financial management and other operations. She was hired as the Finance and Administration manager for the Ghana plant to advance the next phase of her career.

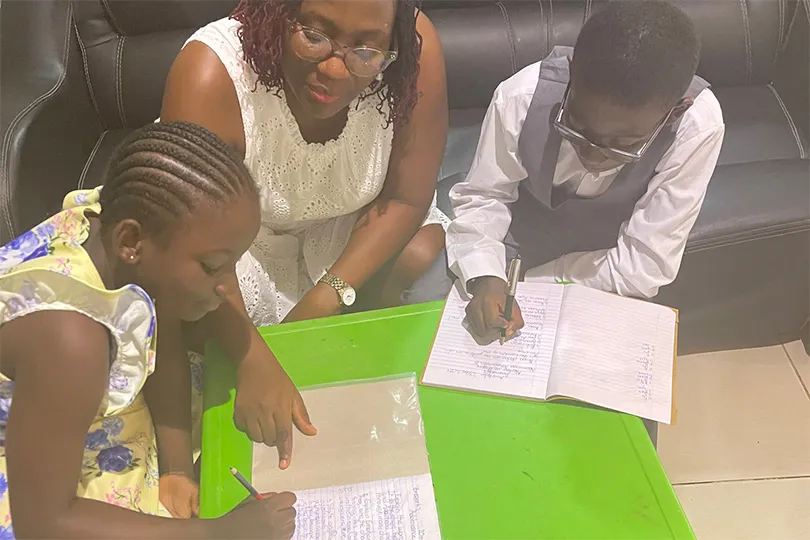

In the office, Angela works as a manager, managing local associates, but in her private life she is a mother of two. She is excited to balance work and family life every day.

In the office, Angela works as a manager, managing local associates, but in her private life she is a mother of two. She is excited to balance work and family life every day.

Every day is full of irregularities, such as when parts do not clear customs at the port, and deliveries are delayed. However, our mission is to continue stable production by negotiating with the authorities with the cooperation of the president and everyone involved. I find it very rewarding when such everyday efforts accumulate to achieve our goals.

Honda philosophy takes root in Ghana

Angela, who performs a wide range of duties, has gained a firm grasp of Honda’s corporate culture and philosophy, and applies them in her daily efforts.

I most identify with Honda’s basic philosophy of “Respect for the Individual.” I learned this during my training period, and I always feel it in my actual work. I believe that a corporate culture that allows employees to communicate issues and problems without hesitation, even to management, will lead to new and improved measures.

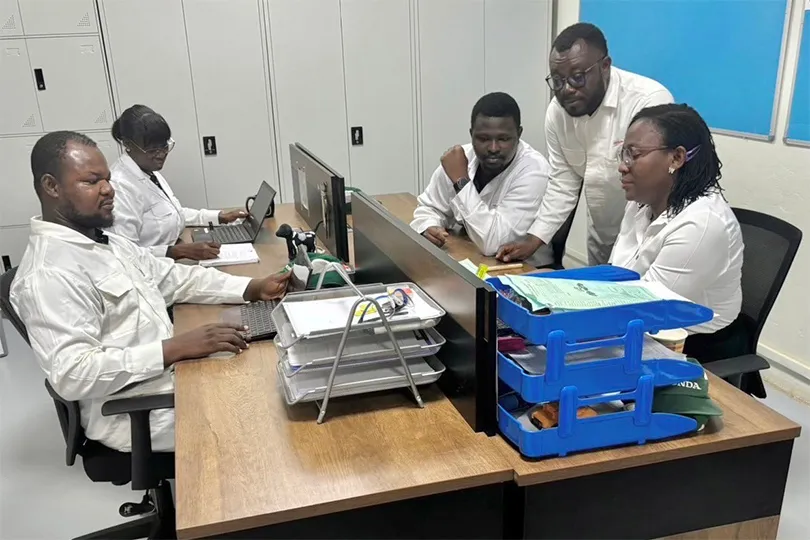

Angela (right) with local associates at the Ghana plant. They have daily discussions unconcerned with position.

Angela (right) with local associates at the Ghana plant. They have daily discussions unconcerned with position.

Angela also had thoughts about the future development of the Ghana factory, and her hopes for the future.

I would like to make the Ghana factory one of the leading factories in West Africa. It is my dream and goal to contribute to the development of our country by making the factory outstanding in every way, not only in quality, but also in production capacity, efficiency, and human resources. I also want to offer programs that promote employment for local residents and contribute to the local community. Furthermore, I would like to create a more comfortable working environment for local associates by further improving management leadership and skills.

And finally, Angela explained the significance of Honda producing the HR-V in Ghana.

Many people recognize Honda as a car brand. They understand that the quality is good, and the durability and high resale value are also well known. Ghanaians like things that are luxurious and special. The HR-V produced at our plant is not only a global model, but also a car produced in Ghana, by Ghanaians, for Ghanaians.

Memorial board in the factory’s office, with the slogan “Made in Ghana by Ghanaians for Ghanaians with Honda Global Quality” that the local associates cherish, is on display.

Memorial board in the factory’s office, with the slogan “Made in Ghana by Ghanaians for Ghanaians with Honda Global Quality” that the local associates cherish, is on display.

As of 2024, imported used cars account for around 90% of the Ghanaian automobile market, and the challenge is how to increase new car sales in the future.

Conducting market research at a Ghanaian imported used car dealer. “The best part of doing business in Africa is that you can experience your own growth every day in a challenging environment. Working together with energetic local associates, I feel energized every day,” says Ryota Udaka (right) who works in the Honda Africa and the Middle East Representative office (HAMER), the regional headquarters in Dubai overseeing the Africa and Middle East region, supporting the Ghana business.

Conducting market research at a Ghanaian imported used car dealer. “The best part of doing business in Africa is that you can experience your own growth every day in a challenging environment. Working together with energetic local associates, I feel energized every day,” says Ryota Udaka (right) who works in the Honda Africa and the Middle East Representative office (HAMER), the regional headquarters in Dubai overseeing the Africa and Middle East region, supporting the Ghana business.

The dreams and passions of Honda associates all over the world who put the Honda Philosophy into practice are the source of products and services that move people’s hearts.

To provide customers in West Africa with the “joy, fun and freedom of mobility and the joy of making changes that make their lives more enjoyable,” the young and small Ghana plant, which has only been in production for one year, has the potential to contribute to the development of Honda’s automobile business in the future.

Driven by the Power of Dreams, Honda will continue to pursue the creation of new value and excitement in the West Africa region.

I am in charge of accounting, administration, human resources, including cost control to increase profits. I also manage about 15 local associates, including assembly workers. Since the Ghana plant is still small, the scope of my duties is very diverse.

During my training period, I was most surprised by Honda’s strict time management. Many local associates are loose with time due to Ghanaian business customs, so I was sometimes perplexed by the difference in sense of time when managing them. However, punctuality allows work to proceed smoothly and work to be completed on schedule. I try to tell the local associates that this leads to the company’s profit, and as a result, guarantees their own profit, and I try to adjust the gap in their sense of time.