Honda Develops New Energy-Efficient, Home-Use Equipment

March 12, 1998, Japan

Tokyo, March 12, 1998 - Honda Motor Co., Ltd. announced today the development of both a compact, lightweight home-use "absorption-type heat pump air conditioner" and a "home-use cogeneration system" together with the GF160V gas-powered engine to serve as their power source.

- Home-use absorption-type heat pump air conditioner

This world's first ultra-small absorption-type heat pump air conditioner for home-use relies neither on electricity nor Freon. Work centered on the development of the best refrigerant/absorbent combination for use in an absorbent-type air conditioner. Using air as the cooling medium, we have been able to develop a system with a weight and size adapted to home applications. It is suited to cold climates and also functions as a heat pump heater. - GF160V gas-powered engine

Running on either natural gas or LPG, this newly developed unit is the smallest gas engine in the world with a capacity of 163cc. Compactness, low noise, clean exhaust and long life make it the power source of choice for home-use gas heat pump air conditioners, and cogeneration systems. - Home-use cogeneration system

This cogeneration system can serve either to supply hot water or generate electricity. Using the GF160V gas engine as its power source, it achieves 80% energy utilization and is the first in the world to offer dimensions allowing home applications. Besides its very high-energy conversion rate, it can also serve as a source of electricity, to help meet peak electric power need during the season of high demand.

These new technologies will be displayed in Twin Ring Motegi's Fan Fun Lab scheduled to open to the public on March 21, 1998.

Technical features:

1) World's smallest home-use absorption-type heat pump air conditioner

World's first ultra-small absorption-type heat pump air conditioner for home-use relies neither on electricity nor on Freon.

Main characteristics:

- Non-crystallizing, highly corrosion-resistant trifluoroethanol (TFE) coolant and high-boiling-point dimethylimidazole (DMI) absorbent are used in place of Freon-type coolant.

- Economical air-cooled system (no water consumption).

- World's first heat pump heater capability using an absorption-type system.

- Aluminum used throughout the system for low cost, and reduced dimensions and weight.

- All-year-round 3-mode air conditioner (automatic mode selection function).

Absorption-type heat pump air conditioner cycle of operation

Mode 1: Cooling

- 1.Heated by the burner, the coolant/absorbent gas mixture separates within the regenerator's purifier.

- 2.Coolant vapor enters the condenser and liquefies upon contact with the cooling water coming from the air-cooled heat exchange.

- 3.The coolant in liquid form is sent into the evaporator where the difference in pressure helps it turn into vapor.

- 4.The cold water created by the evaporation process is drawn into the indoor unit to serve as a cooler.

- 5.The coolant vapor is drawn from the evaporator into the absorber, liquefies again upon contact with the absorbent coming from the regenerator and is warmed up in the solution heat exchange on its way back to the purifier.

- 6.The system functions as an air conditioner (cooler) as this cycle is repeated. Apart from the heat energy provided by the regenerator's burner, the system is self-contained as the liquefaction/vaporization process is promoted by the indirect air-cooling created by using the difference in temperature with the outside.

Mode 2: Heating (1)

Upon the actuation of a valve, the cooling water warmed by the condenser and absorber is drawn into the indoor unit, turning the heat pump air conditioner into a heater.

Mode 3: Heating (2)

Whenever outside temperature falls below 0o, the burner turns into a direct heater unit warming up the water drawn into the indoor unit.

The system automatically selects the most appropriate of the three modes depending on outside temperature and the temperature selected inside to offer all-year-round comfort.

Cycle of Operation

| Cooling power | 2.5 kW |

| Heating power (heat pump) | 4.0 kW |

| Heating power (burner) | 4.5 kW |

| External unit dimensions (L x W x H) (mm) | 800 x 250 x 680 |

2) World smallest gas-powered engine "GF160V"

The power source of choice for home-use gas heat pump air conditioners and cogeneration systems, this newly developed GF160V is the smallest gas engine in the world.

Main characteristics:

- Lean-burn combustion for clean exhaust emissions with low NOx content.

- Multi-chamber intake silencer, large-capacity air cleaner, and high rigidity design for low noise and reduced vibrations.

- Minimum life of 20,000 hours (about 10 years of average use*1).

- Large capacity oil tank and long-life spark plug for maintenance reduced to every 6,000 hours (or about 3 years average use*1).

- Compressor located right above the engine for a vertical-type*2 engine layout.

- *1As per the home-use gas heat pump air conditioner industry standard

- *2Vertical-type: The cylinder is set horizontally so the crankshaft axis is in a vertical position. By opposition the engine layout with a horizontal crankshaft axis is called horizontal-type.

Gas heat pump air conditioner: Instead of the usual electric motor, a gas-powered (city gas- [13A] or LPG-powered) engine is used to drive the compressor of the air conditioner unit. Research in this direction is conducted to reduce peak electricity power need during seasons of highest demand.

GF160V gas-powered engine

GF160V gas-powered engine specifications:

| Model name | GF160V |

| Construction | 4-stroke horizontal single cylinder OHV |

| Dimensions (L x W x H) (mm) | 408 x 235 x 422 |

| Engine capacity (cc) | 163 |

| Bore x Stroke (mm) | 62 x 54 |

| Normal engine speed range (rpm) | 1,500 to 3,300 |

| Fuel | City gas (13A)/LPG |

| Life cycle (hours) | 20,000 |

| Maintenance interval (hr) | 6,000 |

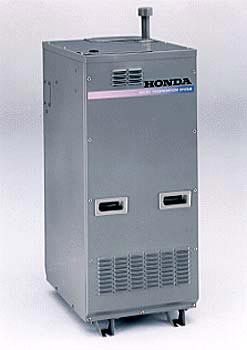

3) World smallest home-use cogeneration system

Main characteristics:

- Highly efficient electricity generation and hot water supply using natural gas (city gas 13A) for reduced carbon dioxide emissions.

- 3-way catalytic converter and oxygen sensor feedback for extremely low NOx emissions.

- A multi-polar sinusoidal inverter generator for electricity quality on a par with industrial power generation.

- Combines electricity generation and hot water supply for a total thermal efficiency of 80%.

- Noise level on a par with traditional home-use air conditioner outdoor unit.

Micro cogeneration system

Specifications:

| Fuel | natural gas (city gas 13A) |

| Engine name | GF160V |

| Engine construction | water-cooled 4-cycle single cylinder OHV |

| Engine capacity (cc) | 163 |

| Generator type | Multi-polar sinusoidal inverter generator |

| Electric output (kW) | 1.8 |

| Hot water caloric energy (kcal/h) | 4,100 |

| Dimensions (L x W x H) (mm) | 480 x 520 x 1,000 |