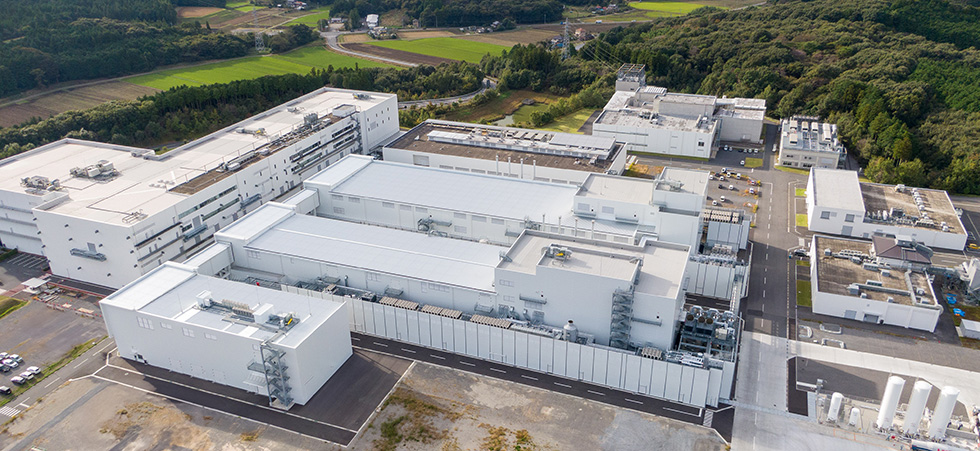

Honda Unveils Demonstration Production Line

for All-Solid-State Batteries Located in Sakura City, Tochigi Prefecture, Japan

TOKYO, Japan, November 21, 2024 – Honda Motor Co., Ltd. today unveiled the demonstration production line for all-solid-state batteries, which is being developed independently by Honda toward mass production. The line was constructed on the property of Honda R&D Co., Ltd. (Sakura), located in Sakura City, Tochigi Prefecture, Japan. While conducting technical verification to establish a mass production process on this demonstration line, Honda will determine the basic specifications of the battery cells, with an aim to begin applying its all-solid-state batteries to electrified models that will be introduced to market in the second half of the 2020s.

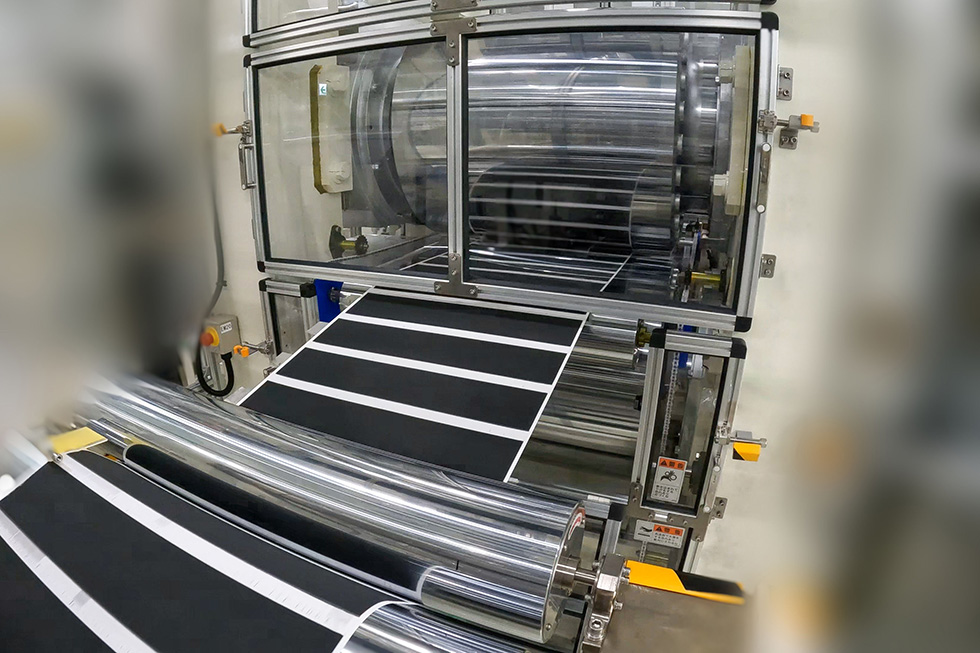

For the purpose of establishing the mass production process for its all-solid-state batteries, Honda built this demonstration line that replicates processes required for the mass production. The demonstration line has a total floor area of approximately 27,400 m2 (295,000 ft2), and is equipped with facilities and equipment that enable verification of each production process, including weighing and mixing of electrode materials, coating and roll pressing of electrode assembly and the formation of cells, and assembly of the module. The construction of the facility building was completed in spring of this year, with almost all of the key equipment necessary for the verification now installed. Honda is planning to begin battery production on this demonstration line in January 2025 and will conduct verification of mass production technologies and costs for each process, while also developing battery cell specifications.

Based on the conventional production process for liquid lithium-ion batteries, the Honda all-solid-state battery production process adopts a roll-pressing technique which will contribute to an increase in the density of the solid electrolyte layers, a process unique only to the production of all-solid-state batteries, and makes continuous pressing possible. With the adoption of the roll-pressing technique, Honda will strive to increase the degree of interfacial contact between the electrolyte and the electrodes and also increase overall productivity. Moreover, by consolidating and speeding up a series of assembly processes, including the bonding of positive and negative electrodes, Honda will strive to significantly reduce the production time per cell. Furthermore, Honda is also working to reduce indirect costs of battery production, including power consumption, by implementing various measures, including the establishment of production control technology that minimizes the low dew point environment necessary to ensure work safety and battery performance.

By increasing cost competitiveness of its all-solid-state batteries through the adoption of a highly efficient production process and by expanding application of the batteries to a wide range of Honda mobility products, not only automobiles but motorcycles and aircraft, Honda aims to further reduce battery costs by taking advantage of economies of scale. Through these initiatives, Honda will offer new value made possible by its innovative all-solid-state battery technologies to an even greater number of customers and expand the joy of mobility.

Honda has abundant manufacturing expertise and a proven track record of achieving mass production of new technologies, such as solar cells and fuel cells. Now, in the area of all-solid-state batteries, Honda is conducting speedy research and development in two core areas – material specifications and manufacturing methods – with the aim of starting mass production of the battery in the second half of the 2020s. Even before the battery materials and specifications are determined, the production engineering division has been participating in development and taking part in decisions on battery structure, materials, and production methods, which would be most suitable for vehicle installation. As a result, Honda was able to begin operation of this demonstration line quickly, and is making efficient progress in material selections.

Striving to realize carbon neutrality for all Honda products and corporate activities by 2050, Honda has set a target to make battery-electric and fuel cell electric vehicles represent 100% of its new vehicle sales globally by 2040. Due to their characteristics of high energy density and excellent heat resistance, all-solid batteries are expected to be the next-generation batteries that will solve issues that hinder the popularization of EVs such as range, price, and charging time. In addition to the high energy density and durability achieved by its original material design technology, Honda is striving to lower the cost of the batteries by simplifying the cooling structure by taking advantage of high heat resistance and realizing highly efficient production processes, thereby achieving a significant advancement of EV performance and creation of new value for its customers.

Comments by Keiji Otsu, President and Representative Director of Honda R&D Co., Ltd.

“The all-solid-state battery is an innovative technology that will be a game changer in this EV era. Replacing engines that have been supporting the advancements of automobiles to date, batteries will be the key factor of electrification. We believe that advancement of batteries will be a driving force in the transformation of Honda. Now, the start of operation of our demonstration production line for our all-solid-state batteries is in sight, and we can say that we have reached an important milestone for Honda and the country of Japan. We will continue taking on challenges to launch our mobility products equipped with our all-solid-state batteries as quickly as possible so that Honda can offer new value to our customers.”

<About the demonstration production line for all-solid-state batteries>

Location |

1220-32 Shimokodo, Sakura City, Tochigi Prefecture, Japan |

Lot size |

Approximately 12,900 m2 (139,000 ft2) |

Total floor area |

Approximately 27,400 m2 (295,000 ft2) |

Investment amount |

Approximately 43 billion yen |

Note: This demonstration line is partially funded by a grant from the Green Innovation Fund of the New Energy and Industrial Technology Development Organization (NEDO) of Japan.